Combined treatment process for flue-cured tobacco, burnt hairy tobacco and white hairy tobacco

A technology for processing and pasting hairy tobacco, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as differences in reproducibility and poor overall coordination, and improve the quality of smoking, the quality of tobacco leaves, and the overall quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

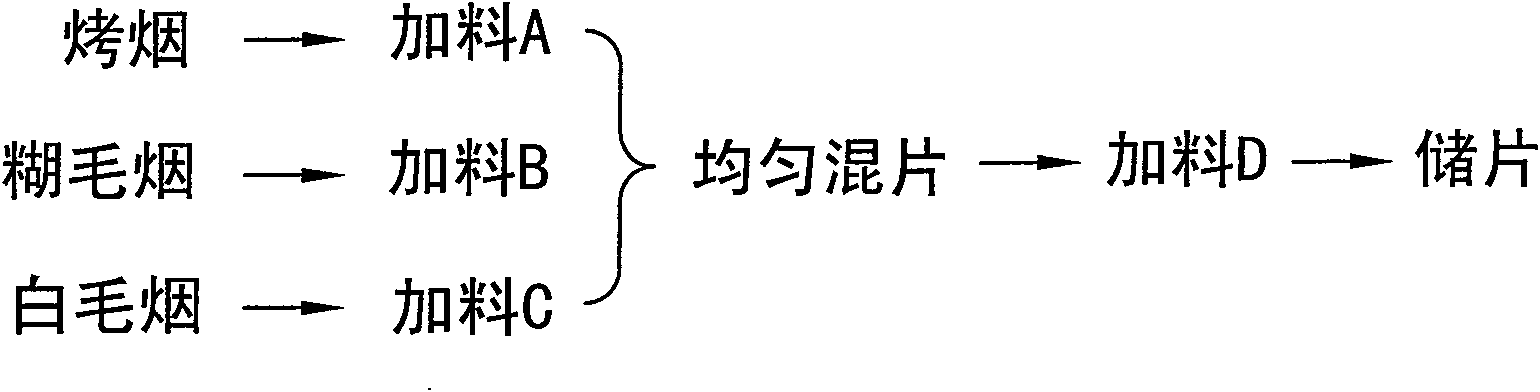

[0010] As can be seen from the accompanying drawings, the specific practices of the present embodiment for the combined treatment of flue-cured tobacco, fumed tobacco, and white tobacco are as follows:

[0011] 1. After the flue-cured tobacco sheet has been loosened and regained moisture, add treatment material A for treatment, and then send it to No. 1 storage cabinet; Send it to the No. 1 storage cabinet; after the white hair tobacco sheets are loosened and regained moisture, add treatment material C for treatment, and then send them to the No. 1 storage cabinet. At this time, the layout of the smoke sheets in the No. 1 storage cabinet Yes, the flue-cured tobacco sheet is on the bottom layer, the paste tobacco sheet is in the middle, and the white hair tobacco sheet is on the top layer;

[0012] 2. Then carry out the cabinet inversion, put the mixed tobacco sheet from the No. 1 storage cabinet into the No. 2 storage cabinet, and perform multiple inversions back and forth. m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com