Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2168 results about "Curing of tobacco" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is necessary to cure tobacco after harvesting and before it can be consumed. Tobacco curing is also known as color curing, because tobacco leaves are cured with the intention of changing their color and reducing their chlorophyll content.

Tobacco processing

InactiveUS6895974B2Lower Level RequirementsInhibition formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:R J REYNOLDS TOBACCO COMPANY

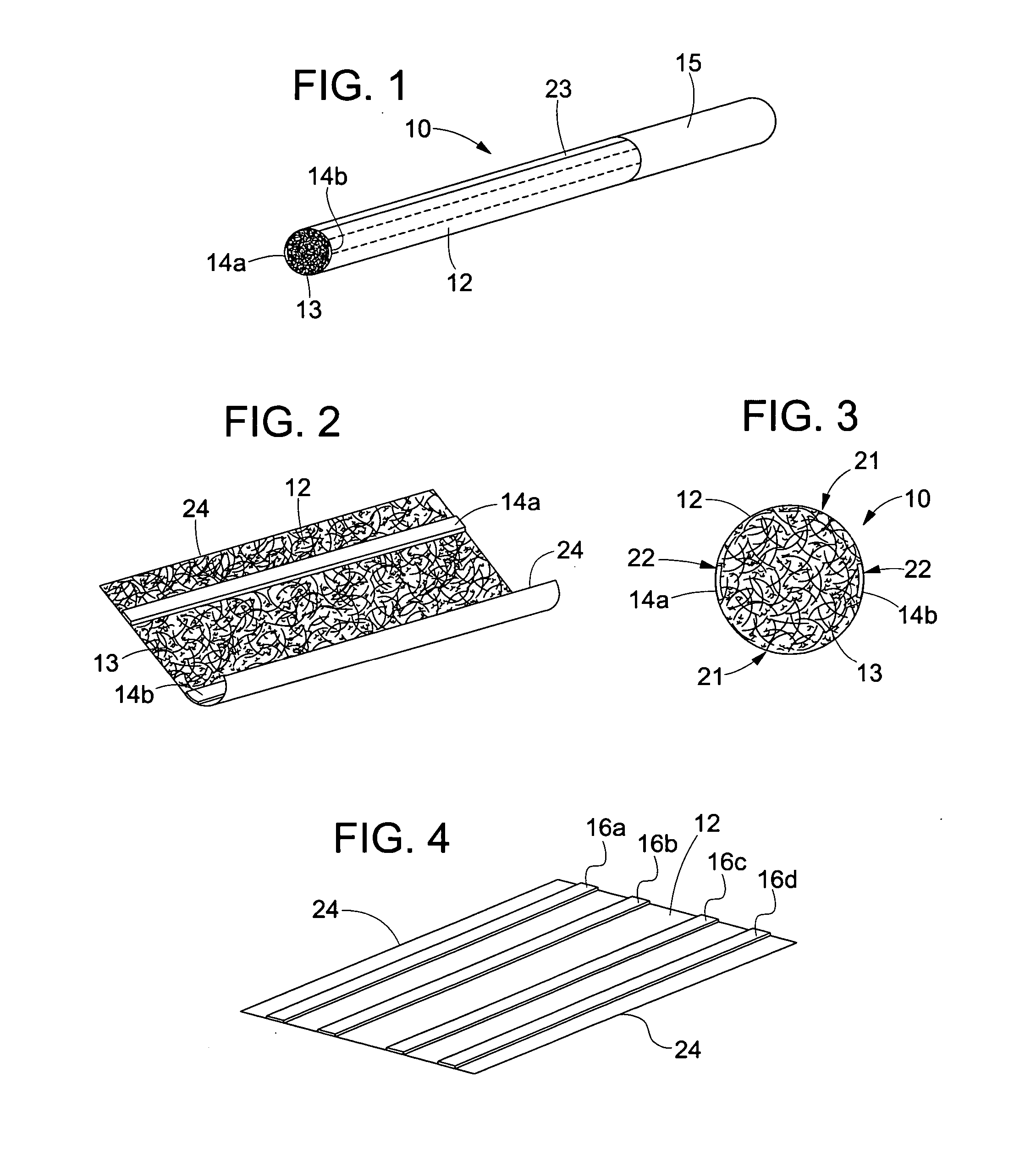

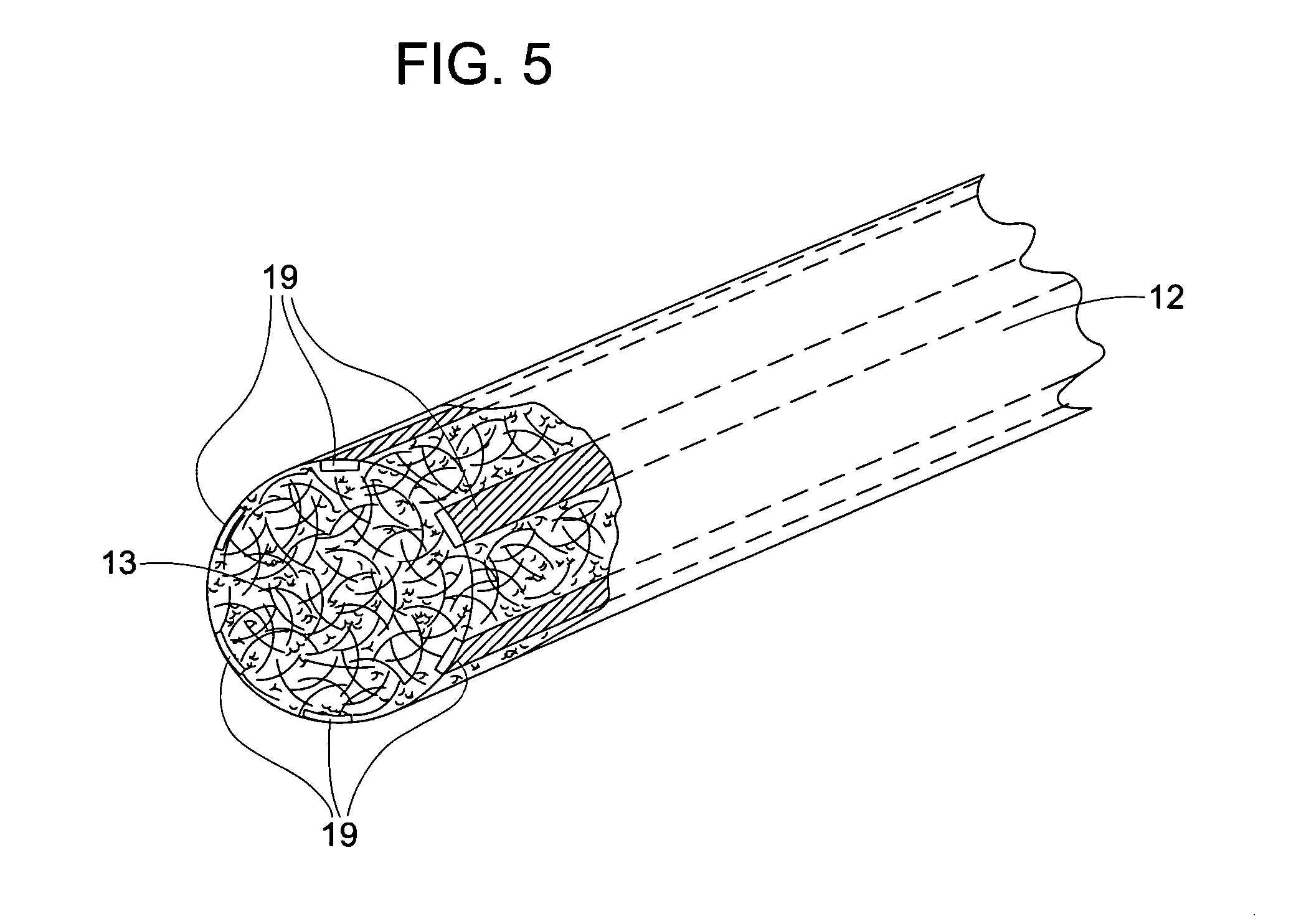

Reconstituted tobacco sheet and smoking article therefrom

InactiveUS20050039767A1Good smoke flavorLow ignition propensityTobacco preparationTobacco treatmentTobacco-specific nitrosaminesAnalyte

A smoking article having one or more reconstituted tobacco split inner wrap strips is described. One or more split inner wrap strips extend coaxially along the tobacco column between the inner surface of an outer wrap of cigarette paper and the tobacco column. The tobacco blend includes burley and a second tobacco, such as flue-cured, oriental, Maryland, or rare and exotic tobaccos, and combinations thereof. This blend improves burley smoke character without increasing Hoffman analyte levels, especially tobacco-specific nitrosamines (i.e., TNSAs). A cigarette with an improved burley smoke character without increasing Hoffman analyte levels is also described.

Owner:R J REYNOLDS TOBACCO COMPANY

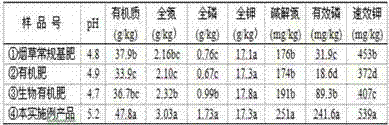

Tobacco composite microbial fertilizer and its preparation method

ActiveCN102515951AImprove qualityTo achieve a long-term mechanismFertilizer mixturesPotassiumRapeseed

Disclosed are a tobacco composite microbial fertilizer and its preparation method. The tobacco composite microbial fertilizer contains an active functional bacteria ingredient, an organic fertilizer ingredient and an inorganic composite fertilizer ingredient, wherein the active functional bacteria ingredient contains phosphate solubilizing bacteria-Bacillus megaterium powder, potassium bacteria-Bacillus mucilaginosus powder, tobacco growth-promoting rhizobacteria-Bacillus amyloliquefaciens powder and tobacco endophytic antagonistic bacteria-Brevibacillus laterosporus powder; and the organic fertilizer ingredient contains decomposed manure, a rapeseed cake fertilizer and straws. The invention also relates to a preparation method of the tobacco composite microbial fertilizer. The fertilizerprovided by the invention has advantages of an organic fertilizer, an inorganic fertilizer and a microbial fertilizer. According to the invention, utilization rate of the fertilizer can be raised, soil organic matters can be increased, tobacco plant rhizosphere microbial proliferation can be promoted, soil physical and chemical property and biological activity can be improved, comprehensive and balanced nutrients can be provided for the early growth of tobacco seedling, the occurrence of soil borne disease can be decreased, and flue-cured tobacco output and quality can be substantially improved.

Owner:湖南润邦生物工程有限公司

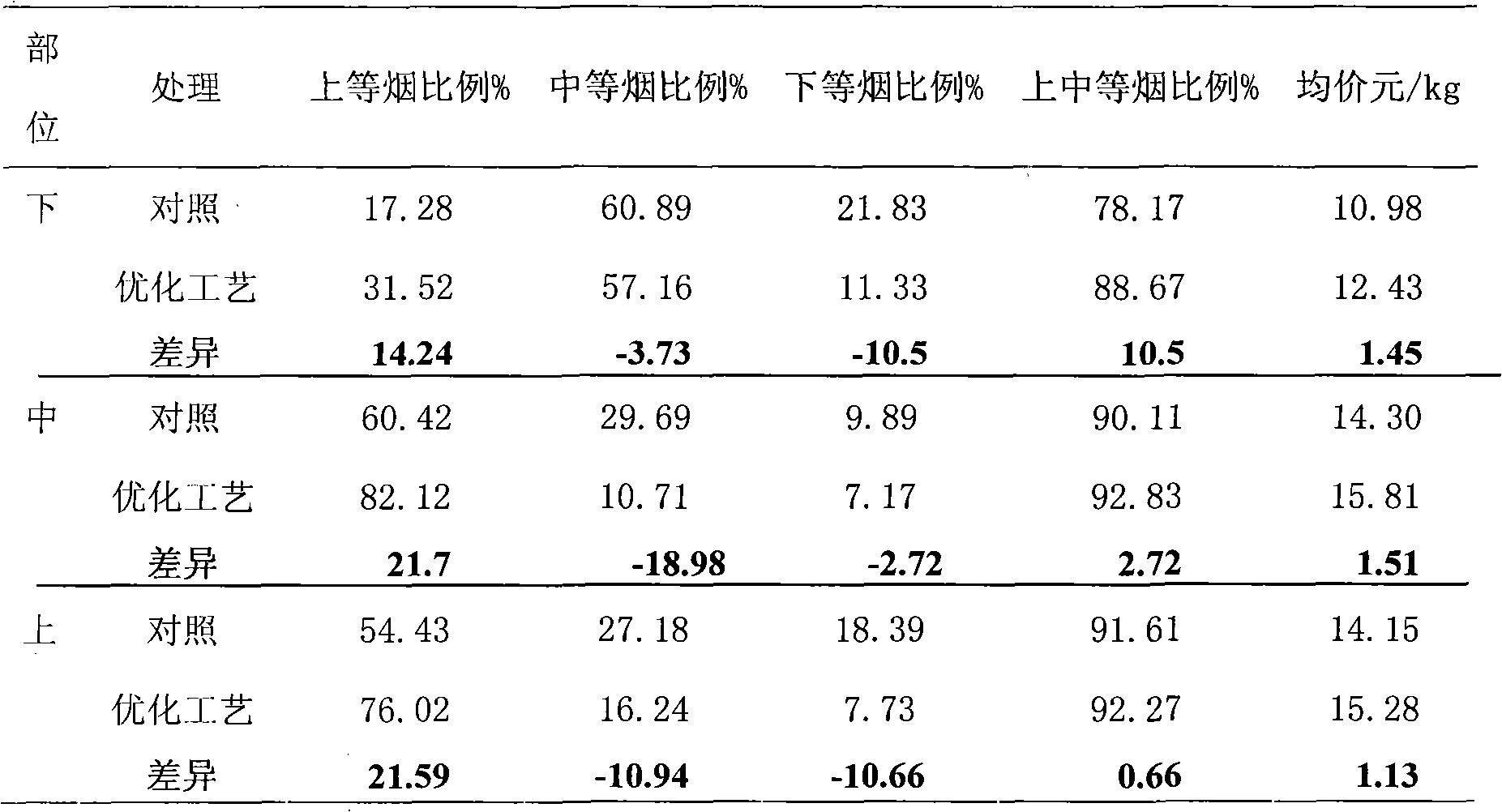

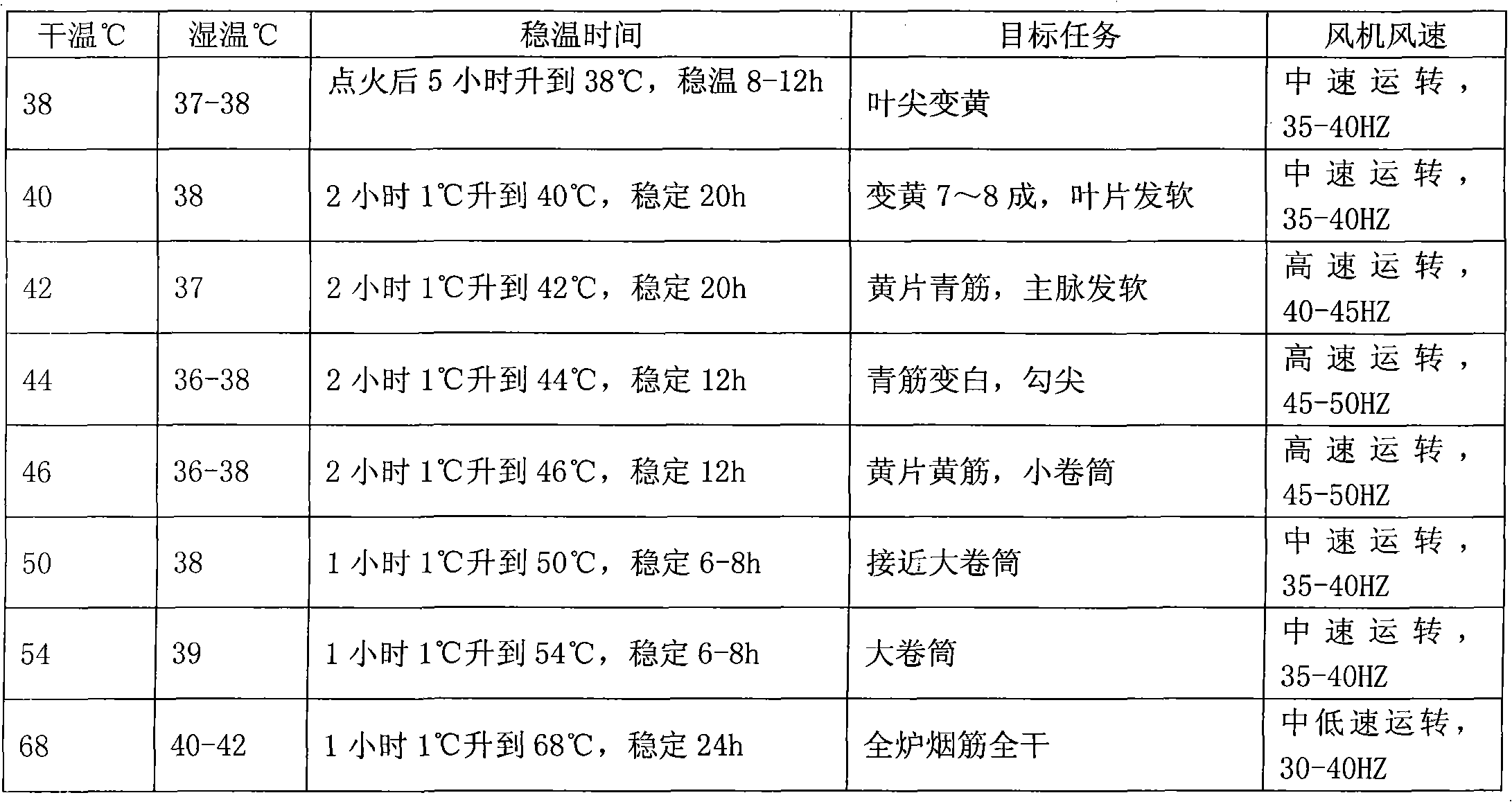

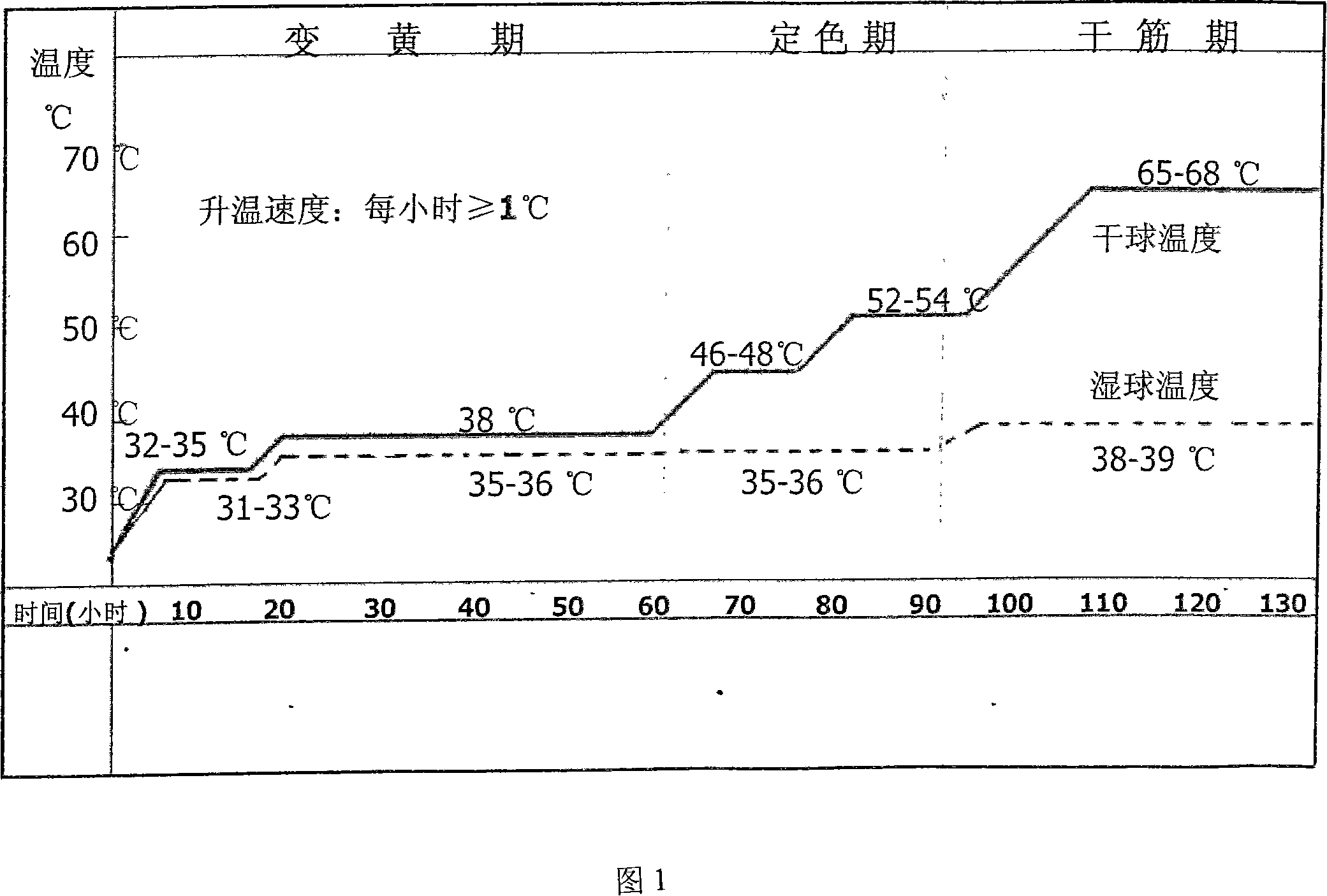

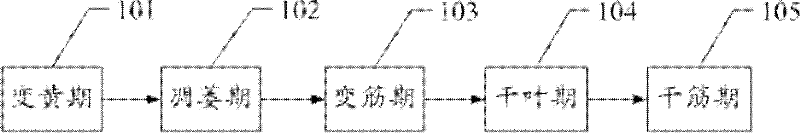

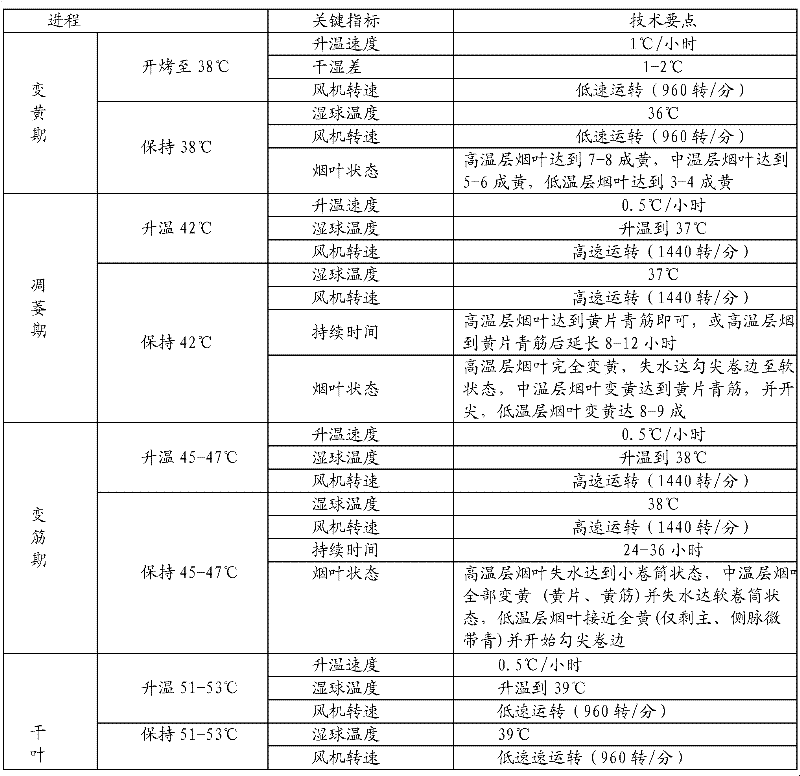

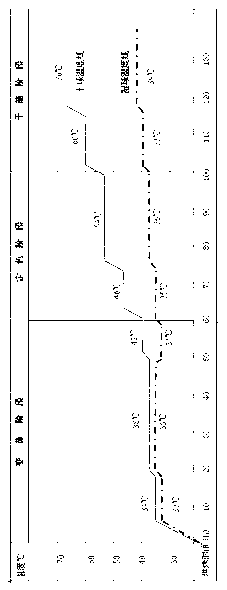

Intensive curing barn precise curing process for flue-cured tobacco

InactiveCN102178335AFully automatedRaise the ratioTobacco preparationAutomatic controlControl system

The invention discloses an intensive curing barn precise curing process for flue-cured tobacco. The process mainly comprises three curing stages, namely a yellowing stage, a color fixing stage and a stem drying stage, wherein three key temperature and humidity points are controlled in the yellowing stage; four key temperature and humidity points are controlled in the color fixing stage; one key temperature and humidity point is controlled in the stem drying stage; a flue-cured tobacco temperature and humidity automatic control system is adopted in an entire curing process; and a temperature sensor and a humidity sensor are arranged on the top layer of a down-draft intensive curing barn or the bottom layer of an up-draft bulk curing barn. Through the process, error and loss of manual operation brought by operation by experience are reduced, curing quality of tobacco leaves is improved, curing cost is reduced, and high operability is guaranteed. As proved, badly cured tobacco such as green and miscellaneous tobacco and the like is obviously reduced, proportion of orange tobacco and first-class tobacco is increased, the cured tobacco has a loose structure and increased oil content, and appearance quality inside and outside the tobacco leaves and availability are obviously improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

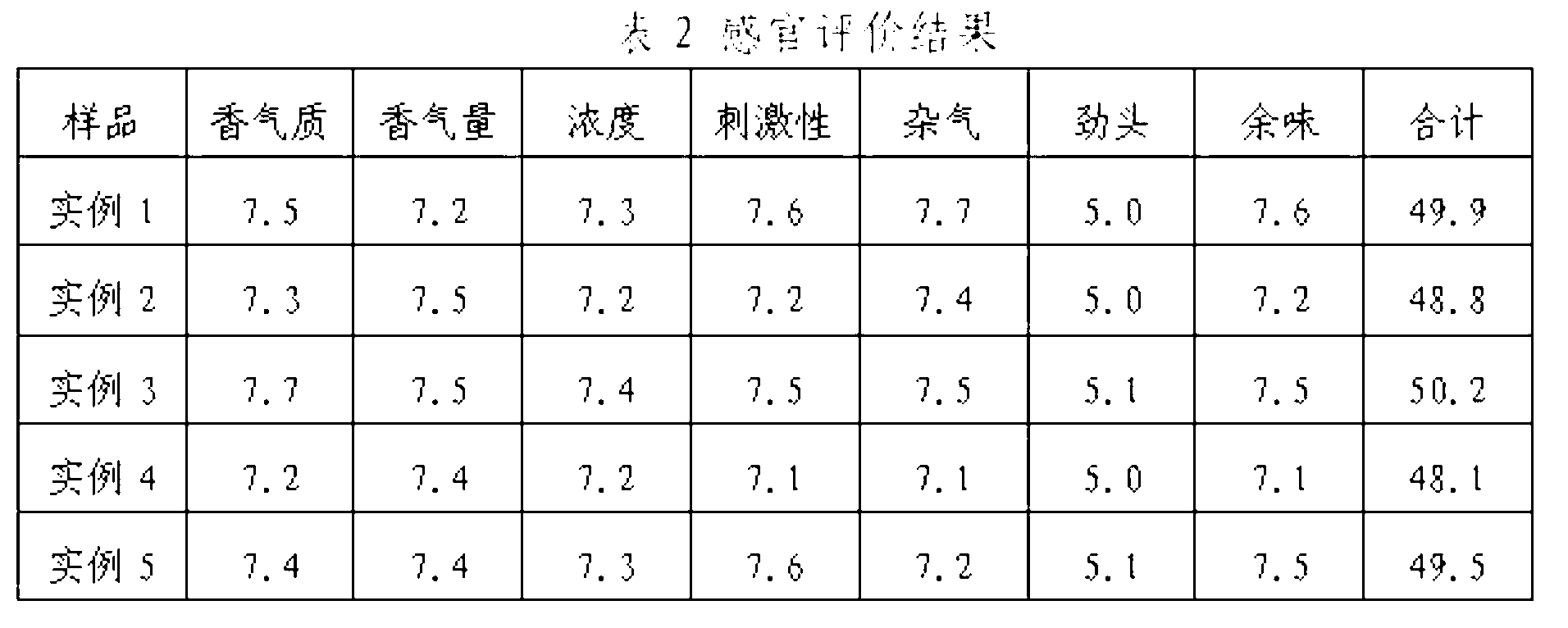

Electronic cigarette liquid prepared from strong-flavor tobacco

The invention discloses an electronic cigarette liquid prepared from strong-flavor tobacco. The liquid is made by mixing 10% to 30% of strong-flavor tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. The strong-flavor tobacco leaf extract is selected from the group consisting of strong-flavor flue-cured tobacco leaf extract in Henan, Anhui, Guangxi, Guangdong and Hunan, or the mixtures thereof. The electronic cigarette liquid takes the strong-flavor tobacco leaf extract as a main component, so that the smell and the taste of electronic cigarettes are closer to the traditional cigarette. The electronic cigarette liquid is used for atomization of the electronic cigarettes without production of tar or carbon dioxide, so that the harm to consumers is greatly reduced and the harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Loose tobacco compression type baking technics in the baking room

InactiveCN101116461ASolve the problem of poor bake through rateSolve the problem of thin and non-retractable sheetsPre-extraction tea treatmentEngineeringTemperature gradient

The present invention discloses a roasting technics with loose-tobacco curing bulk barn, wherein the main roasting stages include a yellowing stage, a fixation stage and a stem-drying stage. The present invention is characterized in that the technics is provide with stepped temperature rise to carry out the tobacco roasting, wherein the temperature is raised with a transition no less than 1 DEG C between different temperature grads, and steady-temperature roasting is provided for each roasting stage, wherein an automatic controlling system on roasting humidity and temperature of the tobacco is provided throughout the roasting process. The roasting technics with loose-tobacco curing bulk barn provided by the present invention solves the problem of the poor roasting penetrability of the tobacco, and the problems including the thin slice of the roasted tobacco, the failed stretching and folding of the tobacco, and the mal-roasted tobacco. The present invention has the advantages of amelioration of the whole set of roasting technics of tobacco, simplification of the roasting stages, thereby greatly decreasing the labor cost involved in the roasting stages. The roasting technics can be doubtless used for roasting the tobacco with the rod-hanging method and the tobacco-nipper method.

Owner:GUIZHOU TOBACCO SCI INST

Tree-sections and five-steps type method for flue-curing tobacco leaves

A process for baking tobacco leaves by 5 steps in 3 stages divided according to temp, humidity and the open degree of window and tunnel is disclosed. Its advantages are high quality of baked tobacco leaves and high operatability.

Owner:CHINA TOBACCO SHANDONG IND

Chinese style flue-cured tobacco odor type electronic cigarette tobacco juice capable of improving smoking satisfaction sense

The invention discloses application of diglycerol in electronic cigarette tobacco juice preparation, and discloses electronic cigarette tobacco juice prepared through the application. The electronic cigarette tobacco juice is made of the raw materials, by mass, five percent to ten percent of tobacco extracts, two percent to four percent of tobacco flavor, one percent to three percent of tobacco essence, two percent to six percent of edible essence, one percent to two percent of natural nicotine, one percent to four percent of natural phytoextraction essence, 30 percent to 85 percent of the diglycerol, and the balance one or more kind of propylene glycol, glycerol, ethyl alcohol, butanediol and triethylene glycol. The natural phytoextraction essence is formed by mixing agilawood, sandalwood, elecampane, bee sage roundleaves, sauropus spatulifolius and vitex leaves according to the mass ratio of (1-3):(1-2):(1-2):(1-2):(1-2):(1-2), and is obtained through supercritical CO2 extraction. The invention further discloses a method for preparing the electronic cigarette tobacco juice. The Chinese style flue-cured tobacco extractive and tobacco flavor and essence ingredients are included in the electronic cigarette tobacco juice, the odor and taste are close to those of traditional Chinese style flue-cured tobacco odor type cigarettes, and the smoking satisfaction sense is improved.

Owner:CHINA TOBACCO SHANDONG IND

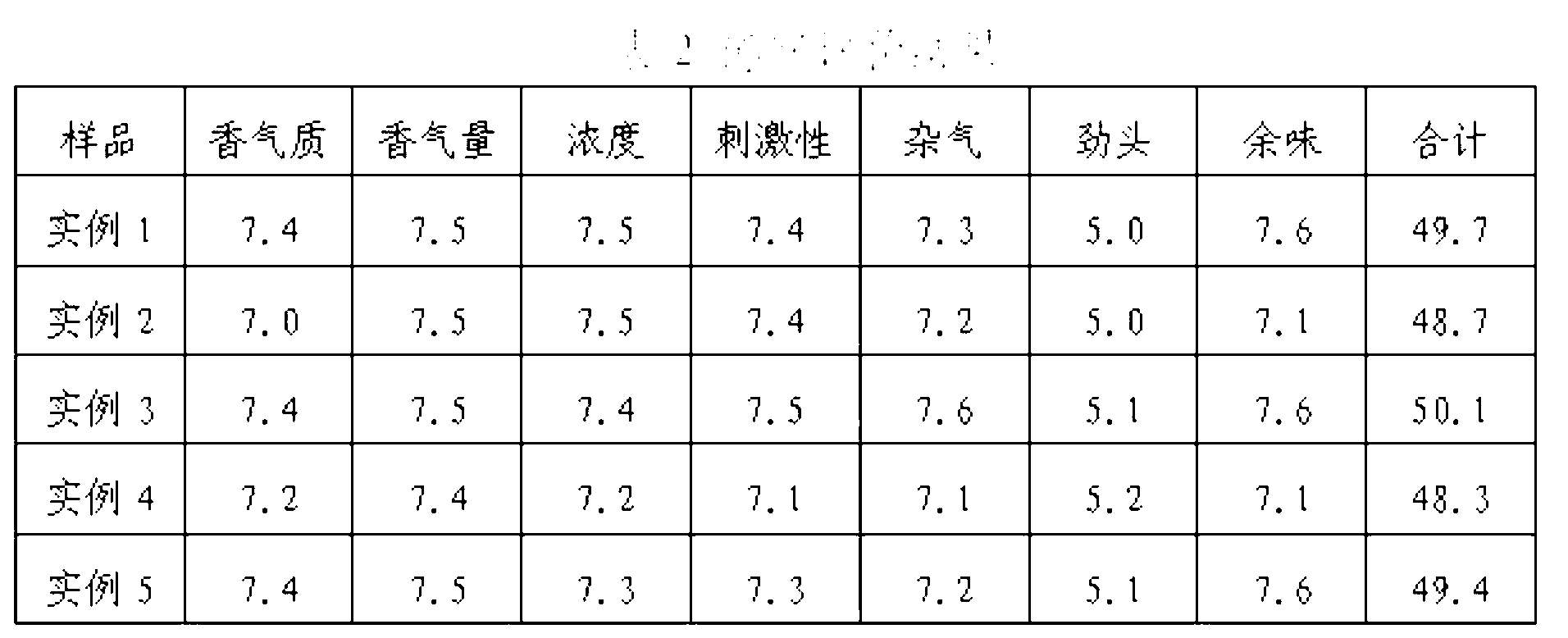

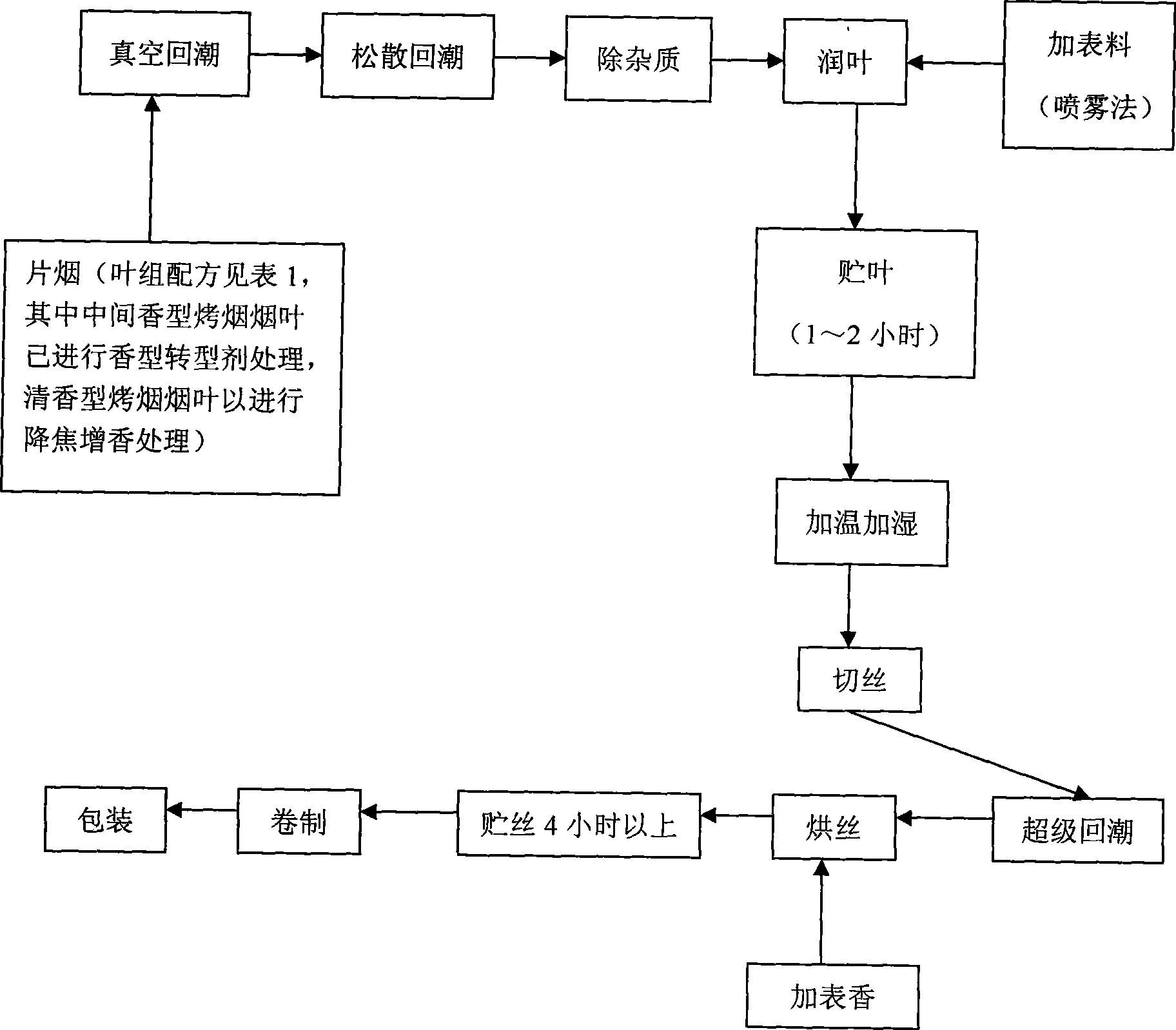

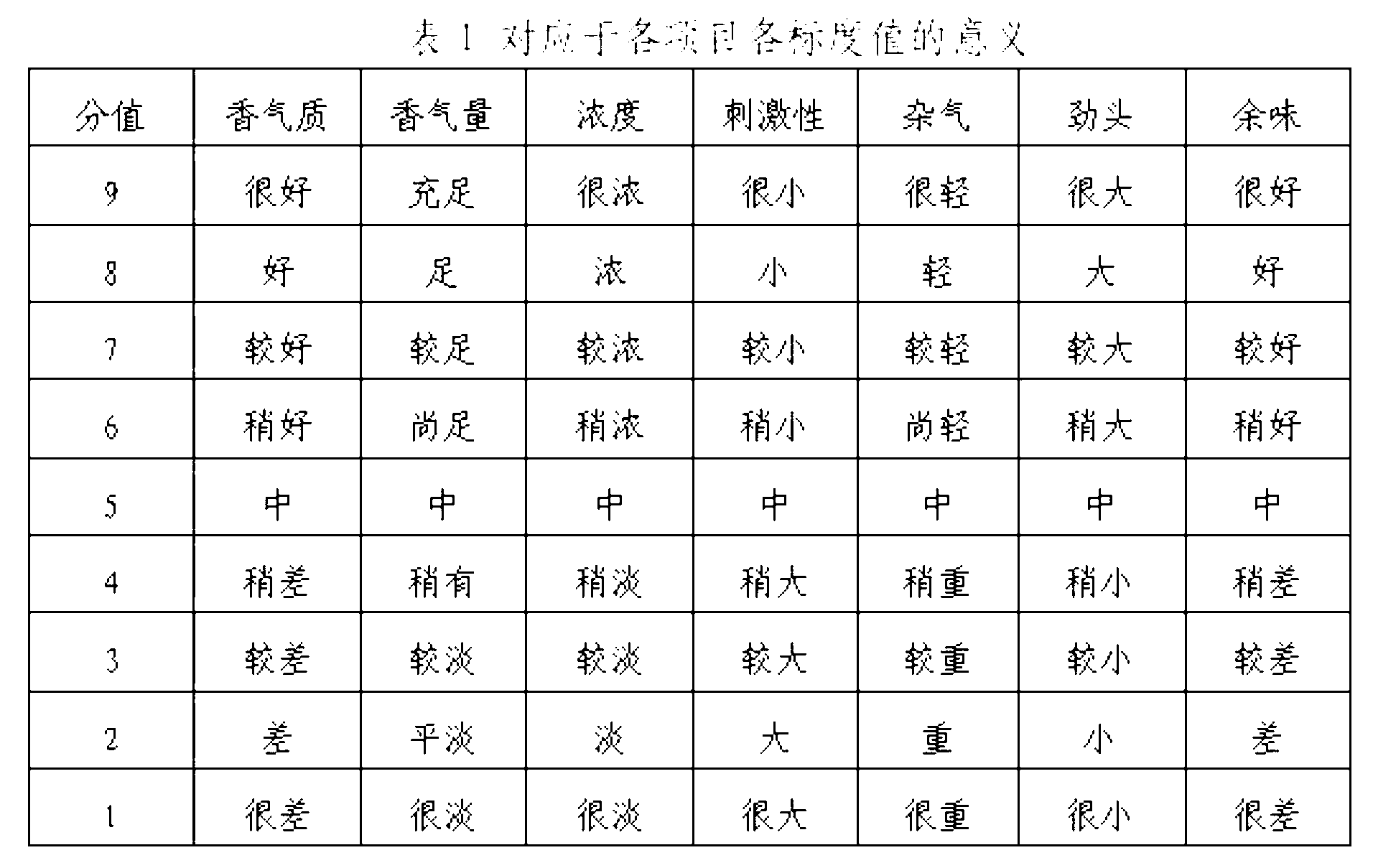

Fire-cured tobacco type low-coke tar cigarette and technique for preparing the same

The invention discloses a cured tobacco type low-tar cigarette prescription and preparation thereof. The cured tobacco type low-tar cigarette comprises cut tobacco, a filter rod, and cigarette paper. The cut tobacco is prepared by: 15-22 by weight parts of faint scent type tobacco leaf, 28-40 by weight parts of aroma type tobacco leaf, 25-35 by weight parts of middle scent type tobacco leaf, 8-15 by weight parts of air-cured tobacco, 10-20 by weight parts of papermaking flake, 10-20 by weight parts of stalk. The middle scent type tobacco leaf in the prescription is processed by tobacco leaf scent type modifier, so as to add fragrance to tobacco leaves, and modify scent type. The faint scent type tobacco leaf in the prescription is processed by cured tobacco leaf tar lowering fragrance adding agent, so as to make faint scent feature more outstanding and lower tar releasing quantity. An odor-absorbing modifying agent and a fluid producing agent are added combined with perfuming in cigarette making process, and a safe cured tobacco type low-tar cigarette with fragrant, gentle smell, and obvious individual characteristic. Tar content of the cured tobacco type low-tar cigarette is 3mg-8mg per one cigarette.

Owner:延吉烟悦科技有限公司 +1

Electronic cigarette liquid prepared from flat-flavor tobacco

The invention discloses an electronic cigarette liquid prepared from flat-flavor tobacco. The liquid is made by mixing 10% to 30% of flat-flavor tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. The flat-flavor tobacco leaf extract is selected from the group consisting of flat-flavor flue-cured tobacco leaf extract in Guizhou, Sichuan, Shandong, Hubei, Heilongjiang, Liaoning and Jilin, or the mixtures thereof. The electronic cigarette liquid takes the flat-flavor tobacco leaf extract as a main component, so that the smell and the taste of electronic cigarettes are closer to the traditional flat-flavor cigarette. The electronic cigarette liquid is used for atomization of electronic cigarettes without production of tar or carbon dioxide, so that the harm to consumers is greatly reduced and the harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

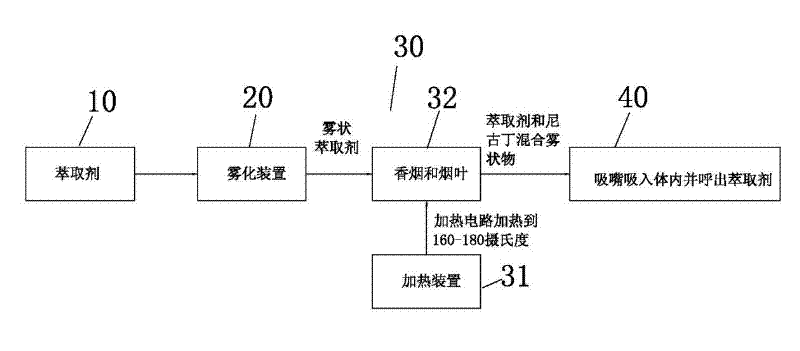

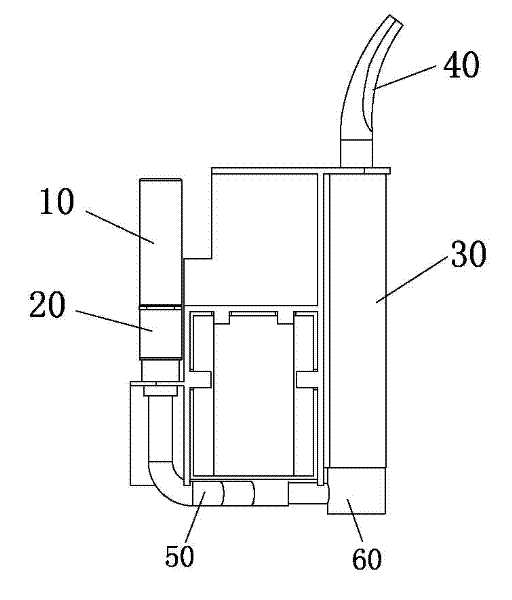

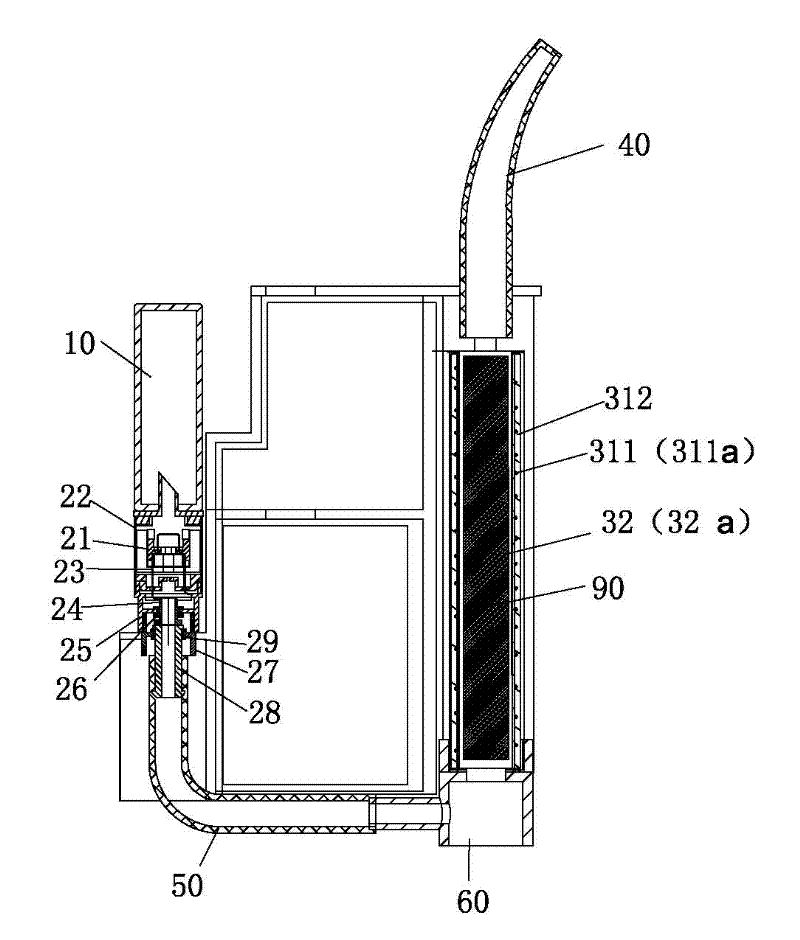

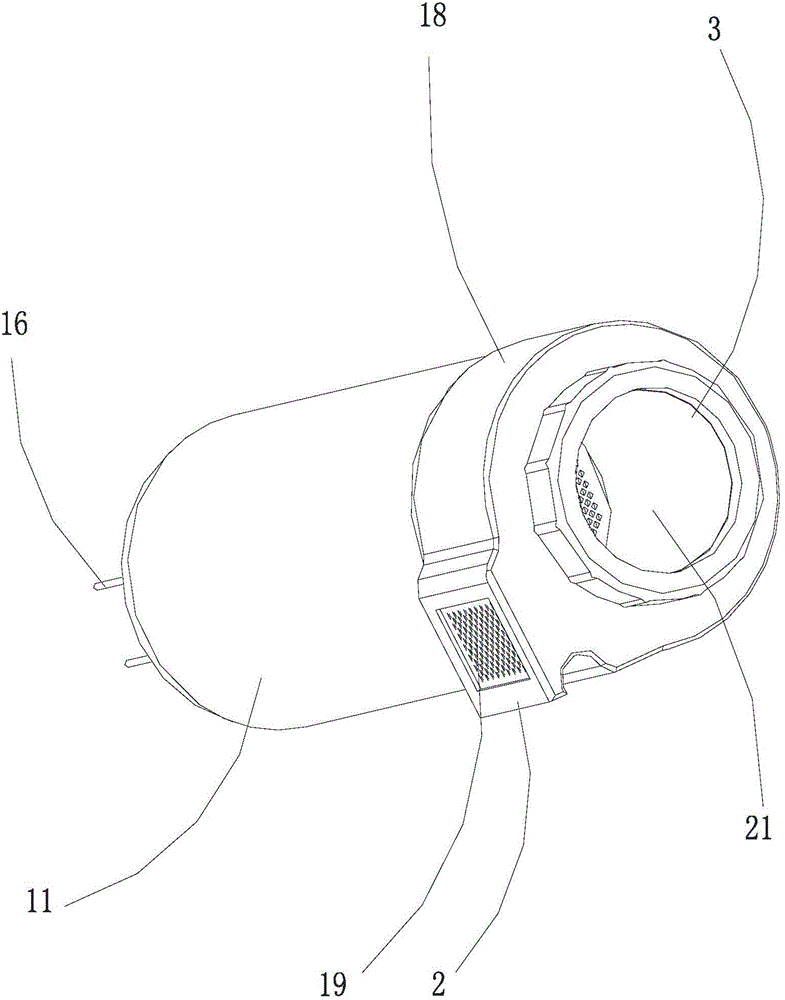

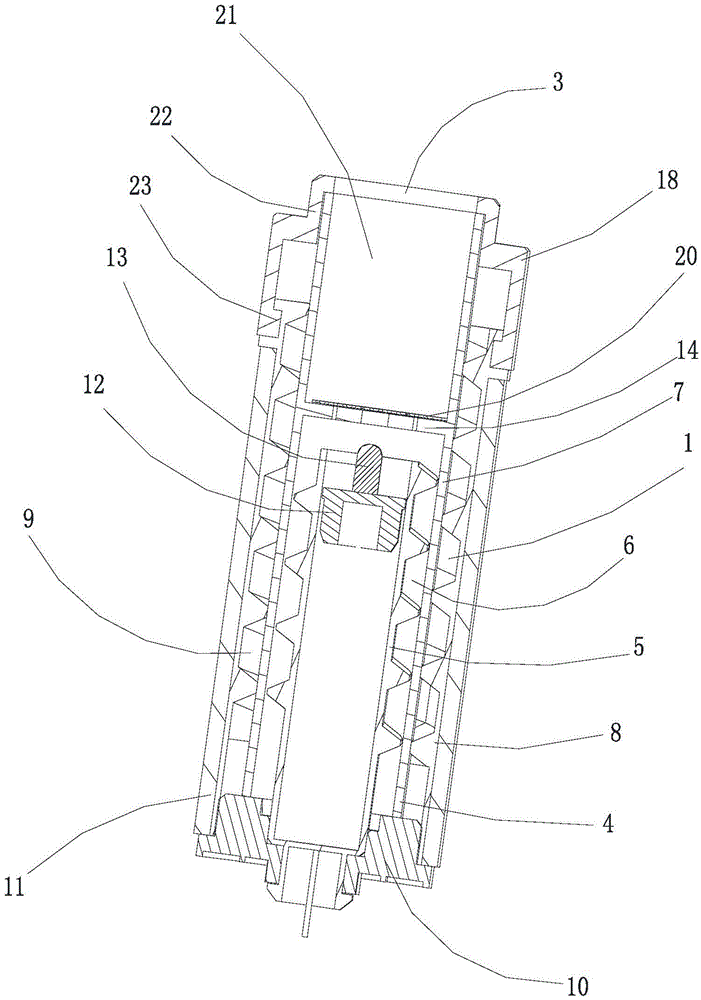

Electronic cured tobacco

The invention relates to electronic cured tobacco, which comprises an oil storage tank, an atomizing device and a tobacco curing device, wherein the oil storage tank is filled with an extracting agent; the tobacco curing device comprises a heating mechanism and a heated cavity for accommodating cigarettes or tobacco leaves; the heating mechanism comprises a heating element and a heating circuit for controlling the heating element to heat to a set temperature range; the air inlet end of the heated cavity is communicated with the air outlet end of the atomizing device; the air outlet end of the heated cavity is connected with a suction nozzle port; and in the smoking state, the atomizing device is used for atomizing the extracting agent and feeding the extracting agent into the heated cavity, heat released by the heating element acts on cigarettes or tobacco leaves in the heated cavity for curing nicotine out, and nicotine is mixed with the mist extracting agent and is sucked out of the suction nozzle port. After the structure is adopted, mist nicotine is easily absorbed by lungs, so that most of gas sprayed by a smoker is an ingredient of the extracting agent, environmental pollution and passive smoking can be prevented, and the mouthfeel of the smoker is satisfied.

Owner:HUIZHOU KIMREE TECH

Electronic cigarette tobacco juice prepared from faint scent tobacco leaves

The invention discloses electronic cigarette tobacco juice prepared from faint scent tobacco leaves. The electronic cigarette tobacco juice is prepared by uniformly mixing 10 to 30 percent of faint scent flue-cured tobacco leave extract, 5 to 10 percent of tobacco flavor, 1 to 5 percent of tobacco perfume, 5 to 10 percent of deionized water, 10 to 20 percent of glycerol and the balance of propylene glycol. The faint scent flue-cured tobacco leave extract is one of a Yunnan faint scent flue-cured tobacco leave extract and a Fujian faint scent flue-cured tobacco leave extract, or a mixture of the Yunnan faint scent flue-cured tobacco leave extract and the Fujian faint scent flue-cured tobacco leave extract. The electronic cigarette tobacco juice takes a faint scent tobacco leave extract as a main component, so that the aroma and mouthfeel of an electronic cigarette are close to those of the traditional faint scent cigarette. The electronic cigarette tobacco juice is used for atomizing the electronic cigarette and does not generate tar and CO, the harm to consumers is greatly reduced and the product cannot generate the harm of passive smoking.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

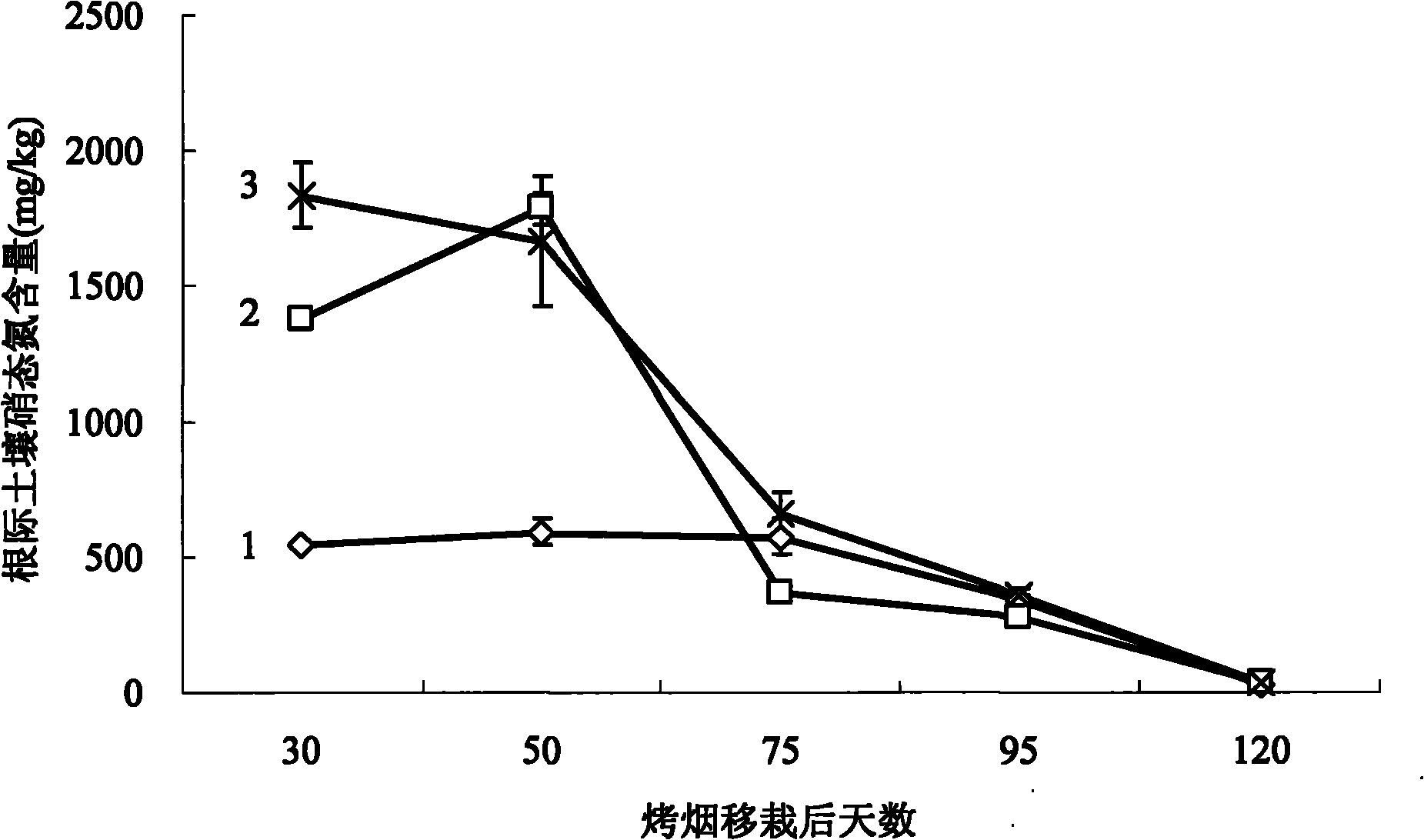

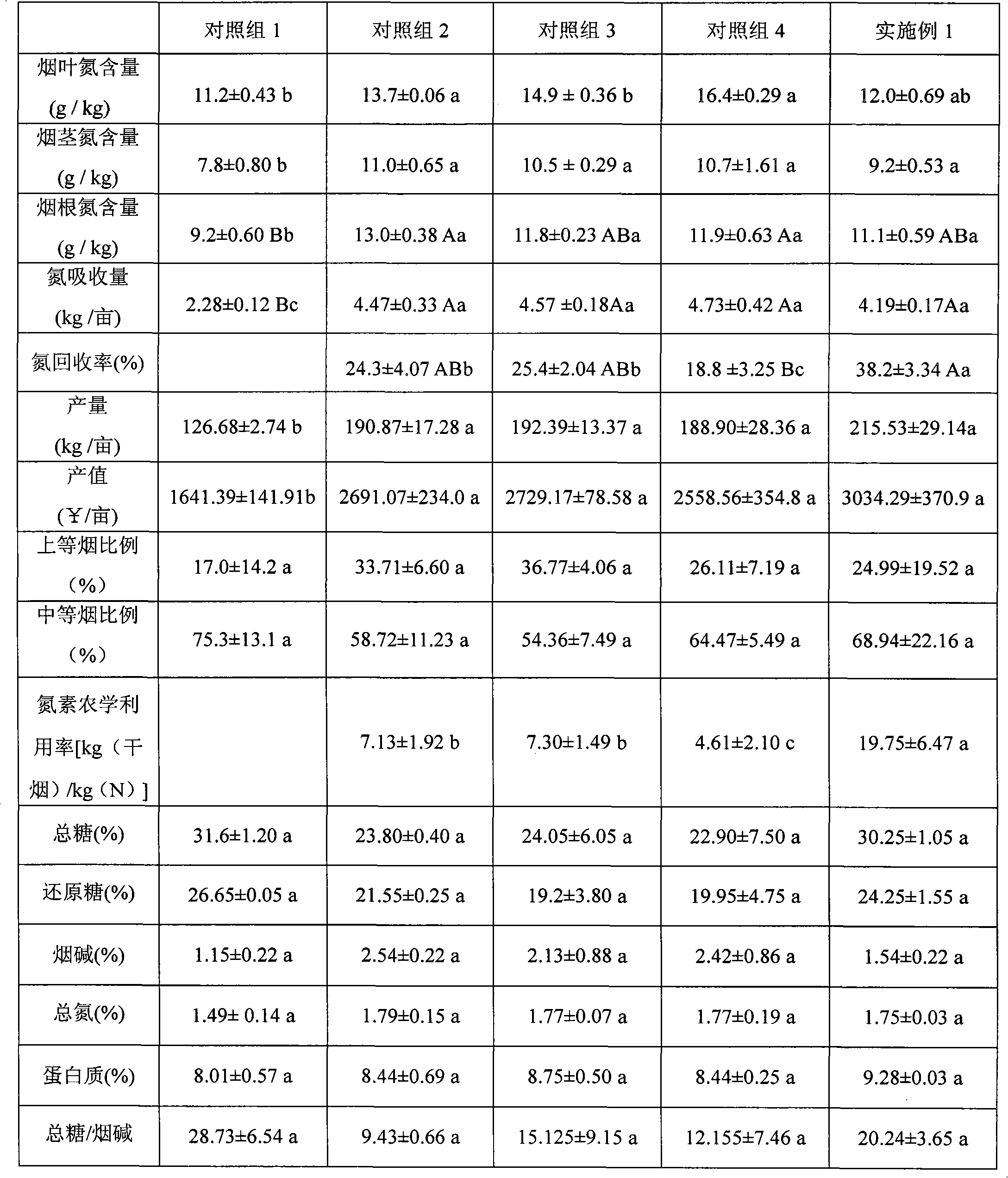

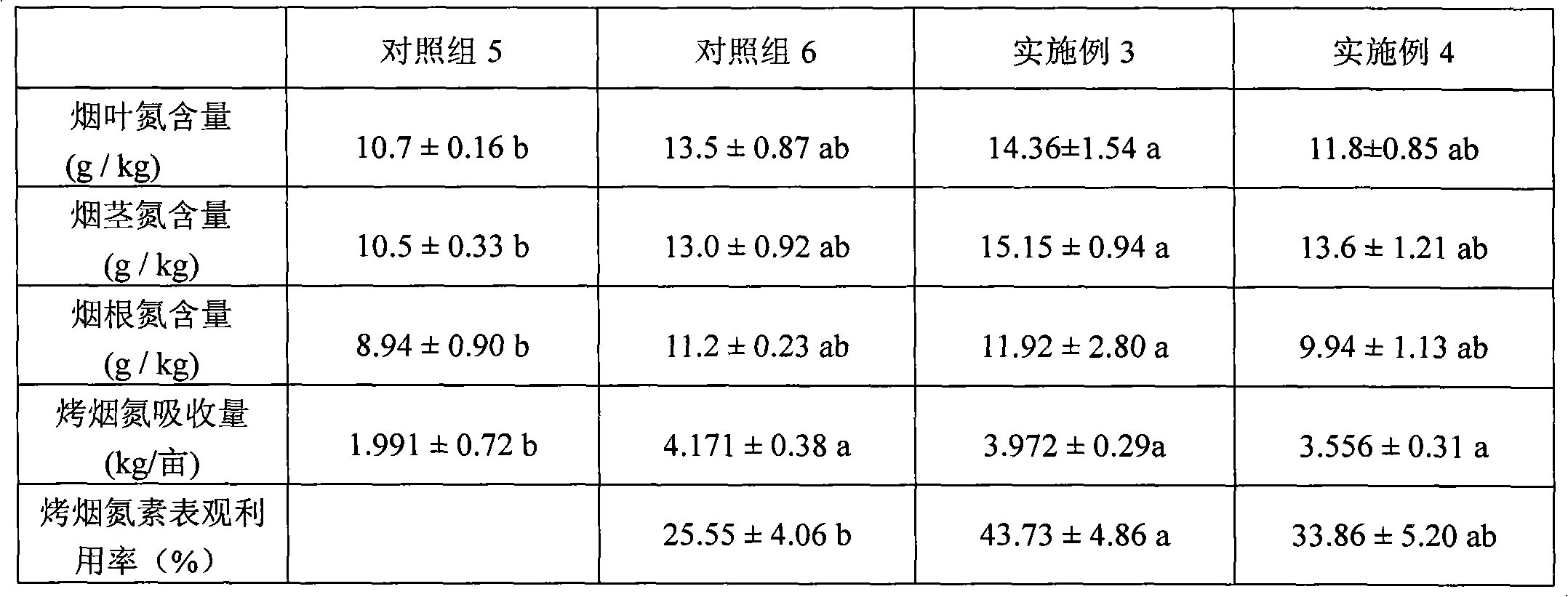

One-time nitrogen supply and fertilizer application method capable of improving applied nitrogen fertilizer effect of cured tobacco

InactiveCN102007843AStrong continuous nitrogen supply capacityEnhanced long-lasting nitrogen supply performanceFertilising methodsHorticultureRidgeHigh heat

The invention relates to a one-time nitrogen supply and fertilizer application method capable of improving applied nitrogen fertilizer effect of cured tobacco. The method is characterized in that: organic fertilizer decomposed cake fertilizer, decomposed pig manure, inorganic potassium nitrate fertilizer, special compound fertilizer for the cured tobacco and calcium superphosphate are used as base fertilizers; the fertilizers are applied in holes uniformly at the same day of transplanting the cured tobacco, tobacco ridges are covered by using a double-color plastic film, furrows of the tobacco ridges are connected with a drainage ditch, and the nitrogen amount of the organic fertilizer is 55 to 65 percent of the nitrogen amount of the base fertilizers; the nitrogen amount of the inorganic fertilizer is reduced by 45 to 55 percent according to the nitrogen amount of the inorganic fertilizers of the local base fertilizers and additional fertilizers, wherein the nitrogen of the potassium nitrate form accounts for 55 to 63 percent; in 25 to 35 days after the cured tobacco is transplanted, the film is uncovered, soil dressing is performed, and first top dressing is performed by using potassium sulfate and adopting a spraying mode; and second top dressing is performed in 40 to 45 days after transplanting, and third top dressing is performed after topping. In the method, the utilization rate of the cured tobacco nitrogen fertilizer is improved by 30 to 70 percent compared with the traditional fertilizer application, and the agricultural utilization rate of the cured tobacco nitrogen element is improved by 63 to 176 percent compared with the conventional fertilizer application; and the method is suitable for southern high-temperature rainy tobacco regions such as Guangdong and the like.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI +2

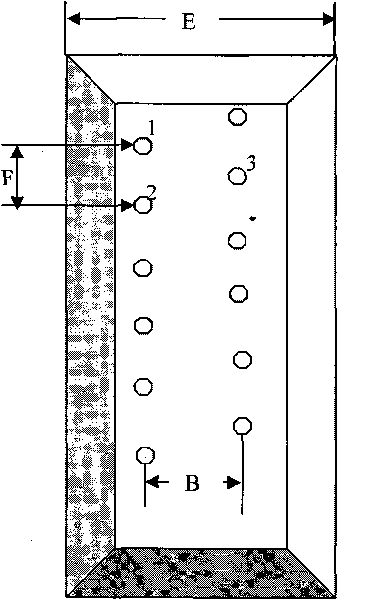

Method for baking tobacco leaf of intelligentized miniature compact tobacco flue-curing house

InactiveCN101342006ASolve insufficient capacityImprove roast qualityTobacco preparationPulp and paper industryIntelligent control

The invention relates to a method for curing tobacco leaves in a small intelligent concentrated tobacco curing barn; an air inlet is arranged in the curing barn; the top part is provided with a clearstory and a return intake; a hearth, a main fire tube, branch fire tubes, a chimney, a hot air course and an air outlet are arranged on a horizon; the main fire tube is connected with the hearth; a plurality of branch fire tubes are arranged in a circuitous way; the distribution of the hot air course below the fire tube is consistent to the fire tube; a clapboard is arranged above a hot air chamber; a fan is arranged above the opening of a branch hot air course and is connected with the return intake and the air inlet to form a hot air circulating system; intelligent control is formed by a temperature controller, a humidity controller, a temperature sensor, a humidity sensor, the fan, a blower and an air door in a connection way; the technique of the curing barn is divided into a yellowingstage,a leaf drying stage and a stem drying stage; the temperature of the stem drying stage is controlled to be 32 to 36 DEG C for 10 to 15 hours; then the temperature is raised to 39 to 42 DEG C for 10 hours; the temperature of the leaf drying stage is 45 to 48 DEG C for 12 hours; then the temperature is raised to 50 to 52 DEG C for 12 hours; then the temperature is raised to 54 to 55 DEGC for 12hours; the temperature of the stem drying stage is raised to 60 to 68 DEG C; the stems of tobacco is cured to be completely dry; then the fire is stopped; then dampening and removing from a kang are carried out.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

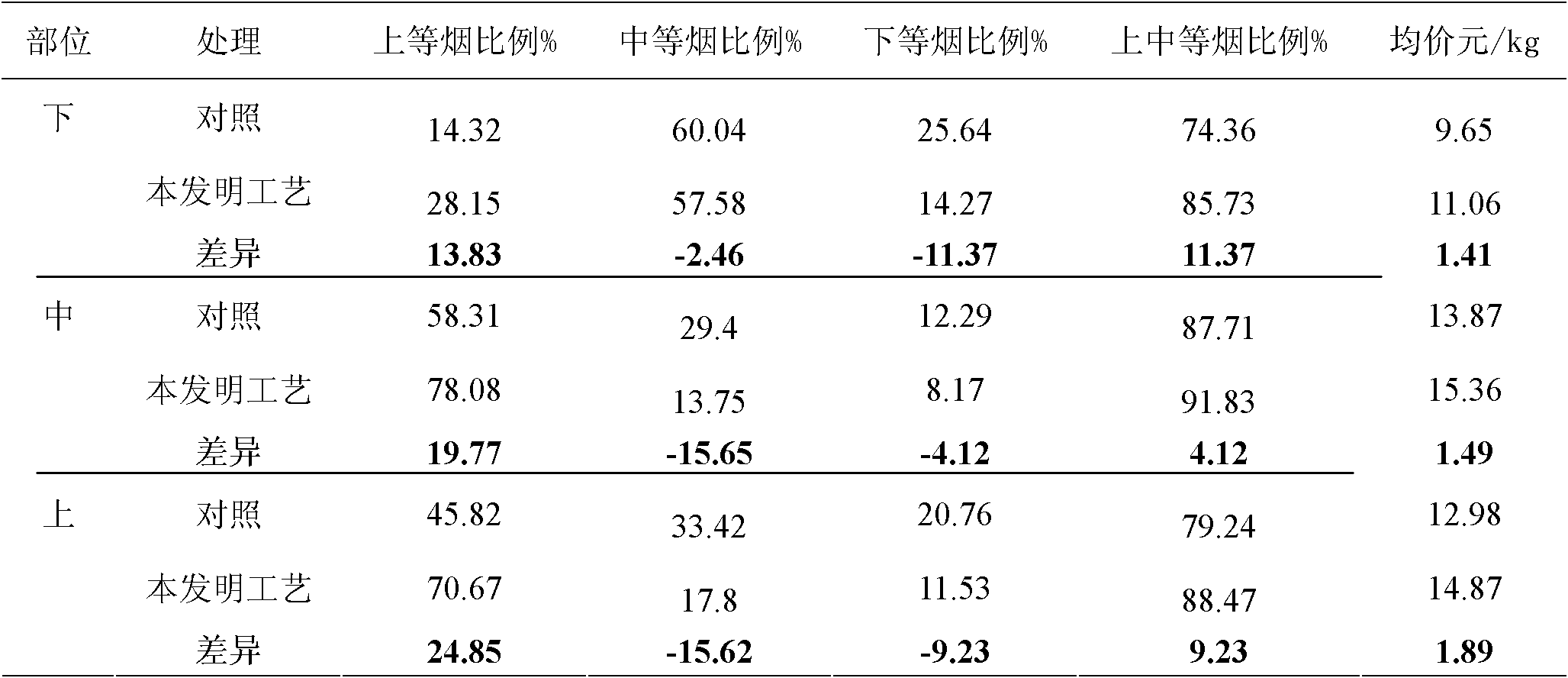

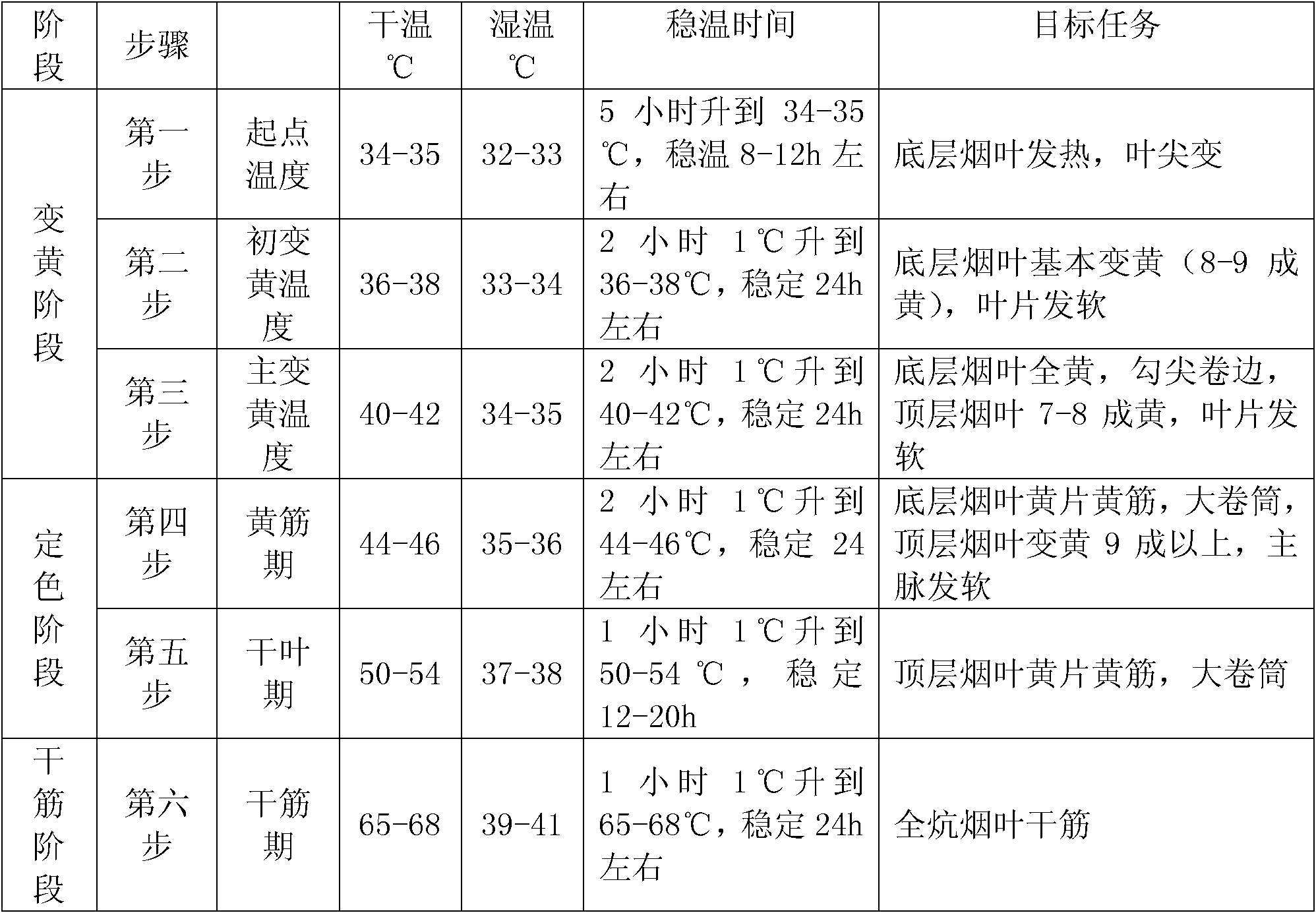

Three-stage six-step baking technology for flue-cured tobacco in common flue-curing barn

InactiveCN102488311AImprove roast qualityEasy to masterTobacco preparationCooking & bakingThree stage

The invention discloses a three-stage six-step baking technology for flue-cured tobacco in a common flue-curing barn, and belongs to the technical field of modulation of flue-cured tobacco. The technology mainly comprises three baking stages, namely a yellowing stage, a color fixing stage and a stem drying stage. The technology is characterized in that: the yellowing stage comprises three key temperature and humidity steps; the color fixing stage comprises two key temperature and humidity steps; and the stem drying stage has a key temperature and humidity step. The whole braking process has the three baking stages and the six key temperature and humidity steps, and the temperature and the humidity in the flue-curing barn are controlled in the temperature and humidity ranges required by the corresponding steps of the six key temperature and humidity steps according to the change conditions of tobacco leaves, so that the aim of regulating and controlling the baking process of the flue-cured tobacco is fulfilled, a good effect is achieved, the destroyed tobacco such as green impure tobacco and the like is obviously reduced, the proportion of orange tobacco and high-grade tobacco is improved, the flue-cured tobacco has a loose structure, the oil content of the flue-cured tobacco is increased, and the inner and outer view quality and the availability of the tobacco leaves are remarkably improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

Cured tobacco perfume formulation

The invention provides a formula of a cured tobacco flavor, and pertains to the technical field of flavors. The formula of the cured tobacco flavor takes vanillin, isoamyl isovaleriate, aglaia odorate flower concrete extract, rhodinol and Maillard reactant as the main raw materials. The formula is applied to the tobacco to cause the cigarette to have a novel and nice fragrance, in particular to cause the cigarette to have a pure and mellow fragrance, thus obviously improving the impure fragrance and the smoke taste and causing the characteristic of the cigarette fragrance to be obvious. The formula has available flavor raw materials, and does not need to increase devices and change the production process. The addition amount is 1.2-2.5 per mill of the tobacco usually.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

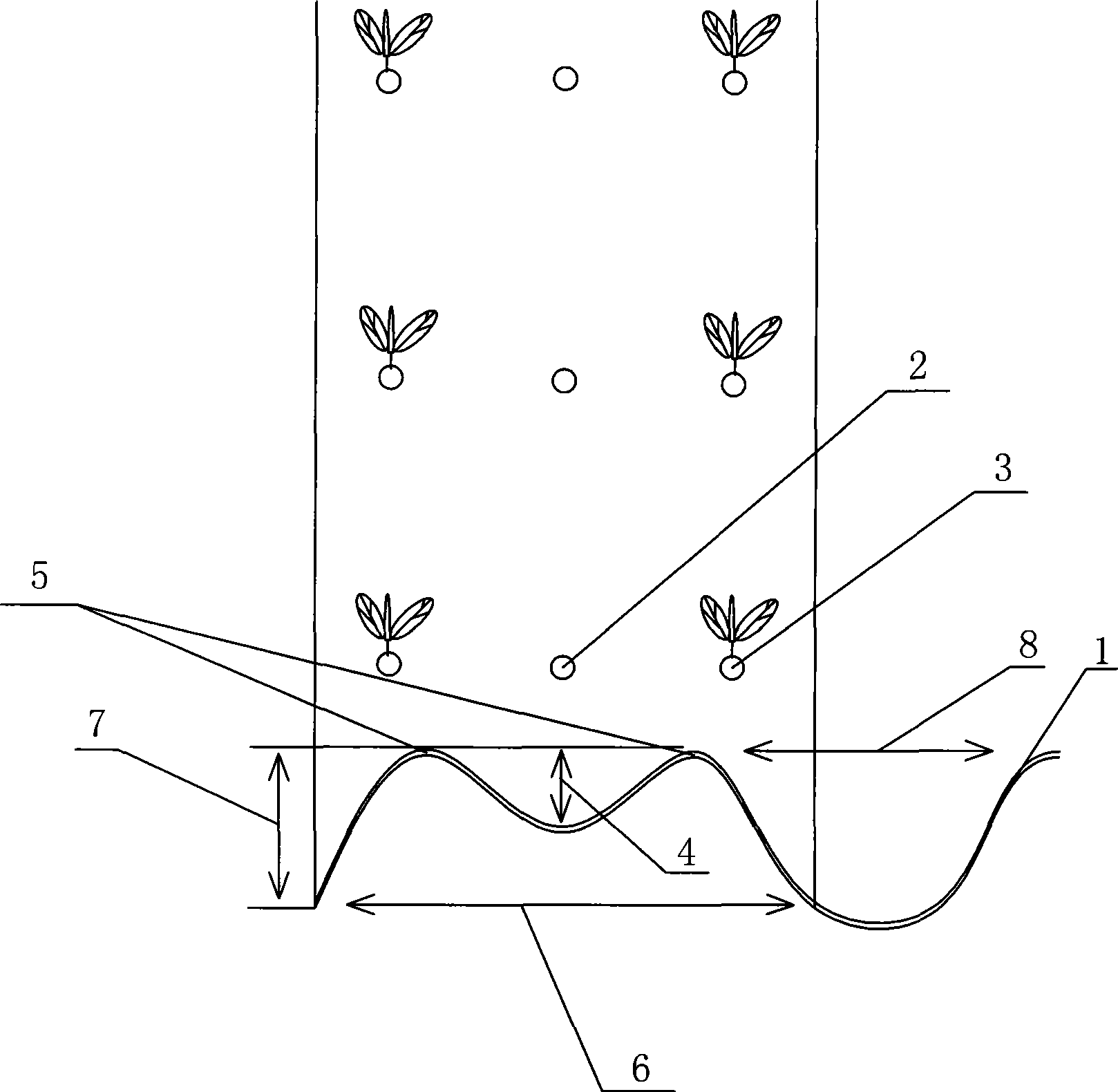

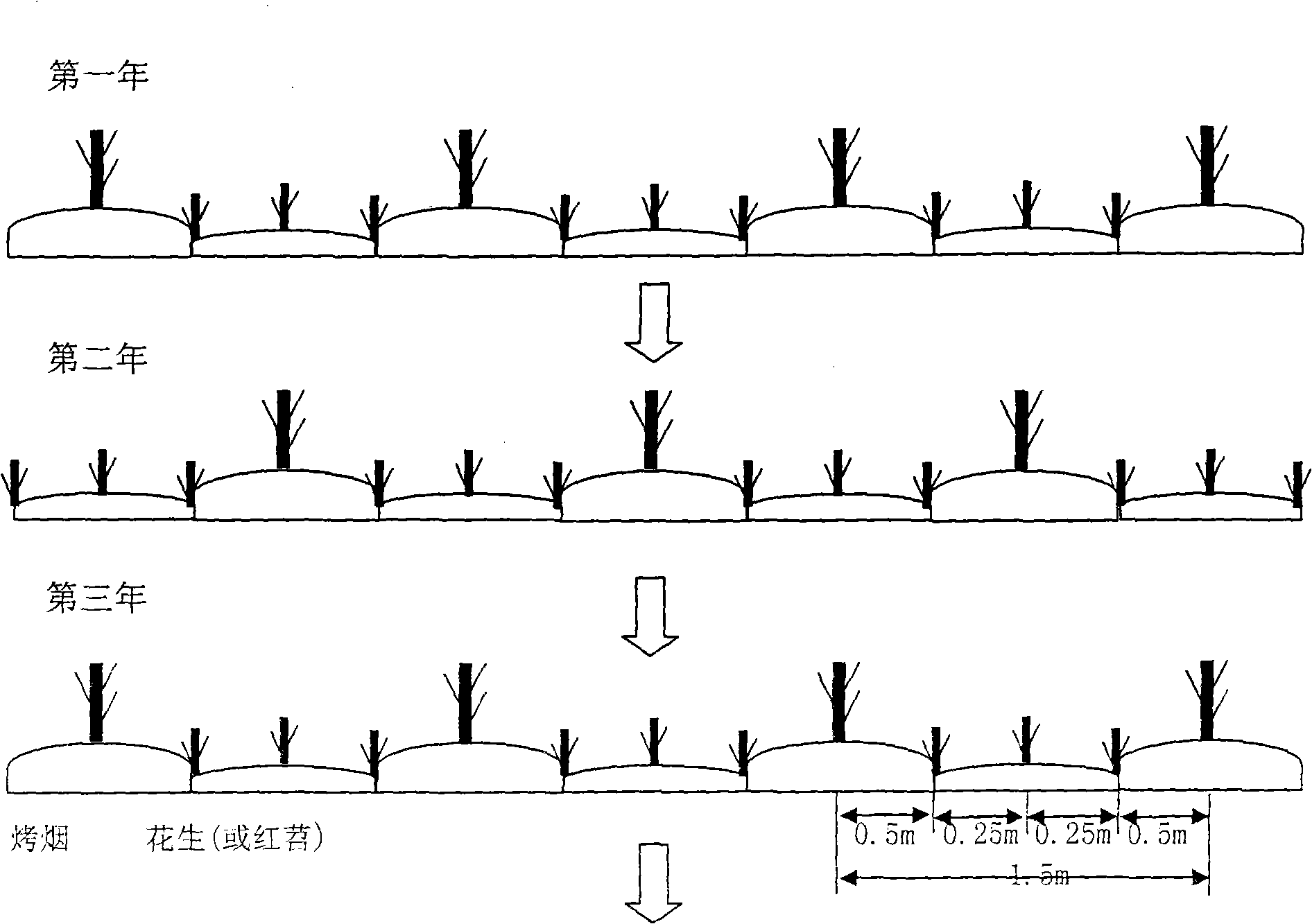

Culturing method of one-ridge double-row flue-cured tobacco dislocation

InactiveCN101699954AGuaranteed housekeepingGuaranteed incomeHorticultureSoil-working methodsOrganic fertilizerDislocation

The invention discloses a culturing method of one-ridge double-row flue-cured tobacco dislocation, comprising the following steps: (1) selecting tobacco field and preparing soil; (2) ridging; (3) applying base fertilizer; (4) transplanting; and (5) uncovering film, ridging and loading. The method has the following advantages that: (1) on the premise that the use amount of fertilizer for soil in unit area is not changed, the fertilizer use amount of single plant in flue-cured tobacco field is reduced, and the use amount of field organic fertilizer, especially oil cake fertilizer is increased to lead the field tobacco plant to present the growth of middle-plant tobacco, thus obviously improving the tobacco leaf quality; (2) compared with the conventional single ridge, the one-ridge double-row tobacco reduces the labor capability of ridging by about one third, the ridging height is obvious lower than the conventional height, thus reducing ridging labor intensity of tobacco growers; and (3) the one-ridge double-row flue-cured tobacco increases flue-cured tobacco planting density, and meanwhile, a dislocated equal plant distance planting method improves utilization rate of tobacco field to the utmost, ensures the housework operation of tobacco growers, and the row space of the ridge just satisfies growth space of tobacco plants in the field, thus ensuring the income of the tobacco growers.

Owner:GUIZHOU TOBACCO SCI INST

Method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for electronic cigarette

ActiveCN104041935ASuitable for needsCigarette tobacco smell strongTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention discloses a method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for an electronic cigarette. The method comprises the following steps: 1, blending flue-cured tobacco type tobacco leaves, tobacco shreds or tobacco powder; 2, applying cigarette feed liquid or materials with high sugar content on the tobacco leaves, tobacco shreds or tobacco powder; 3, performing destructive distillation on the tobacco leaves, tobacco shreds or tobacco powder by different temperature sections; 4, collecting fractions. The fractions collected by the method can directly serve as electronic cigarette juice, and cigarette essence perfume having characteristic flavor, or edible essence perfume also can be added to enrich the styles of the electronic cigarette tobacco juice; the electronic cigarette juice collected by the method has the style characteristic and flavor similar to those of a Chinese-style cigarette, the satisfaction is good, the fragrance is harmonious, and the taste is pure and mild.

Owner:CHINA TOBACCO SHANDONG IND

Non-mulching-film well pit type cured tobacco young seedling transplanting method

InactiveCN102498920ARealize deep plantingStay hydratedFertilising methodsHorticultureDiseasePlastic mulch

The invention disclosed a non-mulching-film well pit type cured tobacco young seedling transplanting method which comprises the following steps of: (1) preparing land and ridging; (2) determining transplanting time; (3) forming transplanting well pits; (4) transplanting tobacco seedlings; (5) spraying root fixing water and carrying out top dressing; and (6) filling with soil and sealing. The method is a technological innovation of the mulching film cultivation of the cured tobacco, and has the advantages that: the problems of seedlings with high and slim stems as well as exposure of tobacco stems brought by non-standard conventional transplanting method, the problem that the drought climate at the transplanting time is unfavorable to transplanting, the problems in the improving the survival rate of planted tobacco seedlings and shortening the seedling restitution stage and the problem of slow transplanting progress are solved; the characteristics of relatively maintaining the heat and humidity of the well pits are utilized to realize young seedling transplanting and to finish cultivation and field deep-planting of high and strong seedlings in the well pits at one time; the seedling raising time is shortened, the seedling raising cost and facility investment are reduced, and the comprehensive utilization benefit of the seedling raising greenhouses is improved; and the disease infection opportunity during the leaf cutting link is reduced, the utilization rate of the fertilizer is improved, the root systems of the young seedling are flourishing and the drought defying capability is enhanced. The method is suitable for planting of cured tobacco, burley tobacco, sun-cured tobacco and other crops.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

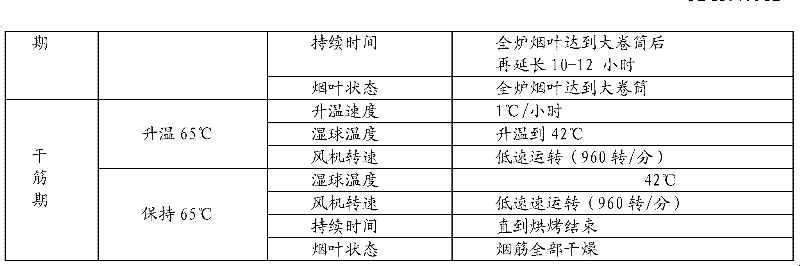

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

Fire-cured tobacco cultivation technique mode by concave double-ridge plastic membrane mulching during whole breeding season

InactiveCN101438657AReduce the amount of applicationIncrease productionFertilising methodsAgriculture gas emission reductionPlastic mulchEngineering

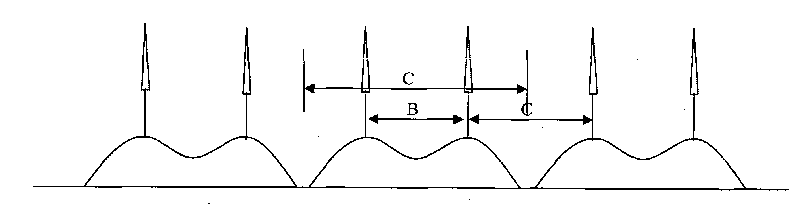

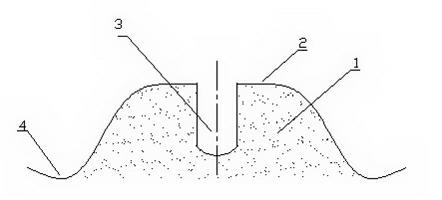

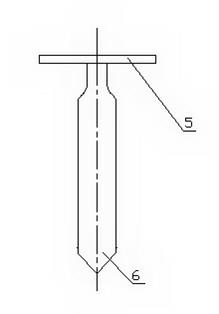

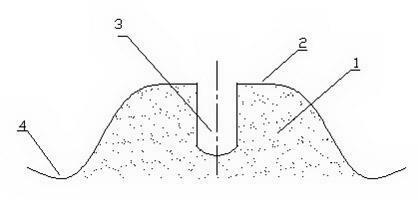

The invention discloses a whole-growth period plastic mulching cultivation technical mode with double-row concave ridges in a flue cured tobacco field. The tobacco field is plowed and divided to form the double-row concave ridges with a width of 220cm and a height of 15-35cm; a row distance which is 100cm is arranged between the two rows of the concave ridge peaks, and a concave ridge groove is arranged between two rows of the ridge peaks; the peak of the double-row concave ridge is 120cm away from the peak of another double-row concave ridge; the double-row concave ridges are covered by an agricultural plastic mulch with a width of 200cm; tobacco seedling holes are dug on the peaks of the concave ridges at a plant distance of 55-60cm in each row; the depth of the concave ridge groove is 8-12cm, and pervious holes with a diameter of 1cm are dug on the agricultural plastic mulch on the valley of the groove at a vertical distance of 60cm; a basic fertilizer is applied before mulching, and an additional fertilizer is applied 20 days after transplanting. The technical mode can help realize effective water collection, water conservation, fertilizer conservation, temperature adjustment, soil moisture preservation and weed suppression, reduce fertilizer input, save labor, effectively increase the yield and quality of tobacco leaves, and increase economic benefit of tobacco growers.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

Preparation method for regenerating tobacco leaves by using aromatic tobacco papermaking method

ActiveCN102018274AFull price to take advantage of abundanceImprove qualityTobacco preparationSlagPapermaking

The invention discloses a preparation method for regenerating tobacco leaves by using an aromatic tobacco papermaking method, belonging to the technical field of tobacco leaf regeneration by using a papermaking method in the tobacco industry. The preparation method is characterized by comprising the following steps of: extracting aromatic tobacco with an aqueous solution containing an organic solvent, separating solid and liquid, a concentrating extract into extractum, adding aromatic tobacco seed powder and a mixed solvent to the extractum to prepare coating fluid; mixing aromatic tobacco slag with tobacco cabo slag extracted through water to pulp into a film base through manufacturing and forming paper with pulp; coating the film base with the prepared coating liquid, drying, cutting and crushing into finished regenerating tobacco leaf products of aromatic tobacco type by using the aromatic tobacco papermaking method. The invention provides the tobacco regenerating method by using the papermaking method which can fully utilize the whole leaves, scraps, broken leaves and aromatic tobacco seed resources and have the characteristic of producing typical aromatic tobacco.

Owner:YUNNAN RES INST OF TOBACCO SCI

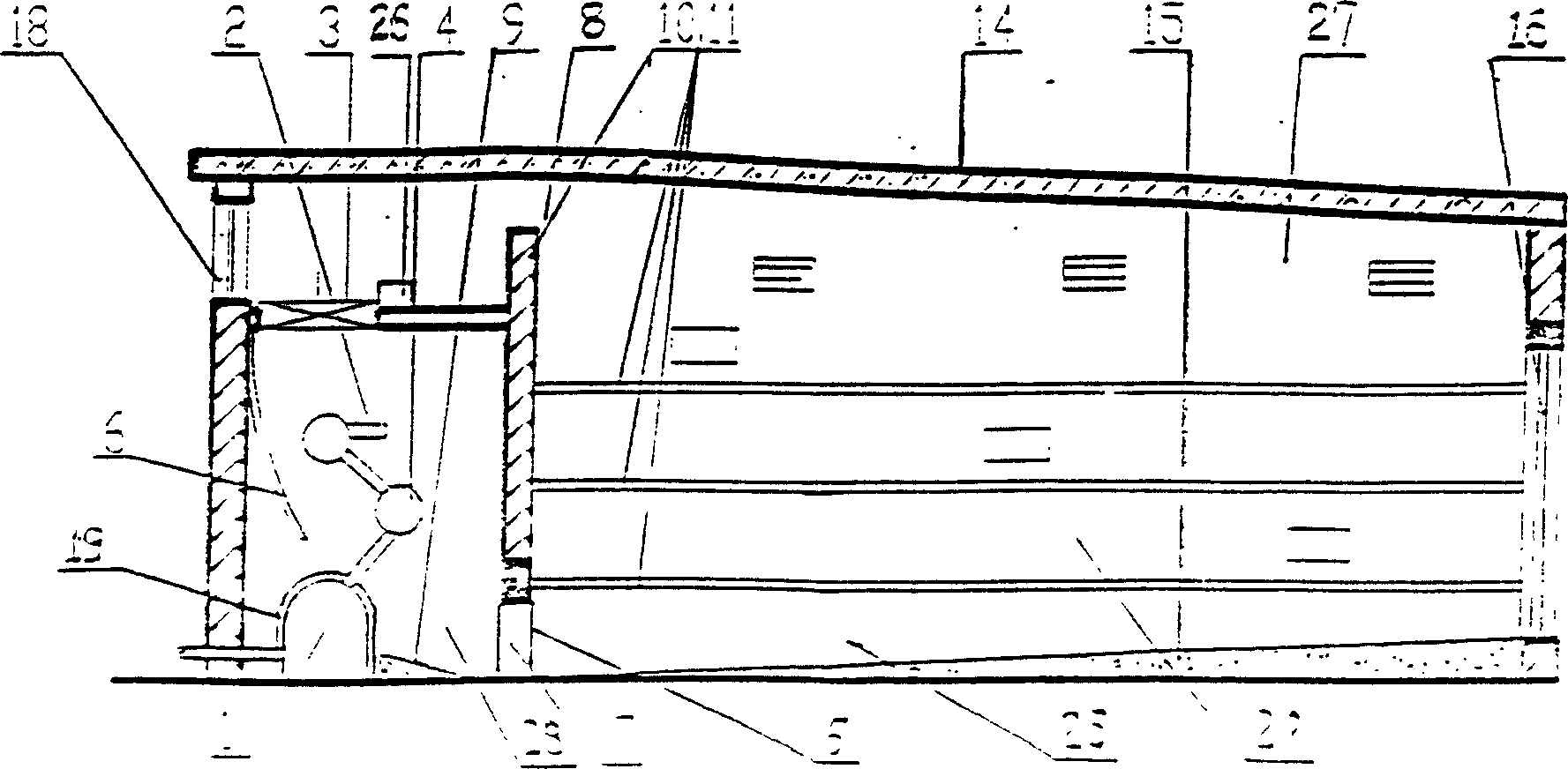

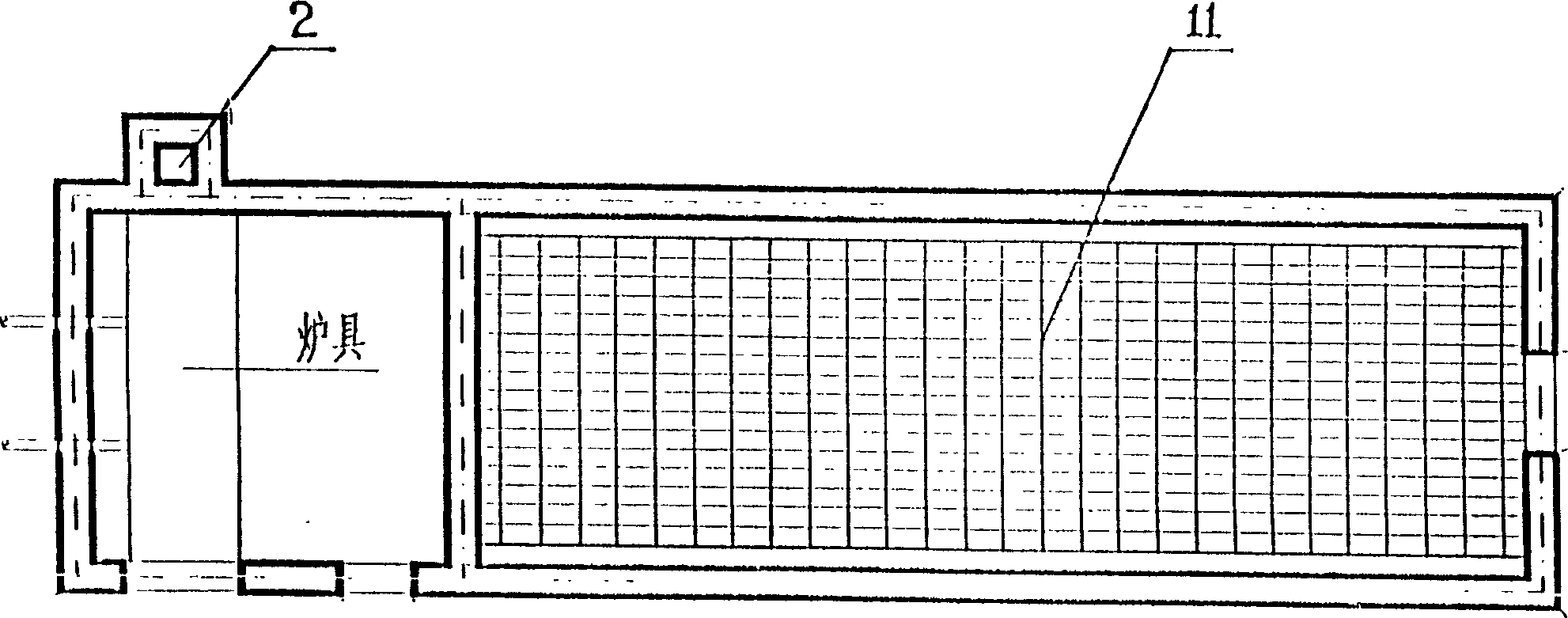

Scattered leaf stacked tobacco-roasting house and its leaf roasting method

The present invention discloses a scattered leaf stacked tobacco-roasting house and its leaf roasting method, which includes two juxtaposed rooms: a heating room and a tobacco filling room; the said heating system is disposed in the heating room, and a tobacco stacking gate is disposed in the tobacco filling room; the said hot air circulation system which makes the hot air circulate between the heating room and the tobacco filling room is diposed in the heating room and the tobacco filling room and connects the heating room and the tobacco filling room; the layers and the height of the scattered leaf stacked tobacco-roasting house are both lower than that of the conventional roasting house, which avoids the high-altitude operation in the filling house, and the operation being safe and convenient; the scattered leaf stacked tobacco-roasting house adopts that the heating room and the tobacco filling room are mutually isolated with each other, therefore, no fire will occur and it is more secure; the roasting house has a lower-cost, a low vertical temperature, and a uniform surface temperature; and it save labor costs according to the conventional roasting house, thereby improving the quality of tobacco, and increasing the output.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

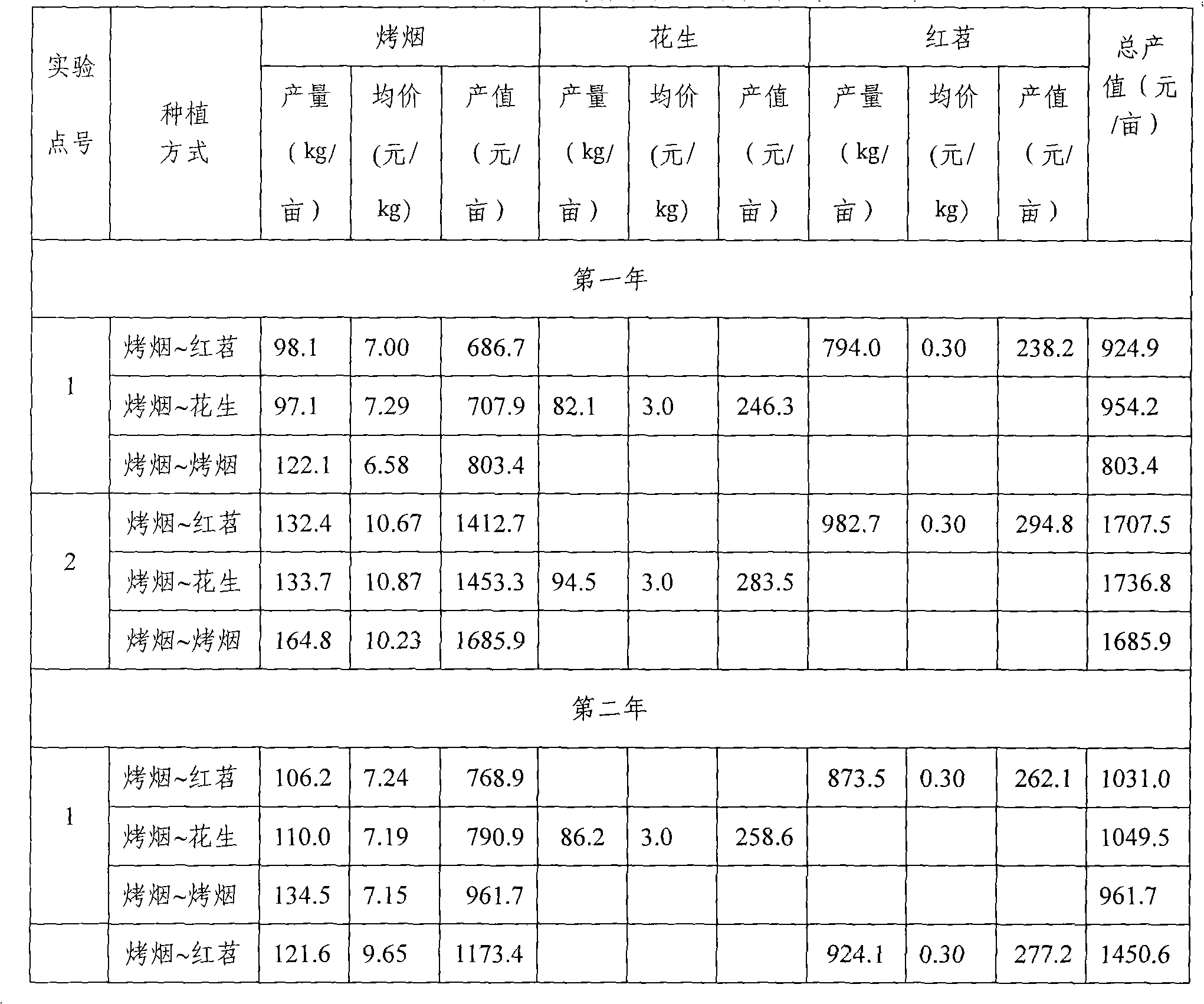

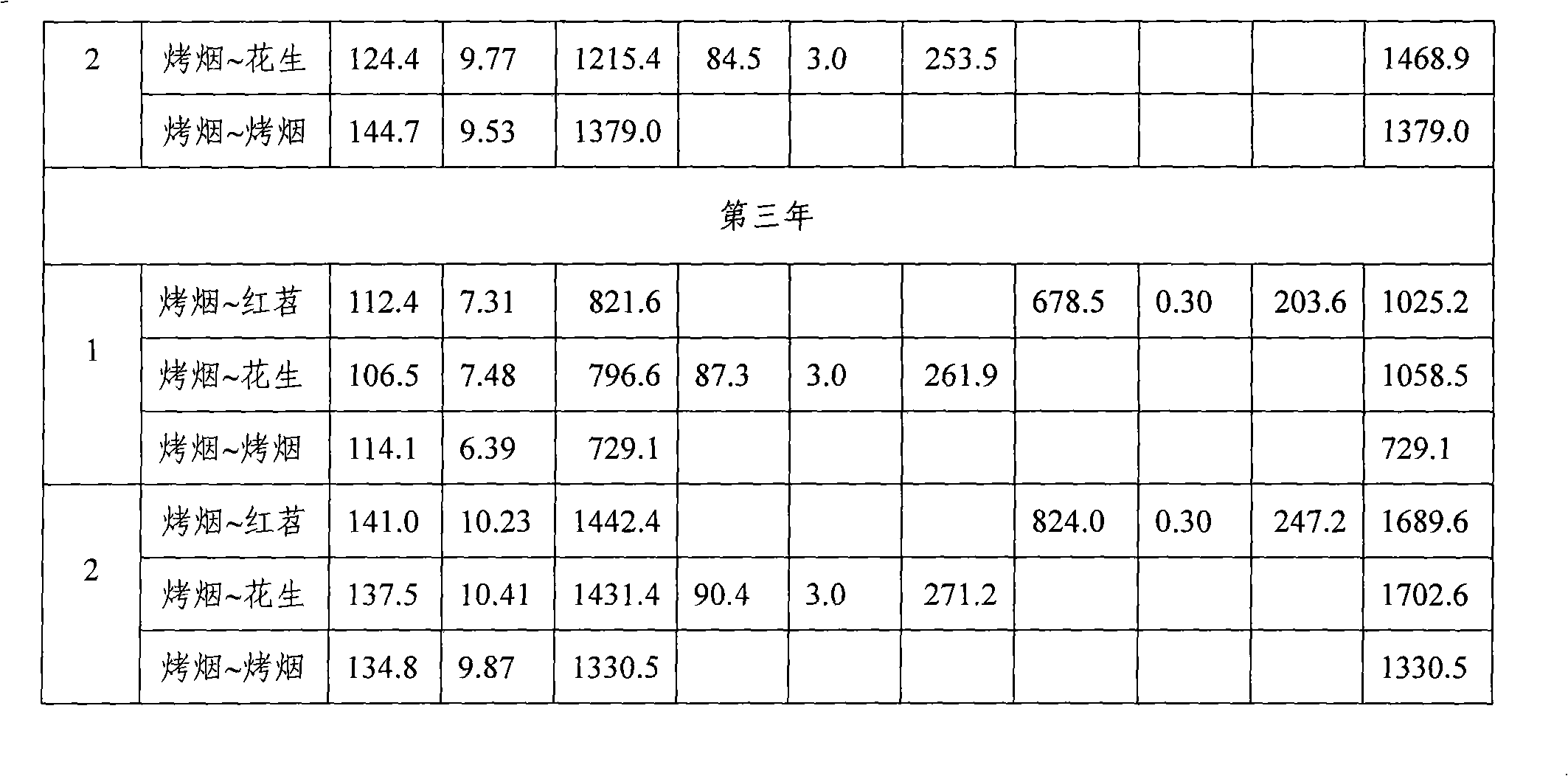

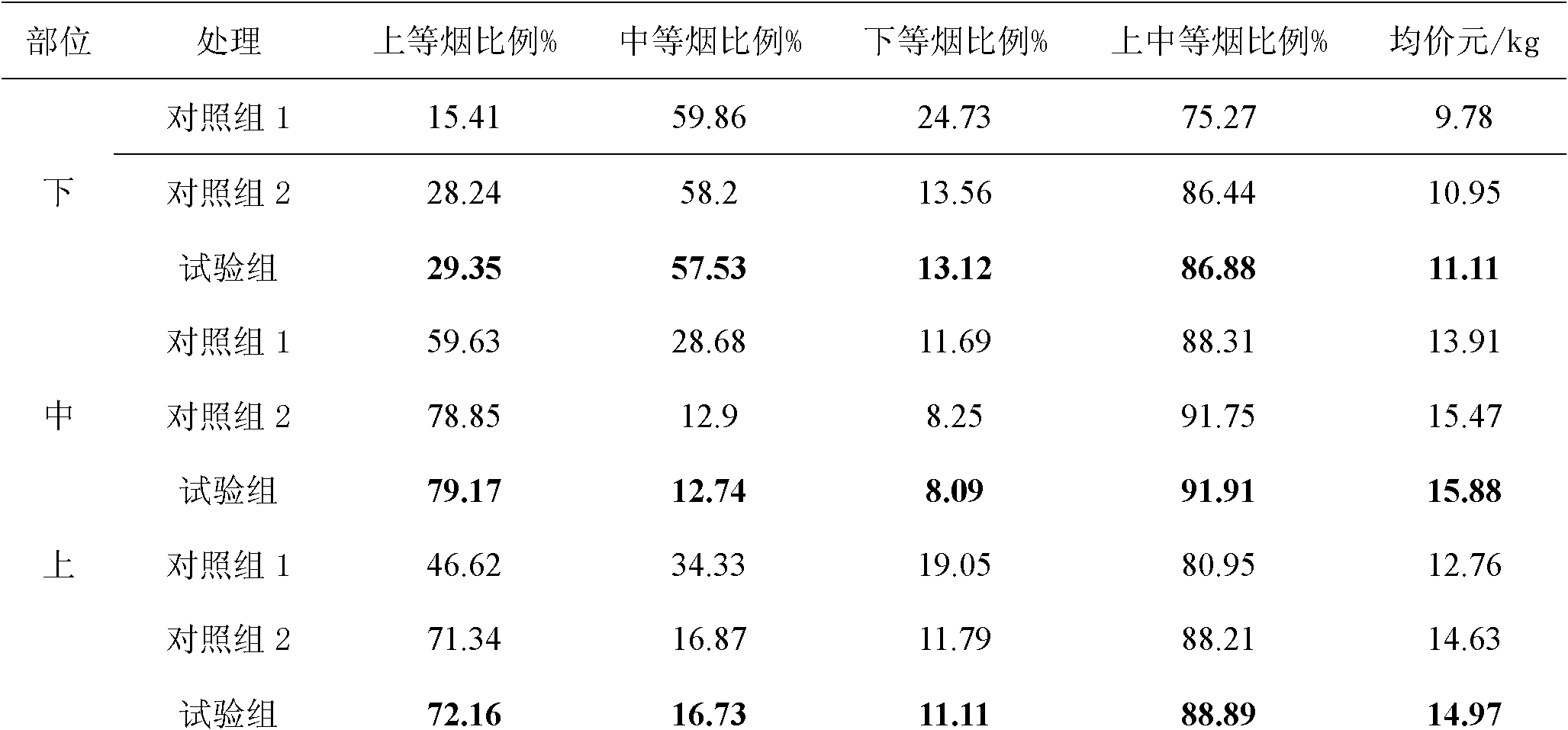

Planting method for conquering the continuous cropping obstacle of cured tobacco

InactiveCN101305670AAlleviate continuous cropping obstaclesGuaranteed sustainable productionFertilising methodsHorticultureContinuous croppingDisease

The invention relates to a planting method for overcoming the continuous cropping problems of flue-cured tobacco. The quality of the flue-cured tobacco is improved by alternately intercropping the flue-cured tobacco and peanuts or sweet potatoes so as to improve the ratio of the medium and high rank tobacco, and both the output value per unit of land and the income of the tobacco grower are increased; and meanwhile, the flue-cured tobacco planting is integrated with the generalized agriculture production, therefore, the continuous cropping problems (such as growth inhibition, disease and insect pest epidemiology and product quality reduction, etc.) of the flue-cured tobacco are remarkably lightened, the flue-cured tobacco can be basically planted for a long term and in successive years, the problem of serious tobacco field resources in the southwest region is solved, and the sustainable production of the flue-cured tobacco is guaranteed.

Owner:SOUTHWEST UNIVERSITY

Three-ladder seven-step method for baking scattered flue-cured tobacco leaves

InactiveCN102793260ANot easy to dehumidifyNot easy to burnTobacco preparationCooking & bakingEngineering

The invention discloses a three-ladder seven-step method for baking scattered flue-cured tobacco leaves. In the seven steps, the yellowing stage belongs to the first three steps, the color fixing stage belongs to the middle two steps, and the vein drying stage belongs to the last two steps. The three-ladder seven-step method is mainly characterized in that the self characteristics of the baking of the scattered leaves are taken as the basis, the characteristics of a controller are combined, the humidity and the temperature of all the stages are quantized, the time in parts of stages is quantized, so that the complicated scattered leaves baking technology is simplified to the maximum degree, a tobacco grower can learn quickly and master quickly by using, further, the accumulated baking of the scattered leaves in a bulk curing barn is popularized, and the popularization is not restrained by the complicated baking technology and insufficient guidance personnel.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

Tobacco leaf curing process capable of improving curing quality of flue-cured tobacco variety KRK26

ActiveCN101991180AMaintain moisture contentImprove roast qualityTobacco preparationDecompositionCell membrane

The invention relates to a tobacco leaf curing process capable of improving the curing quality of a flue-cured tobacco variety KRK26, belonging to the technical field of flue-cured tobacco modulation processes. The curing process comprises the following steps of: regulating the humidity at low temperature to yellow tobacco leaves; stabilizing the temperature and removing moisture for withering; ventilating and dewatering for drying the leaves; and controlling the temperature and the humidity to dry leaf ribs. In the invention, the method of keeping the tobacco leaves at lower temperature to reduce water evaporation in the tobacco leaves and guarantee the water content of the tobacco leaves is adopted to solve the problems of less water and difficult yellowing of the tobacco leaves of the KRK26 variety in the yellowing period; the dry-bulb temperature is between 41 DEG C and 44 DEG C, and the tobacco leaves can be sufficiently dewatered and shrunk to reduce the cell membrane turgor; the tobacco leaf cell membranes cannot be broken between 45 DEG C and 48 DEG C so as to smoothly fix the color; and in the whole process of tobacco leaf curing, the wet bulb temperature is controlled tobe between 34 DEG C and 38 DEG C so as to actively promote the decomposition and the conversion of macromolecular substances and the synthesis of flavoring substances. The invention has the advantages of simple and convenient operation, safety and insurance, can ensure that the tobacco leaves of the variety KRK26 can be smoothly yellowed, timely subjected to color fixing and subjected to rib drying in good time and improves the tobacco leaf curing quality.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Three-section and five-step bulk curing process for flue-cured tobacco

InactiveCN102488310ALow hardware requirementsReduce construction costsTobacco preparationEngineeringFlue

The invention discloses a three-section and five-step bulk curing process for flue-cured tobacco, and belongs to the technical field of tobacco modulation. The process mainly comprises three curing stages, namely a yellowing stage, a fixation stage and a stem drying stage, and is characterized in that: the yellowing stage and the fixation stage are also decomposed into two key temperature and humidity steps respectively; by increasing a key temperature and humidity step of the stem drying stage, three curing stages and five key temperature and humidity steps are set for the entire curing process; according to variation condition of tobacco leaves and by controlling the temperature and humidity of a curing room in the temperature and humidity ranges required by corresponding steps of the five key temperature and humidity steps, the aim of adjusting and controlling flue-cured tobacco curing process is fulfilled, a better effect is achieved, poor curing of green miscellaneous tobacco and the like is obviously reduced, the proportion of yellow tobacco and high-grade tobacco is increased, the structure is loose, the oil content is increased, and the internal and external appearance quality and the availability of the tobacco are obviously improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

Cured tobacco baking technique capable of improving quality and flavoring

ActiveCN101416767AHigh oil contentIncrease the amount of aromaTobacco preparationEcological environmentMetallurgy

The invention relates to a quality-improving, flavouring, roasting technique of tobacco leaves, belonging to the technical field of roasting tobacco technique. The key technology lies in that: (1) adjusting humidity at a low temperature until turning yellow, roasting the tobacco leaves on the base frame of a roasting room until stems turn green and leaves turn yellow, with the temperature in a furnace less than 39 DEG C, the temperature of a wet bulb less than 35 DEG C and the relative humidity between 92% and 75%; (2) stabilizing the temperatures and discharging moisture until the leaves wilt, roasting until all the tobacco leaves in the furnace fully wilt and diachyma is 7.5-8.5 dried, with the temperature in the furnace between 40 DEG C and 48 DEG C, and the relative humidity in the furnace between 67% and 38%; (3) ventilating and dehydrating until the leaves are dry, roasting until the tobacco leaves on the base frame roll a lot and the upper leaves are 7.5-8.5 dried and roll a little, with the temperature in the furnace between 49 DEG C and 53 DEG C, and the relative humidity in the furnace between 42% and 31%; (4) controlling temperature and humidity until the stems are dry, roasting until all the tobacco leaves in the furnace are dry, with the temperature in the furnace between 54 DEG C and 68 DEG C, and the relative humidity in the furnace between 29% and 12%. The invention has advantages of a simple operation, safety, stable yellow tobacco leaves keeping property, good wrinkling degree of leaves, increased oil, and greatly increased fragrance of leaves; and is applied to roasting tobacco leaves in different ecological environments.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

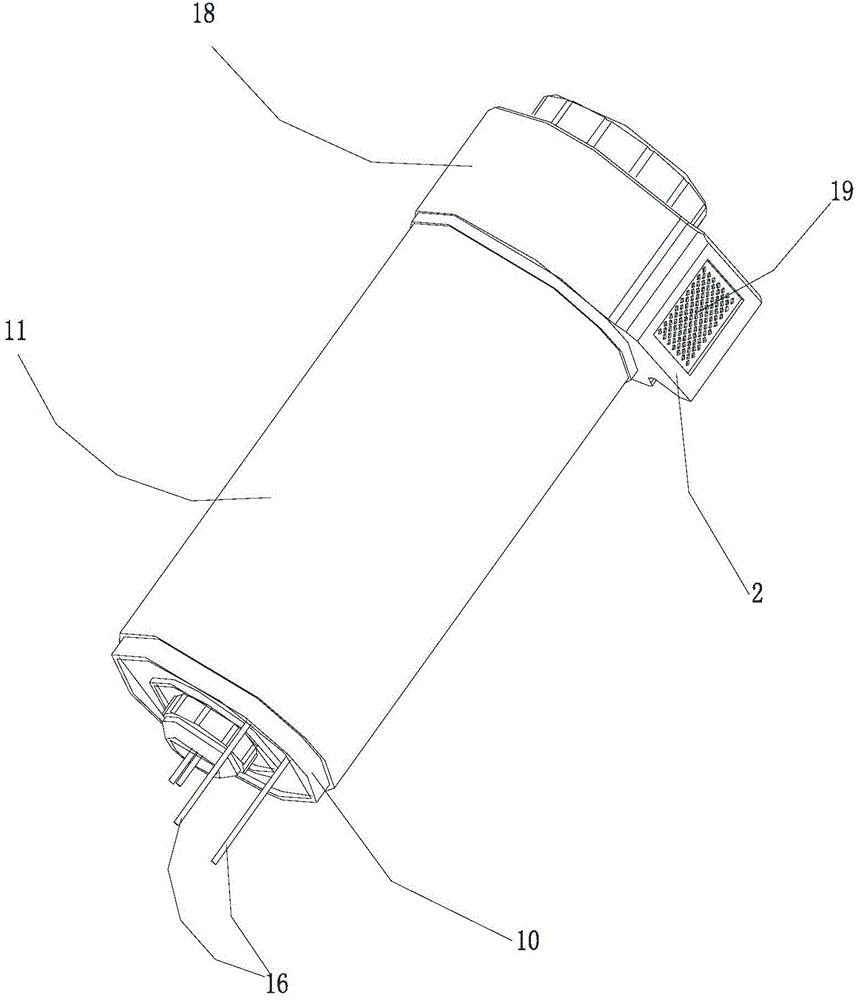

Air preheater

The invention discloses an air preheater, comprising an air passage. One end of the air passage is provided with an air inlet. The other end of the air passage is provided with an air outlet. A heater for heating the air flowing in the air passage is provided within the air passage. The use of the air passage and the heater allows full curing of tobacco shreds, reduction in harmful substances and improvement in taste.

Owner:SMISS TECH

Chicken manure fermented fertilizer

InactiveCN102924185ASave resourcesAvoid pollutionBio-organic fraction processingClimate change adaptationNutrientPlant Alkaloids

The invention belongs to the technical field of bio-organic fertilizer, and particularly discloses chicken manure fermented fertilizer, which is prepared through normal temperature fermenting, three-time mixing and separating adding of dry chicken manure, rice bran powder, flue curing straw, EM (Effective Microorganisms), basalt powder and camellia shell powder, and has the benefits that the nutrient in the agricultural waste is utilizes, so as to avoid environmental protection; the plant alkaloid and the perfume oil in the flue curing straw and the camellia shell powder are utilized to kill the pest in the field; the EM can produce microorganisms beneficial to the growth of organisms, so as to accelerate the fertility releasing and the crop growth; and the basalt powder can provide the rich elements necessary for the crop as calcium, magnesium, sulfur, iron, copper, zinc and cobalt. Through practice, the chicken manure fermented fertilizer is applicable to all sorts of food crop and fruit and vegetables, enables the soil fertilizer efficiency to last 4 months with one-time fertilization, and enables the average increase of the crop to be 15%, as a result, not only is the labor intensity during agricultural production reduced, but also the soil ecological balance can be adjusted and the soil permeability is improved as well.

Owner:重庆润绿生物有机肥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com