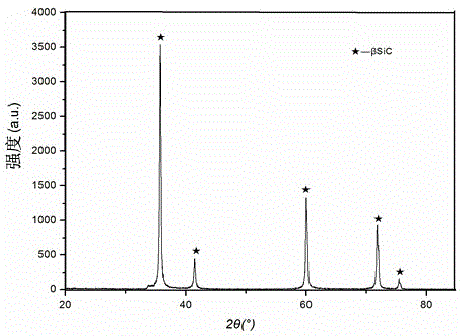

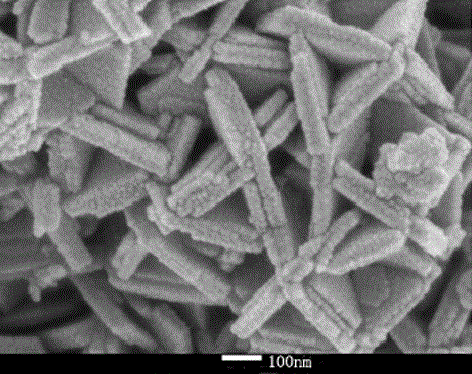

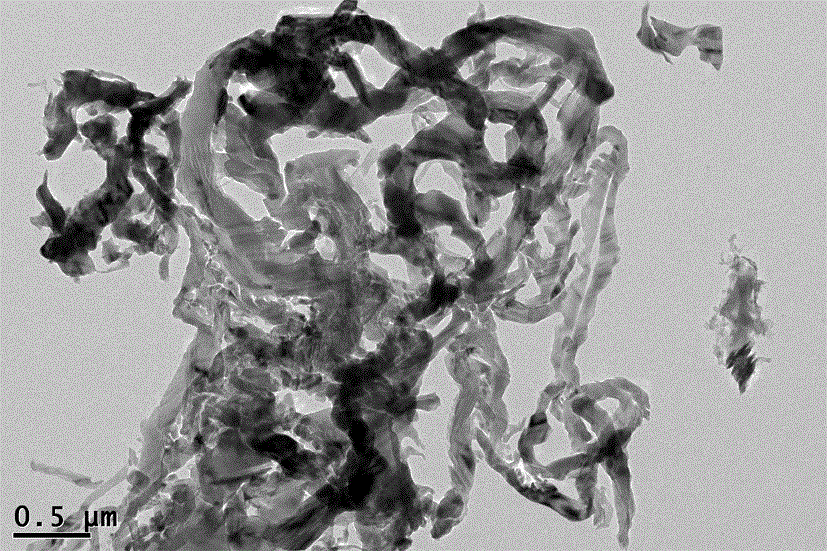

Preparation method of nanoscale silicon carbide particles and product of nanoscale silicon carbide particles

A nano-scale silicon carbide and silicon carbide technology, applied in nanotechnology and other directions, can solve the problems of expensive reaction raw materials and high cost, and achieve the effects of low cost, low price and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of nano-scale silicon carbide particles;

[0026] The first step is raw coal pretreatment. 200 grams of Taixi coal with an ash content of 5.9% was crushed, ground and sieved to obtain 250 mesh coal powder as a carbon source for future use;

[0027] The second step is the preparation of silicon carbide precursor. Weigh 28.4g of analytically pure sodium silicate, dissolve it into a beaker filled with 100ml of distilled water to obtain an aqueous sodium silicate solution with a concentration of 22% by mass as a silicon source; then, add 4.56g The above-mentioned coal powder, 1.175g of basic nickel carbonate as a metal catalyst, stirred for 20min, then placed the beaker in a water bath at 100°C and heated until the solution was black and viscous and kept warm for 20min, and finally the black viscous was transferred into Dry it in a watch glass at 100°C to a constant weight to obtain 36 g of a silicon carbide precursor with a water content of 0.87% for...

Embodiment 2

[0032] The first step is raw coal pretreatment. 200 grams of Taixi coal with an ash content of 5.9% were crushed, ground and sieved and classified to obtain 100 grams of 200-mesh coal powder for subsequent use;

[0033] The second step is the preparation of silicon carbide precursor. Weigh 9.6g of analytically pure silicic acid, dissolve it into a beaker containing 100ml of distilled water to obtain an aqueous solution of silicic acid with a concentration of 22% by mass; 20min, then place the beaker in a water bath at 85°C and heat until the solution is black and viscous and keep it warm for 60min. 36g of 0.87% silicon carbide precursor is reserved.

[0034] In the third step, the crude silicon carbide product is prepared by carbothermal reduction method. After the above-mentioned silicon carbide precursor is ground to 200 mesh, it is put into a corundum boat, and the corundum boat is put into the constant temperature zone of the alumina tube furnace. Under the protection ...

Embodiment 3

[0038] The first step is raw coal pretreatment. 200 grams of electric calcined Taixi coal with an ash content of 5.9% was crushed, ground and sieved and classified to obtain 100 grams of 225-mesh coal powder for subsequent use;

[0039]The second step is the preparation of silicon carbide precursor. Weigh 8g of technical grade white carbon black, place it in a beaker filled with 100ml of distilled water; then, add 8g of the above-mentioned coal powder, 0.645g of basic nickel carbonate and iron nitrate mixture successively at room temperature and magnetic stirring as catalyst , the molar ratio of Fe and Ni in basic nickel carbonate and iron nitrate in the above catalyst is 1:1, stir for 20 minutes, then place the beaker in a water bath at 90°C and heat until the solution is black and viscous and keep it warm for 40 minutes. Finally, the black viscous material was transferred to a watch glass and dried at 100°C to a constant weight to obtain 16.64 g of a silicon carbide precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com