Production technology of dual-crop compound protein isolates

A protein isolate and production process technology, applied in the field of oil crop protein isolate processing, can solve problems affecting application, application restriction, poor functionality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

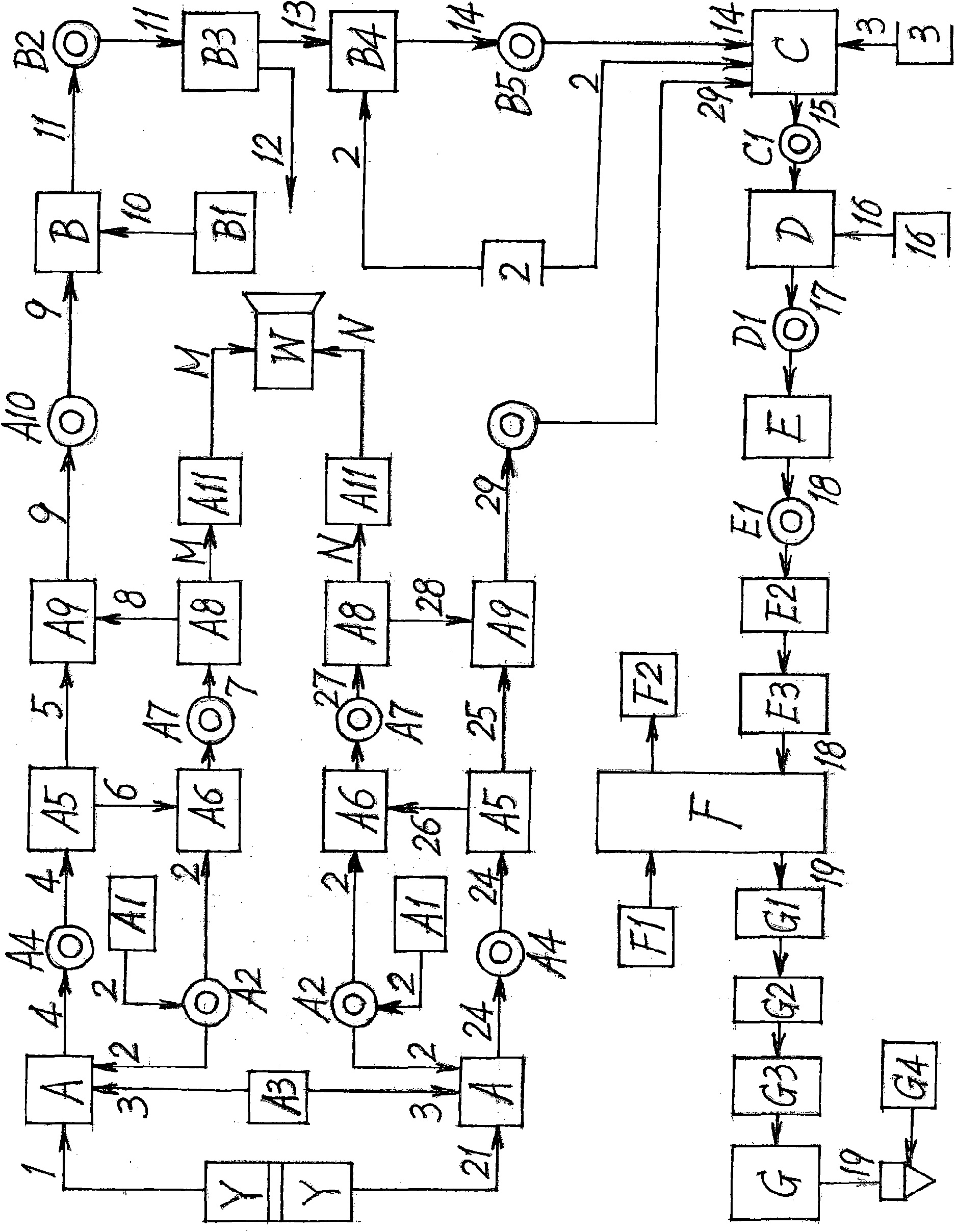

[0008] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0009] The invention consists of production equipments connected together to form a special production line, including extraction process, acid precipitation process, neutralization process, enzymolysis process, sterilization process, drying process and packaging detection process. Before the neutralization process, soybean acid precipitation emulsion 14 and peanut extraction mixed emulsion 29 are respectively prepared from soybean low-temperature meal 1 and peanut flour 21 as raw materials.

[0010] The preparation of soybean acid precipitation emulsion 14 is through extraction process and acid precipitation process, and the technological process of extraction process is: water 2 in hot water tank A1 is heated to 48~52 ℃, by hot water pump A2 according to material-water ratio 1:9 The ratio is added to the first extraction tank A, stirred at high speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com