Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Promotes grain refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122AImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel

The invention relates to a preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel. The steel is prepared from 0.15-0.22% of C, 0.60-1.70% of Si, 1.10-2.40% of Mn, 0.1-0.5% ofMo, 0.1-0.5% of Al, 0.05-0.11% of V, 0.01-0.05% of Y, 0.02-0.04% of P, 0.005% or below of S, 0.040-0.0700% of Nb, 0.0060% or below of N, 0.001-0.006% of B and the balance Fe and unavoidable impurities. After batching, the raw materials are smelt by a converter and refined and continuously cast by a vacuum furnace to obtain a cast blank, then trace alloy powder is added into an arc-melting furnace, a secondary cast blank is obtained, and heating and hot rolling are conducted in sequence; cold rolling is conducted after acid pickling; then the blank is heated to a two-phase region for heat preservation; carbon partitioning and tempering are conducted to obtain the final steel. According to the preparation method, through the addition of an appropriate quantity of various beneficial alloy elements, the contents of C, Si, Mn and other elements in traditional steel species are reduced, the weldability and corrosion resistance are improved, crystal grains are refined, produced steel plateshave good comprehensive mechanical properties, and lightweight, energy conservation and emission reduction of vehicles are facilitated.

Owner:SHANDONG JIANZHU UNIV

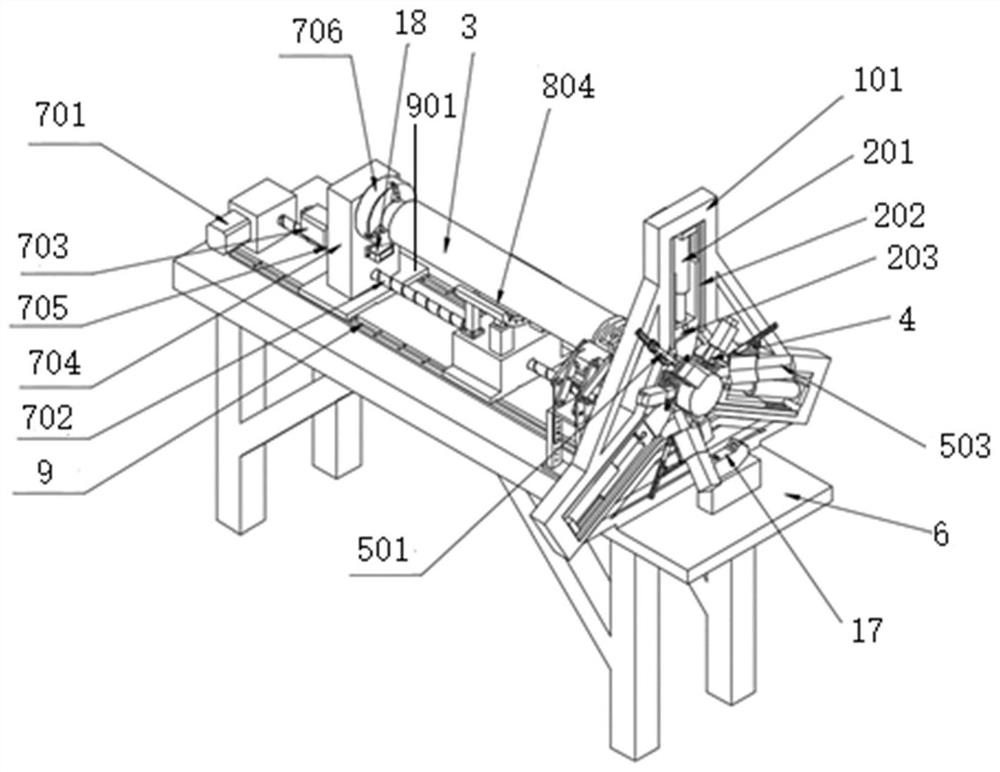

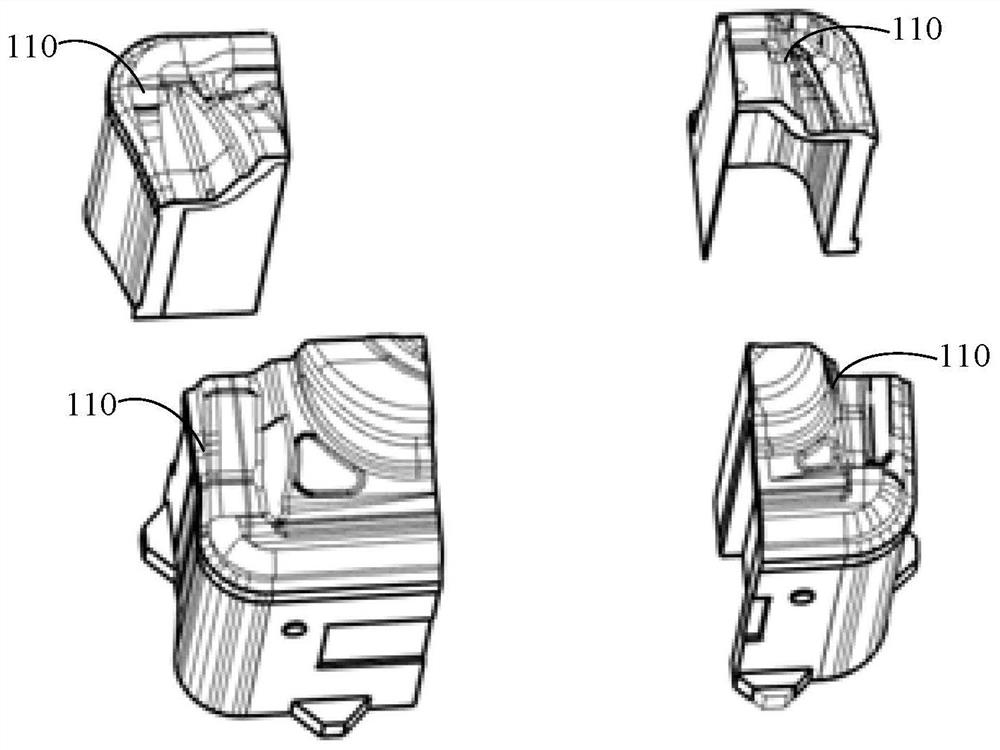

Shaft surface repairing system and method for additive composite micro-rolling

ActiveCN112846193APromotes grain refinementReduced cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencySpinningComputer printing

The invention relates to the technical field of additive shaft repairing, and provides a shaft surface repairing system and method for additive composite micro-rolling. The system comprises a frame, a plurality of groups of spinning units evenly distributed in the circumferential direction are arranged on the frame, and a middle wear shaft repairing area is constructed; each of the spinning units comprises a first driving device, a first guide rail, a first sliding block and a roller, wherein the first driving device and the first guide rail are fixed to the frame, an output end of the first driving device is connected with the first sliding block, the first sliding block is movably arranged on the first guide rail, the roller is connected with the first sliding block, and the roller surface of the roller is opposite to the circumferential surface of a wear shaft in the middle wear shaft repairing area; and a heating mechanism and an additive printing mechanism are arranged on the frame. According to the shaft surface repairing system for the additive composite micro-rolling provided by the invention, additive shaft repairing and micro-rolling of a repaired part are synchronously achieved, the microstructure and the mechanical property of the repaired shaft are comprehensively improved, the overall performance of the repaired shaft is improved, and the repaired shaft can be put into use again.

Owner:CRRC IND INST CO LTD +1

Preparation and application of amorphous nanocrystalline alloy

InactiveCN107686946AEnhanced Amorphous Formation AbilityPromotes grain refinementWater contaminantsWater/sewage treatmentQuenchingNanometre

The invention discloses preparation of an amorphous nanocrystalline alloy. The amorphous nanocrystalline alloy comprises the components of, by mass, 0.5-8% of Ni, 0.1-0.3% of Co, 1-2% of Cu, 0.01-0.03% of Nb, 3-11% of B, 2-9% of Si, 0.01-3.5% of C, 0.1-3% of P and the balance Fe, and the sum of the content of all the components is 100%. The amorphous nanocrystalline alloy is prepared in the modesthat a master alloy ingot is prepared through induction smelting and then is prepared into a strip belt through the single roll rotating quenching method, then the strip belt is cut to be with the required length and placed in a vacuum annealing furnace, vacuum pumping is conducted, and annealing treatment is conducted under protection of inert gas. The prepared amorphous nanocrystalline alloy canbe used in the field of azo dye wastewater treatment and can be reused, and the preparation cost is low.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

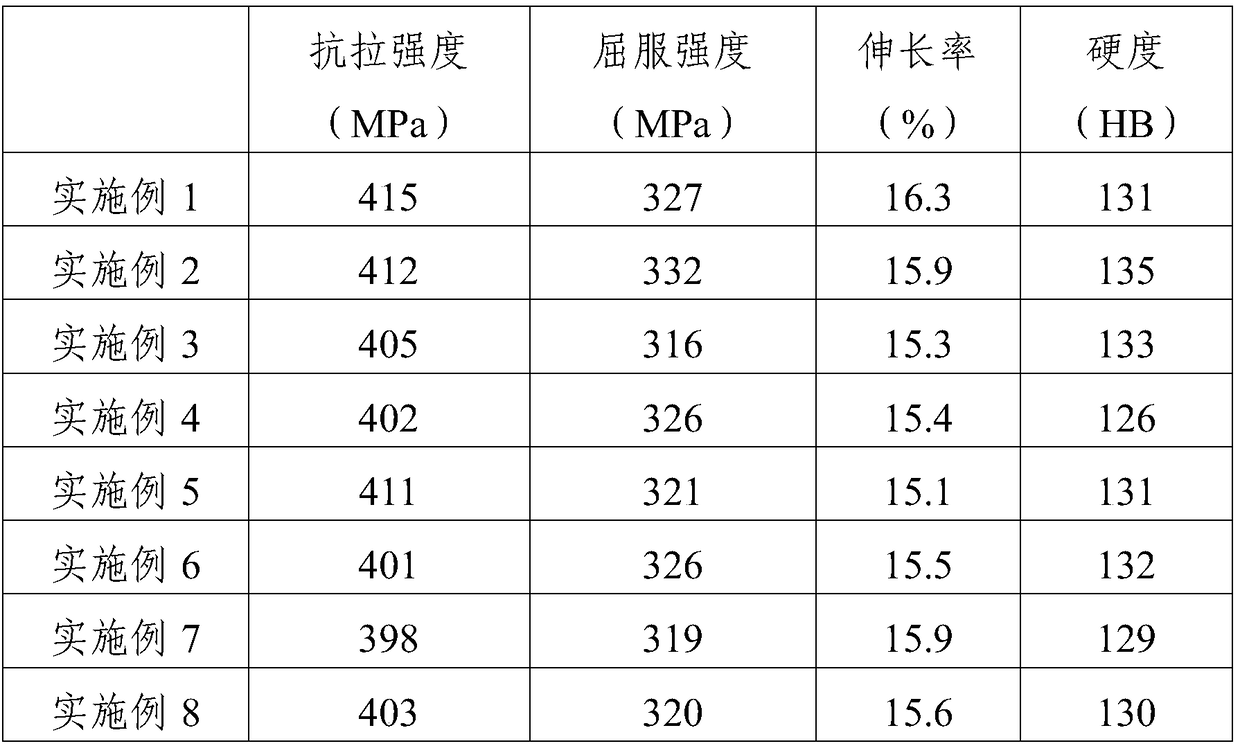

High-toughness and high-strength aluminum alloy hub for automobile and manufacturing method of high-toughness and high-strength aluminum alloy hub

ActiveCN109252074ARefined recrystallized grainsRaise the recrystallization temperatureHubsMass ratioHigh intensity

The invention provides a high-toughness and high-strength aluminum alloy hub for an automobile and a manufacturing method thereof, and relates to the technical field of automobile hub manufacturing. The aluminum alloy hub is prepared from the following components in percentage by mass: 3.3-4.8% of Si, 1.2-1.7% of Mg, 0.45-0.7% of Mn, 0.2-0.6% of V, 0.35-0.7% of Ti, 0.05-0.13% of Zr, 0.05-0.12% ofRE, and the balance of Al; RE is composed of Yb, Pr, Nd and Sc with the mass ratio being 1:(0.2 to 0.6):(0.3 to 0.8):(0.6 to 1.2). The manufacturing method comprises the steps of smelting, refining, casting, solid solution treatment, deep cold treatment, aging treatment and the like. The manufactured aluminum alloy hub is uniform and dense in structure, high in toughness, high in strength, good incorrosion resistance, high in dimensional stability, excellent in comprehensive performance and long in service life, and has great using prospects.

Owner:江苏创斯达科技有限公司

Zn-Al-Mg alloy layer used for being hot-dipped to bridge steel wire surface and manufacturing method for Zn-Al-Mg alloy layer

ActiveCN105420653AReduced corrosion resistanceImprove corrosion resistanceHot-dipping/immersion processesAlloyZinc

The invention relates to a Zn-Al-Mg alloy layer used for being hot-dipped to a bridge steel wire surface and a manufacturing method for the Zn-Al-Mg alloy layer. The alloy layer comprises, by mass, 30%-97% of Zn, 5%-60% of Al and 0.02%-11% of Mg, wherein the sum of the percentages of all the components is 100%. The manufacturing method includes the steps that a bridge steel wire is unoiled and derusted; the alloy layer is hot-dipped; and stabilizing treatment is conducted. According to the alloy plating layer, the corrosion resistance is superior to that of an existing zinc plating layer and that of an existing zinc aluminum alloy plating layer, the alloy plating layer is easy to use, meets the requirements of the special environments, such as the requirement for bridge steel wires in the marine corrosion atmosphere environment and has wide market prospects.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

Iron-chromium-aluminum alloy machining process

InactiveCN104561799APrevent oxidationStable mechanical propertiesNon-metallic inclusionsMetal machining

The invention discloses an iron-chromium-aluminum alloy machining process and relates to the field of metal processing. The iron-chromium-aluminum alloy machining process comprises high-frequency smelting processing and cast rolling processing, and specifically comprises ten process steps of smelting, refining, filtering, casting, repairing, cold rolling, thermal treatment, finishing, checking and screening. In the processing method, vacuum melting is adopted to effectively protect the alloy from being oxidized and guarantee stable mechanical properties of the alloy; a refining agent and a foamed ceramic filter plate are capable of removing harmful gases and nonmetallic inclusions in the liquid alloy and improving the clarity of the alloy; water-cooling semi-continuous casting is adopted to reduce the time of cast cooling and effectively promote grain refinement; and as a result, the machining performance and the production efficiency are improved.

Owner:DANYANG ZHISHENG ALLOY

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122BImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

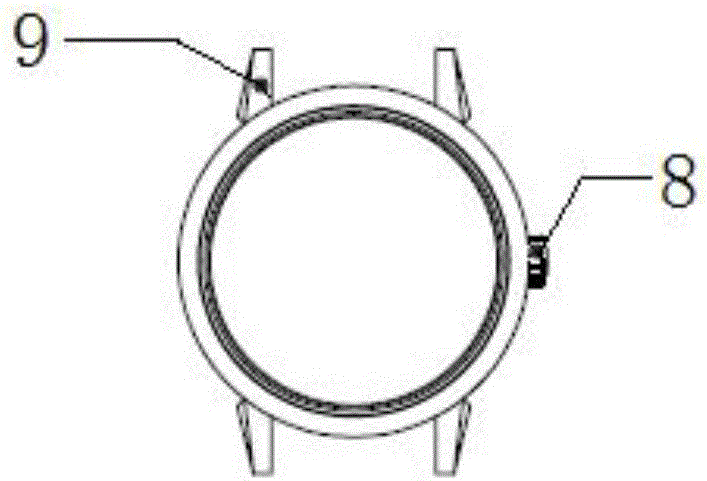

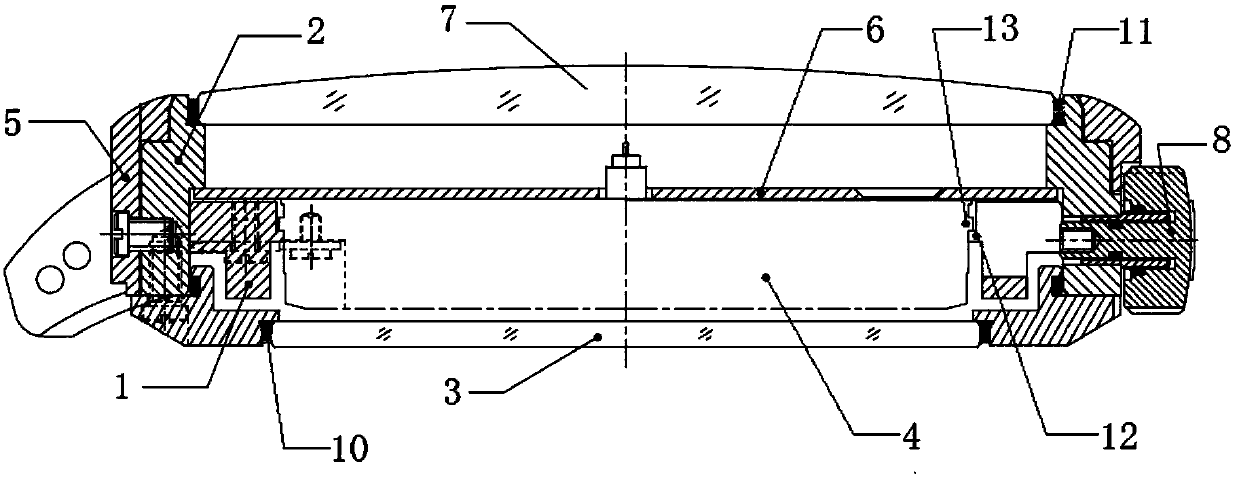

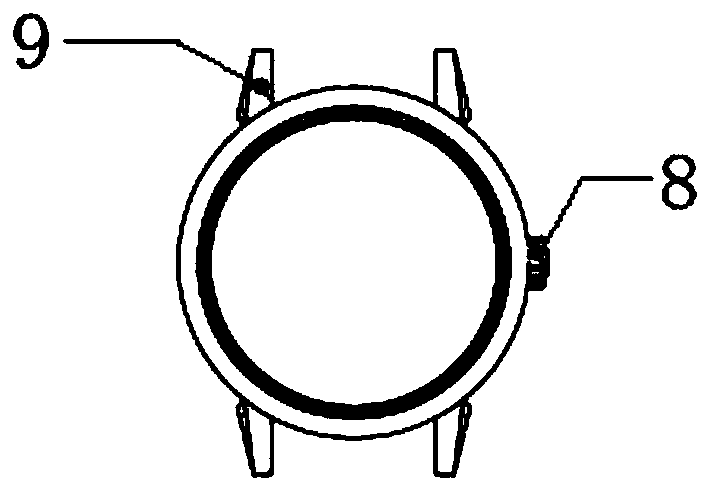

Pure-gold watchcase and manufacturing method thereof, and dial plate comprising same

The invention relates to a pure-gold watchcase manufacturing method, comprising raw material melting, rough blank forming, stamping treatment and cutting treatment. The invention also relates to a pure-gold watchcase obtained by the above method, and a dial plate comprising the pure-gold watchcase. The dial plate also comprises an inner container, a movement, a graduated disk, a watch glass, a watch crown and an ear part. The inner container comprises an inner container body and a fixed part. The pure-gold watchcase is wrapped at the outer wall of the inner container. The movement is arranged inside the inner container. The graduated disk is arranged on the top surface of the movement in a covering manner. The watch glass is disposed at an opening of the inner container in a covering manner. With the gold content higher than nine hundred and ninety per one thousand, the pure-gold watchcase achieves good machining performance, allows surface treatment, has high strength and hardness and is adapted to normal knock and collision when used. The rejection rate in the pure-gold watchcase manufacturing process is low, and the production efficiency is high. The dial plate comprising the pure-gold watchcase has good waterproofness, and the strength of an outer shell of the dial plate is further enhanced, so the service lifetime of the dial plate is prolonged.

Owner:JUNSON SHENZHEN CHUANJINDAIYIN TECH CO LTD

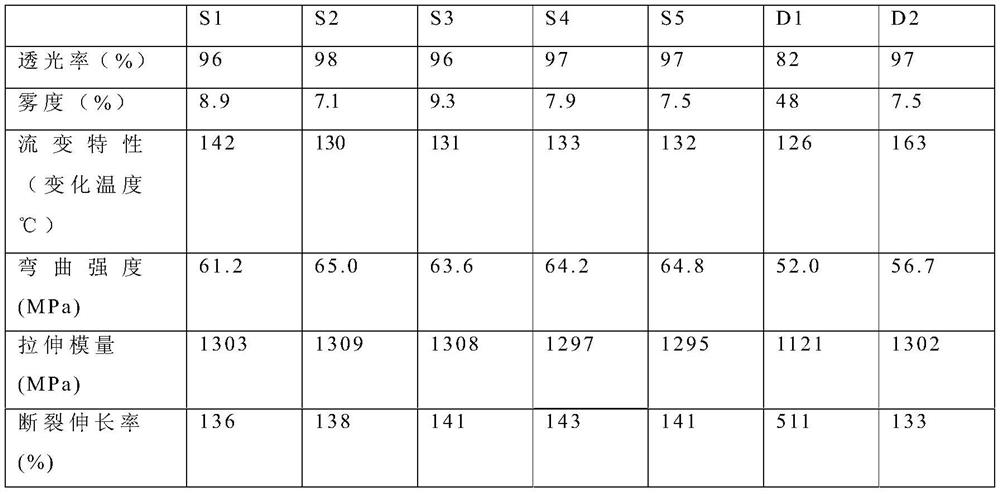

High-transmittance polypropylene composition

The invention discloses a high-transmittance polypropylene composition, which comprises the following components in parts by mass: 100 parts of isotatic polypropylene, 0.01-2 parts of a modified nucleating agent, 0.01-1 part of an antioxidant and 0.01-1 part of a light stabilizer, and the modified nucleating agent is prepared from a hydroxyl-free sorbitol derivative and a sorbitol nucleating agent. According to the hydroxyl-free sorbitol derivative, due to the fact that original hydrogen bonds and pi-pi interaction recognition site structures are reserved, the recognition efficiency of non-covalent interaction between derivative molecules and nucleating agent molecules is higher, combination is better, meanwhile, the hydroxyl-free sorbitol derivative molecules are small organic molecules, and are easy to disperse in polypropylene resin, so that the composite modified nucleating agent has good improvement effects on the properties such as grain refinement, fog uniformity and modulus of polypropylene while realizing no gelation effect.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

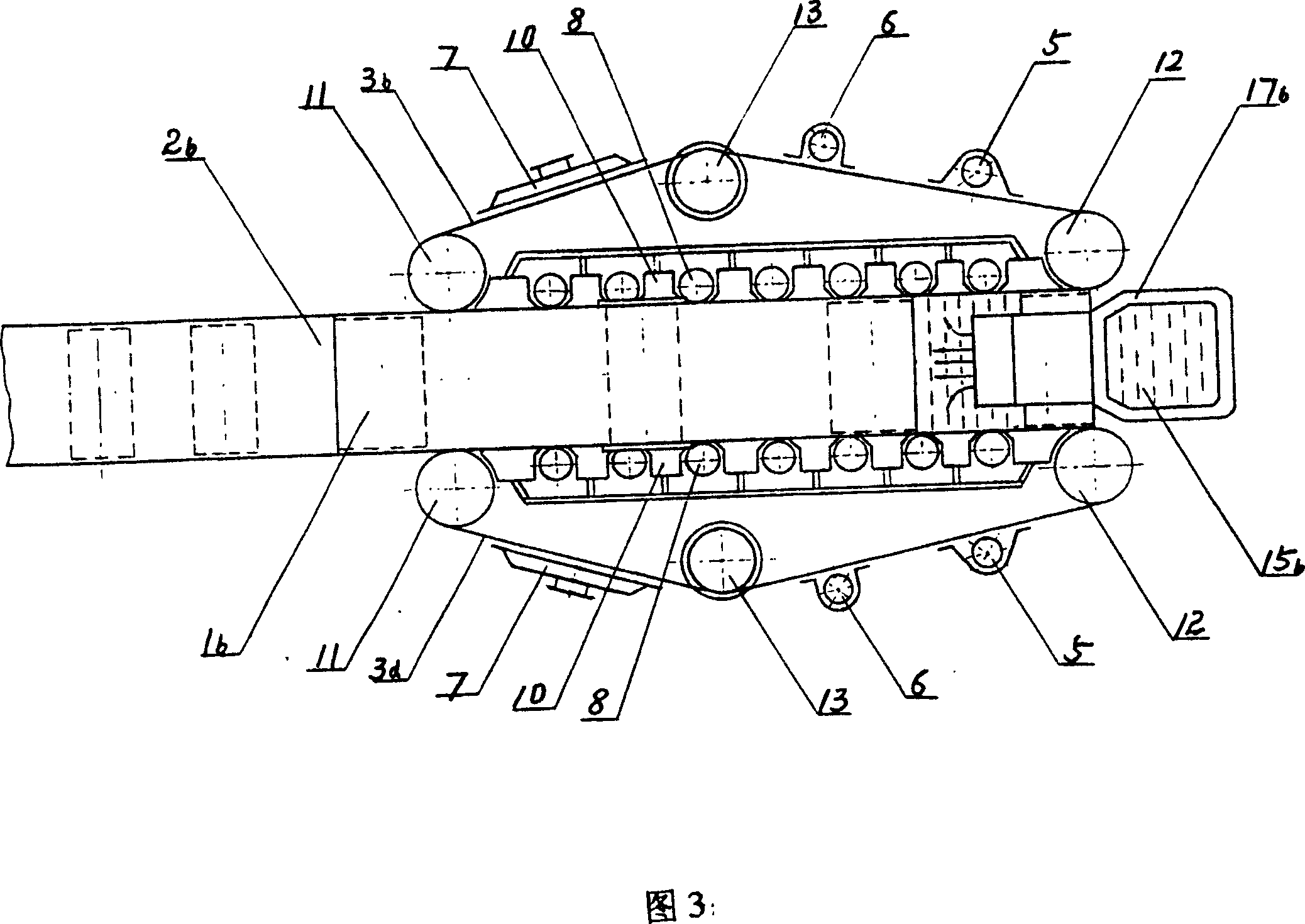

Continuous casting machine for stainless compound steel plate strip blank

The invention relates to a stainless steel clad plate billet conticaster. It belongs to a continuous casting device in the art of metallurgical industry. The device can be characterized in that: it comprises three synchronous circulating mobile steel band crystallizers A, B and C, which are Y- type equipped, the lower cooling steel band 2 of crystallizer A being common with the right-side cooling steel 2c of the crystallizer C, and the lower cooling steel band 2b of crystallizer B being common with the left-side cooling steel 2d of the crystallizer C. After the strand being forged by from multigroup flexible guiders, multigroup steam- water spray devices and traction roller which are under the crystallizer C, the clad plate billet is aligned to horizontality by a blending guider and a smoothing roll, and then is sent to shearer to be sheared into a definite length or sent to continuous rolling mill to roll down. The merit is characterized in that: it improves the production efficiency of the conticaster, and guarantees the quality of strand and rolled metal.

Owner:李铁铎

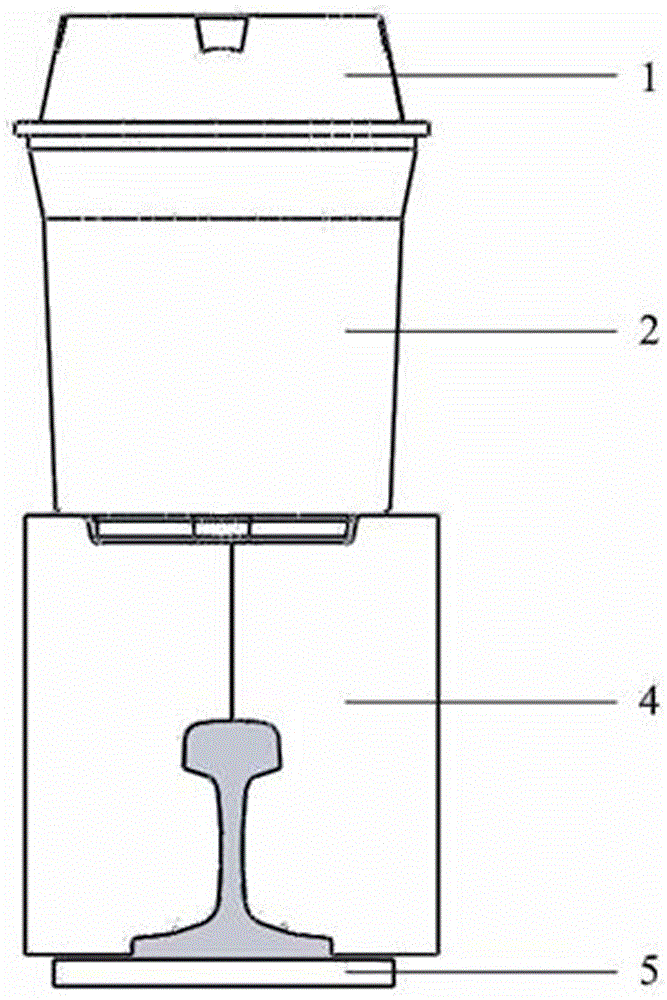

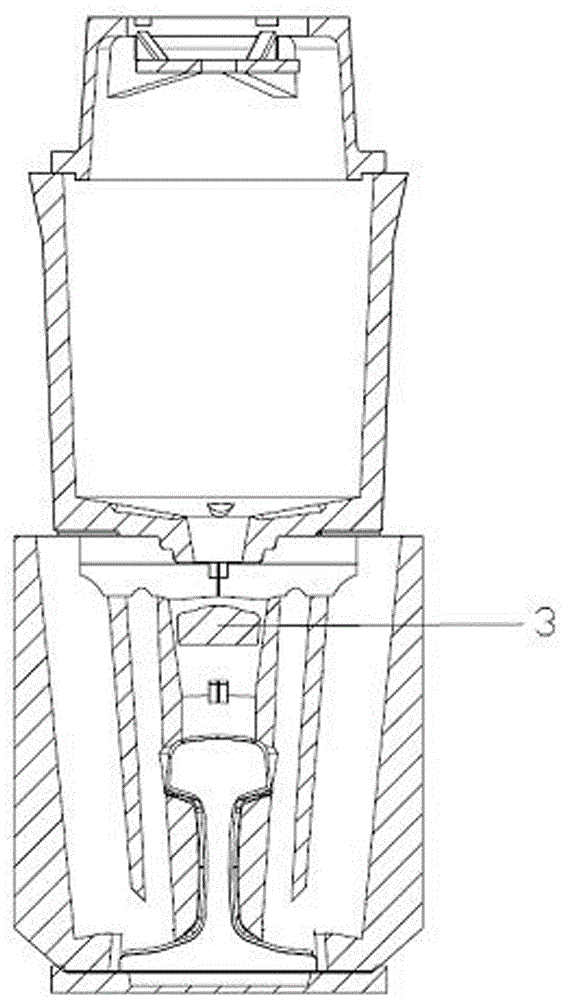

Steel rail thermite welding gating system

The invention relates to a steel rail thermite welding gating system. The system comprises a sand mold, a crucible body arranged above the sand mold, a crucible cover matched with the crucible body, a shunting plug arranged inside the sand mold, and a base plate arranged at the bottom of the sand mold. According to the system, a reaction crucible and a pouring gate system are both designed to be of a liquid deslagging structure, and the purity of molten steel in a purifying cavity is fully considered. The crucible top cover of the system is in a pneumatic layout mode, reaction high-temperature gas can be dredged and high-temperature liquid-solid splash can be blocked. Two risers at the bottom of the sand mold in the system communicate with each other, and thus the casting feeding capacity is enhanced.

Owner:洛阳双瑞橡塑科技有限公司

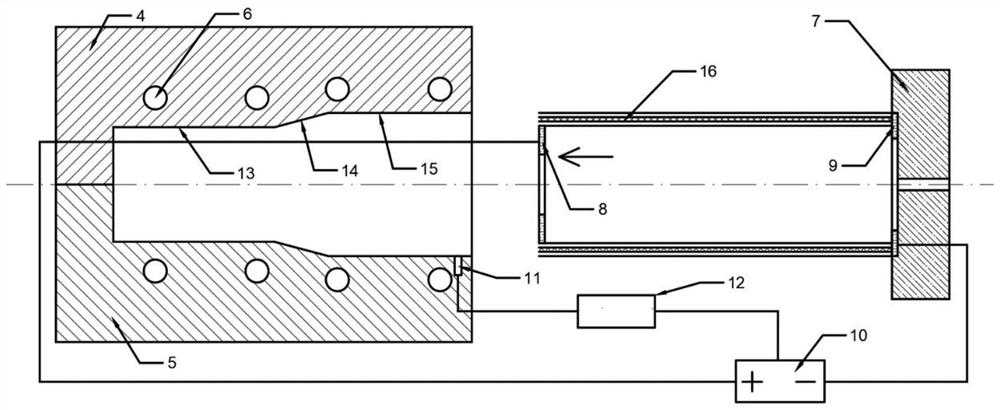

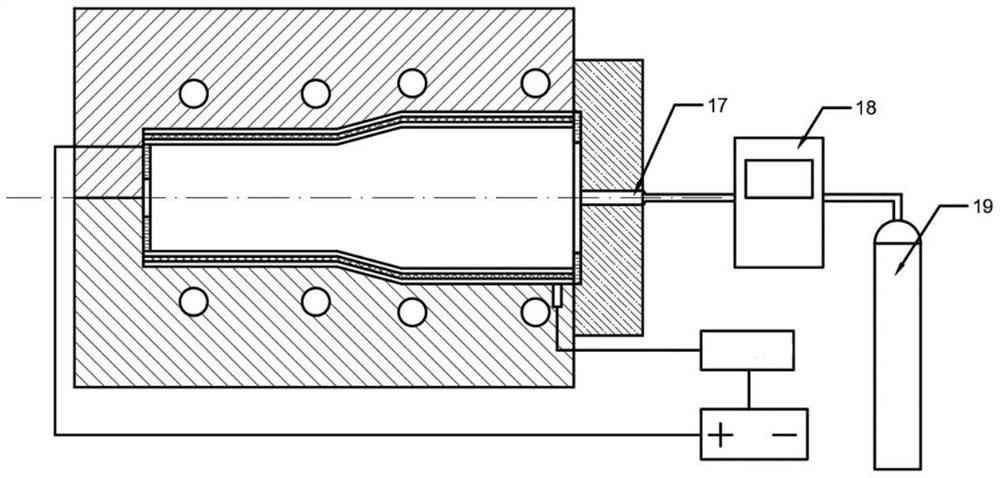

Light alloy plate stamping forming process and stamping device

ActiveCN112058984AImprove diffusion abilityImprove plasticityShaping toolsFurnace typesAlloyForming processes

The invention discloses a light alloy plate stamping forming process and stamping device. The light alloy plate stamping forming process comprises the following steps that 1, a light alloy material isheated to the solid solution temperature of the light alloy material or above; 2, the heated light alloy material is placed between a female die and a male die; 3. the detection temperature of each area of the light alloy material is obtained; and 4, when the female die and the male die are closed for stamping, electric pulse treatment is carried out on the areas according to the detected temperature. According to the technical scheme, the production quality, the production energy efficiency and the production efficiency can be favorably improved.

Owner:深圳新顿科技有限公司

High-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for railway freight open wagon and production technology of high-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for railway freight open wagon

InactiveCN113462964AHigh strengthImprove plastic toughnessTemperature control deviceTension/compression control deviceThermodynamicsWeather resistance

The invention discloses high-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for a railway freight open wagon and a production technology of the high-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for the railway freight open wagon, and belongs to the technical field of steel rolling production. The cap-shaped steel comprises the following components in percentage by mass: 0.10 to 0.15 percent of C, 0.20 to 0.65 percent of Si, 1.40 to 1.55 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.3 to 1.0 percent of Cr, 0.025 to 0.065 percent of Ni, 0.30 to 0.55 percent of Cu, 0.030 to 0.045 percent of Nb, less than or equal to 0.0002 percent of H, less than or equal to 0.008 percent of N, 0.020 to 0.040 percent of Alt and the balance Fe and trace residual elements. The preparation technology of the high-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for the railway freight open wagon comprises the steps of blast furnace molten iron production, molten iron pretreatment, converter smelting, argon blowing, LF refining, RH refining, continuous casting full-protection casting, cap-shaped steel rolling and cap-shaped steel straightening. The cap-shaped steel has excellent appearance quality, strength, weather resistance and low temperature resistance at the same time, and the use requirements of the cap-shaped steel in the railway freight open wagon are effectively met so that the safety of the whole wagon can be improved, and the cap-shaped steel has high economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

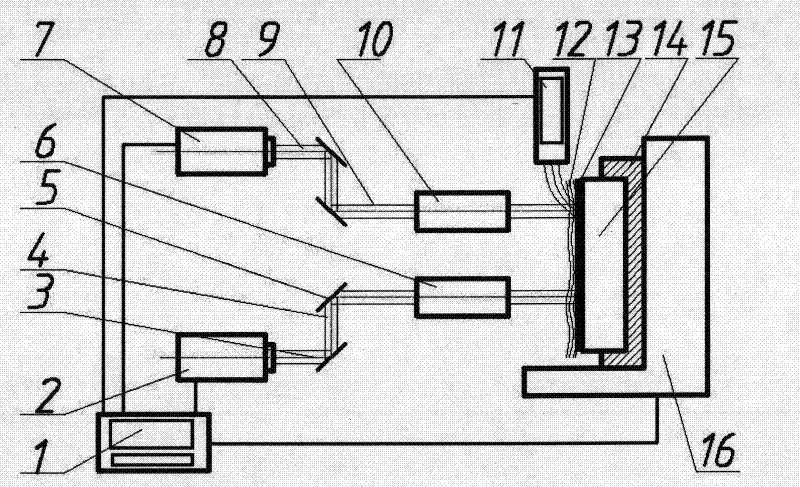

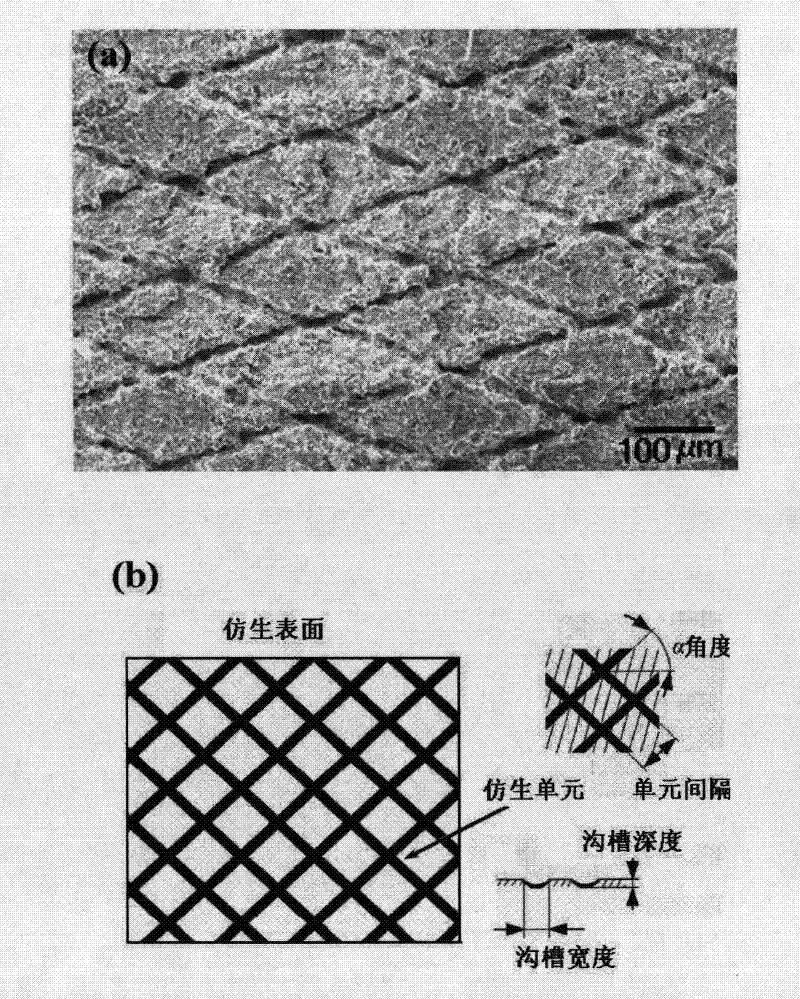

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569BNo wearSimple processLaser beam welding apparatusNanosecond laserLaser processing

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing aregular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

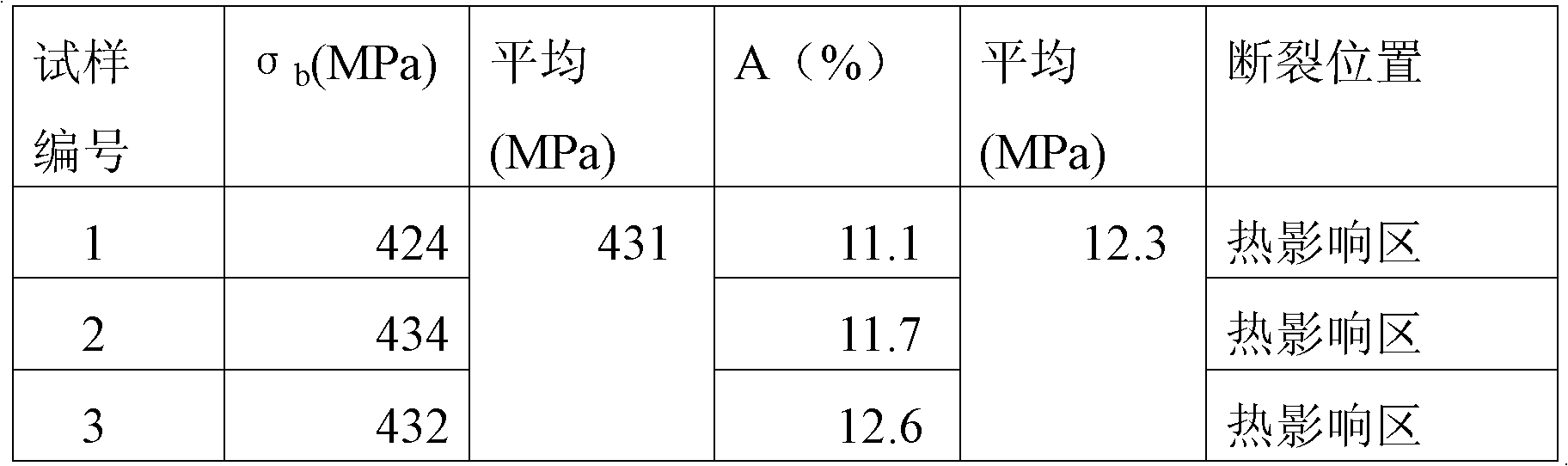

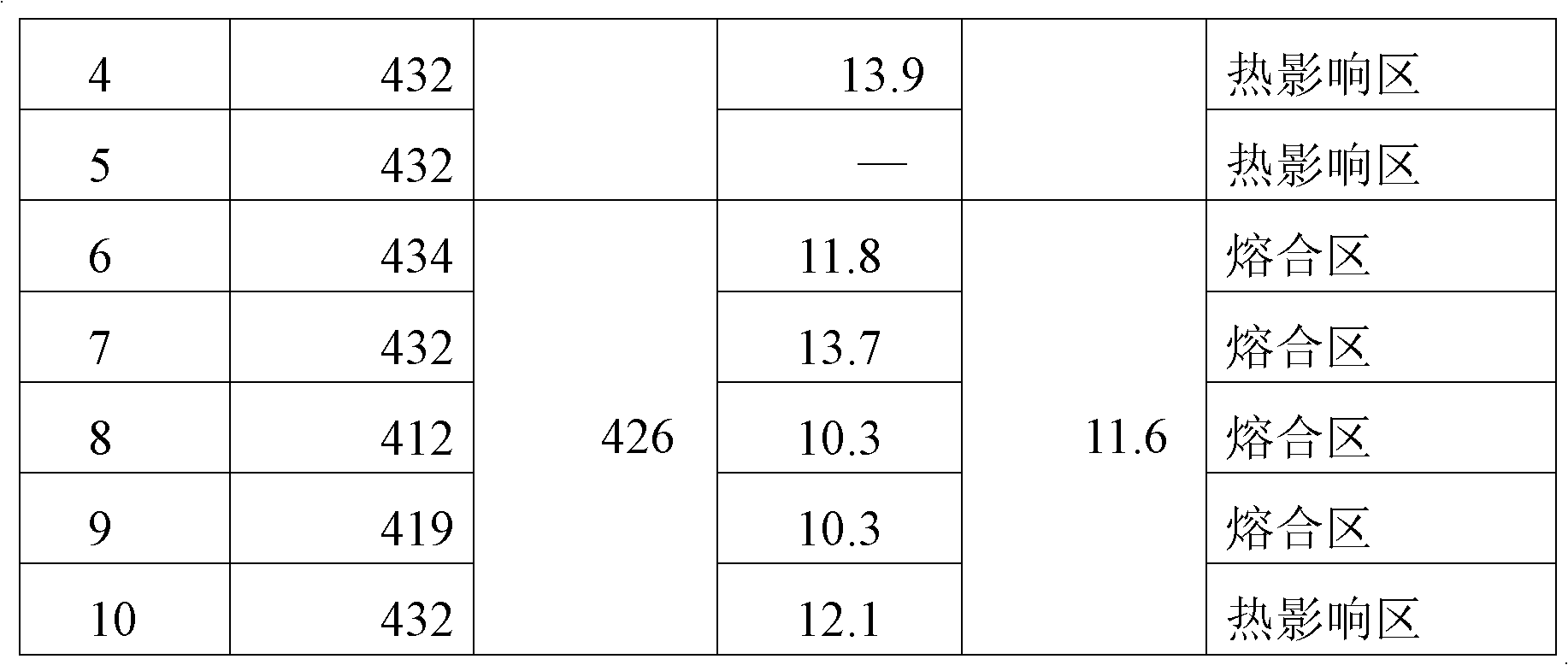

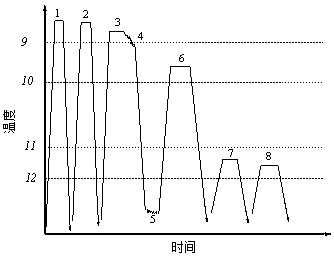

Welding wire for high-strength aluminum-zinc-magnesium-scandium alloy and preparation method thereof

ActiveCN103273214BReduce contentHigh tensile strengthWelding/cutting media/materialsSoldering mediaRare-earth elementZinc alloys

The invention relates to a high-intensity welding wire for aluminum-zinc-magnesium-scandium alloy. The high-intensity welding wire comprises the following components of, by mass, 1.0% to 5.0% of Zn, 1.0% to 6.0% of Mg, 0.05% to 0.25% of Sc, 0.05% to 0.25% of Zr, 0.1% to 0.4% of Mn, 0.5% to 1.0% of Cu, 0.05% to 0.25% of Ti, 0.01% to 0.15% of the rare earth element Y or 0.01% to 0.15% of the rare earth element Ce, 0.05% to 0.25% of Cr, and the balance Al. According to the high-intensity welding wire, on the base of Al-Zn-Mg, the small amount of Cu is added so that the extension strength of a joint can be effectively improved, and the Sc and the Zr which are the same in content are added so that the heightening effect of aluminum alloy performance by single Sc can be remarkably improved. In addition, the micro-alloy elements of Ce, Ti, Cr and the like are added so that more excellent structural performance and welding process margins can be obtained, the sensitivity of welding cracks of the alloy can be reduced, comprehensive mechanical performance of the joint can be improved, and the high-intensity welding wire has good stress-corrosion resistant performance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

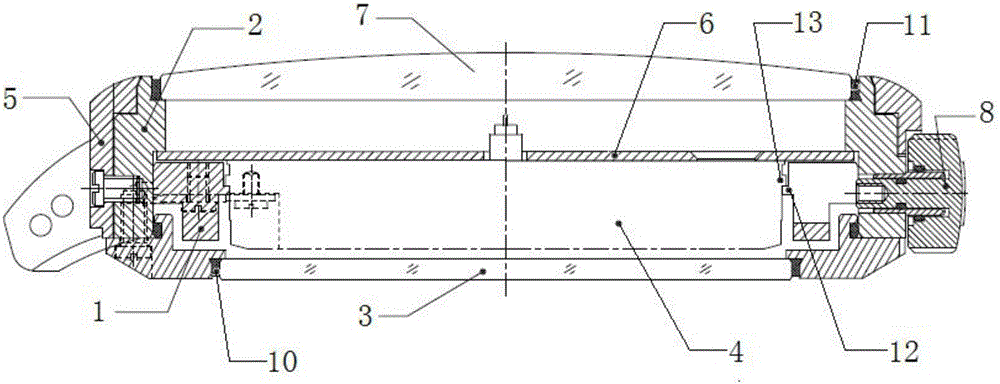

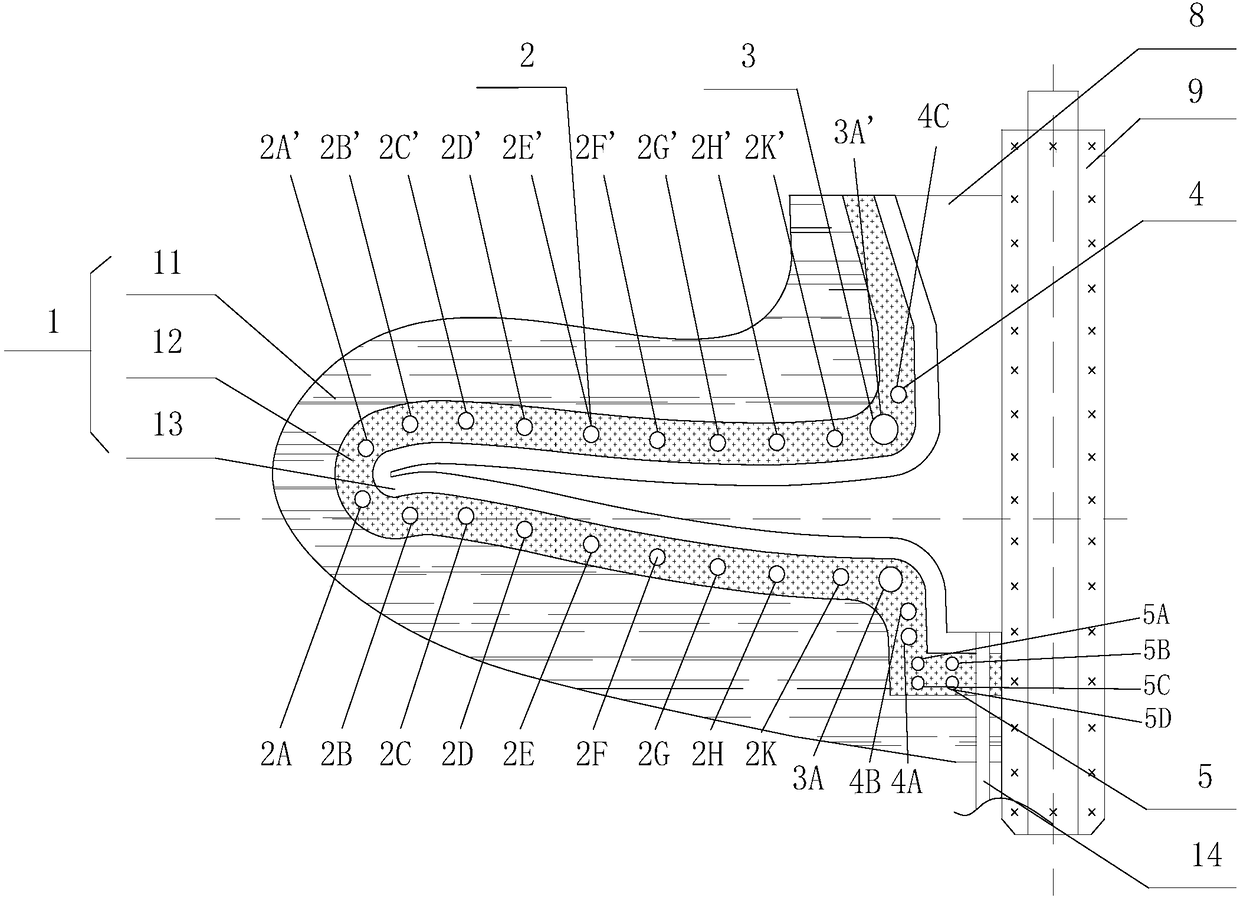

Propeller casting forming solidification sequence control device and control step thereof

The invention discloses a propeller casting forming solidification sequence control device and a control step thereof, and relates to a propeller casting machining device and step, in particular to aforming sequence solidification device and a control step thereof. The control device comprises a sand mold, a propeller blade part control system, a blade root part control system and a propeller hubpart control system; the propeller blade part control system, the blade root part control system and the propeller hub part control system are sequentially arranged from the propeller sand mould blade part to the propeller hub part. The device has the beneficial effects that the structure is novel, machining is easy and convenient, use is convenient, work efficiency is improved, product quality is improved, and cost is reduced; the novel propeller casting forming solidification sequence control device and the control step therefore are integrated with economy and practicability.

Owner:DALIAN MARINE PROPELLER CO LTD

Casting process of 7475 aluminium alloy slab ingot

The invention relates to a casting process for a 7475 aluminium alloy slab ingot. By the control to chemical components, regulation of the casting stress, improvement on melt purity, strengthening of grain refinement and the like, the defects of cracks and loosening of the 7475 aluminium alloy slab ingot in the casting process are prevented.

Owner:JIANGSU JIANGXU CASTING GROUP

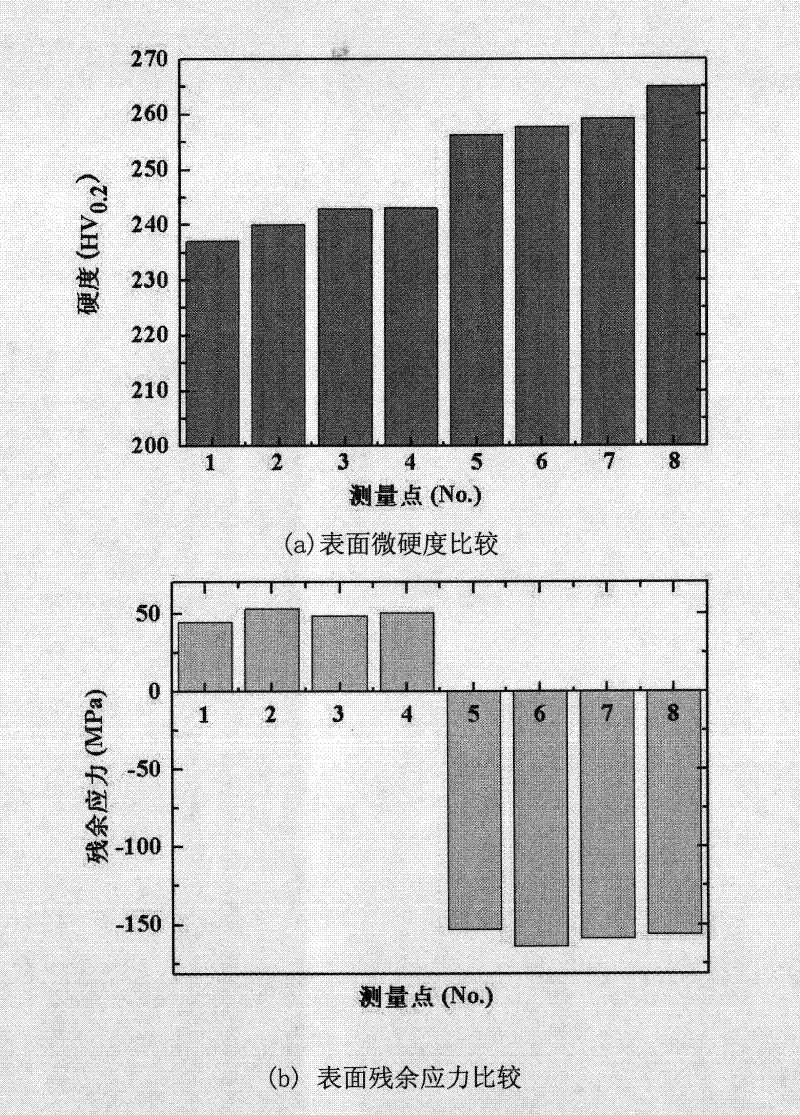

Powerful spinning and laser shock peening combined device and machining method for thin-wall part

The invention discloses a powerful spinning and laser shock peening combined machining method for a thin-wall part. The method comprises the following steps that (1) the outer surface of a blank workpiece is peened, namely laser shock peening is conducted on the blank workpiece through an absorption-layer-free laser shock peening technology; and (2) spinning machining is conducted on the workpiece through mutual cooperation of a spinning wheel and a mold in spinning equipment, and cylindrical or conical large-deformation forming of the metal thin-wall workpiece is achieved. The invention discloses the powerful spinning and laser shock peening combined machining method. The surface of a material is heated and softened by adopting a laser heat effect; the laser force impact effect is adopted to achieve grain refinement, promote part plastic deformation and inhibit springback of the part after spinning, a residual compressive stress layer is introduced, the outer wall tensile stress in the spinning process is counteracted, and initiation and extension of microcracks in the material are inhibited; and forming machining of the thin-wall workpiece subjected to laser shock peening treatment is achieved through the powerful spinning technology, and therefore the material forming precision and performance are remarkably improved.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

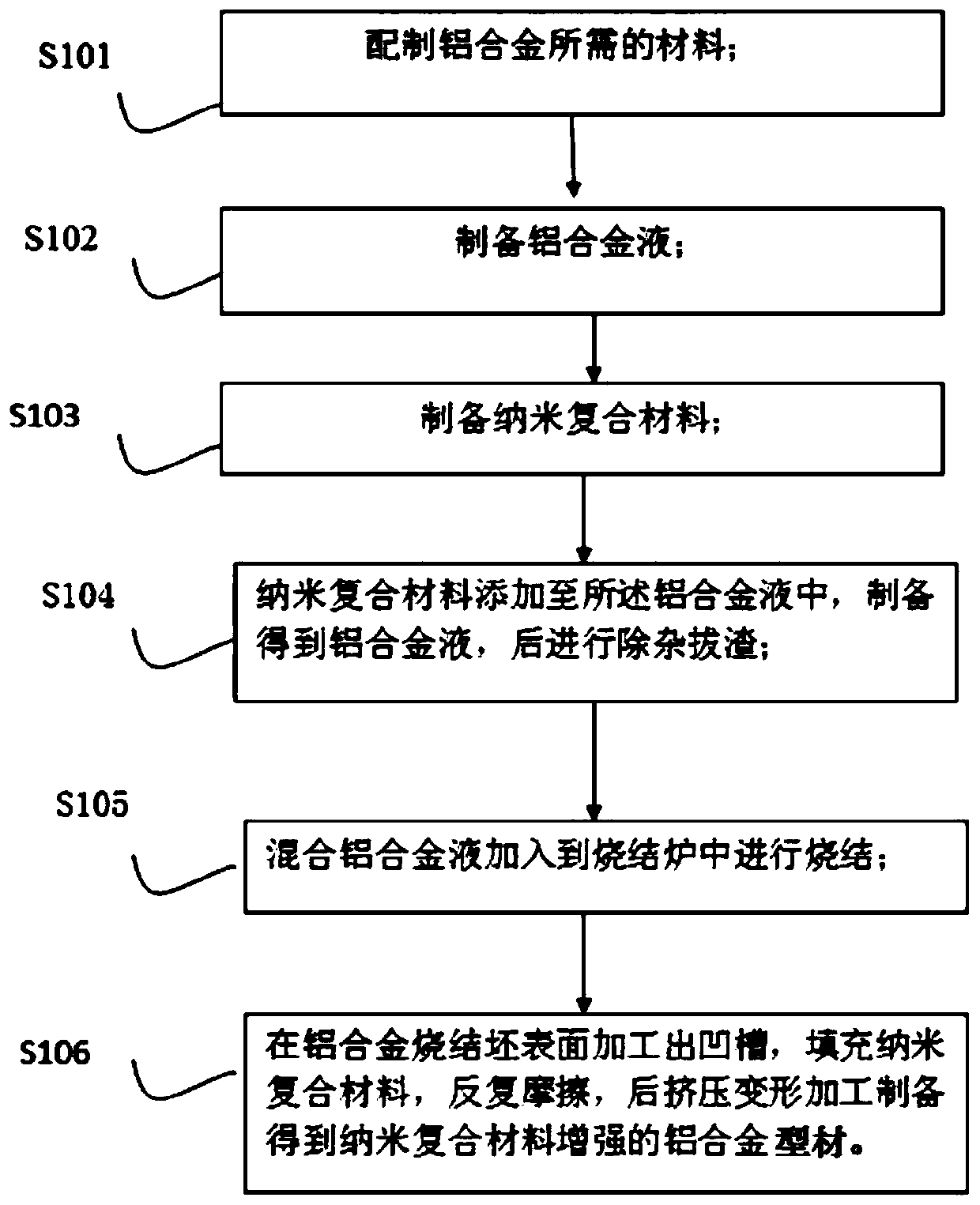

Method for reinforcing aluminum alloy profile through nano composite material

The invention provides a method for reinforcing an aluminum alloy profile through a nano composite material. Al2O3 and carbon nanotubes in a specific proportion are dispersed under the assistance of microwave ball milling; after the nano composite material is formed, 1 / 2 of the nano composite material is mixed with aluminum alloy liquid, the dispersity among components and the uniformity of particle mixing are improved advantageously, and the specific surface area of mixing and the surface interaction force of mixing can be effectively increased. Finally, the remaining 1 / 2 of the nano composite material is added in a filling mode after aluminum alloy is sintered, the combination degree of the nano composite material and the aluminum alloy is reinforced through repeated heating and friction, refining and uniform distribution of crystal grains are further promoted, the crystal boundary stability is improved synergistically, the high strength and plasticity of the aluminum alloy are ensured, and the wear resistance of the aluminum alloy can further be improved significantly. The method for reinforcing the aluminum alloy profile through the nano composite material solves the internal defects of the nano composite material in the aluminum alloy on the whole, and solves the problem of coarse crystal grains of the aluminum alloy.

Owner:佛山市三水凤铝铝业有限公司 +1

High-wear-resistance non-woven fabric

InactiveCN108914380APromotes grain refinementAvoid branches and overly thickNon-woven fabricsMonocomponent polyolefin artificial filamentNano zinc oxidePolypropylene

The invention relates to non-woven fabric, in particular to a high-wear-resistance non-woven fabric. According to the non-woven fabric, a mixed material of polypropylene and nano zinc oxide is adoptedas a raw material, and the non-woven fabric is produced through a continuous one-step method of high-temperature melting, spinneret, laying and hot-press rolling. The non-woven fabric has excellent wear-resistance performance.

Owner:HEFEI JIENUO MEDICAL PROD CO LTD

A kind of hot-dip plating zn-al-mg alloy layer on the surface of bridge steel wire and its preparation method

ActiveCN105420653BReduced corrosion resistanceImprove corrosion resistanceHot-dipping/immersion processesAlloyZinc

The invention relates to a Zn-Al-Mg alloy layer used for being hot-dipped to a bridge steel wire surface and a manufacturing method for the Zn-Al-Mg alloy layer. The alloy layer comprises, by mass, 30%-97% of Zn, 5%-60% of Al and 0.02%-11% of Mg, wherein the sum of the percentages of all the components is 100%. The manufacturing method includes the steps that a bridge steel wire is unoiled and derusted; the alloy layer is hot-dipped; and stabilizing treatment is conducted. According to the alloy plating layer, the corrosion resistance is superior to that of an existing zinc plating layer and that of an existing zinc aluminum alloy plating layer, the alloy plating layer is easy to use, meets the requirements of the special environments, such as the requirement for bridge steel wires in the marine corrosion atmosphere environment and has wide market prospects.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

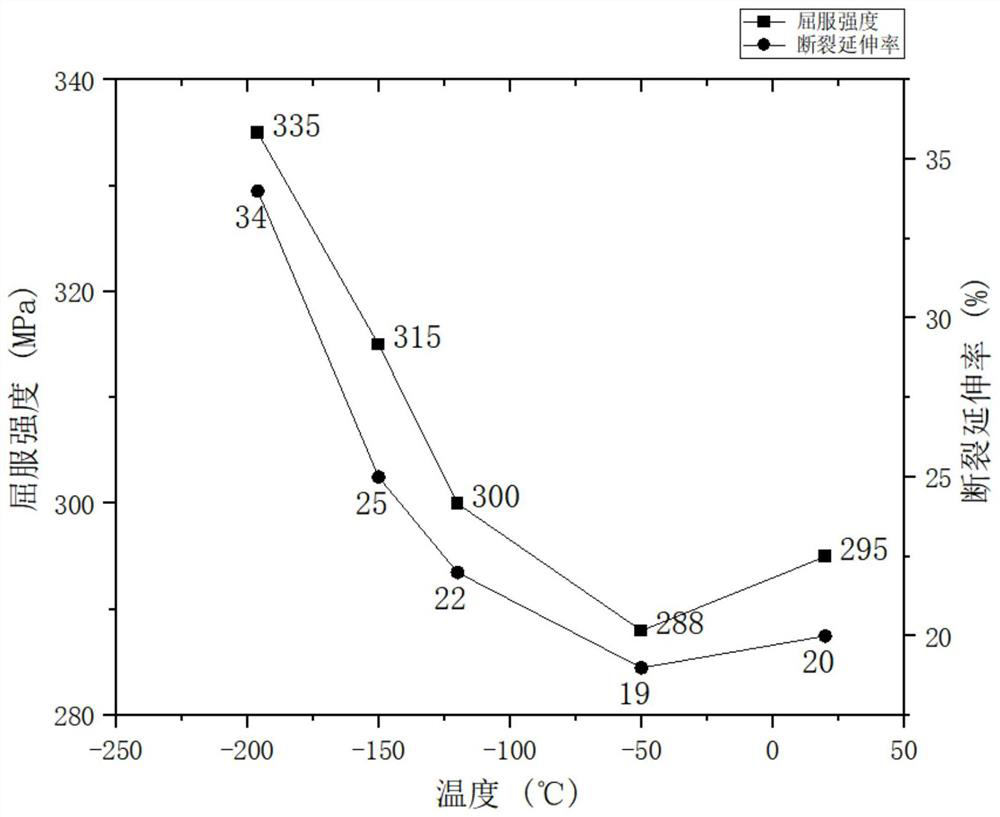

A pipeline steel with excellent toughness for extremely low temperature environment at -45°C and its manufacturing method

The invention discloses pipeline steel with excellent toughness for a minus 45 DEG C extremely-low-temperature environment and a manufacturing method thereof. The steel comprises, in percentage by mass, the following chemical elements of 0.030%-0.060% of C, 0.10%-0.30% of Si, 1.30%-1.60% of Mn, less than or equal to 0.0100% of P, less than or equal to 0.0015% of S, 0.40%-0.55% of Ni, 0.05%-0.20% of Cr, 0.050%-0.075% of Nb, 0.008%-0.020% of Ti, 0.0010%-0.0040% of Ca, 0.010%-0.050% of Al, less than or equal to 0.005% of B, 0.0010%-0.0060% of N, less than or equal to 0.0050% of O, and the balanceFe and inevitable impurities, wherein the elements simultaneously meet the following relationship that the Ni is larger than or equal to 1.6*(C+Mn / 6), log (C*Nb) is less than or equal to minus 2.5, Cplus Mn / 6 plus Cr / 5 is larger than or equal to 0.28% and is less than or equal to 0.35%, and Ti / N is larger than or equal to 2.5 and is less than or equal to 5.0. The yield strength of the pipeline steel is larger than or equal to 450 MPa, the tensile strength is larger than or equal to 535 MPa, the elongation rate is larger than or equal to 18%, the Charpy impact power AKV at minus 45 DEG C is larger than or equal to 250J, and the shear area rate Sa% of a DWTT fracture at minus 45 DEG C is larger than or equal to 85%.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of necking processing preparation method of fiber-metal tube

ActiveCN112339306BImprove machinabilityImprove heat resistanceFurnace typesTubular articlesFiberCarbon fibers

The invention discloses a fiber-metal tube necking processing preparation method, which relates to the field of material forming; it includes the steps of: (1) pre-treating an alloy plate and a carbon fiber cloth, stacking and then blanking, rolling and forming after blanking, Seamless welding to form circular pipe fittings; (2) Heating the fiber metal pipe fittings in step (1) and extruding them into the variable-diameter shrinking die, so that the pipes are extruded with each other under the action of the variable-diameter shrinking die to produce plastic deformation and fit tightly to obtain the necked composite pipe; (3) apply ultrasonic vibration around the necked composite pipe in step (2) to assist the plastic deformation of the pipe; (4) apply ultrasonic vibration in step (3), Apply air pressure inside the necked composite pipe and heat it; (5) Keep the temperature constant, then release the internal pressure, and finally take it out for air cooling to get the final product. The necking processing and preparation method of the fiber-metal pipe provided by the invention enables the pipe fitting to have high surface quality and good mechanical properties.

Owner:WUHAN UNIV OF TECH

A foot gold case and its production method, and tables including the gold case

Owner:JUNSON SHENZHEN CHUANJINDAIYIN TECH CO LTD

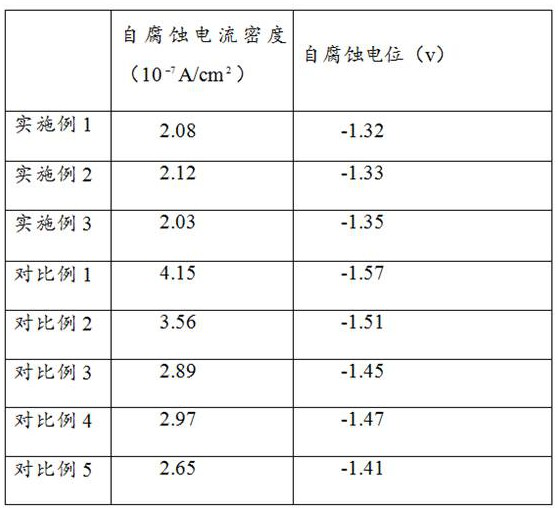

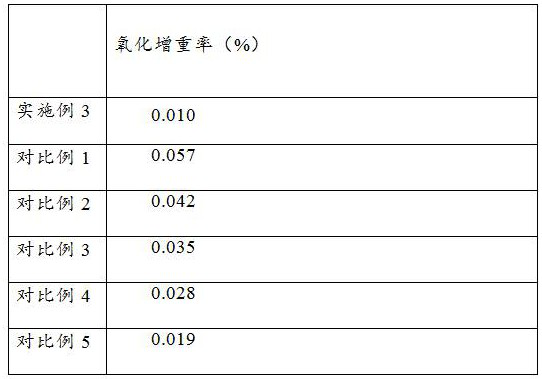

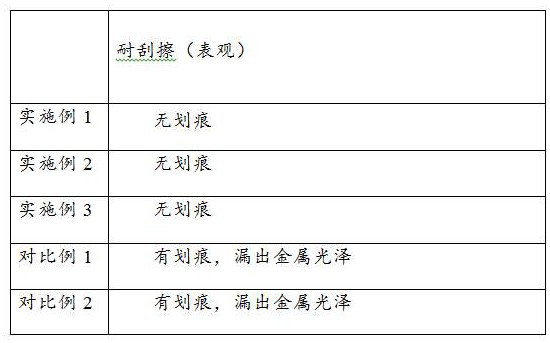

Target material for building glass and preparation method thereof

PendingCN114262874AImprove corrosion resistanceGood resistance to high temperature oxidationVacuum evaporation coatingSputtering coatingArchitectural glassSilicon

The invention discloses a target material for building glass. The target material comprises the following raw materials in parts by weight: 1-5 parts of Sn, 1-2 parts of In, 1-3 parts of Sb, 1-3 parts of Ga, 5-10 parts of Ni powder and 30-40 parts of silicon powder. The target material further comprises 0.5 to 1.5 parts of a refining agent and 0.1 to 0.5 part of an enhancer; the Sn powder, the In powder, the Sb powder, the Ga powder, the Ni powder and the silicon powder are fed into a smelting furnace to be smelted till the raw materials are completely melted; and 2, a refining agent is added into the smelted raw materials, stirring is conducted for 10-30 min at the rotating speed of 100-500 r / min, and then a reinforcing agent is added. The invention relates to a target material for building glass, which is prepared from Sn, In, Sb, Ga and other main metal elements. Architectural glass obtained by coating the target material has excellent corrosion resistance, mechanical scratch resistance, high-temperature oxidation resistance and the like.

Owner:广州市尤特新材料有限公司

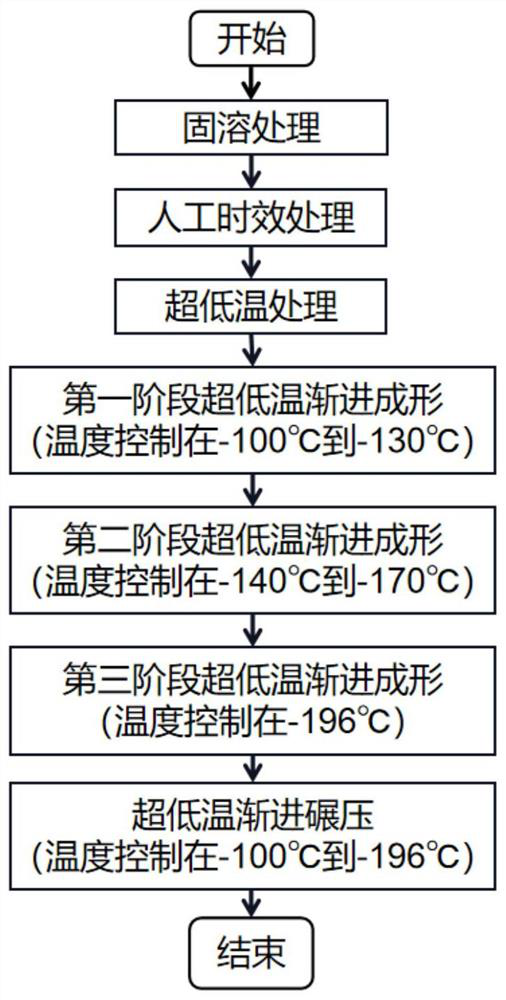

Multi-stage ultralow-temperature shape and surface integrated incremental forming method and obtained plate part

ActiveCN114523267AOvercoming the problem of poor plasticizing effectRaise the forming limitIncreasing energy efficiencyFurnace typesEngineeringForming processes

The invention belongs to the field of plate forming, particularly discloses a multi-stage ultralow-temperature shape and surface integrated incremental forming method and an obtained plate piece, and solves the problems that in the prior art, when an incremental forming process is applied to machining a workpiece, the forming limit of a metal plate is low, and the surface quality of a formed piece is insufficient. According to the process, accurate forming of the macroscopic geometrical shape of the component is achieved through ultralow-temperature incremental forming, then a surface layer gradient gradual change structure is prepared through surface rolling, and the formed component has excellent overall mechanical performance and surface performance. The forming method can be widely applied to ultralow-temperature incremental forming and ultralow-temperature incremental rolling processes for improving the forming limit of metal plates and improving the surface quality of formed parts.

Owner:SHANDONG UNIV

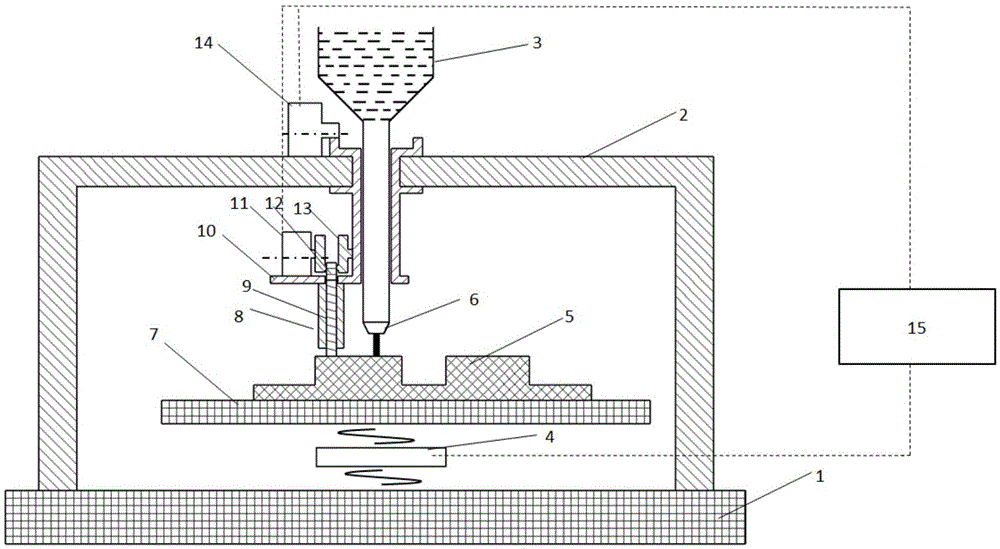

A melting and forging composite metal additive manufacturing device

InactiveCN103962560BPromotes grain refinementReduce the temperatureForging press drivesLagForming processes

The invention relates to a metal additive manufacturing device with the combination of fusing and forging. The metal additive manufacturing device comprises a base unit, a fused deposition unit, a forging unit, a driving unit and a control unit, wherein the fused deposition unit, the forging unit, the driving unit and the control unit are supported by the base unit. A workpiece to be machined is further arranged on the base unit. Material fused deposition is carried out on the surface of the workpiece through the fused deposition unit. The fused deposition unit is driven by the control unit to move according to a worked out path to make the workpiece be formed. The workpiece is forged through the forging unit in the workpiece forming process, and forging is always kept on a track of fused deposition materials and lags behind fused deposition points. Compared with the prior art, the metal additive manufacturing device with the combination of fusing and forging enables the fused deposition materials to be forged, so that the fused deposition materials are compact, defects of looseness, holes and the like are eliminated, dendritic crystals and other undesirable organizations can be smashed, grain refinement of the materials is promoted, grains of the materials are finer, and the surface quality of the forged materials is higher.

Owner:SHANGHAI JIAO TONG UNIV

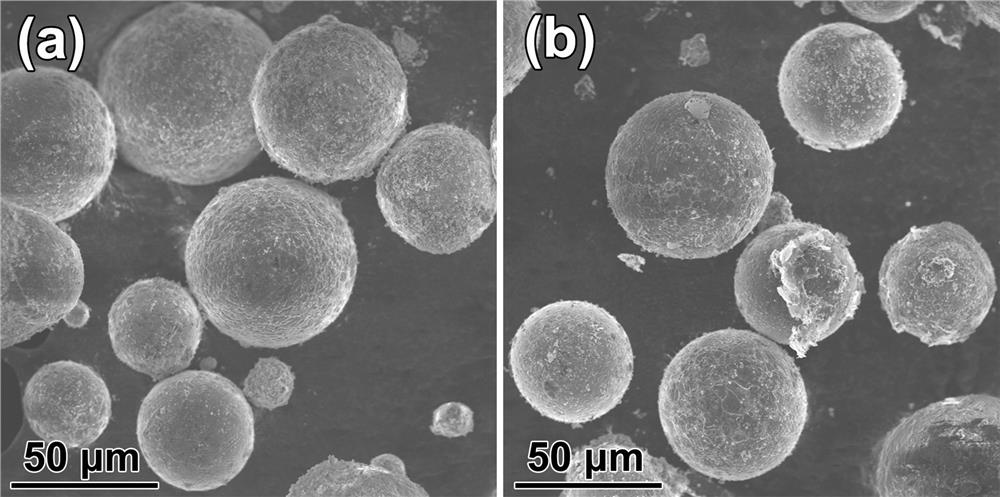

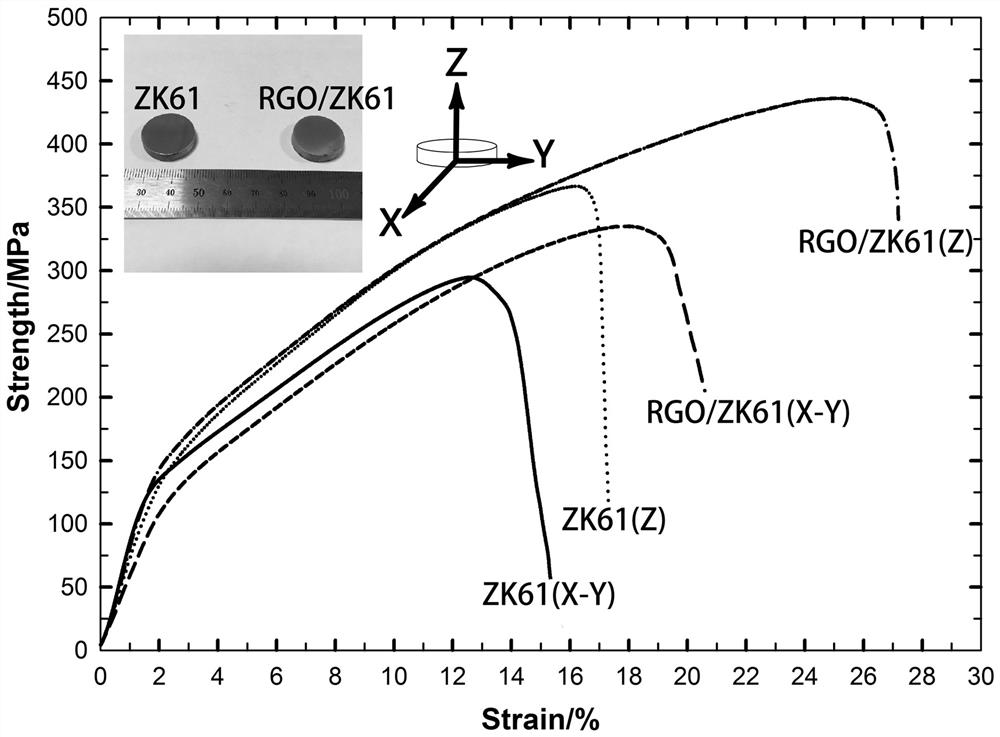

A kind of preparation method of high toughness graphene/zk61 magnesium alloy composite material

The present invention proposes a method for preparing a high-toughness graphene / ZK61 magnesium alloy composite material. In the preparation method, RGO / ZK61 magnesium alloy powder is calcined by adding GO to ZK61 magnesium alloy powder, and graphene is prepared by spark plasma sintering. / ZK61 magnesium alloy composite material. Compared with the ZK61 magnesium alloy without graphene, the graphene / ZK61 magnesium alloy prepared by this method has significantly improved strength and toughness, and shows strong anisotropy in mechanical properties and structure.

Owner:ZHENGZHOU UNIV

A kind of aluminum matrix composite material and preparation method thereof

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com