Steel rail thermite welding gating system

An aluminothermic welding and pouring system technology, which is applied in the field of aluminothermic welding of rails, can solve problems such as hidden safety hazards, lack of slag removal structure, quality problems of welded joints, etc., and achieve the effects of weakening scouring, facilitating slag removal, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in combination with specific embodiments.

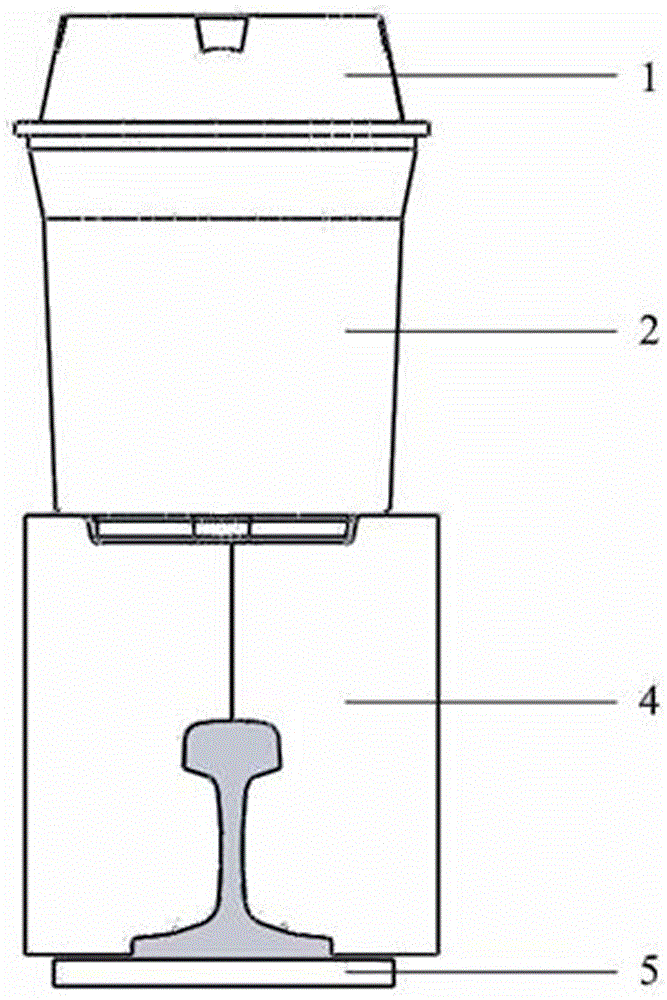

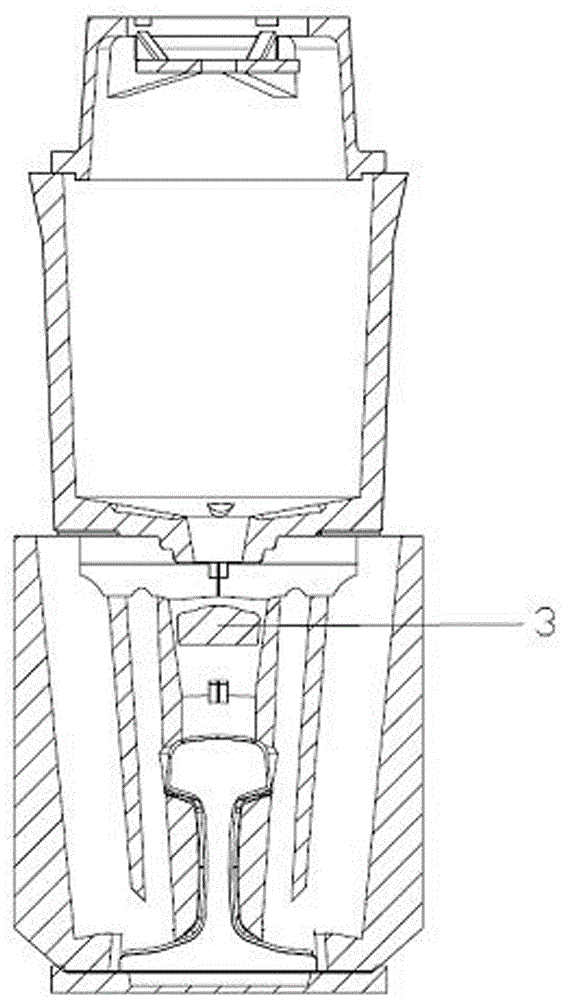

[0037] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the overall structure of the present invention. The system includes a sand mold 4, a crucible body 2 arranged above the sand mold 4, a crucible cover 1 matching the crucible body 2, a diverter plug 3 arranged inside the sand mold 4 and a set Base plate 5 at the bottom of sand mold 4.

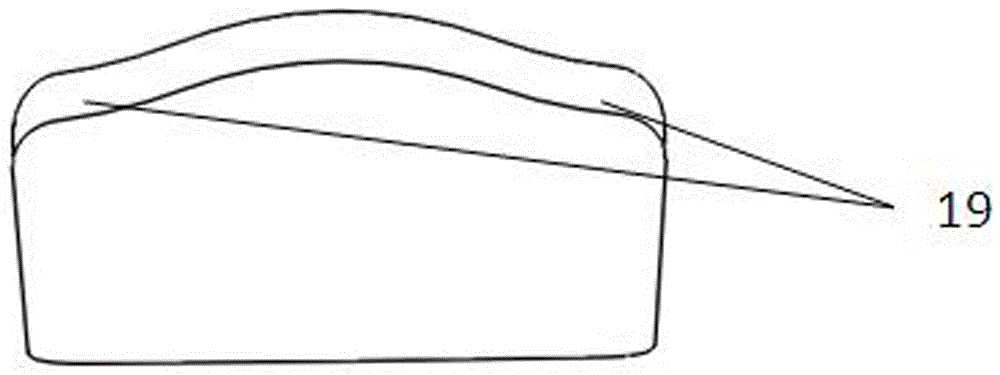

[0038] Such as image 3 As shown, it is the diverter plug 3 of the rail aluminothermic welding gating system of the present invention. The diverter plug 3 is a concave arc-shaped structure on both sides of the central protrusion, and the curved surface is smoothly connected. The lowest position of the concave arc 19 is higher than the two sides of the diverter plug. 3. Located in the cavity formed by the upper part of the sand mold in the pouring system, the diverter plug 3 is fixed by the inclined plane structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com