A kind of necking processing preparation method of fiber-metal tube

A fiber metal and metal pipe technology, which is applied in the field of fiber-metal pipe necking processing and preparation, can solve the problems of easy generation of gaps in the aluminum alloy layer and the carbon fiber layer, complicated steps, insufficient normal pressure, etc., so as to solve the problems of wrinkling and The problem of metal springback, the effect of improving the shrinkage forming limit, and improving the performance of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a necking of a fiber-metal pipe fitting, comprising the following steps:

[0031] (1) The alloy plate and the carbon fiber cloth are pre-treated, stacked alternately, and the aluminum plate is placed on the outer layer for blanking treatment, and the carbon fiber cloth and the alloy plate are stacked into multiple layers by a stacking process, wherein the carbon fiber cloth is middle layer;

[0032] (2) carrying out blanking treatment of the multi-layer material obtained in the step (1), and rounding the blanked pipe fittings according to the specified size and requirements, and then performing seamless welding to form fiber metal pipe fittings;

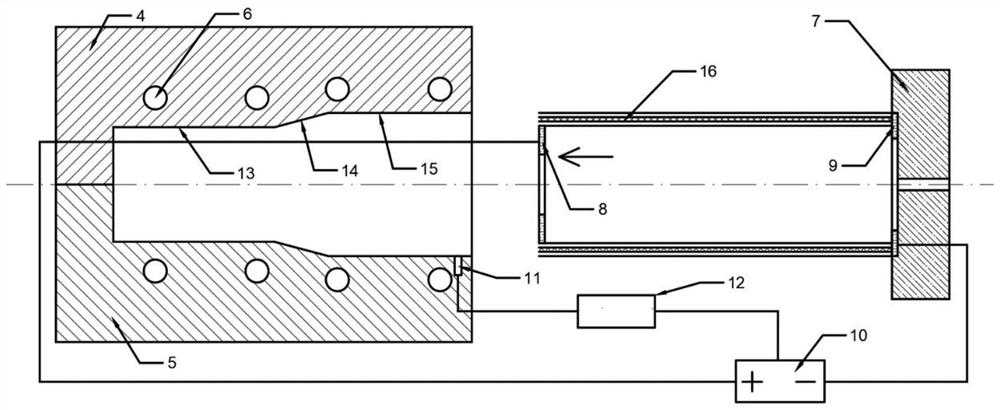

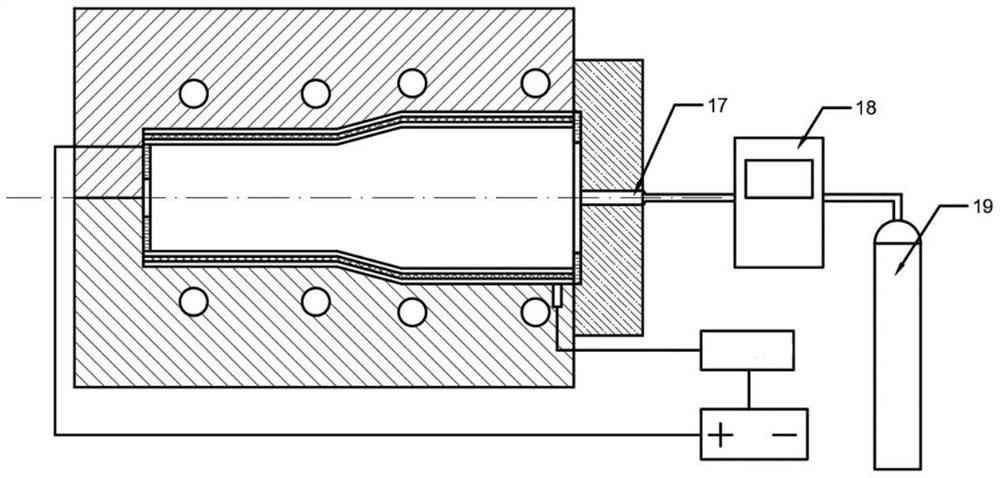

[0033] (3) heating the fiber metal pipe fitting obtained in the step (2) and extruding it into a variable-diameter shrinking die, so that the three-layer pipes are squeezed together under the action of the shrinking die to produce plastic deformation and fit tightly , to obtain a ...

Embodiment 1

[0051] The solid solution 2219 aluminum alloy (thickness 0.8mm) and the carbon fiber composite material (thickness 0.4mm) are alternately stacked, in the order: aluminum alloy - carbon fiber composite material - aluminum alloy, and then rounded and welded seamlessly. , to obtain carbon fiber aluminum alloy pipe fittings (thickness 2mm). The carbon fiber composite material is carbon fiber impregnated with resin, wherein the carbon fiber is T300 type orthogonal direction woven cloth, and the resin material is amino epoxy resin;

[0052] Clamp the top and bottom of the shrinking die, use self-resistance heating to heat the pipe to be shrunk to 75°C, and then squeeze it into the shrinking die. ;Using an ultrasonic probe to apply ultrasonic vibration around the necked fiber metal pipe fittings; the fiber metal pipe fittings heat up with self-resistance heating to obtain a softened shrinkage prototype, and at the same time, high-pressure nitrogen is introduced into the fiber metal p...

Embodiment 2

[0054]The solid solution 2219 aluminum alloy (thickness 0.9mm) and carbon fiber composite material (thickness 0.4mm) are alternately stacked, in the order: aluminum alloy - carbon fiber composite material - aluminum alloy, and then rounded and welded seamlessly. , to obtain carbon fiber aluminum alloy pipe fittings (thickness 2.2mm, outer diameter 49mm). The carbon fiber composite material is carbon fiber impregnated with resin, in which the carbon fiber is a T500 type woven cloth in orthogonal directions, and the resin material is bisphenol A epoxy resin; the necking mold is clamped and installed, and the pipe fittings to be necked are heated by self-resistance heating. Heating to 85°C, and then extruding the fiber metal pipe fitting to be necked into the necking die, and at the same time, the pipe fitting extrusion block 7 and the necking mold are closely attached; the ultrasonic probe is used to apply ultrasonic waves around the necked fiber metal pipe fittings. Vibration; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com