Target material for building glass and preparation method thereof

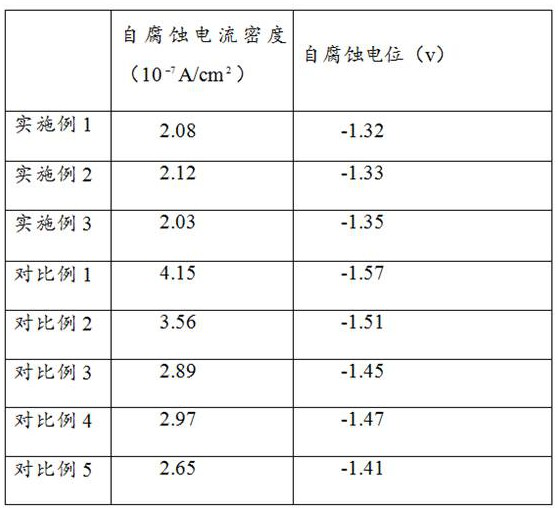

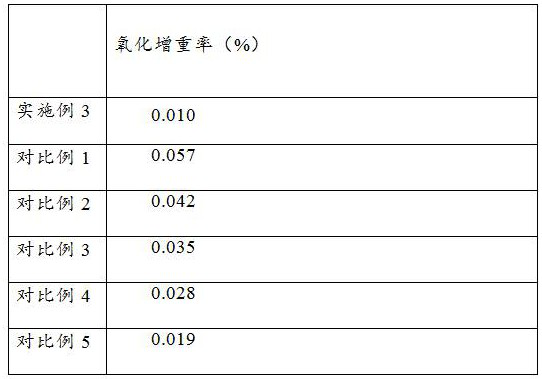

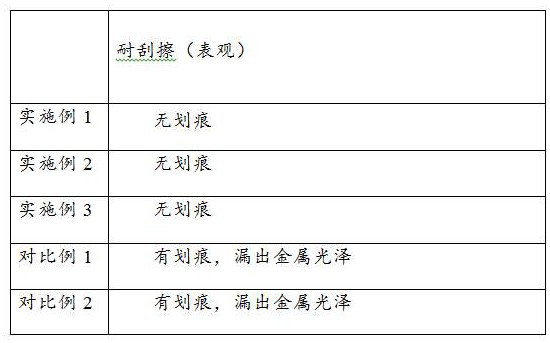

An architectural glass and target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor target corrosion resistance, scratch resistance, high temperature oxidation resistance, etc. Corrosion, enhanced corrosion resistance, increased density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the refining agent of the present embodiment is:

[0047] S1: Mix SiN, LiCl, and light calcium carbonate according to the weight ratio of 3:2:1, and then add them to a ball mill for ball milling. The ball milling speed is 1000-1500r / min, and the ball milling time is 20-30min;

[0048] S2: Then send it to a hot press machine for hot pressing treatment. The hot pressing pressure is 10-20min, and the hot pressing temperature is 800-1000°C. Granulation, the particle size is 1-5 mesh;

[0049] S3: heat-treating the granulated product;

[0050] The specific heat treatment method is:

[0051] First heat treatment at 200-300°C for 15-25min, then heat at 1-3°C / min to 400°C for 10-20min;

[0052] Then anneal to 150-190°C, continue to keep warm for 20-30min, and finally cool down to room temperature at a rate of 1°C / min.

[0053] The preparation method of the strengthening agent of the present embodiment is:

[0054] Mix the rare earth yttrium and bent...

Embodiment 1

[0075] A target for architectural glass in this embodiment includes the following raw materials in parts by weight:

[0076] 1 part of Sn, 1 part of In, 1 part of Sb, 1 part of Ga, 5 parts of Ni powder and 30 parts of silicon powder; the target also includes 0.5 part of refining agent and 0.1 part of strengthening agent.

[0077] The preparation method of the refining agent of the present embodiment is:

[0078] S1: Mix SiN, LiCl, and light calcium carbonate according to the weight ratio of 3:2:1, and then add them to the ball mill for ball milling. The ball milling speed is 1000r / min, and the ball milling time is 20min;

[0079] S2: Then send it to the hot pressing machine for hot pressing treatment. The hot pressing pressure is 10min, and the hot pressing temperature is 800°C. 1 mesh;

[0080] S3: heat-treating the granulated product;

[0081] The specific heat treatment method is:

[0082] Heat treatment at 200°C for 15 minutes, then heat at 1°C / min to 400°C for 10 minu...

Embodiment 2

[0104] A target for architectural glass in this embodiment includes the following raw materials in parts by weight:

[0105] 5 parts of Sn, 2 parts of In, 3 parts of Sb, 3 parts of Ga, 10 parts of Ni powder and 40 parts of silicon powder; the target also includes 1.5 parts of refining agent and 0.5 parts of strengthening agent.

[0106] The preparation method of the refining agent of the present embodiment is:

[0107] S1: Mix SiN, LiCl, and light calcium carbonate according to the weight ratio of 3:2:1, and then add them to a ball mill for ball milling. The ball milling speed is 1500r / min, and the ball milling time is 30min;

[0108] S2: Then send it to the hot pressing machine for hot pressing treatment. The hot pressing pressure is 20min, and the hot pressing temperature is 1000°C. 5 mesh;

[0109] S3: heat-treating the granulated product;

[0110] The specific heat treatment method is:

[0111] Heat treatment at 300°C for 25 minutes, then heat at 3°C / min to 400°C for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com