High-transmittance polypropylene composition

A high-permeability polypropylene and composition technology, applied in the field of polymer composite materials, can solve problems such as increased melt viscosity, and achieve the effects of performance improvement, grain refinement, and high recognition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

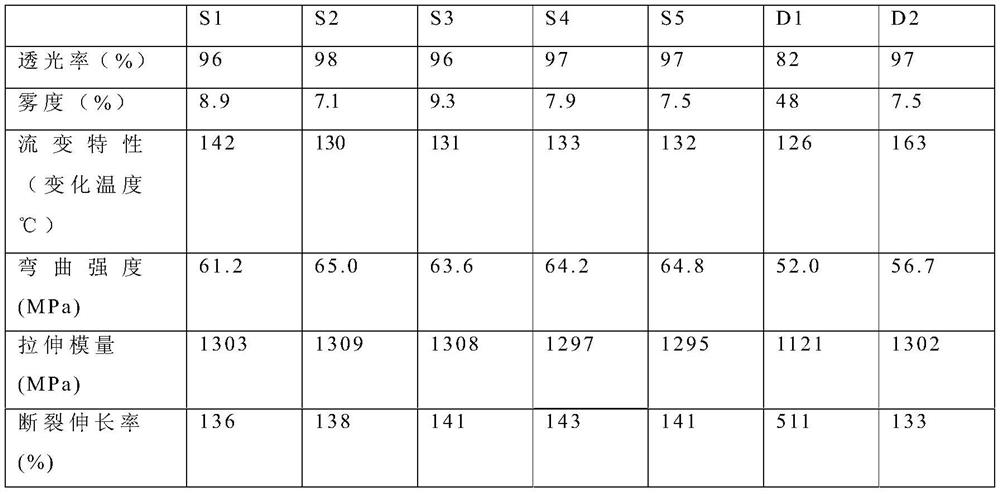

Examples

Embodiment 1

[0034] A high-transparency polypropylene composition, formula and preparation method are as follows:

[0035] Dissolve appropriate amount of DMDBS, sodium hydroxide and tetrabutylammonium bromide (TBAB) in N,N-dimethylformamide (DMF) solvent at 70°C, stir well and add epichlorohydrin (ECH), 60°C Under reaction for 8 hours, the molar ratio of ECH and sorbitol nucleating agent in the raw material is greater than 2:1; multiple times of filtration and washing to remove impurities and drying to obtain DMDBS derivatives without hydroxyl groups;

[0036] The modified nucleating agent is obtained by mixing the hydroxyl-free DMDBS derivative and DMDBS at a mass ratio of 2:1; take 100 parts of isotactic polypropylene K1008 (Yanshan Petrochemical Company), 1 part of modified nucleating agent, 0.1 part of antioxidant Agent 2,6-di-tert-butyl-p-cresol (Beijing Institute of Addition Auxiliaries), 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacic acid The ester (Bei...

Embodiment 2

[0038] A high-transparency polypropylene composition, formula and preparation method are as follows:

[0039] The preparation of DMDBS derivatives without hydroxyl is the same as in Example 1;

[0040] Mix the hydroxyl-free DMDBS derivatives and DMDBS at a mass ratio of 3:1 to obtain a modified nucleating agent; take 100 parts of isotactic polypropylene K1008 (Yanshan Petrochemical Company), 1 part of modified nucleating agent, 0.1 part of antioxidant Agent 2,6-di-tert-butyl-p-cresol (Beijing Institute of Addition Auxiliaries), 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacic acid The ester (Beijing Addition Auxiliary Research Institute) is mixed evenly and put into a high-speed mixer at a speed of 80-120rpm, stirred for 30 minutes, and then the premix is extruded and granulated at 180-230°C.

Embodiment 3

[0042] A high-transparency polypropylene composition, formula and preparation method are as follows:

[0043] The preparation of DMDBS derivatives without hydroxyl is the same as in Example 1;

[0044] The modified nucleating agent is obtained by mixing the hydroxyl-free DMDBS derivative and DMDBS at a mass ratio of 4:1; 100 parts of isotactic polypropylene K1008 (Yanshan Petrochemical Company), 1 part of modified nucleating agent, 0.1 part of antioxidant Agent 2,6-di-tert-butyl-p-cresol (Beijing Institute of Addition Auxiliaries), 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacic acid The ester (Beijing Addition Auxiliary Research Institute) is mixed evenly and put into a high-speed mixer at a speed of 80-120rpm, stirred for 30 minutes, and then the premix is extruded and granulated at 180-230°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com