A kind of preparation method of high toughness graphene/zk61 magnesium alloy composite material

A ZK61, composite material technology, applied in the field of composite material preparation, can solve the problems of weak interface bonding, poor graphene dispersion, easy agglomeration, etc., and achieve the effect of improving plasticity and saving sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

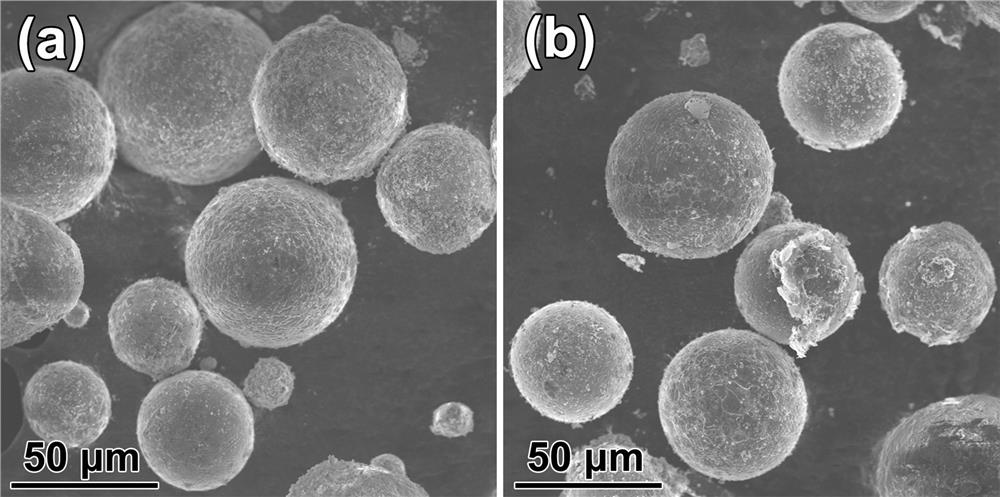

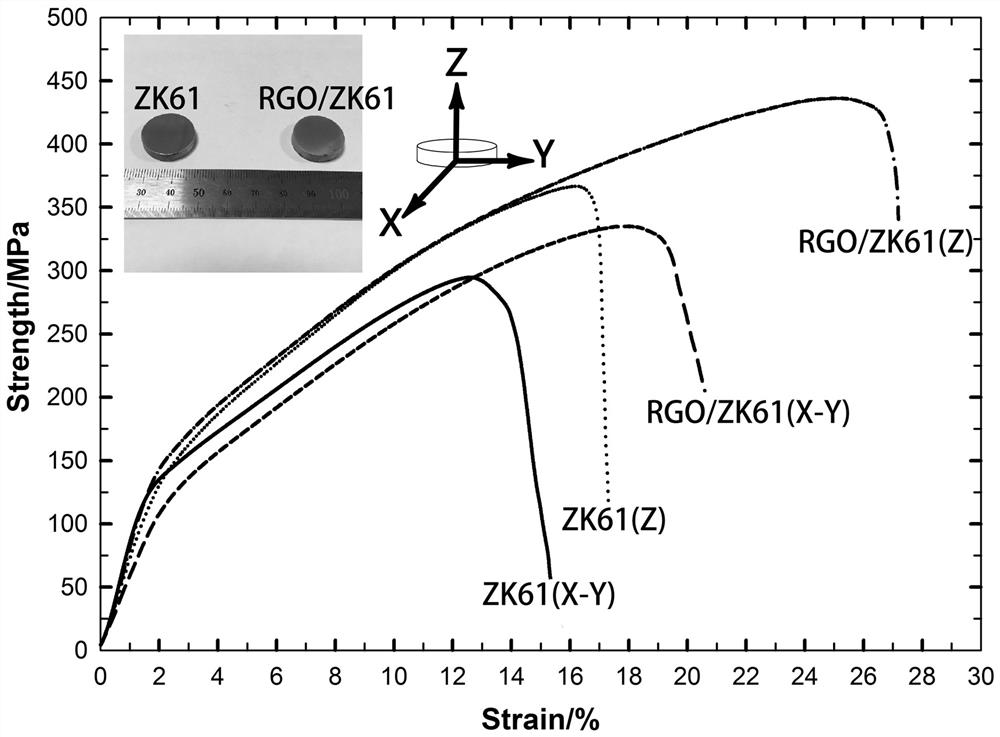

[0024] The invention provides a method for preparing a high-toughness graphene / ZK61 magnesium alloy composite material. The single-layer graphene oxide powder used in the method has a sheet diameter of 0.5-5 μm and a thickness of 0.8-1.2 nm; the ZK61 magnesium alloy powder includes 94.49 wt %Mg, 5.20wt% Zn, 0.31wt% Zr, average particle size 75μm. Specific steps are as follows:

[0025] 01. Disperse GO in a mixture of absolute ethanol and deionized water, and ultrasonically obtain a GO dispersion;

[0026] 02. Add the above GO dispersion into a magnetic stirrer, and add ZK61 magnesium alloy powder under magnetic stirring state, and stir to obtain a mixed solution;

[0027] 03. Let the above mixed solution stand still, remove the supernatant with a dropper and dry it, and grind the dried powder for 30 minutes to obtain GO / ZK61 magnesium alloy powder;

[0028] 04. Put the above GO / ZK61 magnesium alloy powder in H 2 10% volume fraction of H 2 / Ar mixed gas, 400°C for 180min, t...

Embodiment 1

[0032] This embodiment is as a comparative example, and the addition amount of graphene oxide is 0g, specifically:

[0033] Add 10g of ZK61 magnesium alloy powder into 330mL of a mixture of absolute ethanol and deionized water with a volume ratio of 9:1, stir magnetically for 1 hour to obtain a mixed solution; let the above mixed solution stand for 3 hours, and remove it with a rubber dropper The supernatant was dried at 60°C for 12 h, and the dried powder was ground with an agate mortar for 30 min; 2 10% volume fraction of H 2 Under / Ar mixed gas, heat preservation at 400°C for 180min; finally use spark plasma sintering, the axial pressure is 60MPa, and keep at 520°C for 5min.

Embodiment 2

[0035] The preparation method of the graphene / ZK61 magnesium alloy composite material of the present embodiment, the steps are as follows:

[0036] Disperse 50 mg of GO in 330 mL of a mixture of absolute ethanol and deionized water with a volume ratio of 9:1, and ultrasonicate for 2 hours to obtain a GO dispersion; add the above GO dispersion to a magnetic stirrer, and Add 10g of ZK61 magnesium alloy powder and stir for 1h to obtain a mixed solution; let the above mixed solution stand for 3h, remove the supernatant with a rubber dropper, dry at 60°C for 12h, and grind the dried powder with an agate mortar 30min, get GO / ZK61 magnesium alloy powder; Above-mentioned GO / ZK61 magnesium alloy powder is in H 2 10% volume fraction of H 2 / Ar mixed gas, 400 ° C for 180 min to obtain RGO / ZK61 magnesium alloy powder; the above RGO / ZK61 magnesium alloy powder was formed by SPS, the axial pressure was 60 MPa, and kept at 520 ° C for 5 min to obtain the graphite of this embodiment ene / ZK6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com