A pipeline steel with excellent toughness for extremely low temperature environment at -45°C and its manufacturing method

A manufacturing method and pipeline steel technology, which is applied in the field of pipeline steel and its manufacturing, can solve the problems of high production cost and achieve the effects of alleviating stress concentration and excellent low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

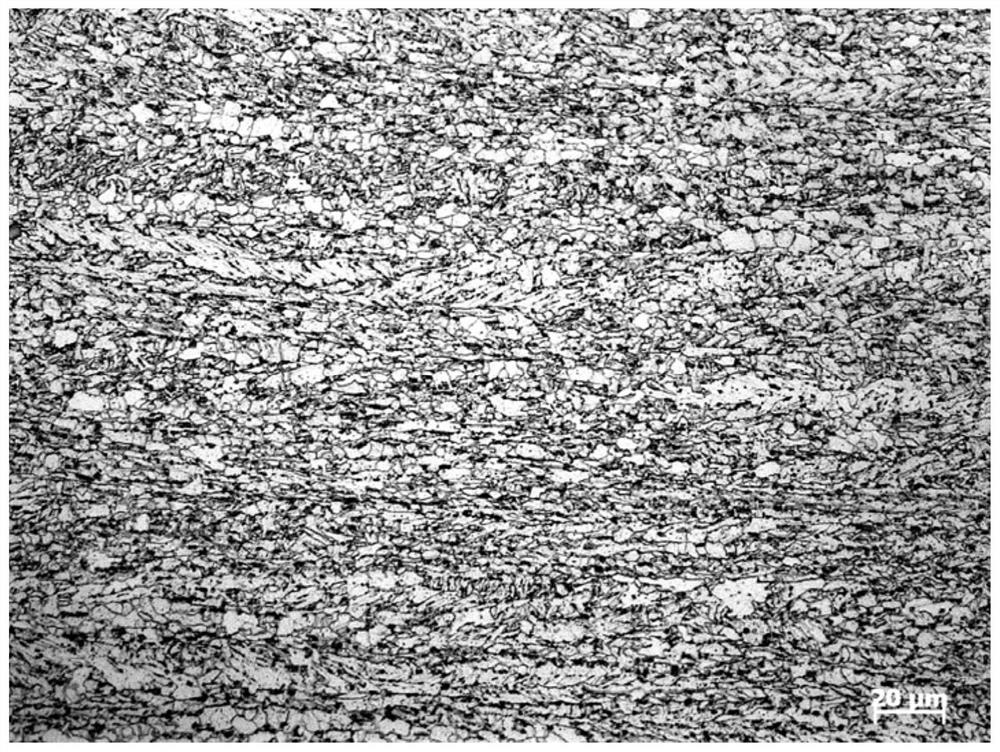

Image

Examples

Embodiment Construction

[0047] In the following, the ultra-low temperature pipeline steel and its manufacturing method according to the present invention will be further explained and described in conjunction with the accompanying drawings and specific examples. However, such explanations and descriptions do not constitute undue limitations on the technical solution of the present invention.

[0048] Table 1 shows the mass percentages of chemical elements in the pipeline steels of the examples of the present invention, Table 2 shows the process parameters of the pipeline steels of the examples of the present invention, and Table 3 shows the properties of the pipeline steels of the examples of the present invention.

[0049] It can be seen from Table 3 that the yield strength Rt0.5≥450MPa, the tensile strength Rm≥535MPa, and the elongation A 50.8 ≥18%, -45°C Charpy impact energy AKV≥250J, -45°C DWTT fracture shear area ratio SA%≥85%, which can meet the toughness requirements of -45°C extremely low temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com