Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduced cracking tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient wear-resistant coating and method for preparing same

ActiveCN105543839AImprove wear resistanceHigh temperature resistantSuperimposed coating processWear resistantUltrasonic oscillation

Provided are a gradient wear-resistant coating and a method for preparing the same. Co50+0.15% CeO2 powder, Co50+0.25% CeO2+6% Ni / Wc powder and Co50+0.4% CeO2+12% Ni / WC powder are used for preparing the gradient wear-resistant coating with the structure of a bottom layer, a transition layer and a wear-resistant layer on the surface of a workpiece in a coaxial powder supply manner and a laser cladding manner, and the wear resisting performance of the work surface of a part is improved. An ultrasonic vibration device and a contour tracing electromagnetic induction heating device are adopted in the cladding process. Ultrasonic oscillation of a certain degree is applied to the area close to a cladded area of the workpiece, the grain size of a cladding layer can be remarkably refined, residual stress can be remarkably eliminated, and therefore generated cracks are reduced, and a cladding layer structure with good performance is obtained. The contour tracing electromagnetic induction heating device can be utilized for effectively reducing thermal stress brought by the temperature gradient of the cladding layer and relieving the cracking tendency. According to the technological parameters of the ultrasonic vibration device, the work frequency ranges from 10 kHz to 20 kHz, the maximum output power is 1,000 W, and the pneumatic pressure ranges from 0.3 MPa to 0.6 MPa. According to the technological parameters of the contour tracing electromagnetic induction heating device, the voltage is 380 V, the frequency is 60 Hz, and the heating temperature ranges from 150 DEG C to 1,000 DEG C.

Owner:CHANGCHUN UNIV OF SCI & TECH

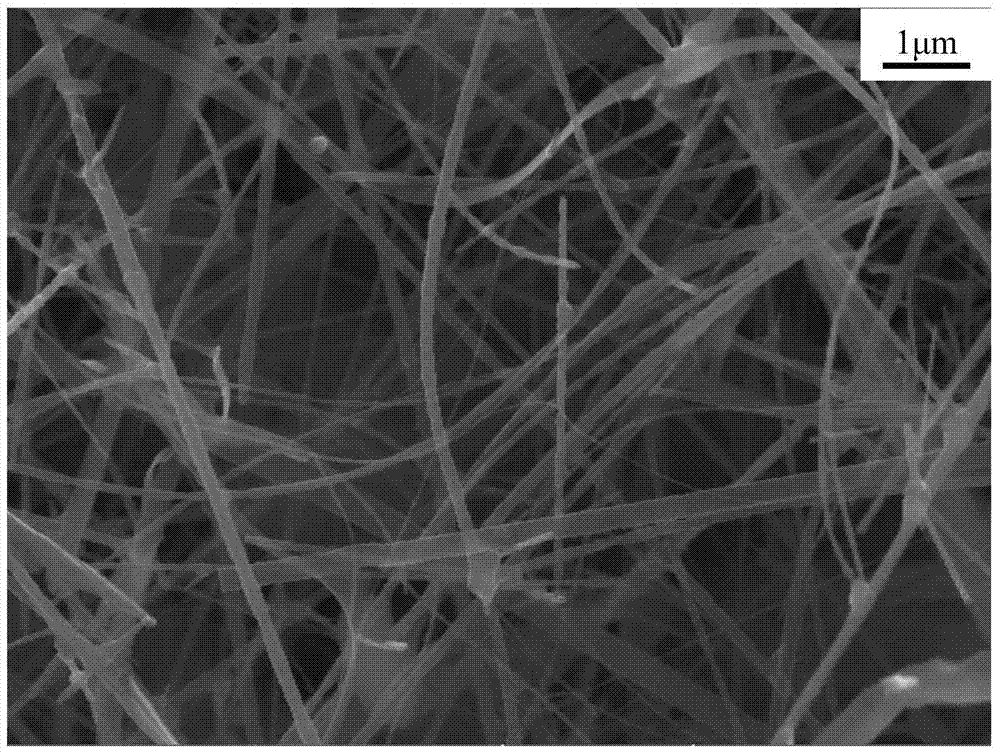

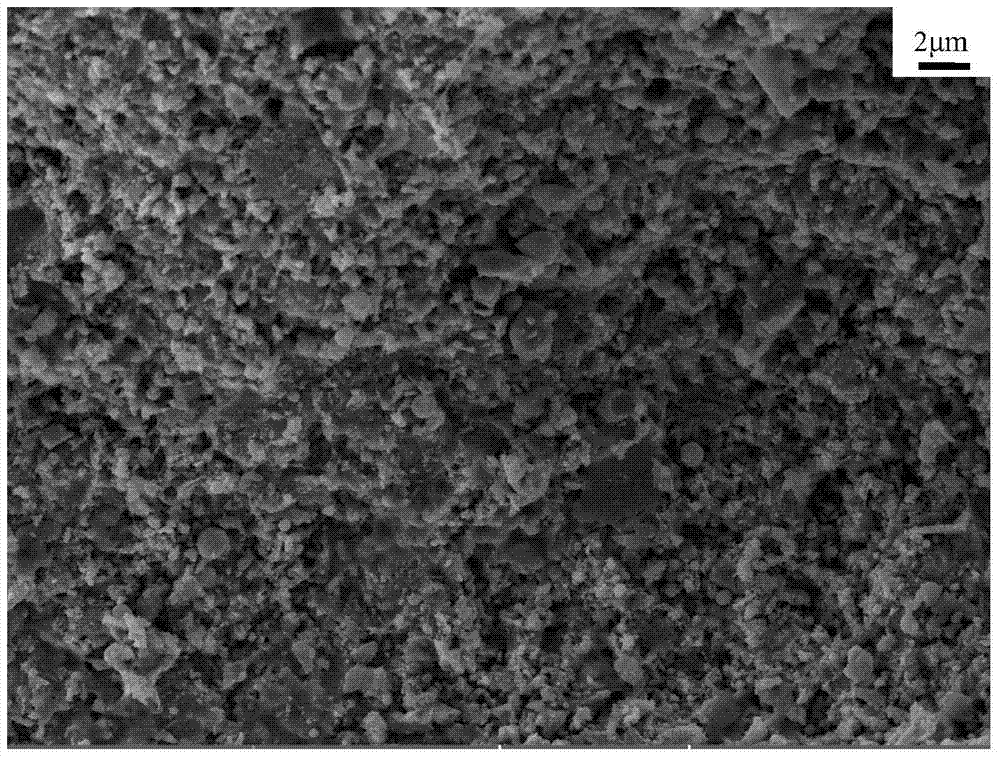

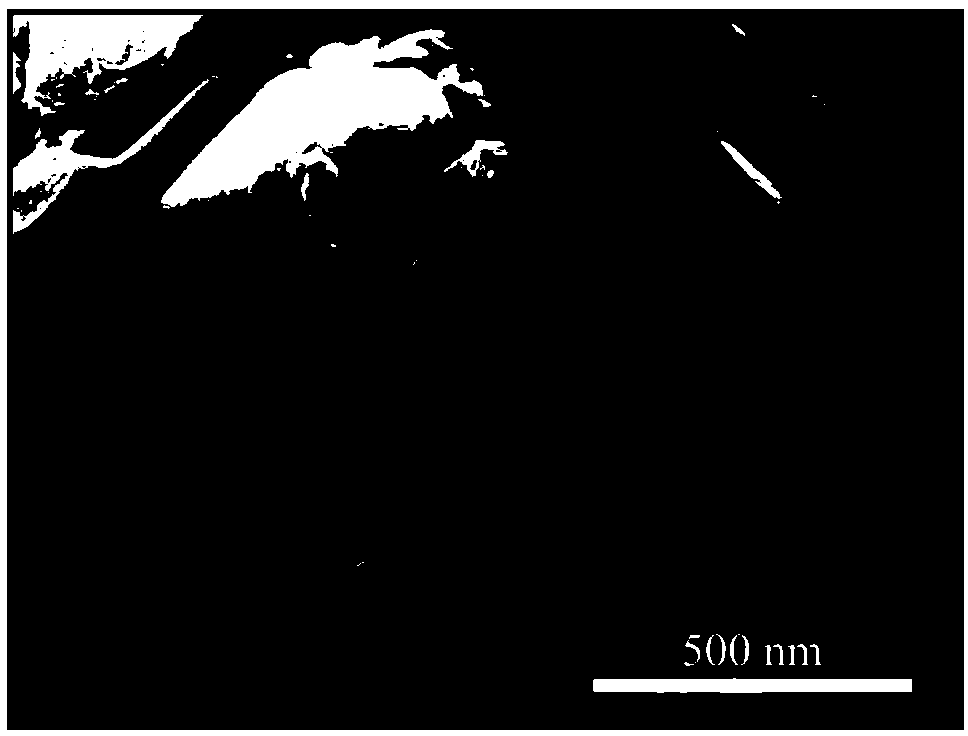

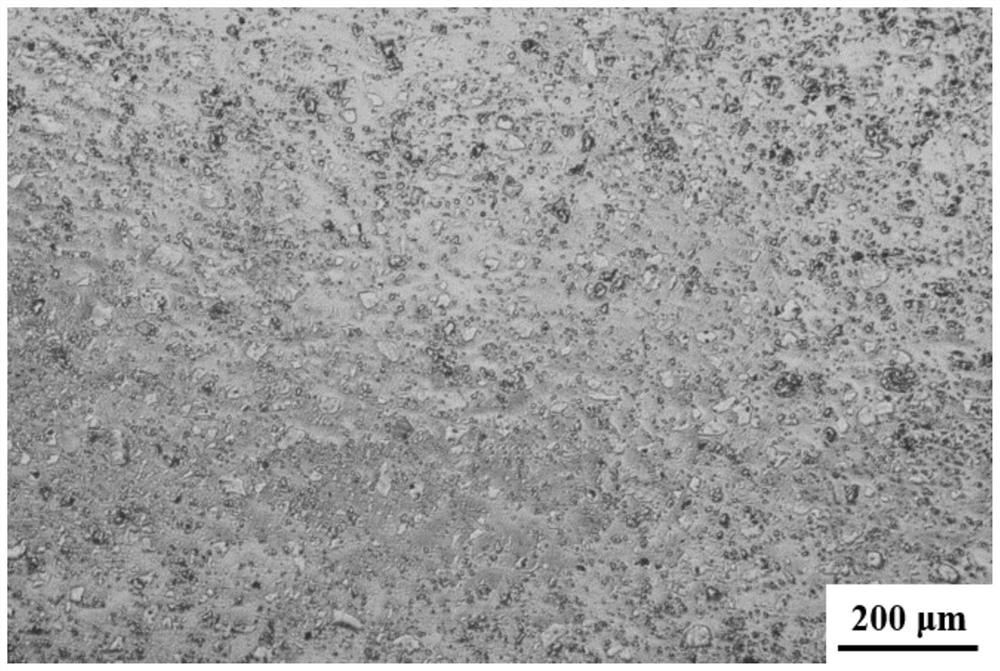

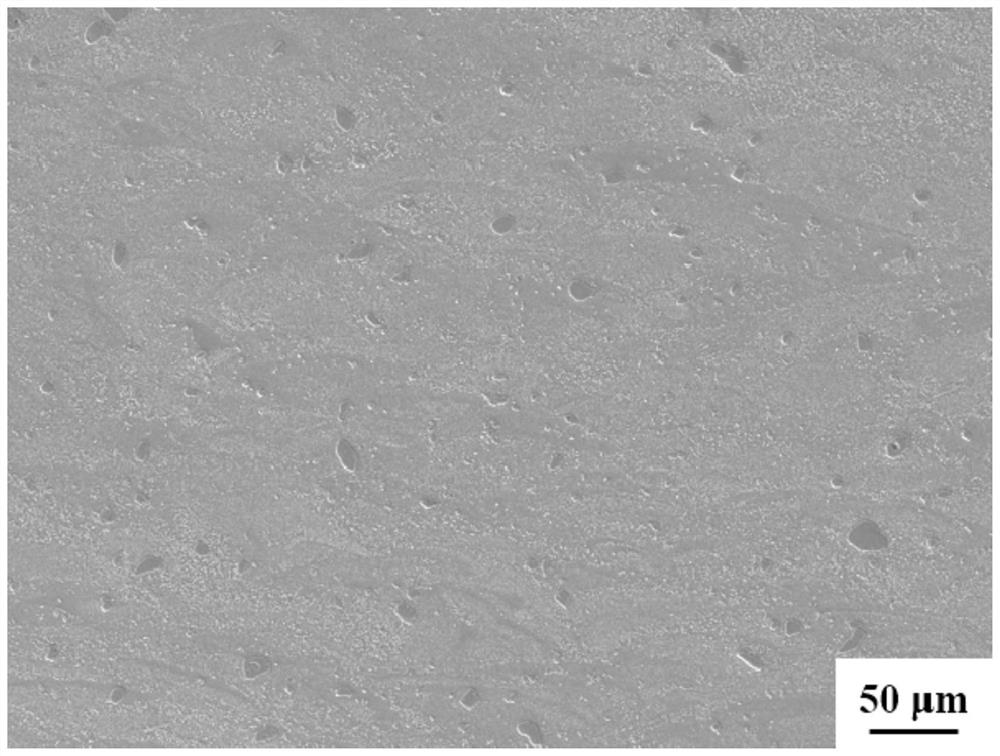

SiC nanowire toughened high temperature ablation resistant ZrB2-SiC composite coating and preparation method thereof

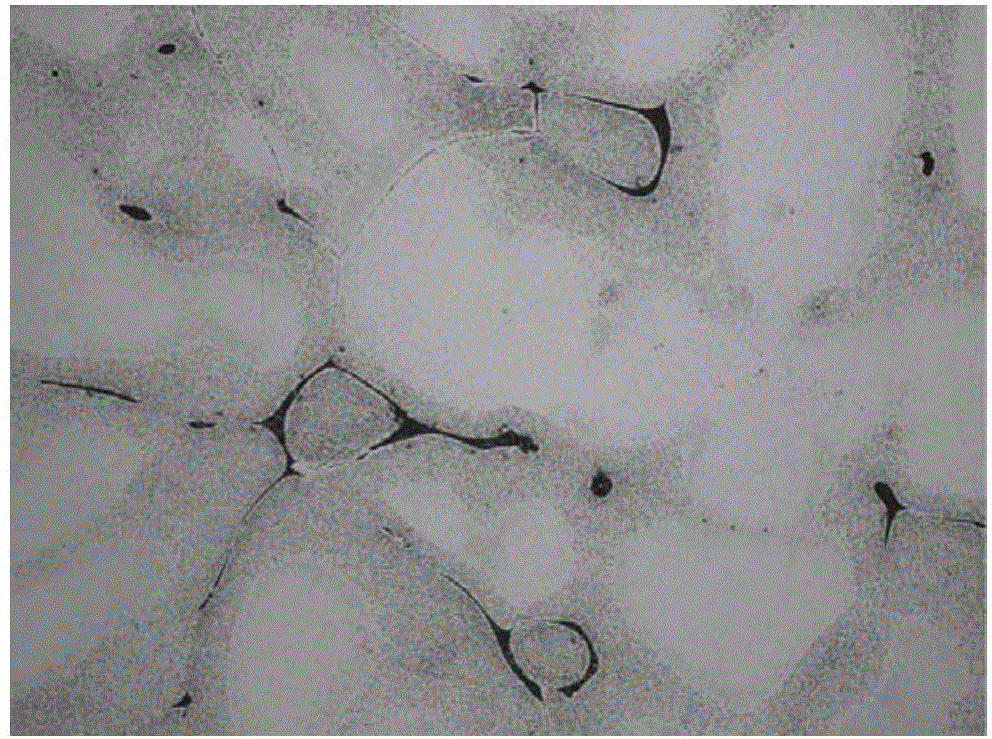

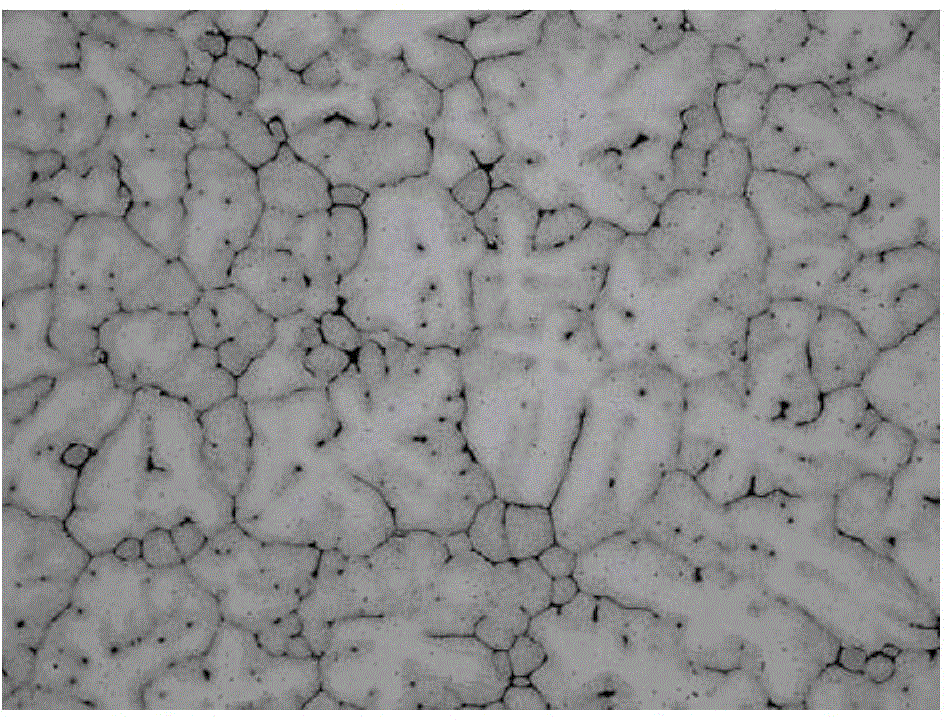

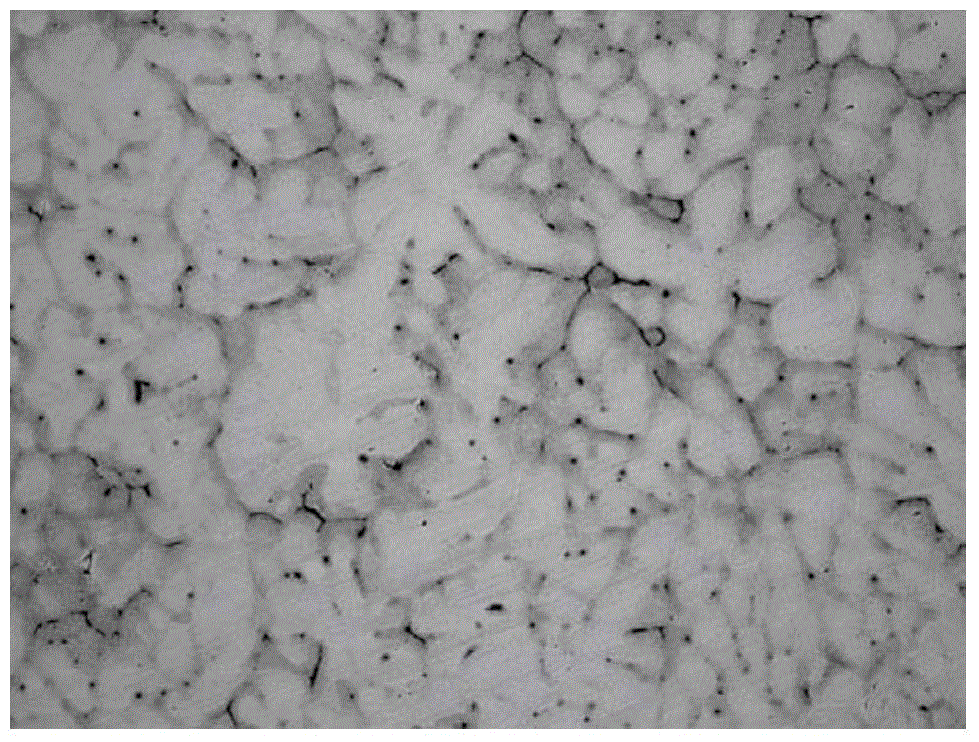

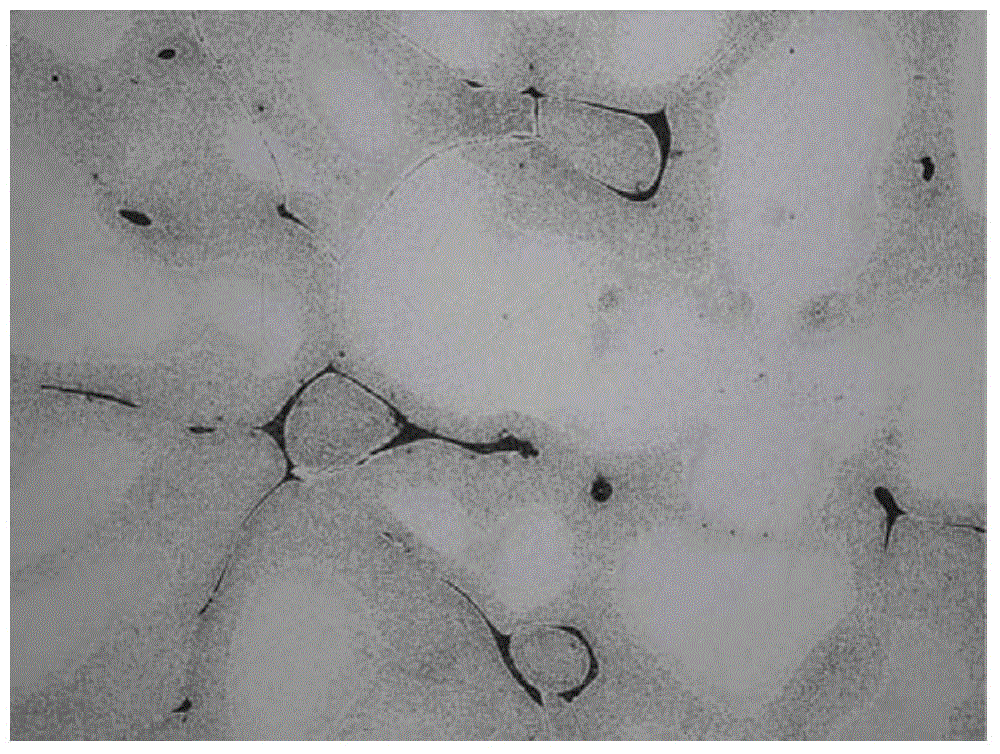

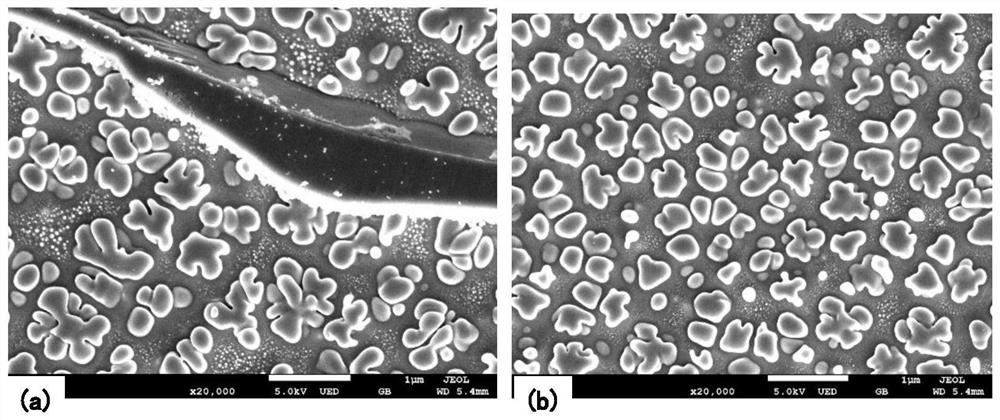

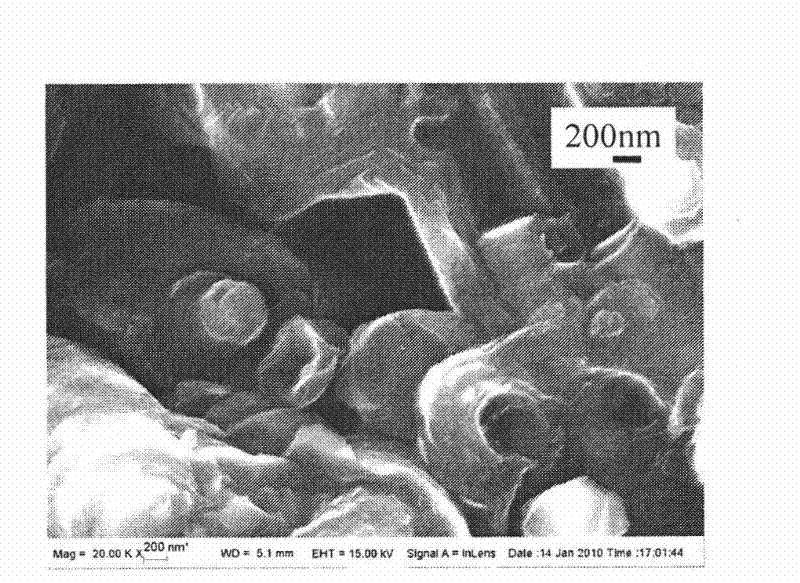

The invention relates to a SiC nanowire toughened high temperature ablation resistant ZrB2-SiC composite coating and a preparation method thereof. The preparation method comprises the steps of firstly, preparing an internal SiC coating on the surface of a C / C (Carbon / Carbon) composite material; then, preparing a SiC nanowire toughened ZrB2-SiC ceramic coating on the internal SiC coating by using a chemical vapor deposition and supersonic plasma spraying combined process; obtaining a ceramic coating with a compact structure through increasing the toughness of the ceramic coating and reducing the cracking tendency of the coating by means of the toughening effect of a nanowire. Known from the drawing 3, the SiC nanowire toughened ZrB2-SiC coating is relatively compact and free of cracks and holes on the surface; known from the drawing 4, a ZrB2-SiC coating which is not toughened by using the nanowire has obvious cracks and more defects on the surface. A SiC nanowire toughened test sample has the linear ablative rate of 8.7mu m / s and the mass ablative rate of 1.5*10<-3>g / s when eroded at the temperature of 2200 DEG C by oxyacetylene, and a test sample which is not toughened by using the SiC nanowire has the linear ablative rate of 16.4mu m / s and the mass ablative rate of 3.3*10<-3>g / s when eroded at the temperature of 2200 DEG C by oxyacetylene.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

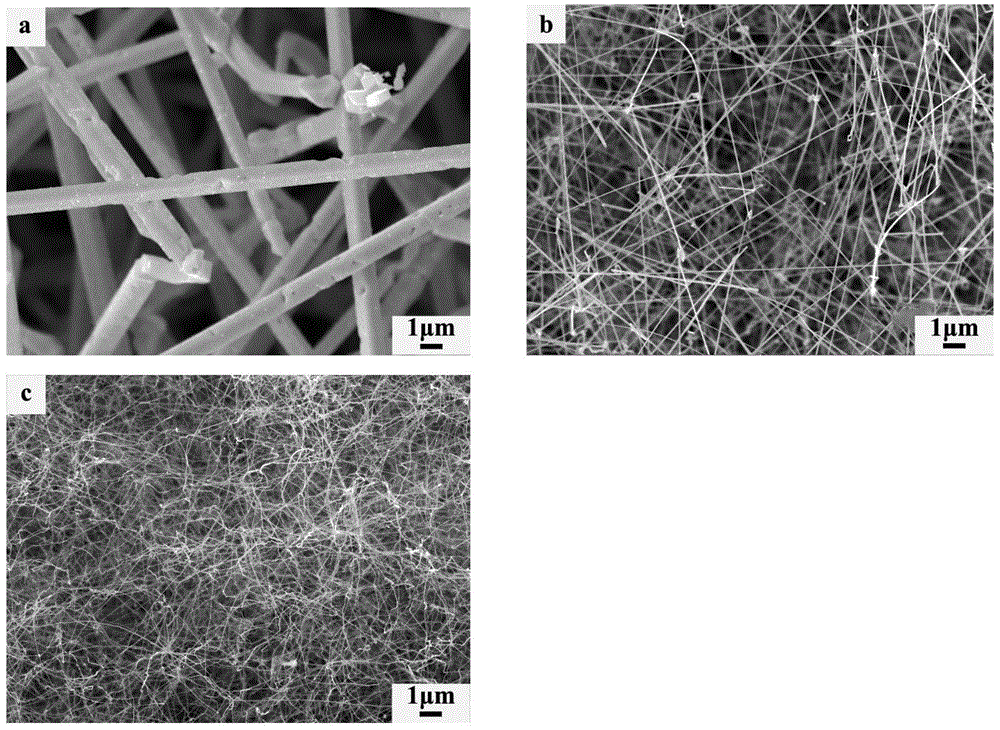

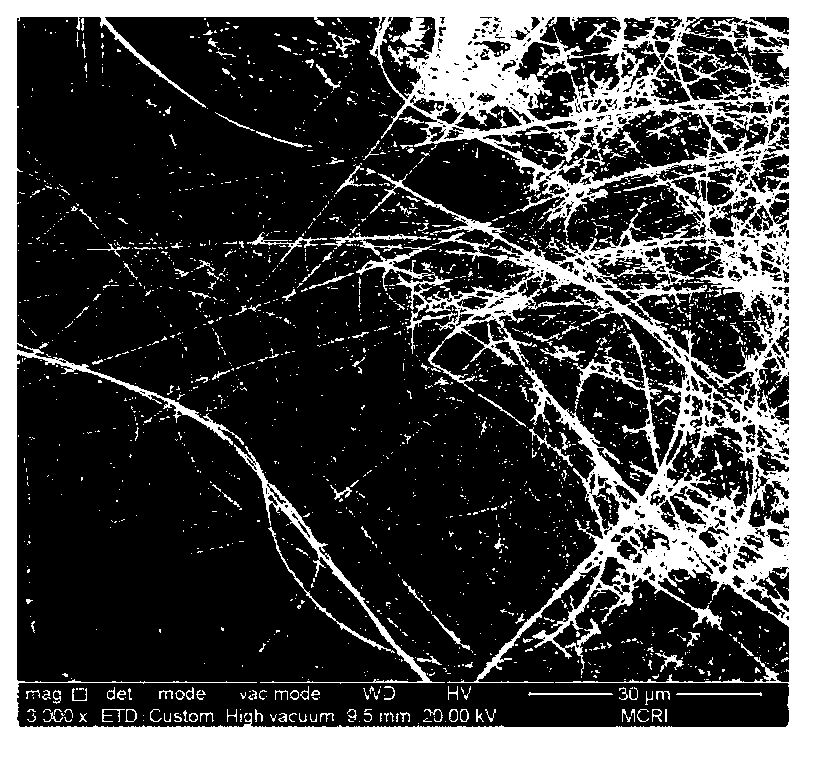

Method for preparing nanowire-toughened carbon/carbon composite material ceramic coating

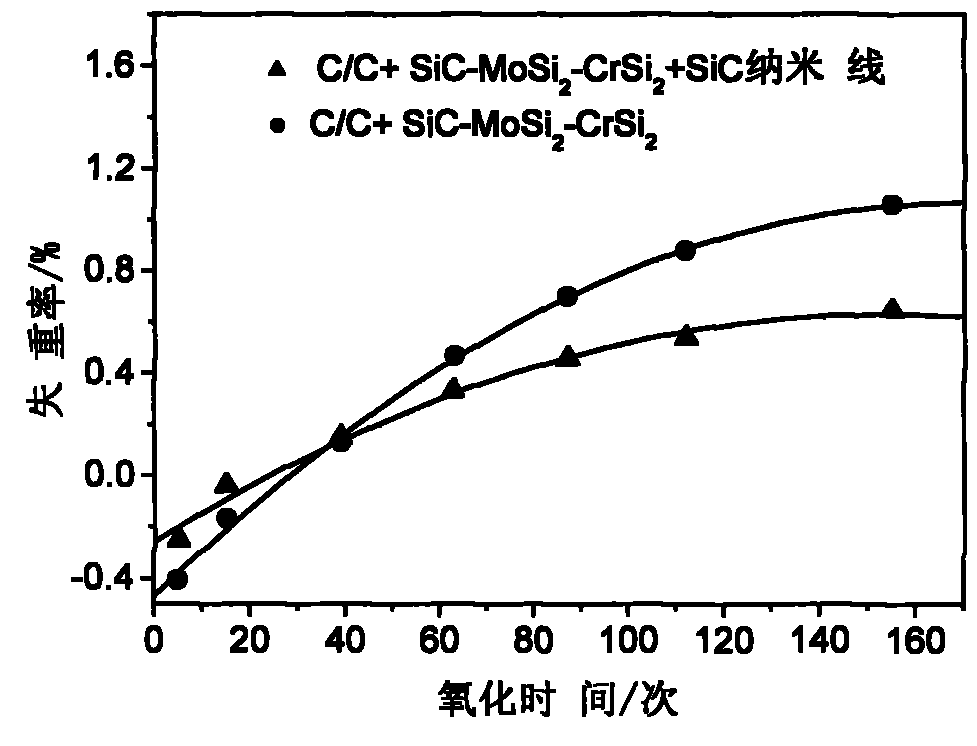

The invention discloses a method for preparing a nanowire-toughened carbon / carbon composite material ceramic coating. The method aims to solve the technical problem that the ceramic coating prepared by a conventional method has poor denseness. The method adopts the following technical scheme that: the nanowire-toughened carborundum (SiC)-molybdenum disilicide (MoSi2)-chromium silicide (CrSi2) ceramic coating is prepared by chemical vapor deposition, the cracking trend of the coating is reduced, and the ceramic coating with a dense structure is prepared by means of the toughening effect of nanowires. The effective anti-oxidization time of the prepared ceramic coating in atmosphere at the temperature of 1,500 DEG C is improved to 140 and 155 hours from 50 hours in background technology.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

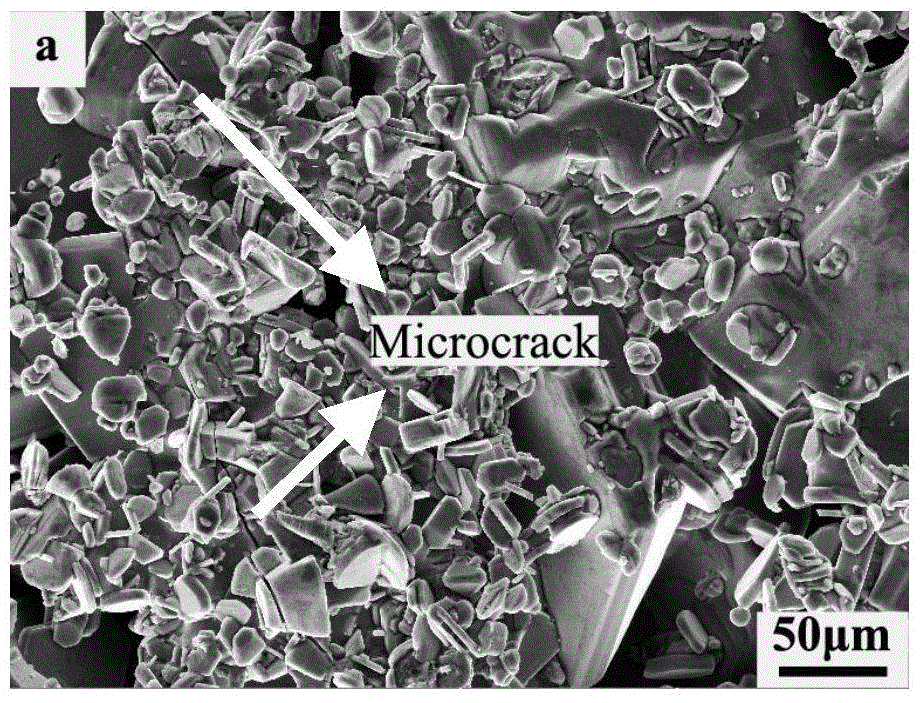

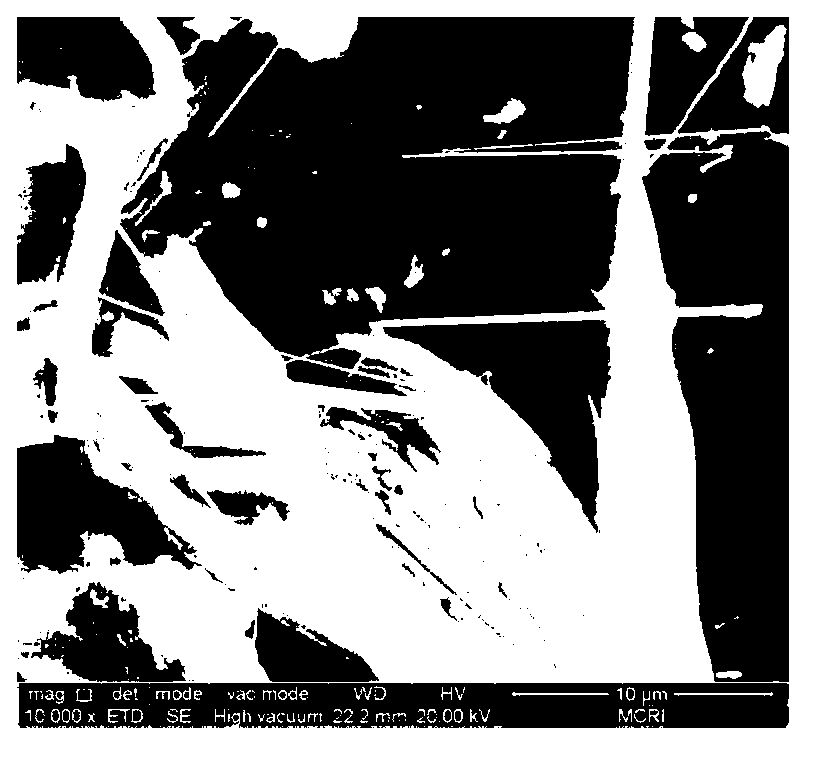

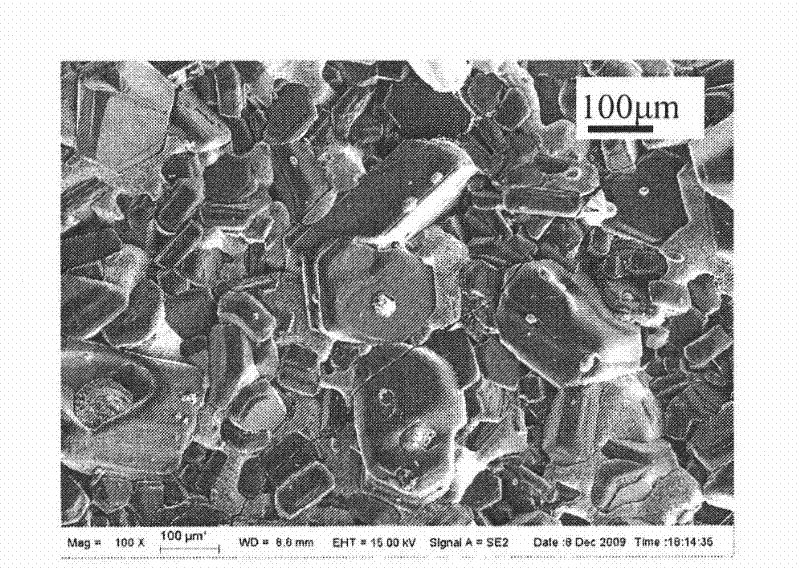

Hafnium carbide nanowire-toughened ceramic coating layer of surface of carbon/carbon composites and preparation method thereof

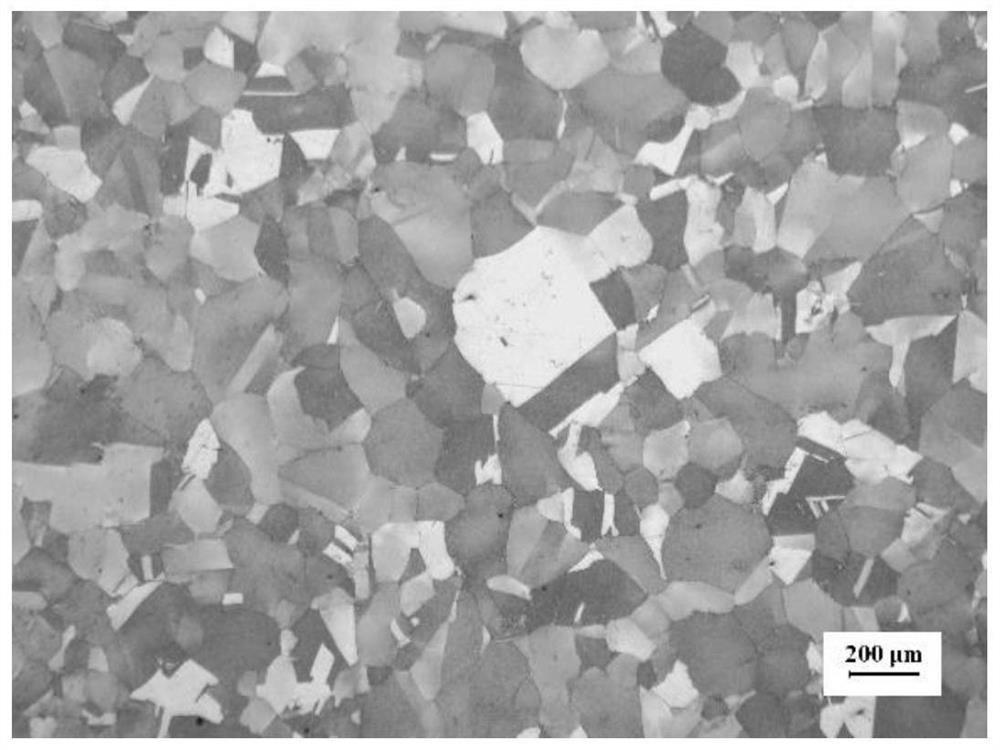

The invention provides a hafnium carbide nanowire-toughened ceramic coating layer of the surface of carbon / carbon composites and a preparation method thereof. The HfC nanowire-toughened SiC ceramic coating layer is prepared by adopting a chemical vapor deposition and embedding two-step method, the toughness of the coating layer can be increased in virtue of nanowire pulling-out, bridging and crack steering mechanisms, and a cracking tendency of the coating layer is decreased. The preparation method has the beneficial effects that the HfC nanowire-toughened SiC ceramic coating layer is prepared by adopting the chemical vapor deposition and embedding two-step method, the toughness of the coating layer can be increased in virtue of the nanowire pulling-out, bridging and crack steering mechanisms, and the ceramic coating layer with a dense structure is prepared. The preparation method of the HfC nanowire-toughened SiC ceramic coating layer is simple, and as seen from figure 2, the HfC nanowire-toughened SiC ceramic coating layer is more dense and complete than an SiC ceramic coating layer, and the crystal particle size in the coating layer is also more uniform.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Laser remelting one-step reinforcing processing method and device thereof for plasma sprayed thermal barrier coating with double-layer structure

InactiveCN103276394AReduced cracking tendencyQuality improvementMolten spray coatingSuperimposed coating processMetallurgyLayer interface

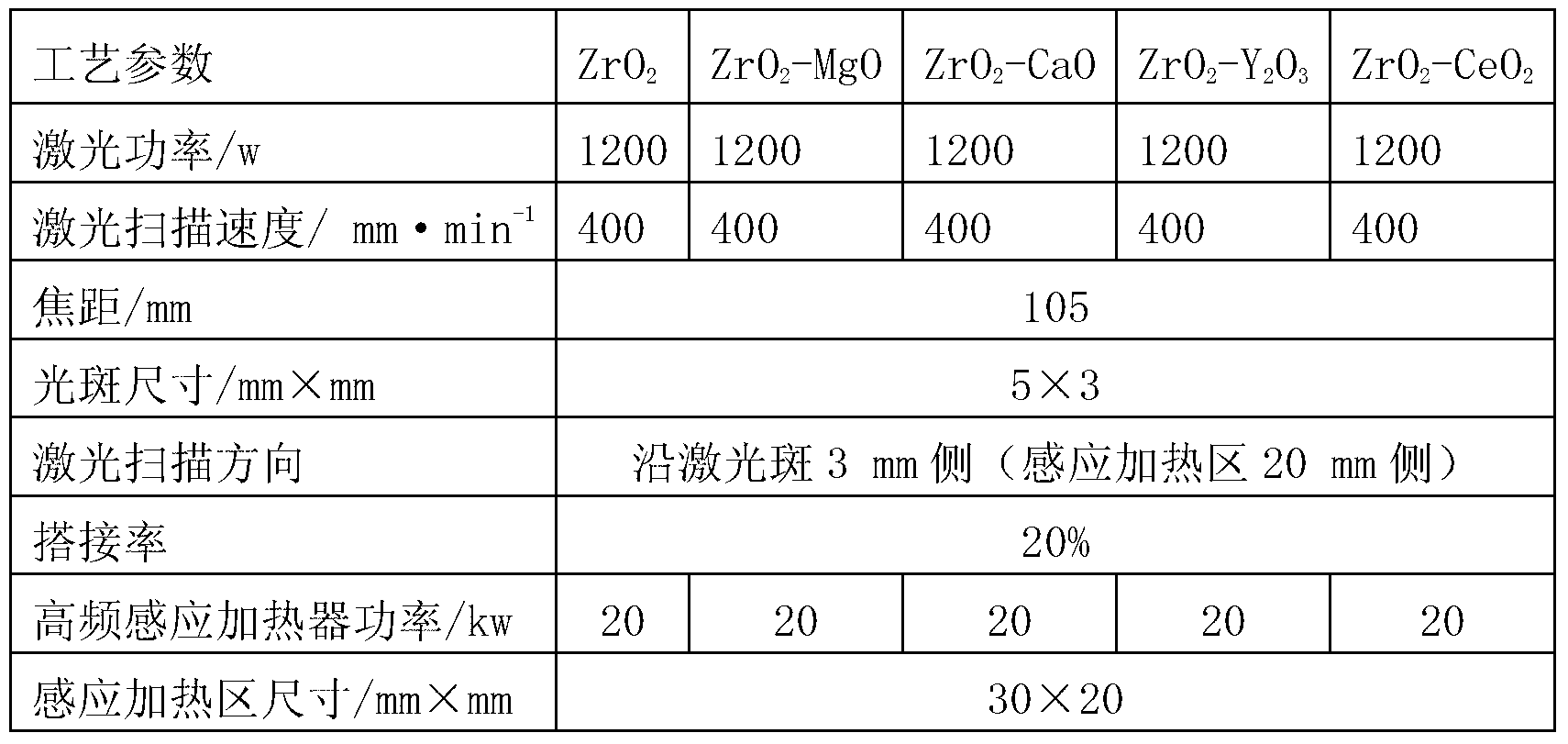

The invention discloses a laser remelting one-step reinforcing processing method and device thereof for a plasma sprayed thermal barrier coating with a double-layer structure. A plasma spraying process is adopted to spray the thermal barrier coating with the double-layer structure on a matrix surface after purification and activating treatment; and an induction heating auxiliary laser remelting compound process is adopted to remelt the thermal barrier coating with the double-layer structure. With the adoption of the induction heating auxiliary laser remelting compound process, the defect of insufficient energy of pure laser remelting can be overcome, so that one-step laser remelting can melt a ceramic layer and a bonding layer in the thermal barrier coating with the double-layer structure simultaneously, and one-step reinforcement of metallurgical bonding between the ceramic layer and the bonding layer interface and between the bonding layer and the matrix interface is achieved simultaneously; and the laser remelting one-step reinforcing processing device has the advantages of simple process, good stability, good remelted coating quality and the like, and accordingly is expected to be applied to key hot-end part surfaces of air-turbine motor blades and the like.

Owner:TONGLING UNIV

High-temperature resistant and abrasion-resistant white cast iron piece and production method

The invention discloses a high-temperature resistant and abrasion-resistant white cast iron piece and a production method to solve the problem in hardness of white cast iron. The high-temperature resistant abrasion-resistant white cast iron piece is characterized in that the white iron casting comprises the following chemical compositions by mass percent: 3.0 to 3.5 percent of C, 30 to 36 percent of Cr, 1.8 to 2.5 percent of Mo, smaller than or equal to 1 percent of Si, 1.0 to 2.0 percent of Ni, 1.05 to 1.5 percent of Mn, 0.5 to 1.0 percent of B, smaller than or equal to 0.10 percent of P, smaller than or equal to 0.08 percent of S, and Fe in balancing amount; and the chromium carbon ratio of the white cast iron is 8.5 to 12. The method comprises the steps of smelting, casting, thermal insulation and cooling. The white cast iron piece has the advantages that casting-state thermal insulation slow cooling hardness HRC is larger than or equal to 61, the hardness HRC after quench tempering is larger than or equal to 66, the hardness HRC can still keep larger than or equal to 61 at 700 DEG C, the corrosion resistance of the white cast iron piece is superior to that of the existing white cast iron piece, and the white cast iron piece is particularly suitable to serve as a wear-resistant part operating under high-temperature condition.

Owner:BAODING FENGFAN PRECISION CASTING

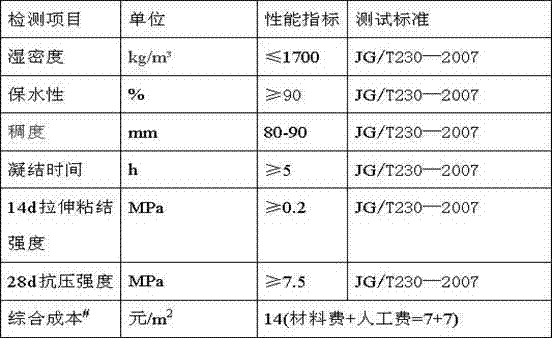

Mechanized construction plastering mortar and preparation method thereof

The invention discloses mechanized construction plastering mortar and a preparation method thereof. The plastering mortar is formed by mixing powder, aggregate and water, and a mass ratio of the powder, the aggregate and the water is (200-300):(700-800):(160-250); the powder is formed by mixing portland cement clinker, plaster, granulated blast-furnace slag, coal ash, limestone powder and a chemical addition agent, and a mass ratio of the portland cement clinker, the plaster, the granulated blast-furnace slag, the coal ash, the limestone powder and the chemical addition agent is (100-300): (50-100): (50-200): (100-400): (100-400): (2-5). According to the invention, after the detection in a factory according to a quality requirement and the measuring packing, the powder and the aggregate are respectively sent to a construction site or a dedicated distributing bin for burdening, and the mechanized construction is performed; compared with dry-mixed mortar, the aggregate is not required to be dried, so that the drying cost and a part of transportation cost of the aggregate are reduced, and the material cost is substantially lowered; and simultaneously the advantages that the dry-mixed mortar quality can be controlled and the construction site environment is good are maintained.

Owner:郑州工大高新材料科技有限公司

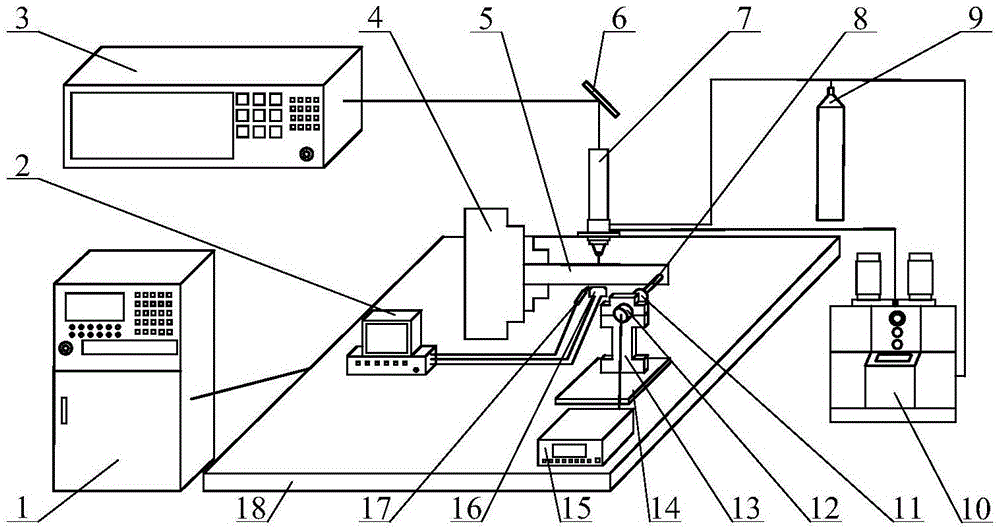

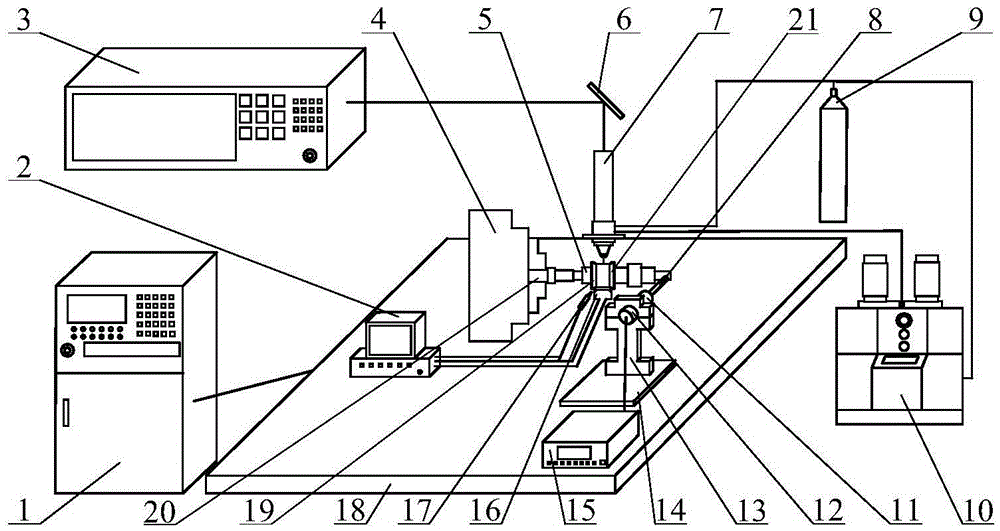

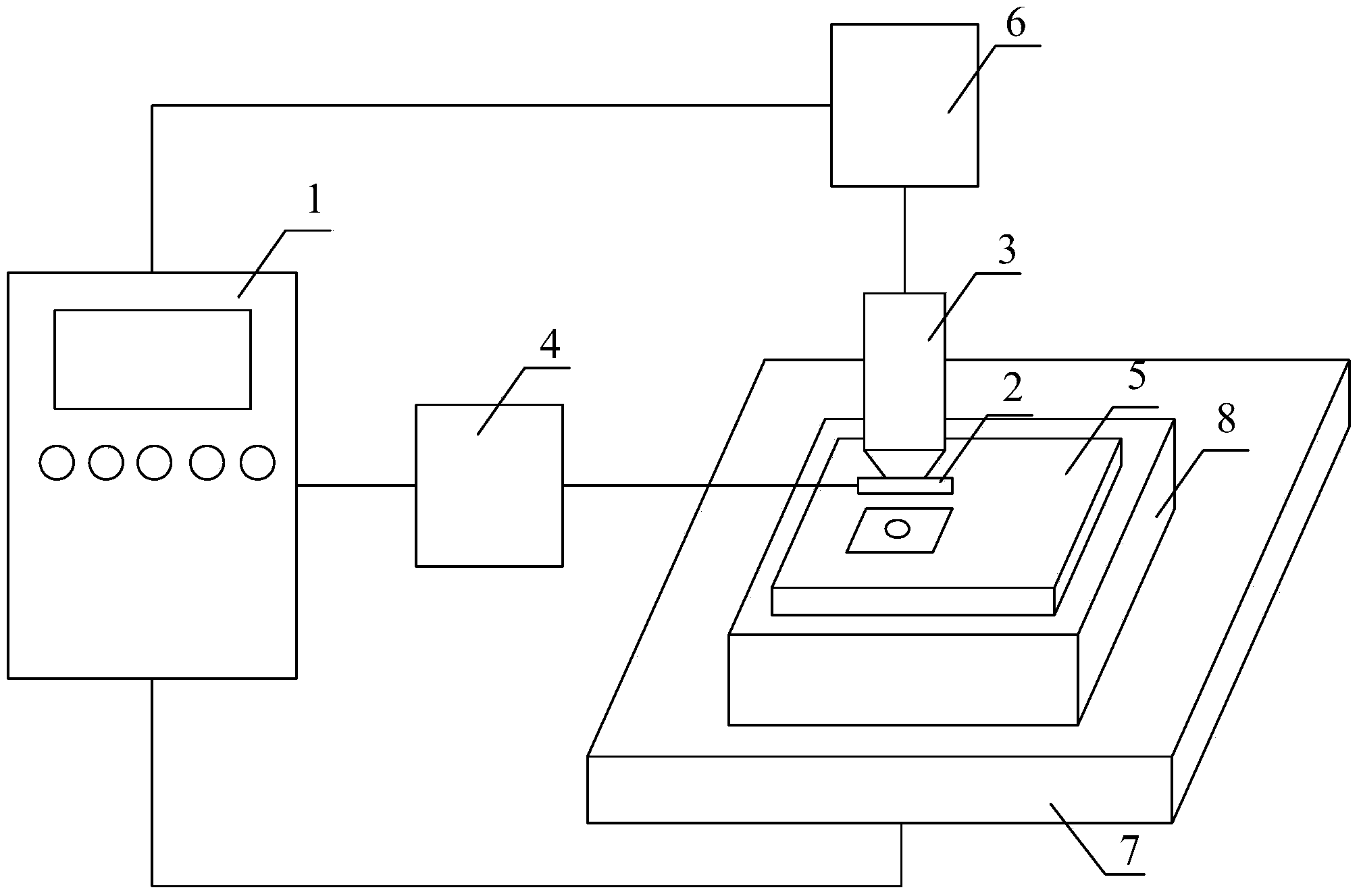

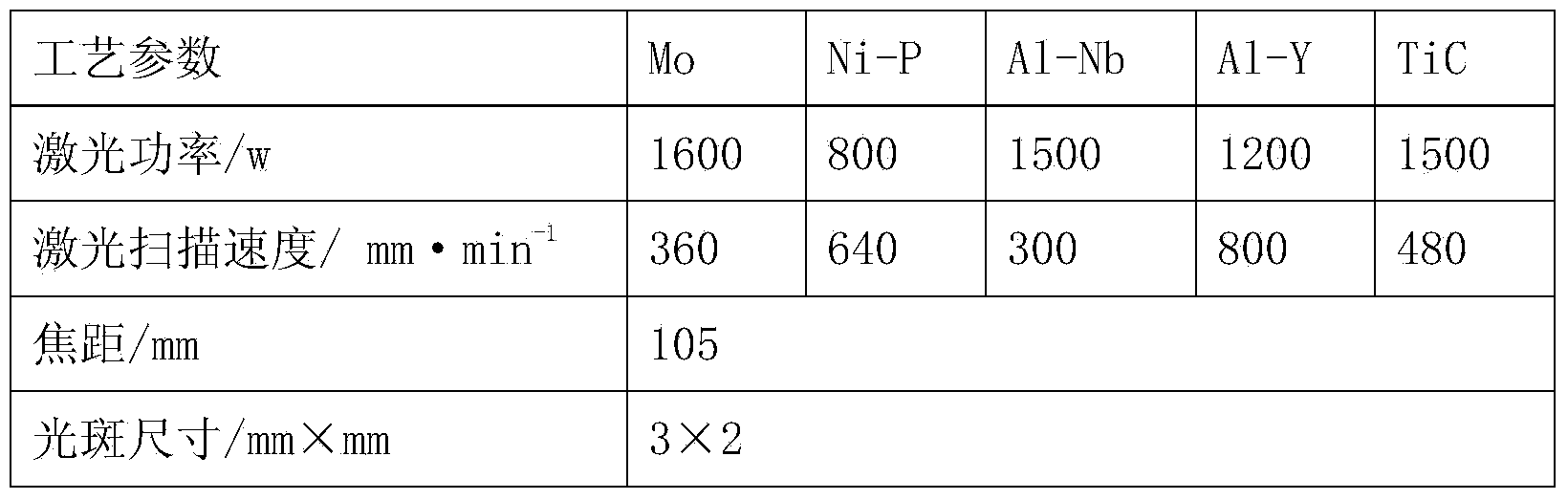

Method and device for alloying composite processing of laser surface through mechanical vibration assisted induction heating

InactiveCN103540931AImproves Structural IntegrityQuality improvementMetallic material coating processesLaser scanningInduction heater

The invention discloses a method and a device for alloying composite processing of a laser surface through mechanical vibration assisted induction heating. The method comprises the steps of delivering alloy powder to a purified and activated metal matrix surface by adopting a preset material method or synchronous powder delivery method; under the protection of argon, assisting laser scanning of a sample surface through induction heating, and performing mechanical vibration at the same time to perform auxiliary processing so as to prepare an alloyed layer. A high-frequency induction heater is connected with an induction heating coil, the induction heating coil is fixed on a laser head, the laser emitted by the laser head is positioned in the center of a heating area of the induction heating coil, and the laser head is connected with a laser. The method and the device disclosed by the invention can achieve the effects of refining grains, improving the completeness of a crystal structure, uniformizing structures, improving the efficiency of alloying the laser surface, increasing the depth of the alloyed layer and reducing the tracking trend of the alloyed layer, and has the advantages of stable processing, high efficiency, high quality of the alloyed layer and the like; therefore, the method and the device are beneficial to industrial popularization and application of the alloying of the laser surface.

Owner:TONGLING UNIV

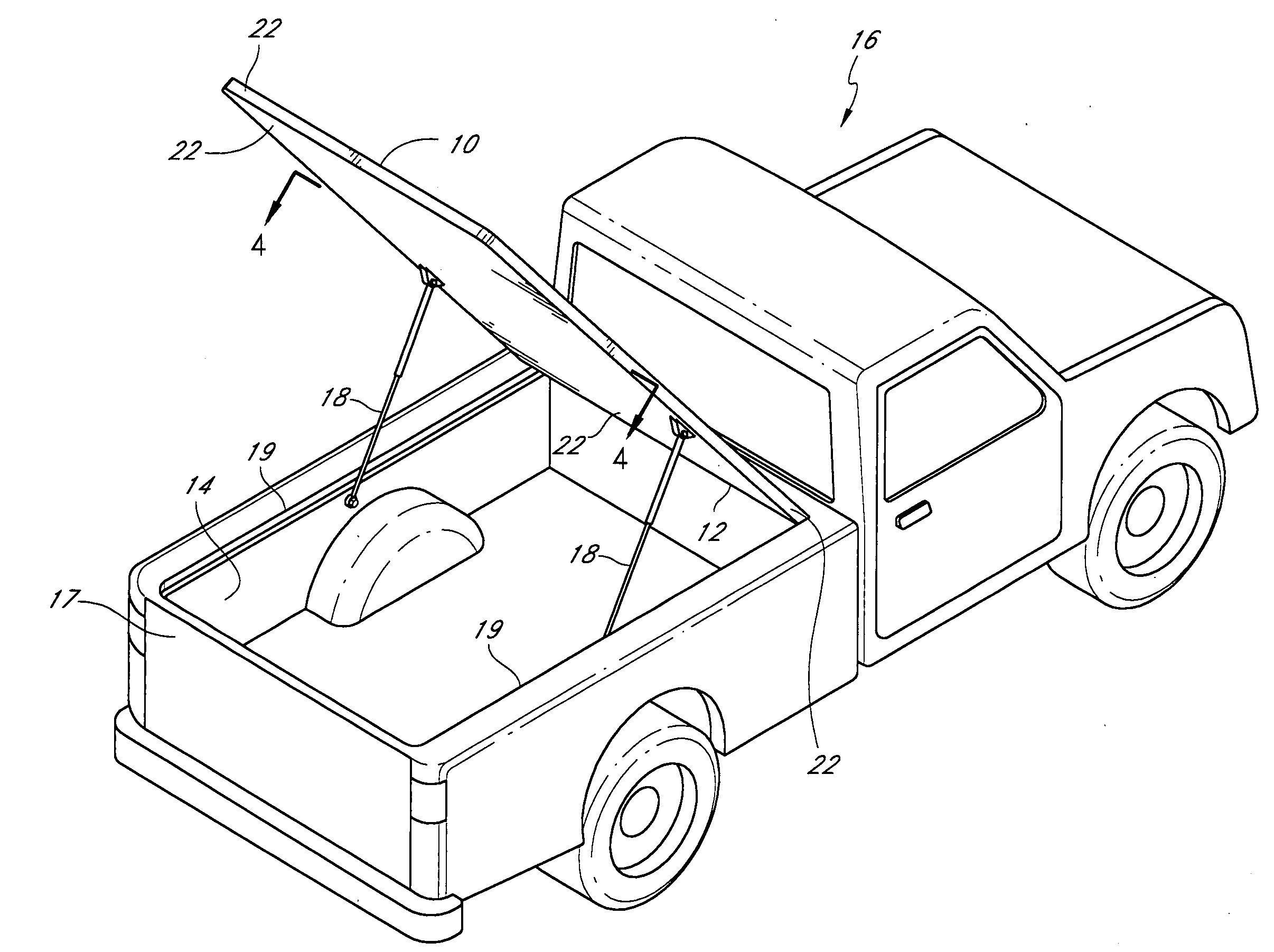

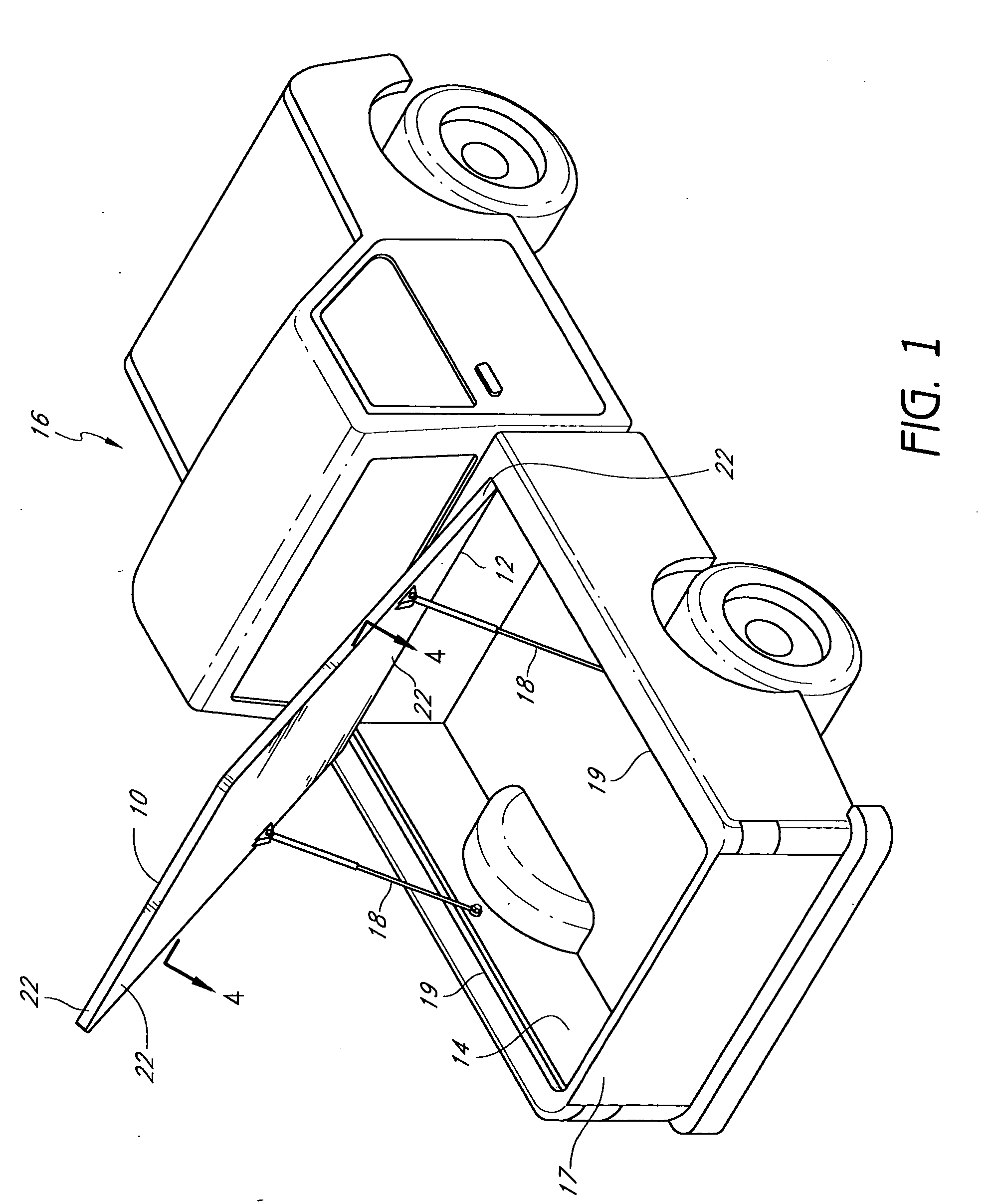

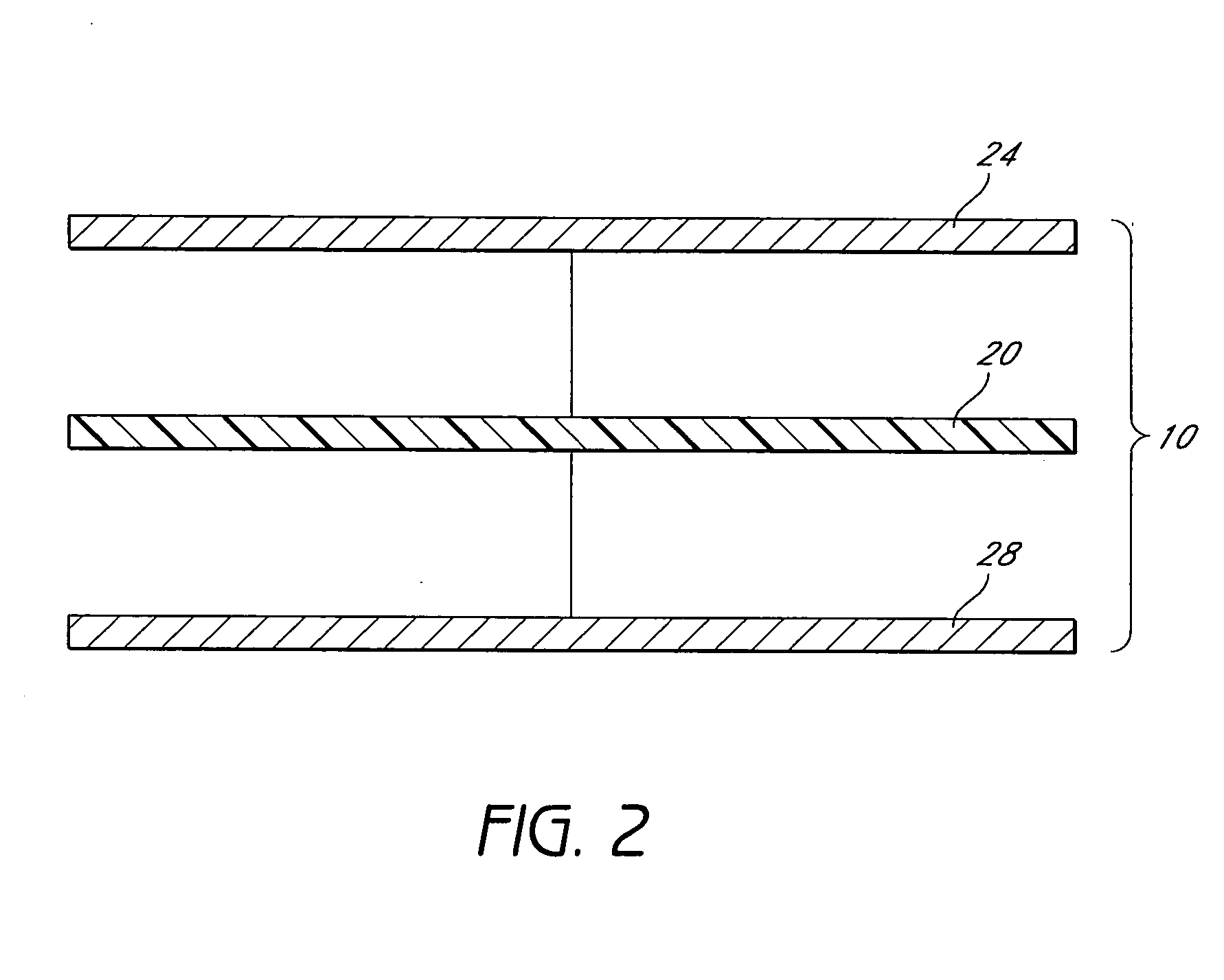

Reinforced tonneau cover

InactiveUS20070284907A1Reduce incidenceReduced cracking tendencyLoad coveringRoofsEngineeringMultiple layer

A tonneau cover for use on a vehicle bed can have a multilayer construction. The multilayer tonneau cover can include an upper layer and a reinforcing layer. The tonneau cover can also have a lower layer. The reinforcing layer can include a reinforcing beam to reduce the potential for cracking of the upper layer. The reinforcing beam can be elongate and non-intersecting along its path.

Owner:CYC ENG

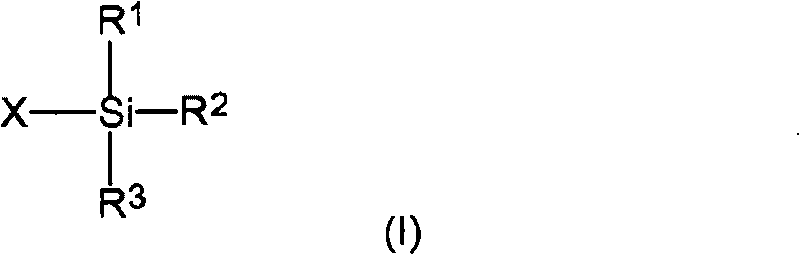

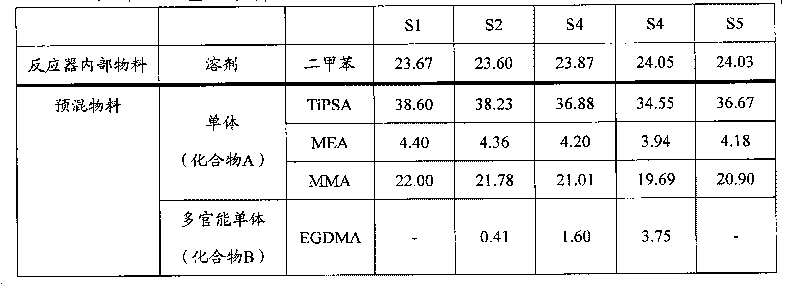

Branched polymer and antifouling coating composition comprising the polymer

InactiveCN101730713AImprove flexibilityReduced cracking tendencyAntifouling/underwater paintsPaints with biocidesRepeat unitChain transfer

Owner:佐顿公司

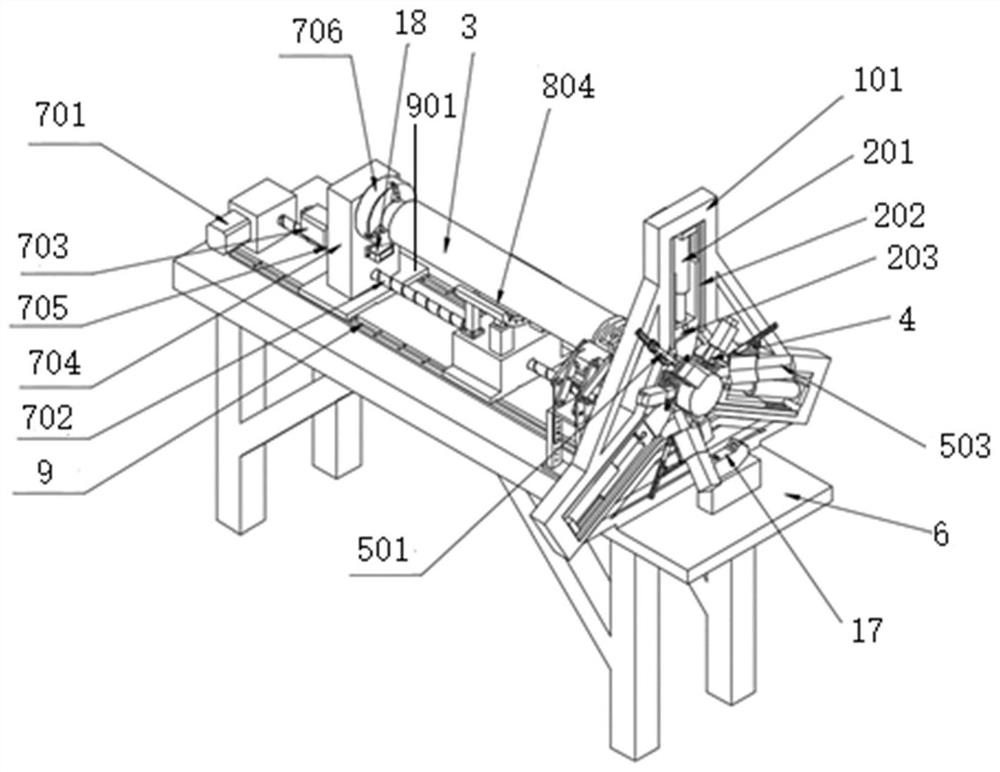

Shaft surface repairing system and method for additive composite micro-rolling

ActiveCN112846193APromotes grain refinementReduced cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencySpinningComputer printing

The invention relates to the technical field of additive shaft repairing, and provides a shaft surface repairing system and method for additive composite micro-rolling. The system comprises a frame, a plurality of groups of spinning units evenly distributed in the circumferential direction are arranged on the frame, and a middle wear shaft repairing area is constructed; each of the spinning units comprises a first driving device, a first guide rail, a first sliding block and a roller, wherein the first driving device and the first guide rail are fixed to the frame, an output end of the first driving device is connected with the first sliding block, the first sliding block is movably arranged on the first guide rail, the roller is connected with the first sliding block, and the roller surface of the roller is opposite to the circumferential surface of a wear shaft in the middle wear shaft repairing area; and a heating mechanism and an additive printing mechanism are arranged on the frame. According to the shaft surface repairing system for the additive composite micro-rolling provided by the invention, additive shaft repairing and micro-rolling of a repaired part are synchronously achieved, the microstructure and the mechanical property of the repaired shaft are comprehensively improved, the overall performance of the repaired shaft is improved, and the repaired shaft can be put into use again.

Owner:CRRC IND INST CO LTD +1

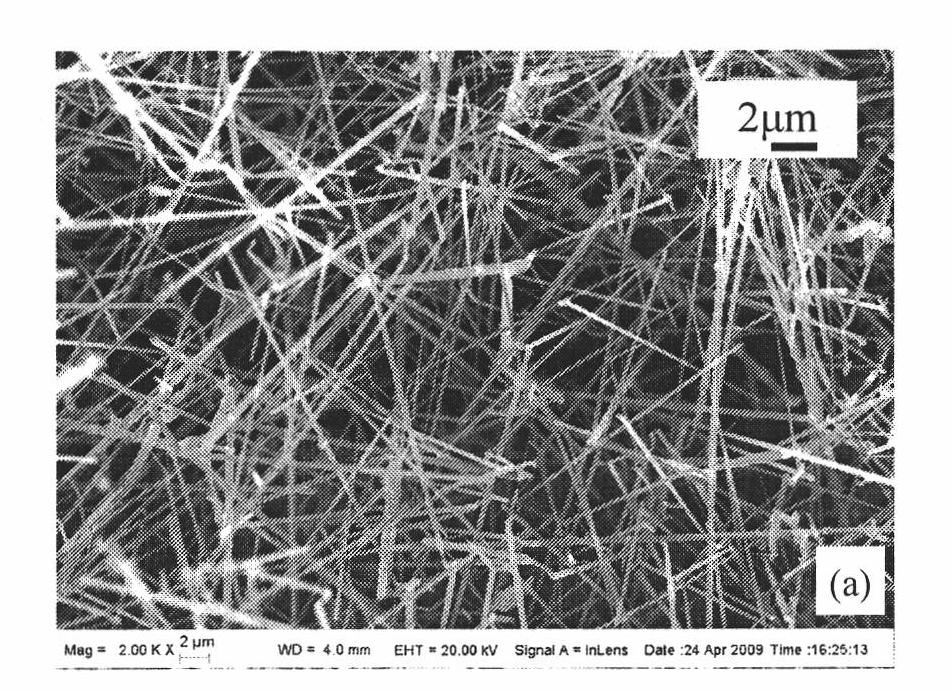

Preparation method of beaded nanowire toughened and reinforced ceramic coat

The invention relates to a preparation method of a beaded nanowire toughened and reinforced ceramic coat. A beaded SiC nanowire toughened and reinforced Si-Cr ceramic coat is prepared through adopting an in-situ synthesis process, and the combination of the special toughening efficacy possessed by the in-situ synthesized beaded nanowire and a strong interface formed between the nanowire and an internal coat reduces the cracking trend of the coat to make the ceramic coat have a compact structure, so the effective anti-oxidation time of the prepared ceramic coat in 1500DEG C static air is prolonged to 165-185h from 40h of a background technology.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

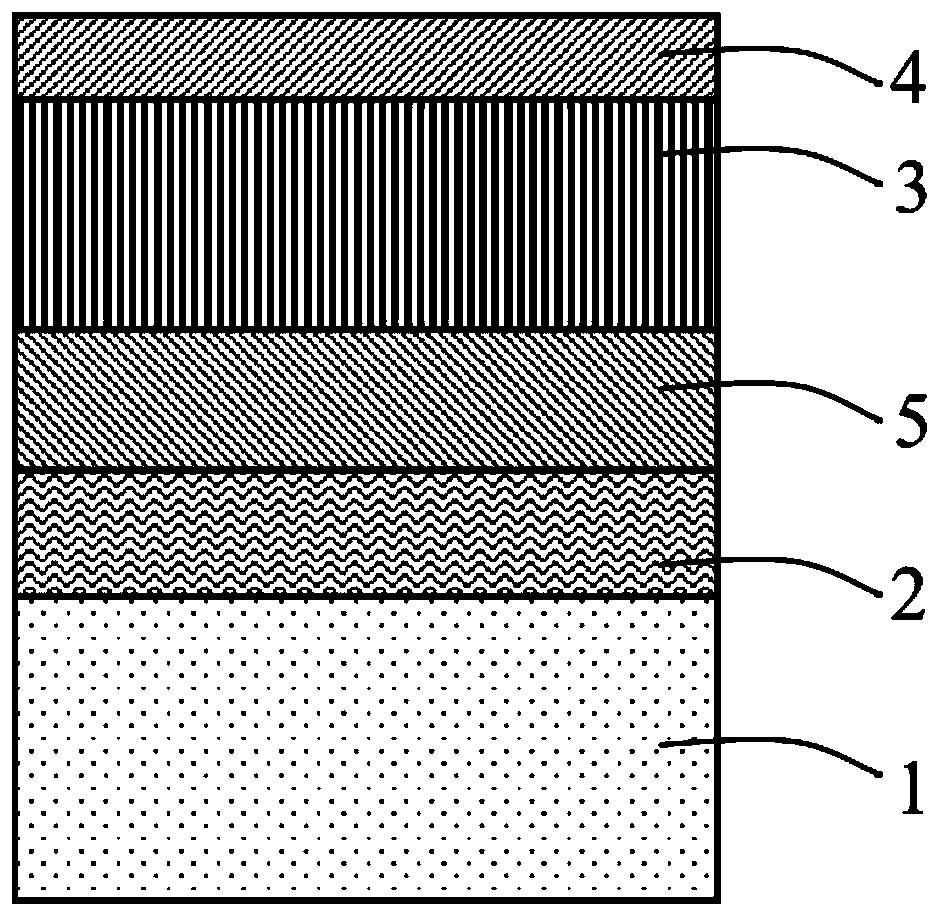

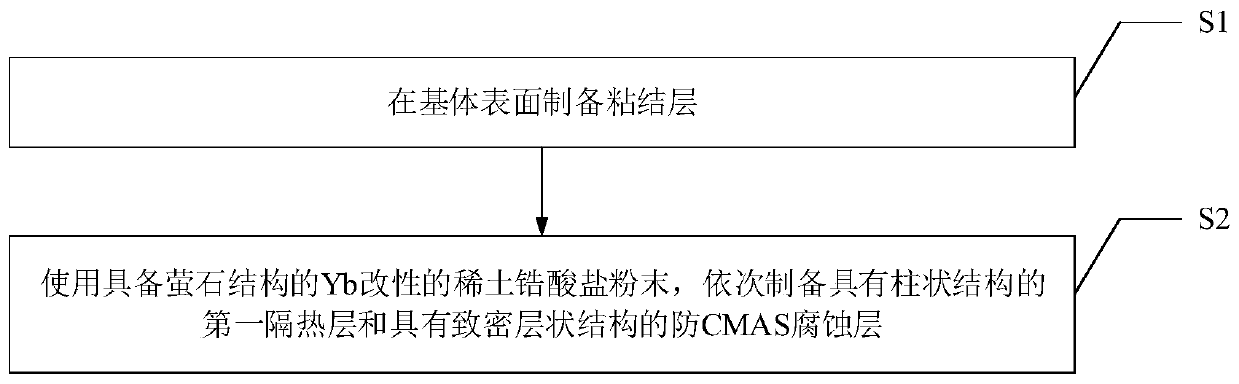

Yb modified CMAS prevention composite structure thermal barrier coating and preparing method thereof

ActiveCN111471998APrevent penetrationImprove thermal shock performanceMolten spray coatingSuperimposed coating processInsulation layerThermal break

The invention discloses an Yb modified CMAS prevention composite structure thermal barrier coating and a preparing method thereof. A CMAS corrosion prevention layer adopts Yb modified rare earth zirconate to form a compact layered structure, at the high temperature, the layered structure can have a reaction with CMAS to form a compact blocking layer, permeation of molten CMAS to the interior of the thermal barrier coating can be prevented, a first heat insulation layer adopts Yb modified rare earth zirconate to form a columnar structure, enough heat insulation performance and high strain tolerance can be provided for the thermal barrier coating, the thermal shock property of the thermal barrier coating is improved, the service life of the thermal barrier coating can be prolonged, the CMAScorrosion prevention layer and the first heat insulation layer are made of materials of the same elements, heat mis-match stress between the two layers can be relieved, combining strength of the two layers can be improved, the thermal barrier coating has the advantages of being low in heat conduction rate, stable in phase, high in combining strength, and high in sintering resisting capacity, the service life under the high-temperature service condition is long, combination strength between dual layers of ceramic can be high, and combination strength between a ceramic layer and a metal bondinglayer is high.

Owner:BEIHANG UNIV

Preparation process of aviation aluminum alloy ingot and aluminum alloy ingot

The invention provides a preparation process of an aviation aluminum alloy ingot. The preparation process of the aviation aluminum alloy ingot comprises the following steps: (A) mixing a Cu source, an Mg source, a Zn source, a Ti source, a Zr source and an Al source, then smelting to obtain a smelted product; (B) sequentially degassing, filtering and refining the smelted product obtained in the step (A) on line to obtain an on-line processed product; (C) casting the on-line processed product obtained in the step (B) to obtain an aviation aluminum alloy ingot blank, wherein the casting rate is 8-14mm / min; (D) carrying out homogenizing treatment on the aviation aluminum alloy ingot blank obtained in the step (C) to obtain the aviation aluminum alloy ingot. According to the preparation process, the proper casting rate is adopted; the flaw detection eligibility rate of the aluminum alloy can be increased; experimental results show that the flaw detection eligibility rate of aluminum alloy 7050 and aluminum alloy 7A85 prepared by the preparation process of the aviation aluminum reaches 97-99%.

Owner:SOUTHWEST ALUMINUM GRP

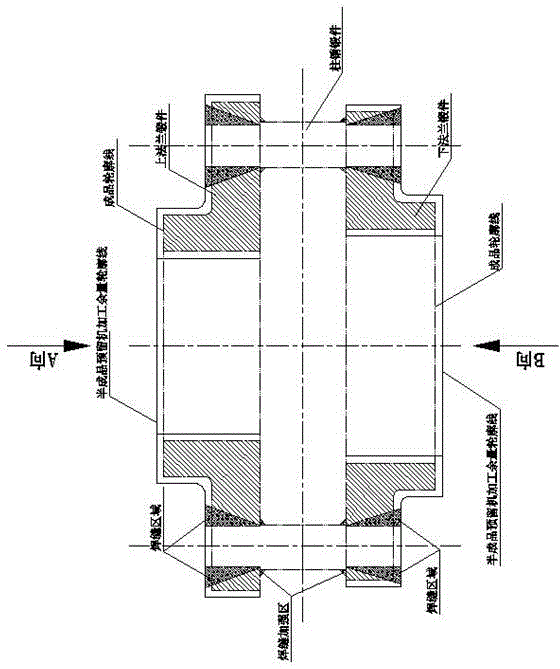

Hot top casting process of 7050 aluminum alloy and 7050 aluminum alloy ingot

The invention provides a hot top casting process of a 7050 aluminum alloy. The process comprises the following steps: (A) mixing a Cu source, a Mg source, a Zn source, a Ti source, a Zr source and a Al source, and then performing smelting to obtain a smelted material; (B) sequentially performing online degassing, online filtration and online refining on the smelted material obtained in the step (A) to obtain an online treatment product; and (C) performing casting on the online treatment product obtained in the step (B) to obtain the 7050 aluminum alloy, wherein the casting speed is 8-14mm / min. The hot top casting process provided by the invention adopts an appropriate casting speed and can be used for improving the flaw detection qualified rate of the aluminum alloy, and experimental results show that the flaw detection qualified rate of the 7050 aluminum alloy prepared by the hot top casting process of aviation aluminum, provided by the invention, is 97-99%.

Owner:SOUTHWEST ALUMINUM GRP

Planet carrier casting material used for self-elevating offshore platform lifting gear box and production method

ActiveCN104482180AImprove stabilityHigh elongationLifting devicesGearing detailsChemical compositionSteel casting

The invention relates to a large-ratio and large-torque planet carrier steel casting material used for a self-elevating offshore platform lifting gear box and a production method. The material comprises the following chemical components in mass by percentage: 0.28 to 0.35 percent of C, 0.20 to 0.35 percent of Si, 0.65 to 0.85 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.030 percent of P, 0.85 to 0.95 percent of Cr, 0.20 to 0.26 percent of Mo, 0.04 to 0.08 percent of V, and 0.02 to 0.06 percent of Ti; and the remaining content is Fe. The planet carrier steel casting material has the advantages that the working procedures are simplified, connection areas between a pin, an upper flange and a lower flange are subject to smooth transition by circular angles, so that the anti damage capacity and the working stability are enhanced; the traditional casting process of 'progressive solidification' by using the casting structure is changed, external chill is arranged at a specific area to change the earliest solidification area, the solidification feeding of the casting can be changed by changing a feeding channel chain, the connection areas between the pin, the upper flange and the lower flange are tightly, the stress of shrinkage solidification is greatly reduced, and cracks are avoided.

Owner:BAODING TECH CO LTD

7A85 aluminium alloy hot-top casting process and 7A85 aluminium alloy ingot

The invention provides a 7A85 aluminium alloy hot-top casting process which comprises the following steps: (A) mixing a Cu source, a Mg source, a Zn source, a Zr source and a Al source, and then smelting to obtain a smelted material; (B) sequentially performing on-line degassing, on-line filtering and on-line refining on the smelted material obtained in the step (A) to obtain an on-line processed product; (C) casting the on-line processed product obtained in the step (B) to obtain a 7A85 aluminium alloy, wherein the casting speed is 8-14 mm / min. The 7A85 aluminium alloy hot-top casting process has the advantages that an appropriate casting speed is adopted, so that the nondestructive inspection qualification rate of the aluminium alloy can be improved. Experimental results show that the nondestructive inspection qualification rate of the 7A85 aluminium alloy prepared by adopting the aviation aluminium hot-top casting process is 97-99 percent.

Owner:SOUTHWEST ALUMINUM GRP

Preparation method for ultralong nanowire toughed ceramic coating

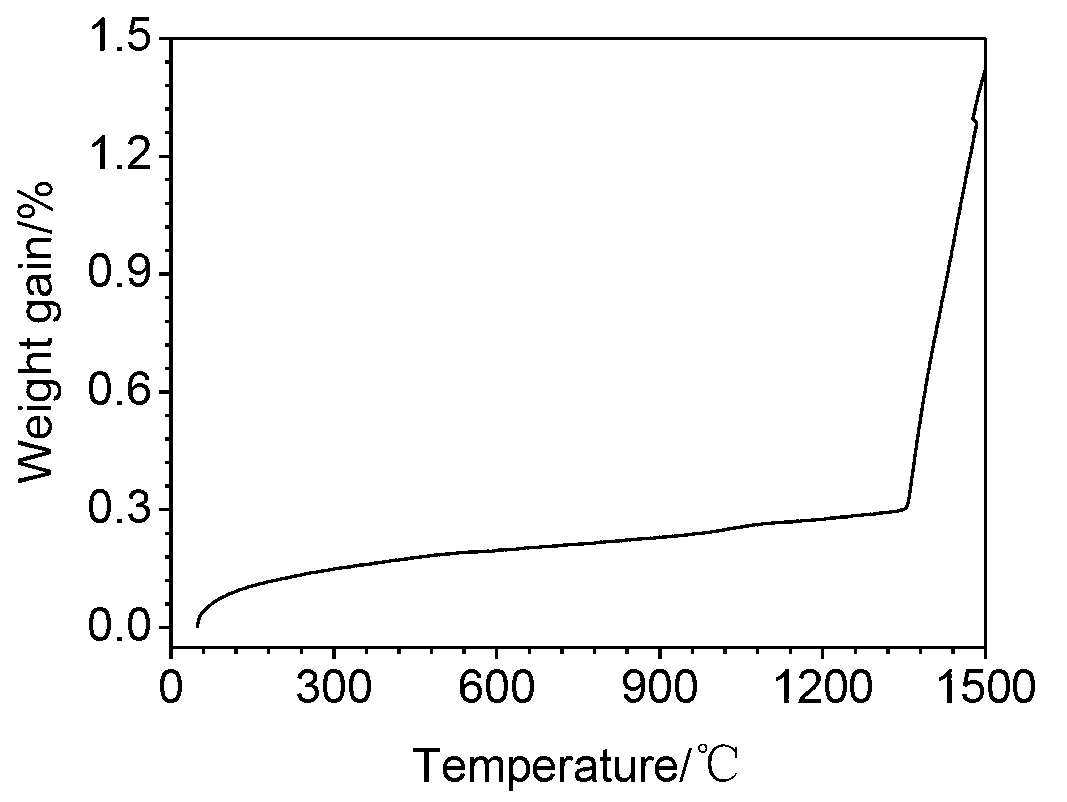

The invention relates to a preparation method for an ultralong nanowire toughed ceramic coating. An anti-oxidation ceramic coating made from a C / C composite material is toughened by adopting an ultralong SiC nanowire, and a load in a base body can be effectively transferred onto the nanowire by higher length-diameter ratio of the nanowire, so that the toughness of the ceramic coating is enhanced, the cracking trend of the ceramic coating is weakened, and the oxidation resistance of the ceramic coating is improved at last. Compared with the prior art, the prepared SiC nanowire toughened ceramic coating can be used for effectively preventing the C / C composite material from being oxidized. The research result shows that a coating test piece is kept in a weight gain state all the time in a thermogravimetry test process at a room temperature of 1500 DEG C, and the maximum weight gain rate is 1.21%-1.43%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

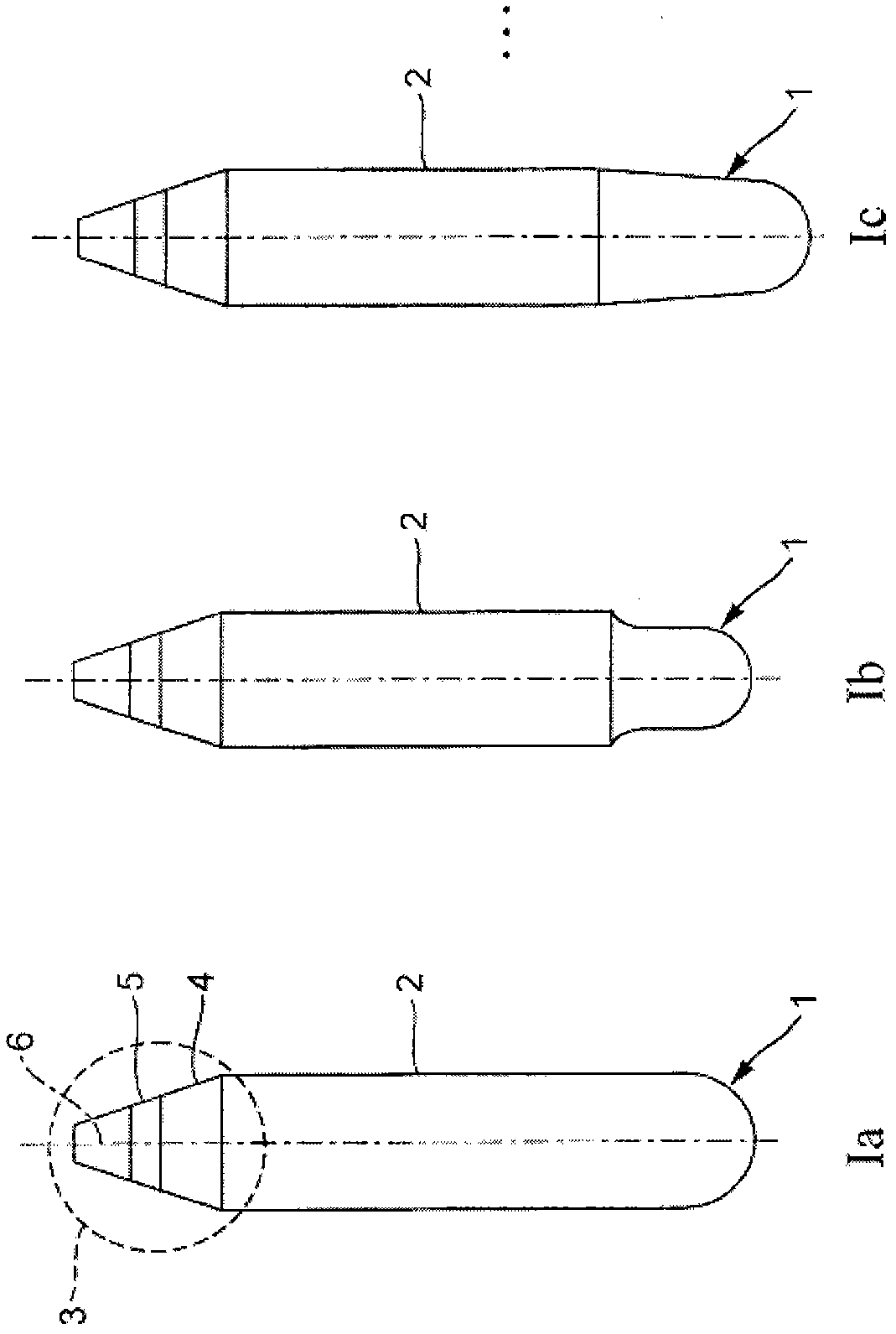

Sheet incremental forming device and method based on auxiliary material superposition

InactiveCN109622777AImprove surface qualitySolve quality problemsShaping toolsStress distributionHigh surface

The invention relates to a sheet incremental forming device and method based on auxiliary material superposition. The device comprises a tool head (1), and further comprises an auxiliary material (3)and lubricating oil (4); the auxiliary material (3) is matched with to-be-machined base metal (2) in shape and laid on the surface of the base metal (2); and the space between the base metal (2) and the auxiliary material (3) is filled with the lubricating oil (4). The tool head (1) applies force to the base metal (2) through the auxiliary material (3) for incremental forming. Compared with the prior art, the manufacturing method is innovated, the effect that the surface of the base metal is free of any residual height and machining marks can be ensured, and high surface quality is achieved; the contradiction between the surface quality and the forming time is successfully resolved, parts can be formed with large feed depth, and the machining efficiency of incremental forming is greatly improved; and the machining environment of base metal forming is improved in principle, stress distribution and thickness distribution are improved, friction force is reduced, sheet springback is reduced, and the contour precision is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Large-size difficult-to-deform nickel-based superalloy cast ingot and preparation method thereof

PendingCN114657398AAdd remelting smelting stepsReduce dendrite segregationSuperalloyElectro-slag remelting

The invention discloses a large-size difficult-to-deform nickel-based superalloy cast ingot and a preparation method thereof. The preparation method comprises the following steps: triple smelting: performing triple smelting on a superalloy raw material through vacuum induction smelting, protective atmosphere electroslag remelting and vacuum consumable remelting to obtain a consumable ingot; homogenization treatment: carrying out multi-section homogenization treatment, and carrying out heat preservation on the consumable ingot; raising the temperature and keeping the temperature; raising the temperature and keeping the temperature; and heating, preserving heat and then cooling to obtain the large-size difficult-to-deform nickel-based superalloy cast ingot. The invention further discloses the large-size difficult-to-deform nickel-based superalloy cast ingot prepared by the method. Through the method provided by the invention, the difficult-to-deform nickel-based superalloy with the specification of phi 660 mm can be stably prepared, the prepared alloy ingot is low in segregation, the cracking problem of a large-size ingot is solved, the metallurgical quality of the difficult-to-deform superalloy is improved, the thermoplasticity is high, the later forging cogging cracking is further reduced, and the product quality is improved. And a foundation is laid for preparing large-size bars and large-size disc forgings.

Owner:BEIJING CISRI GAONA TECH +2

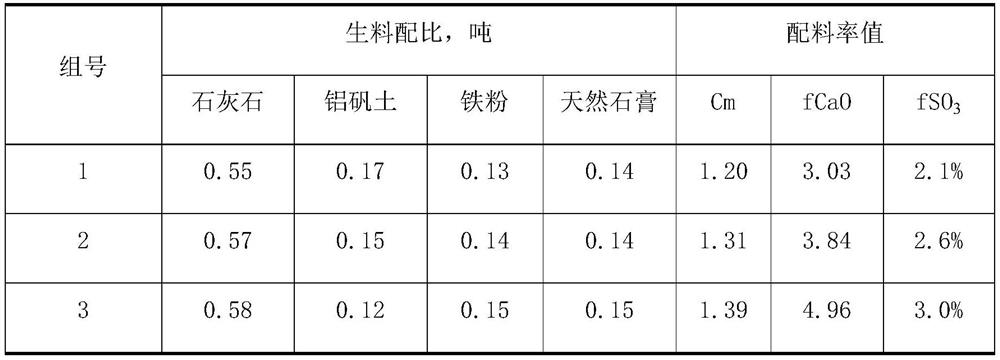

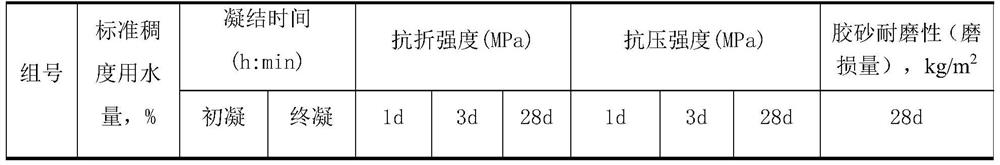

Wear-resistant ultra-high performance concrete and preparation method thereof

The invention discloses wear-resistant ultra-high performance concrete and a preparation method thereof. The wear-resistant ultra-high performance concrete comprises the following raw materials in parts by weight: 600-650 parts of a special cementing material; 120-150 parts of silica fume; 600-650 parts of steel slag aggregate; 300-350 parts of iron tailing sand; 240-260 parts of quartz sand; 15-18 parts of a water reducing agent; 80-100 parts of steel fiber; and 160-180 parts of water. The special cementing material is prepared by uniformly dry-mixing the following raw materials in parts by weight: 65-75 parts of Portland cement clinker powder; 20-30 parts of high iron and high belite sulphoaluminate cement clinker powder; and 5-10 parts of gypsum powder. According to the present invention, the strength generation is rapid, the compressive strength and the breaking strength are high, the impact resistance is strong, the 1d compressive strength can achieve 70 MPa, the breaking strength can achieve 15 MPa, the 28d compressive strength can achieve 180 MPa or more, and the breaking strength can achieve 35 MPa or more; the abrasion value is less than 4.0 cm < 3 >, and the preparation cost is reduced by about 80%.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

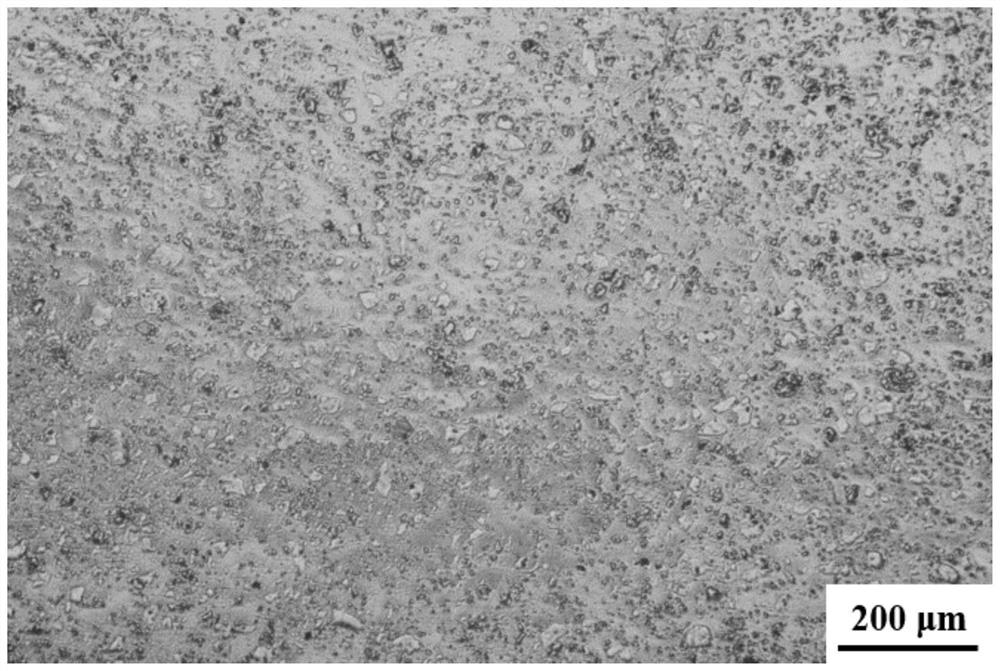

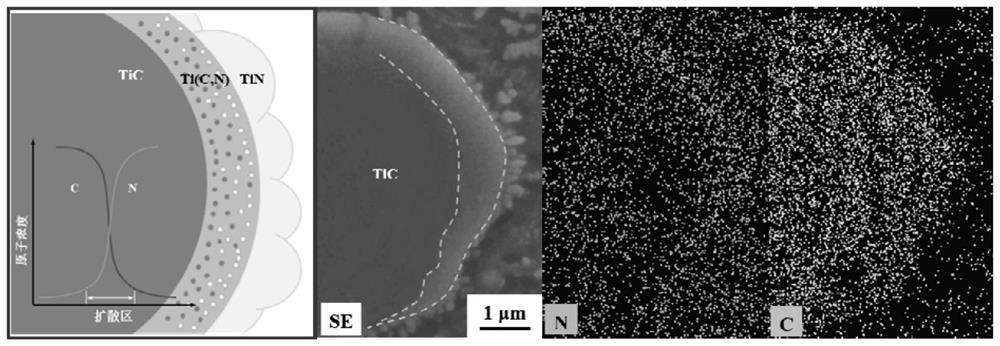

Wear-resistant gradient interface complex-phase reinforced titanium alloy material and preparation method thereof

ActiveCN112030037AEnhanced interface bindingReduce concentrated stressAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesStress concentration

The invention discloses a wear-resistant gradient interface complex-phase reinforced titanium alloy material and a preparation method thereof. The wear-resistant gradient interface complex-phase reinforced titanium alloy material comprises a titanium alloy matrix, and a TiC ceramic reinforced phase and a TiN ceramic reinforced phase which are dispersed in the titanium alloy matrix; the titanium alloy matrix is a titanium-aluminum-molybdenum-vanadium-zirconium alloy, the content of aluminum is 5.5-6.5wt.%, the content of zirconium is 1.6-2.0wt.%, the content of molybdenum is 1.0-1.5wt.%, the content of vanadium is 1.0-1.8wt.% and the balance is Ti; the TiC ceramic reinforced phase accounts for 10-15wt.% of the total mass of the alloy material; and the TiN ceramic reinforced phase accounts for 10-15wt.% of the total mass of the alloy material. Titanium-aluminum-molybdenum-vanadium-zirconium alloy powder and micron-sized TiC and TiN powder serve as raw materials, the ceramic reinforced titanium-based composite material is prepared through a selective laser melting technology after ball milling and powder mixing are carried out, a TiC-Ti (C, N) -TiN gradient interface structure is formed, interface bonding between the ceramic reinforced phases and the titanium matrix is improved, the tendency that the composite material cracks due to stress concentration in the melt rapid condensation process is reduced, cracks in the formed titanium-based composite material are reduced, and the forming quality and the mechanical property of the titanium-based composite material are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing nanowire-toughened carbon/carbon composite material ceramic coating

The invention discloses a method for preparing a nanowire-toughened carbon / carbon composite material ceramic coating. The method aims to solve the technical problem that the ceramic coating prepared by a conventional method has poor denseness. The method adopts the following technical scheme that: the nanowire-toughened carborundum (SiC)-molybdenum disilicide (MoSi2)-chromium silicide (CrSi2) ceramic coating is prepared by chemical vapor deposition, the cracking trend of the coating is reduced, and the ceramic coating with a dense structure is prepared by means of the toughening effect of nanowires. The effective anti-oxidization time of the prepared ceramic coating in atmosphere at the temperature of 1,500 DEG C is improved to 140 and 155 hours from 50 hours in background technology.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for reducing residual stress of base material-additive body interface

InactiveCN113732305AReduce distortionReduced cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencyMaterials preparationMaterial removal

The invention discloses a method for reducing residual stress of a base material-additive body interface, and relates to the technical field of laser powder feeding additive manufacturing. The method comprises the following steps: S1, in a base material preparation stage, removing a base material on the periphery of the base material-additive body interface, and forming a boss structure on the interface; S2, enabling an additive body to grow on the boss structure, designing a transition region between the bottom of the additive body and a base material interface into a fillet transition structure, and then carrying out additive manufacturing; and S3, machining a base material-additive body part. The method has the beneficial effects that the residual stress of the base material-additive body interface in the laser additive manufacturing process can be reduced, and therefore the deformation and cracking tendency of the part is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Bionic gradient antifouling composite coating and preparation method thereof

PendingCN113265608AReduced cracking tendencyHigh densityMolten spray coatingCoated surfaceSand blasting

A bionic gradient antifouling composite coating comprises a base body, a metal bonding layer is deposited on the base body, and a gradient composite coating with the ceramic content gradually increased and the metal content gradually reduced from the surface of the base material to the surface of the coating is deposited on the bonding layer; and the gradient composite coating is of a block-like compact layered structure. A preparation method of the bionic gradient antifouling composite coating comprises the following steps that (1) the surface of the metal base body is polished and subjected to sand blasting treatment; (2) a metal bonding layer is deposited on the surface of the base body through gas hood protection plasma spraying; (3) an atmosphere plasma spraying method is adopted, the powder proportion during spraying is adjusted, and a gradient composite coating with the ceramic content gradually increased and the metal content gradually reduced from the surface of the base material to the surface of the coating is deposited on the surface of the metal bonding layer. According to the gradient composite interface structure, the interface bonding strength can be improved, the density of the coating is improved, the corrosion resistance and toughness of the coating are improved, and the biofouling resistance can be achieved through adjustment of a metal phase.

Owner:XI'AN PETROLEUM UNIVERSITY

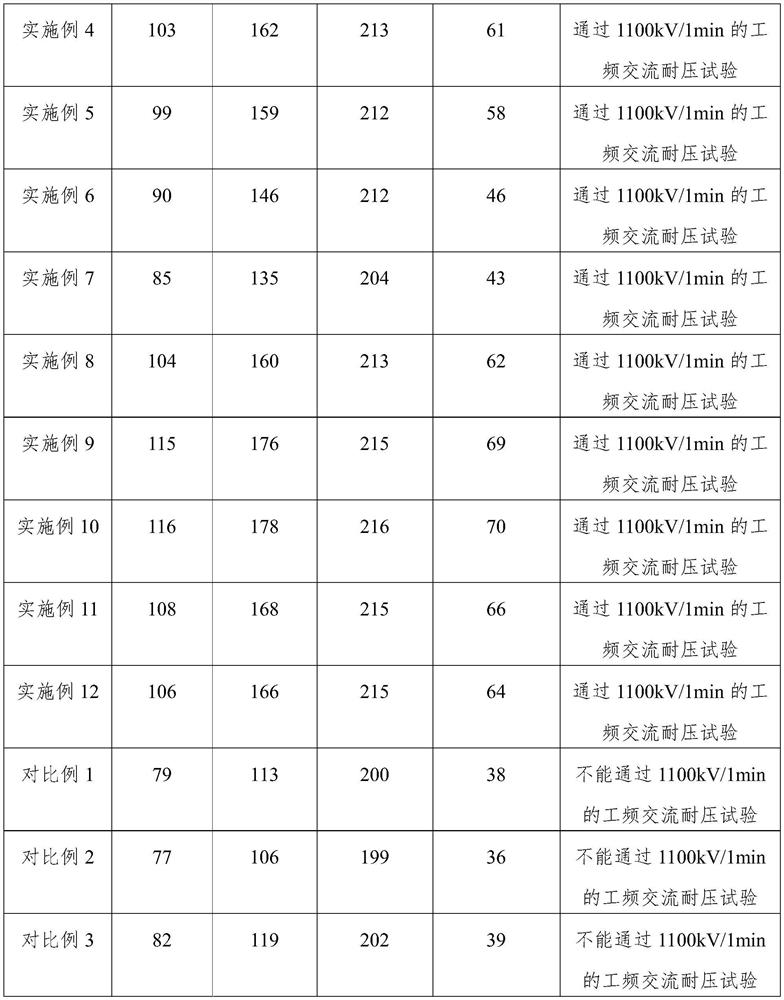

Electrical insulation ultrahigh-voltage epoxy resin composition and preparation method thereof

InactiveCN112063112AHigh thermal decomposition temperatureHigh glass transition temperaturePolymer scienceUltra high voltage

The invention discloses an electrical insulation ultrahigh-voltage epoxy resin composition and a preparation method thereof, and belongs to the technical field of epoxy resin. The electrical insulation ultrahigh-voltage epoxy resin composition comprises the following components in parts by weight: 100-200 parts of epoxy resin, 100-200 parts of a curing agent, 20-40 parts of polysulfide rubber, 20-40 parts of urea melamine formaldehyde resin, 20-40 parts of phenolic resin, 20-40 parts of isocyanate, 20-40 parts of polytetrafluoroethylene, 20-30 parts of an inorganic nano mixture and 10-20 partsof a toughening agent. According to the invention, a good insulating effect can be achieved in ultrahigh-voltage electricity, and the modifier, the inorganic nano mixture and the like are added, so that the thermal decomposition temperature of the composite material is remarkably increased by adding the modifier, and the glass transition temperature of an epoxy resin matrix is greatly increased;the insulating property of the epoxy resin is further improved by selecting the components of the inorganic nano mixture, and meanwhile, the breakdown strength of the epoxy resin can be effectively improved, the dimensional stability is improved and the trend of stress cracking is reduced.

Owner:SHANGHAI XIONGRUN RESIN

Extra-high voltage resistant insulating resin and preparation method thereof

ActiveCN114702788AImprove insulation performanceHigh glass transition temperaturePolymer scienceBall mill

The invention relates to an extra-high voltage resistant insulating resin and a preparation method thereof. The method comprises the following steps: mixing 40-68 parts of matrix resin and 5-15 parts of a toughening agent, and stirring for 1-3 hours at 60-100 DEG C under the protection of inert gas to obtain toughened matrix resin; the preparation method comprises the following steps: carrying out ball milling on 10-35 parts of a ceramic additive and a solvent to obtain a ceramic additive dispersion liquid; stirring the ceramic additive dispersion liquid, toughened matrix resin, 10-25 parts of silane and 3-8 parts of a dispersing agent at room temperature for 2-3 hours to obtain a mixture; carrying out reduced pressure distillation on the mixture to remove the solvent, so as to obtain silane modified toughened matrix resin; and adding 0.5-3 parts of an accelerant into the silane modified toughened matrix resin, and uniformly stirring to obtain the extra-high voltage resistant insulating resin. The extra-high voltage resistant insulating resin prepared by the invention has excellent thermal properties, mechanical properties and electrical insulation properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

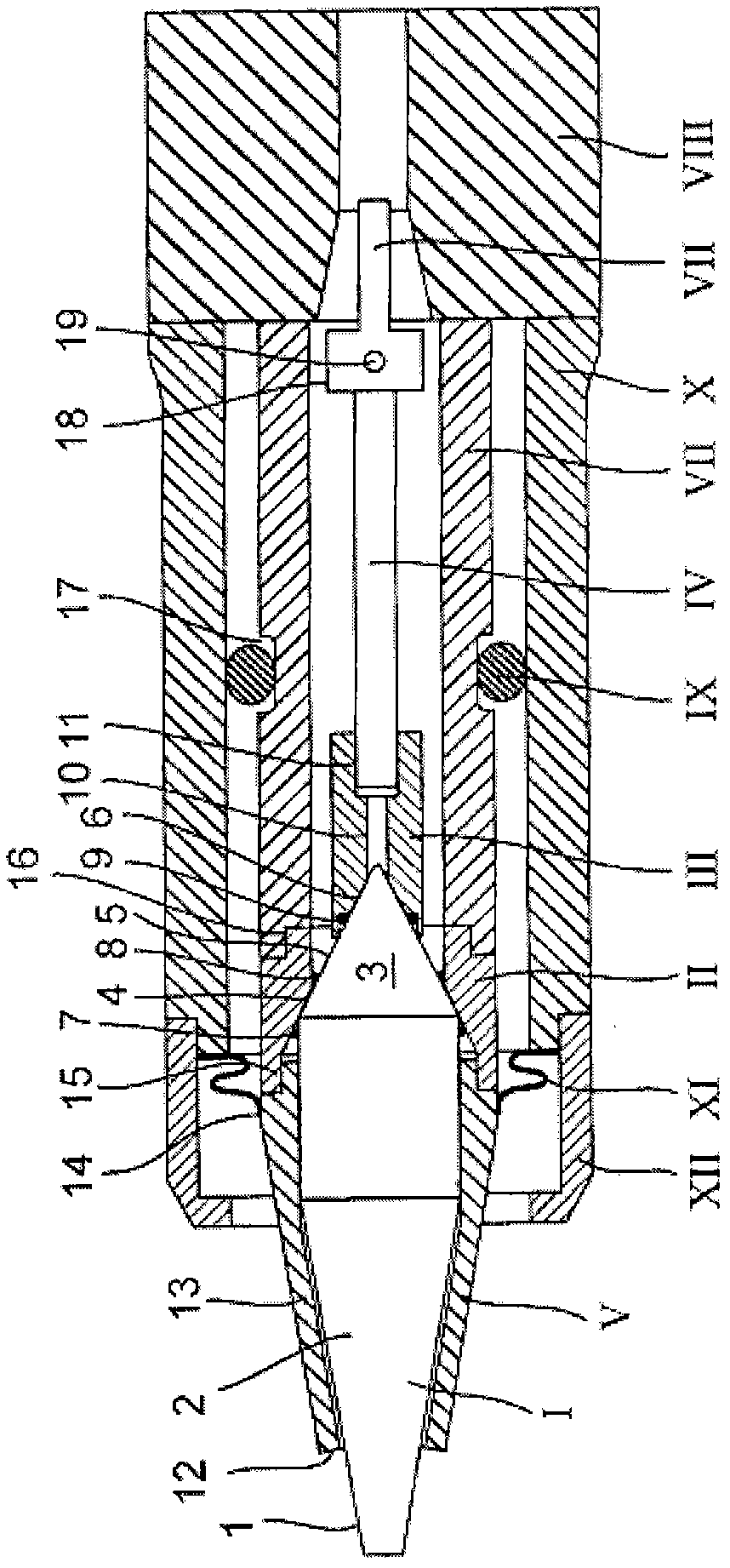

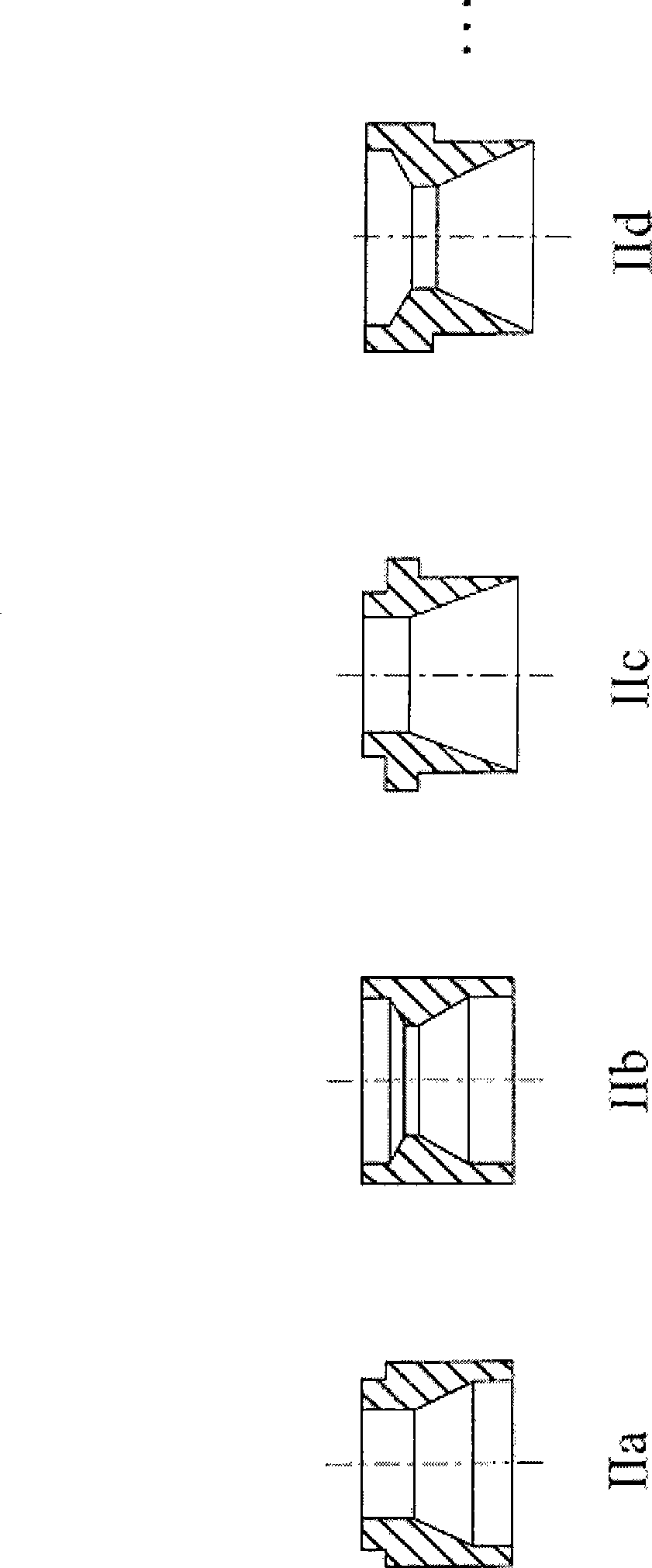

Glow plug and method for producing the same

The invention relates to a glow plug comprising a housing, a ceramic pencil-type glow element which projects from the housing with a first end and is arranged inside the housing with a second end, a feed line which is arranged in the housing and leads to the pencil-type glow element, and a sleeve-type element which surrounds a section of the pencil-type glow element projecting from the housing. The invention is characterized in that the pencil-type glow element has a section surrounded by the housing which section tapers towards the second end, the pencil-type glow element is encircled by a contact element in the housing, which contact element has a section that narrows towards the second end of the pencil-type glow element, said narrowing section encircling at least a subsection of the tapered section of the pencil-type glow element. The invention further relates to a method for producing said glow plug.

Owner:BORGWARNER BERU SYST

A wear-resistant gradient interface multiphase reinforced titanium alloy material and its preparation method

ActiveCN112030037BEnhanced interface bindingReduce concentrated stressAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesSelective laser melting

The invention discloses a wear-resistant gradient interface multiphase reinforced titanium alloy material and a preparation method thereof, comprising a titanium alloy matrix and a TiC ceramic reinforcement phase and a TiN ceramic reinforcement phase dispersed in the titanium alloy matrix; the titanium alloy matrix is titanium- Aluminum-molybdenum-vanadium-zirconium alloy, wherein the content of aluminum is 5.5-6.5wt.%, the content of zirconium is 1.6-2.0wt.%, the content of molybdenum is 1.0-1.5wt.%, the content of vanadium is 1.0-1.8wt.%. The amount is Ti; the TiC ceramic reinforcement phase accounts for 10-15 wt.% of the total mass of the alloy material; the TiN ceramic reinforcement phase accounts for 10-15 wt.% of the total alloy material mass. Using titanium-aluminum-molybdenum-vanadium-zirconium alloy powder and micron-sized TiC and TiN powder as raw materials, the ceramic-reinforced titanium-based composite material is prepared by selective laser melting technology after ball milling and mixing powder to form TiC-Ti(C,N)- The gradient interface structure of TiN improves the interface bonding between the ceramic reinforcement phase and the titanium matrix, reduces the tendency of stress concentration and cracking of the composite material during the rapid condensation of the melt, reduces the cracks in the titanium matrix composite material after forming, and improves its performance. Forming quality and mechanical properties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

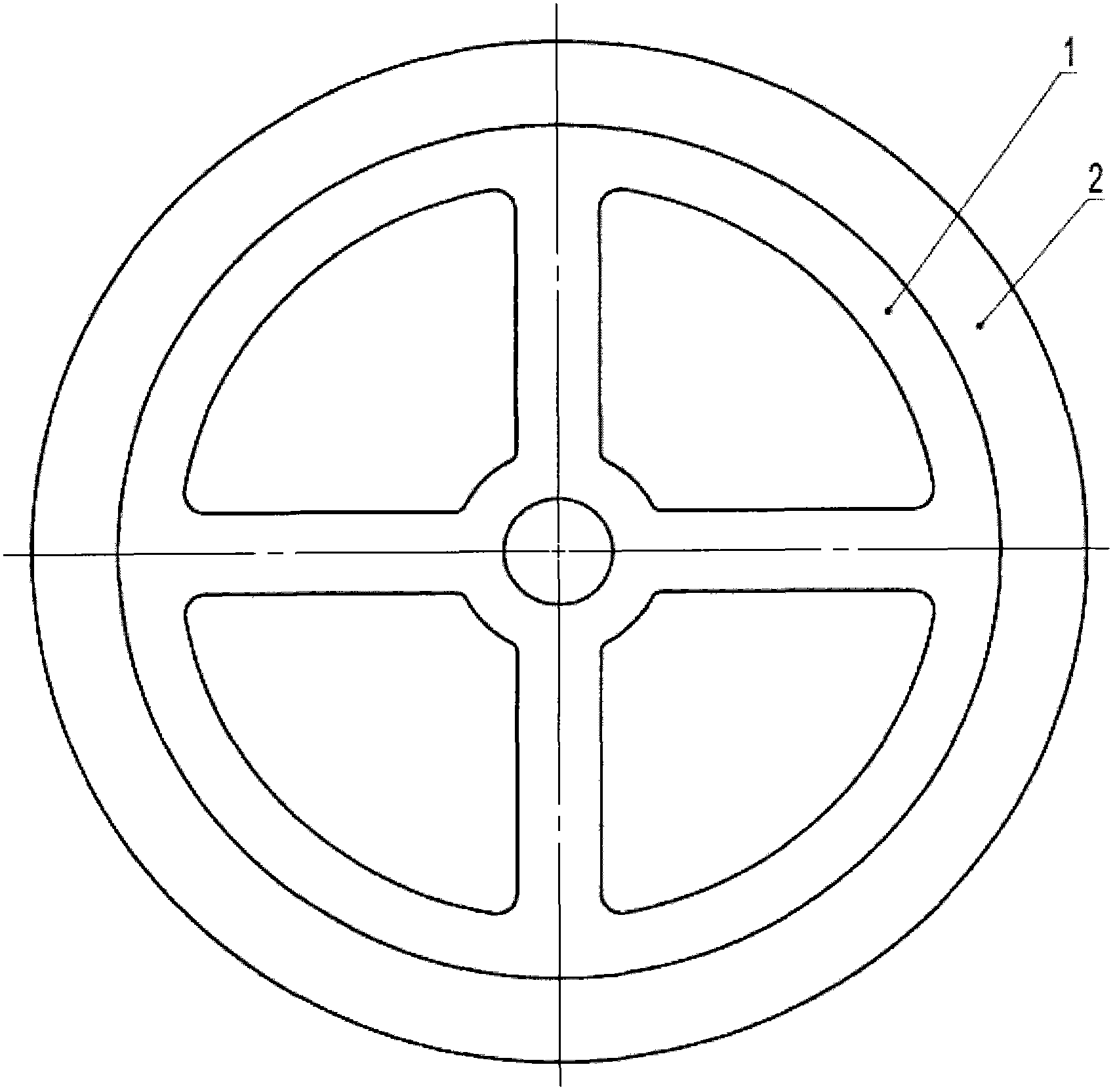

Flywheel rotor hub adopting steel-wire prestressing force winding structure

The invention relates to a flywheel rotor hub adopting a steel-wire prestressing force winding structure, which includes a metal hub base body and a steel-wire winding layer, wherein the metal hub base body is disk-shaped or cylindric; the steel-wire winding layer is formed on the outer surface of the metal hub base body; and the metal hub base body and the steel-wire wind layer are tightly connected in a winding manner through prestressing force. The hub adopting the structure can change the stress state of the hub of the flywheel rotor, greatly improve the service intensity and service performance, reduce the failure and damage ratio of the entire flywheel system, and enable the flywheel rotor to be used reliably; and the flywheel rotor hub provided by the invention can effectively increase the inner and outer radius ratio of the rotor, improve the energy storage density of the flywheel and remarkably reduce the manufacturing cost of the rotor at the same time.

Owner:北京奇峰聚能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com