Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Meet the requirements of green chemical development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

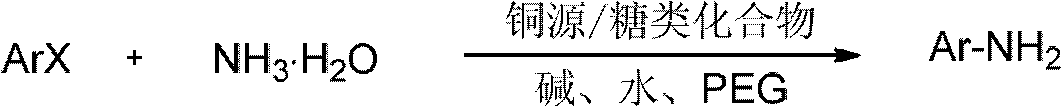

Method for preparing aromatic primary amine by taking ammonia water as ammonia source in water phase system

ActiveCN102050687AImprove friendlinessEasy to operateOrganic compound preparationAmino group formation/introductionAlkaline earth metalPhosphate

The invention provides a method for preparing aromatic primary amine by taking ammonia water as an ammonia source in a water phase system. In the method, aromatic halogenate and the ammonia water are used as raw materials, water is used as a solvent, at room temperature or under the heating condition of common oil bath, carbonates, fluorides, phosphates and hydroxides of alkali metals or alkaline-earth metals are taken as alkalis, and a catalytic reaction is preformed through adding a surfactant and using a temary catalysis system composed of copper catalyst, hydrazide and ketone. The method has the characteristics that the operation is simple, wide substrate application range is wide, the product is simple and easy to separate, the yield is high, the process is economic and is environment-friendly and the like; and reaction conditions are flexible, thus corresponding room temperature or heating mode can be selected according to practical requirements. In addition, the environment friendliness of the reaction is effectively improved by using water as a reaction solvent, thereby better conforming to the development requirements of green chemistry. Especially, the substrate is wide in application range and has wide application prospects in the aspects of preparing natural products, medicines and pesticides.

Owner:SUN YAT SEN UNIV

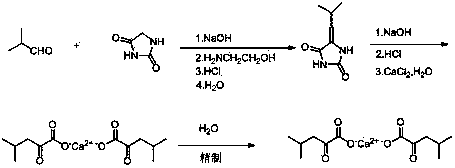

Environment-friendly technology for preparing ketoleucine calcium in aqueous phase

ActiveCN104058954AAvoid pollutionPollution is notCalcium/strontium/barium carbonatesOrganic compound preparationSolventHydrolysis

The invention relates to an environment-friendly technology for preparing ketoleucine calcium in an aqueous phase. Isobutylidene hydantoin and a calcium chloride aqueous solution serve as raw materials, and water serves as a solvent. The environment-friendly technology comprises the steps that heating reflux hydrolysis is carried out on the isobutylidene hydantoin in water and industrial liquid alkali, the calcium chloride aqueous solution is dropwise added, the mixed solution is filtered, filtered liquid is collected and cooled, hydrochloric acid acidification is carried out, vacuum nitrogen displacement is carried out, caustic soda liquid is added for alkalization, cooling is carried out, the calcium chloride aqueous solution is dropwise added, calcium salt is obtained, cooling is carried out, a crude product is obtained through filtering, the crude product is refined in purification water, and a ketoleucine calcium refined product is obtained. The environment-friendly technology for preparing the ketoleucine calcium in the aqueous phase has the advantages of being easy to operate, simple in steps, high in yield coefficient, good in product quality, environmentally friendly and the like. According to the environment-friendly technology for preparing the ketoleucine calcium in the aqueous phase, the environment-friendly water is adopted as the solvent completely, the requirement of green chemistry development is met, the pollution problem is solved from the source, and the environment-friendly technology is suitable for industrialized mass production.

Owner:SHAOXING MINSHENG PHARMA

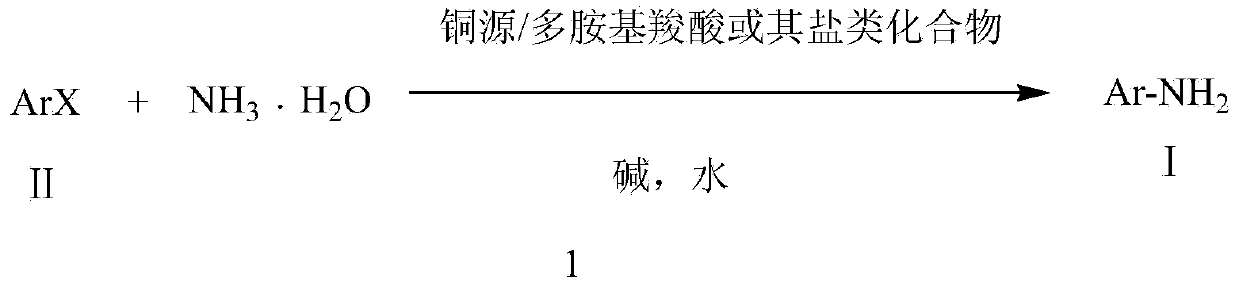

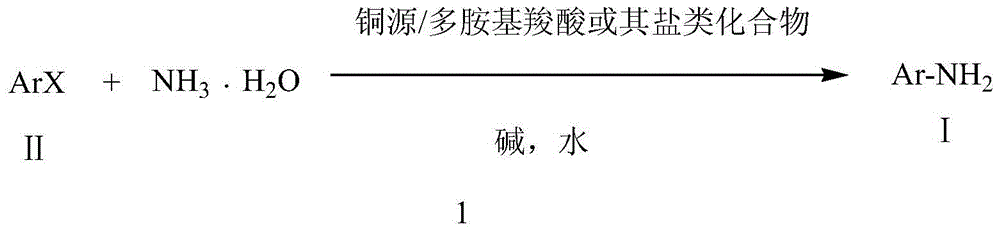

Method for synthesizing aromatic primary amine in circulating water phase system

ActiveCN103739417AImprove friendlinessEasy to separate and purifyOrganic compound preparationCarboxylic acid amides preparationAlkaline earth metalPtru catalyst

The invention discloses a method for synthesizing an aromatic primary amine in a circulating water phase system. According to the method, an aryl halide and ammonia water are taken as raw materials, water is taken as a solvent, a carbonate, a fluoride, a phosphate or a hydroxide of an alkali metal or an alkaline-earth metal or a compound which can be converted to a corresponding alkali in water is taken as the alkali, polyamine carboxylic acid and a salt type compound thereof are taken as ligands, and a copper source catalyst is adopted for catalyzing the formation of the aromatic primary amine from the aryl halide and the ammonia water. According to the method disclosed by the invention, the water is used as the solvent, any phase transfer of the catalyst is not required, and the catalyst, the ligands and the reaction solvent, namely the water, can be recycled, so that the environment-friendly property of reaction is effectively improved, the method is more in line with requirements of green chemical development, a substrate particularly has a wide range of applications, and the method further has broad prospects in the aspects of preparation of natural products, medicaments and pesticides.

Owner:SUN YAT SEN UNIV

Method for synthesis of N-substituted dicarbamate with urea as carbonyl source

InactiveCN106397271ACheap and easy to getAtom utilization is highCarbamic acid derivatives preparationOrganic compound preparationNiobiumNon precious metal

The invention discloses a method for synthesis of N-substituted dicarbamate with urea as a carbonyl source; the method comprises the steps of taking a non precious metal composite oxide as a catalyst, taking polyurea, urea and alcohol as raw materials, and carrying out a reaction at the temperature of 180-220 DEG C for 10-22 hours to obtain N-substituted dicarbamate; an active component of the catalyst is a complex of two non precious metal oxides of zinc, copper, titanium and niobium. The method has the advantages of high conversion rate, high yield, high catalyst activity and good stability, and can be reused.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

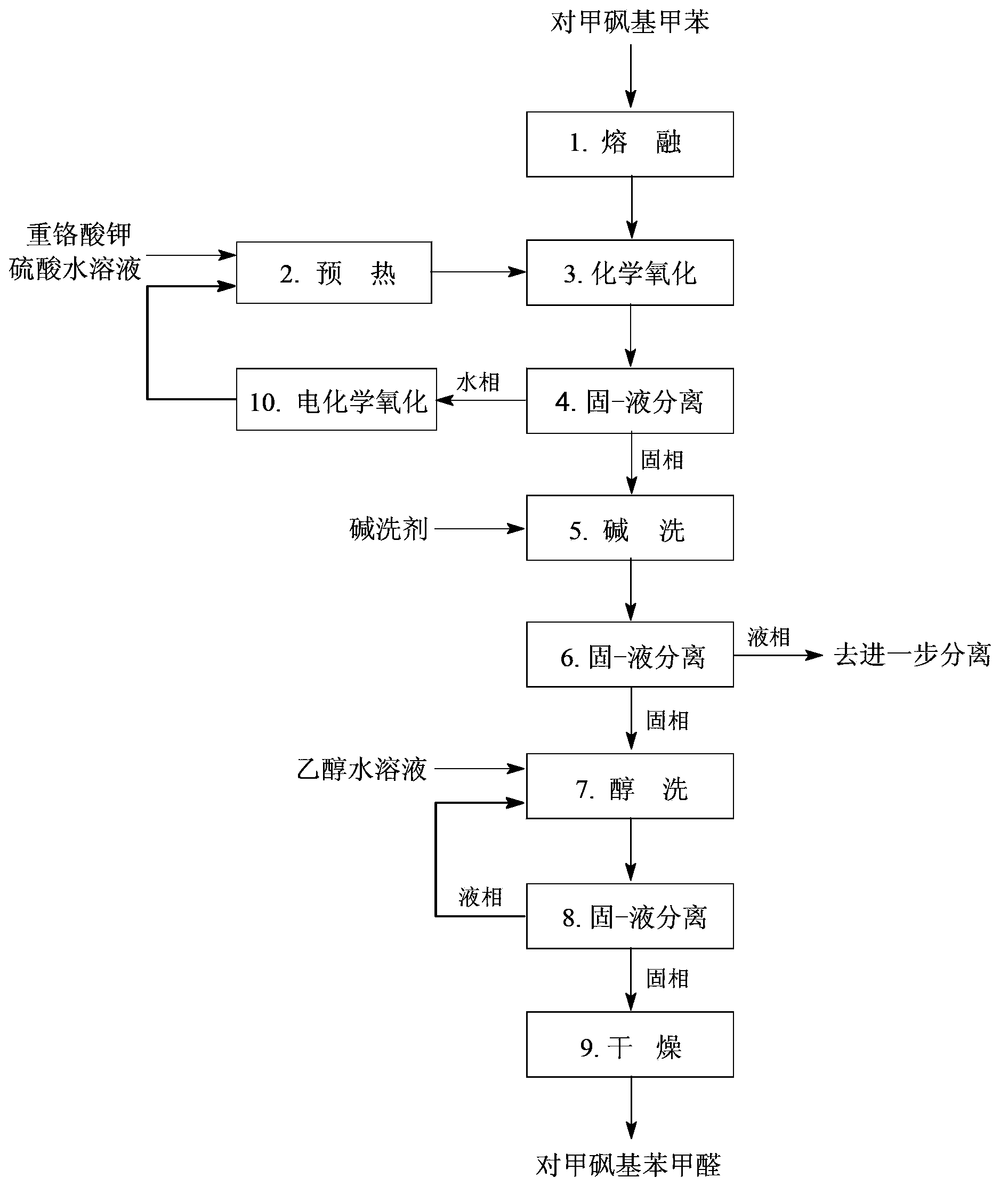

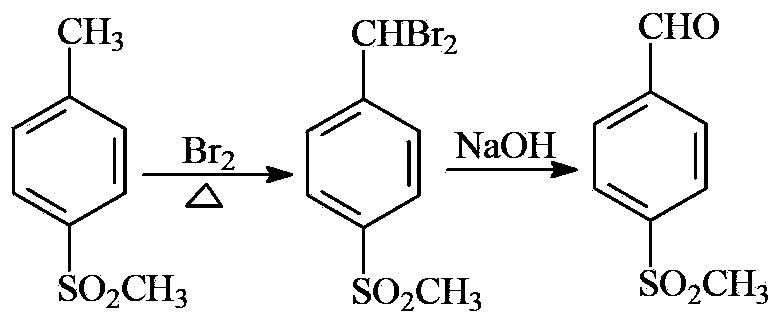

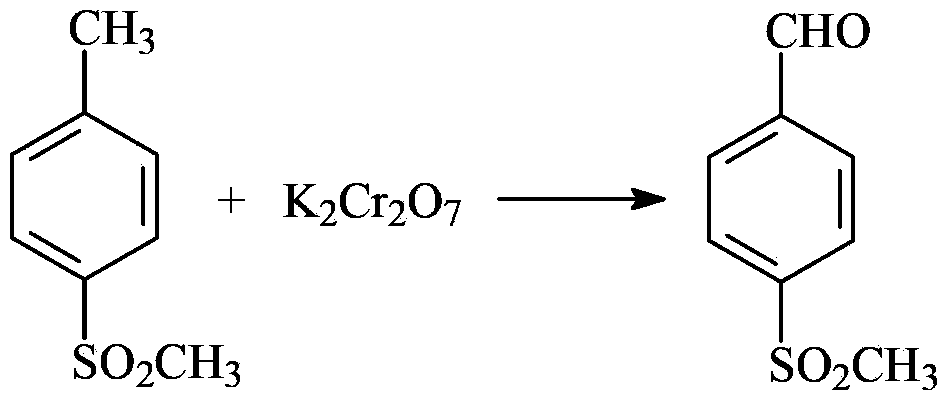

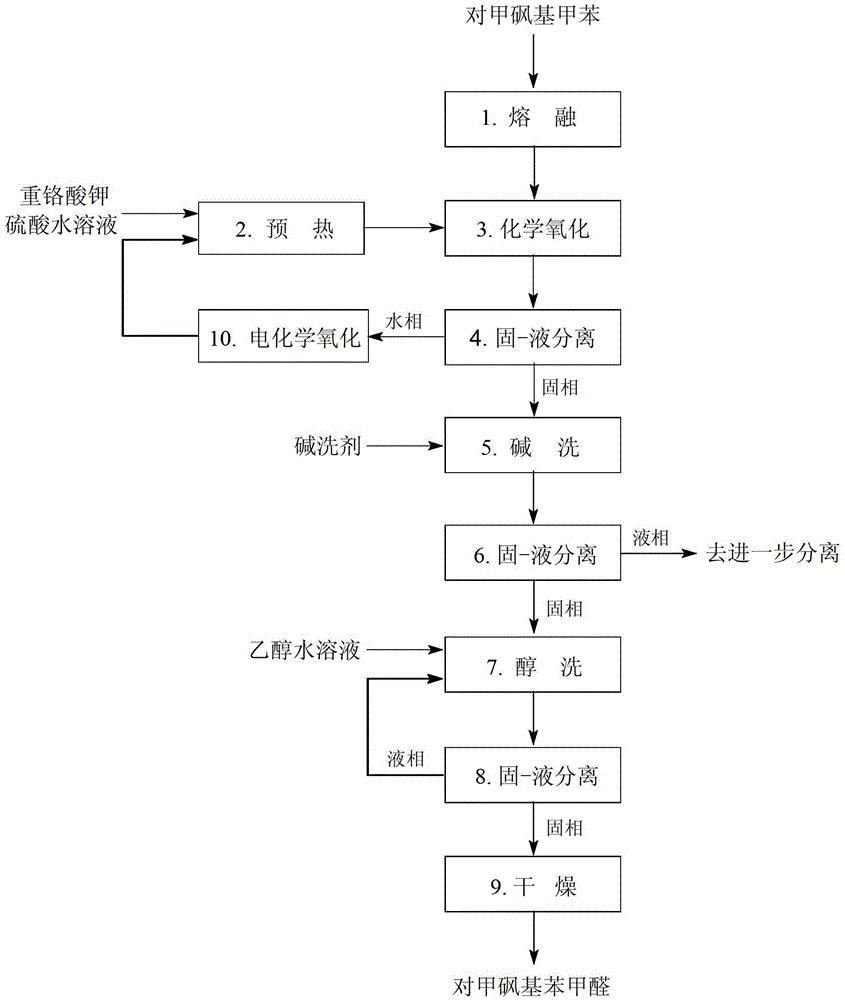

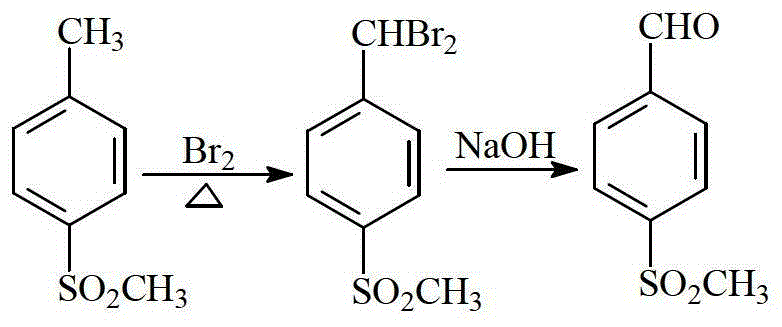

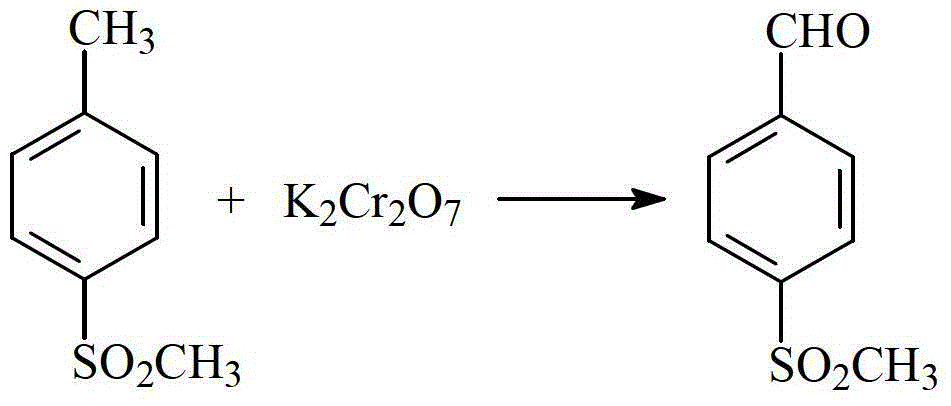

MethyIsuIfino benzaldehyde preparation method

ActiveCN103360287AAchieve recyclingReduce pollutionOrganic chemistryOrganic compound preparationAlcoholBenzaldehyde

The invention relates to a methyIsuIfino benzaldehyde preparation method mainly comprising the steps of: (1) smelting; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) alkali washing; (6) solid-liquid separation; (7) alcohol washing; (8) solid-liquid separation; (9) drying; and (10) electrochemical oxidation. The process provided by the invention is reasonable, the preparation method is simple, production cost is low, product purity is high, and the process is safe. The method is suitable for realizing large-scale industrialization. The process is a clean production process of methyIsuIfino benzaldehyde preparation. The process satisfies the requirement of green chemical engineering development.

Owner:YANGZHOU UNIV

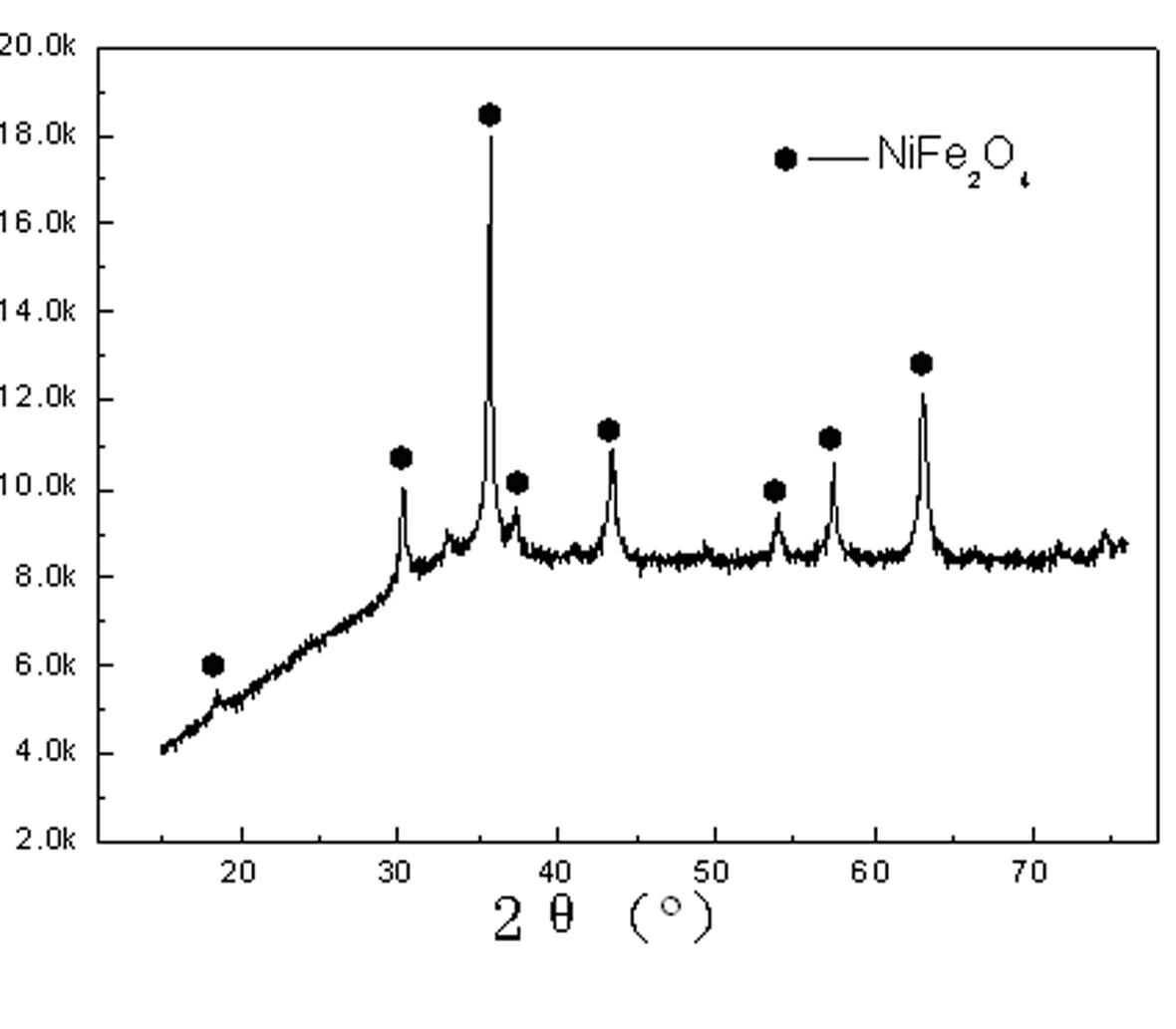

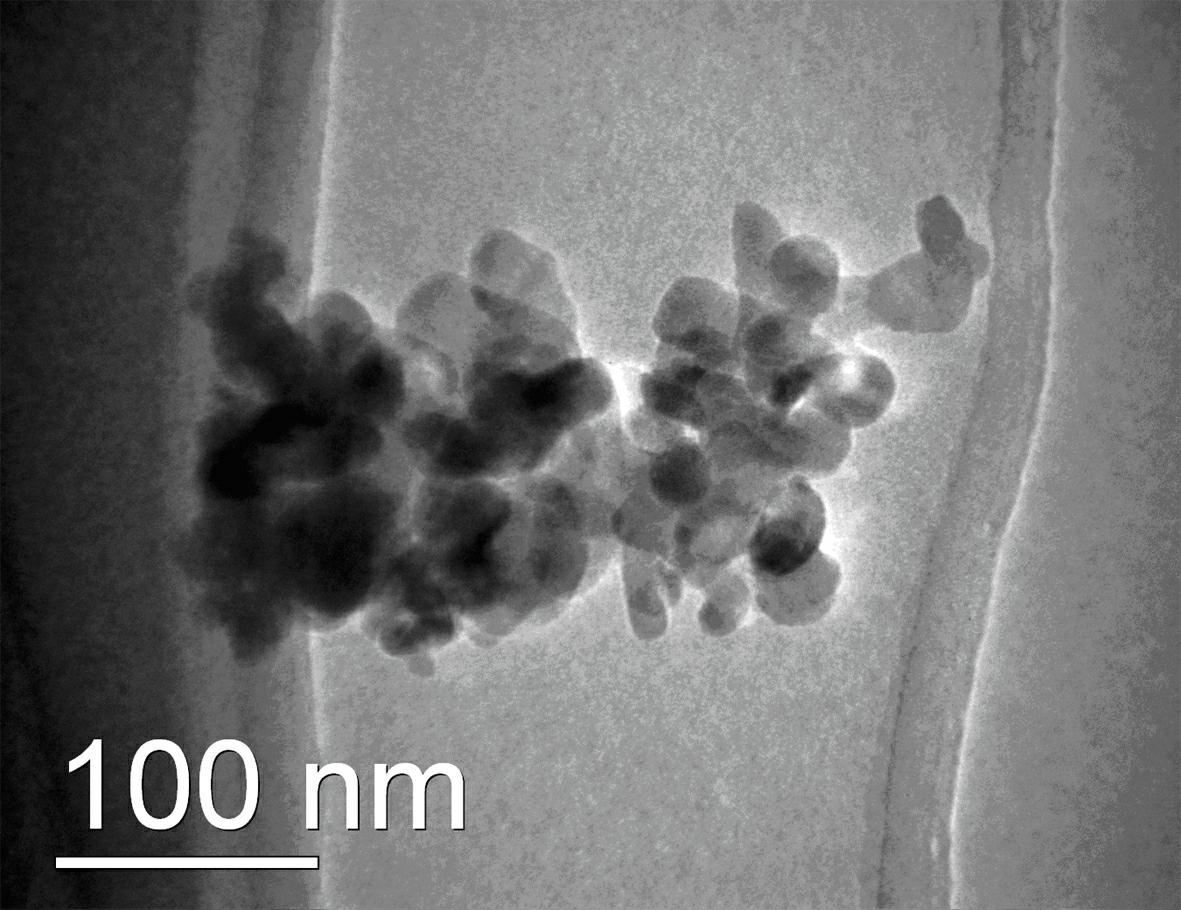

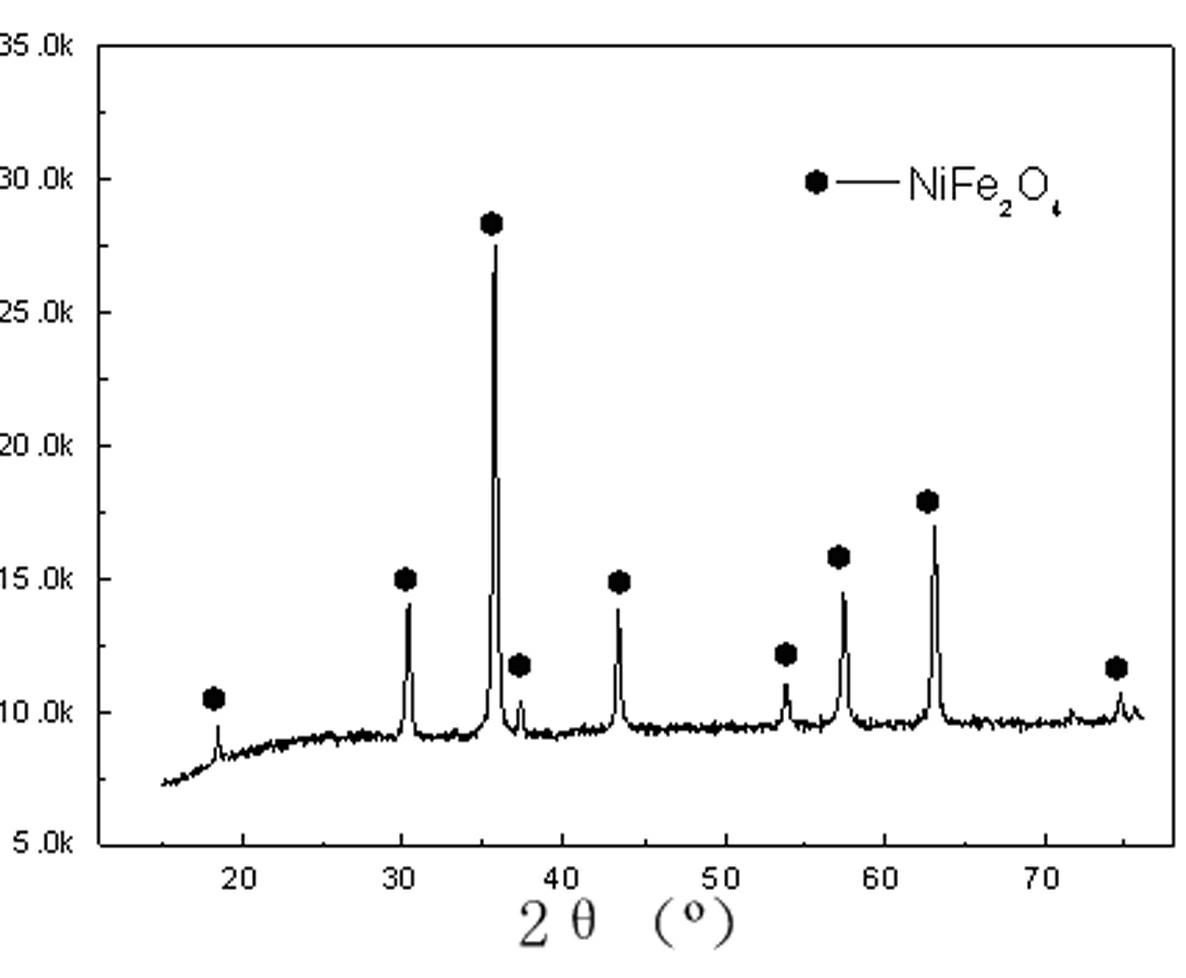

Preparation method of nickel ferrite spinel nano-powder

InactiveCN102515278AGood removal effectEasy to operateNanotechnologyIron compoundsNickel saltMaterial synthesis

The invention relates to a preparation method of nickel ferrite spinel nano-powder, which belongs to the technical field of nano material synthesis, and comprises the following steps that: (1) inorganic ferric salt, inorganic nickel salt and sodium hydroxide (NaOH) are mixed and physically crushed into powder; (2) dispersing agent sodium chloride (NaCl)and the power are put into a grinding machine to be ground until all the materials turn into brown, the materials are dried, and brown precursor blocks are obtained; and (3) the precursors are calcinated, washed by water and then dried, and the nickel ferrite spinel nano-powder is obtained. The method has the characteristics of convenience in operation and control, no use of solvent, high-selectivity, high-yield, little pollution, energy saving, simple synthesis process and the like.

Owner:NORTHEASTERN UNIV LIAONING

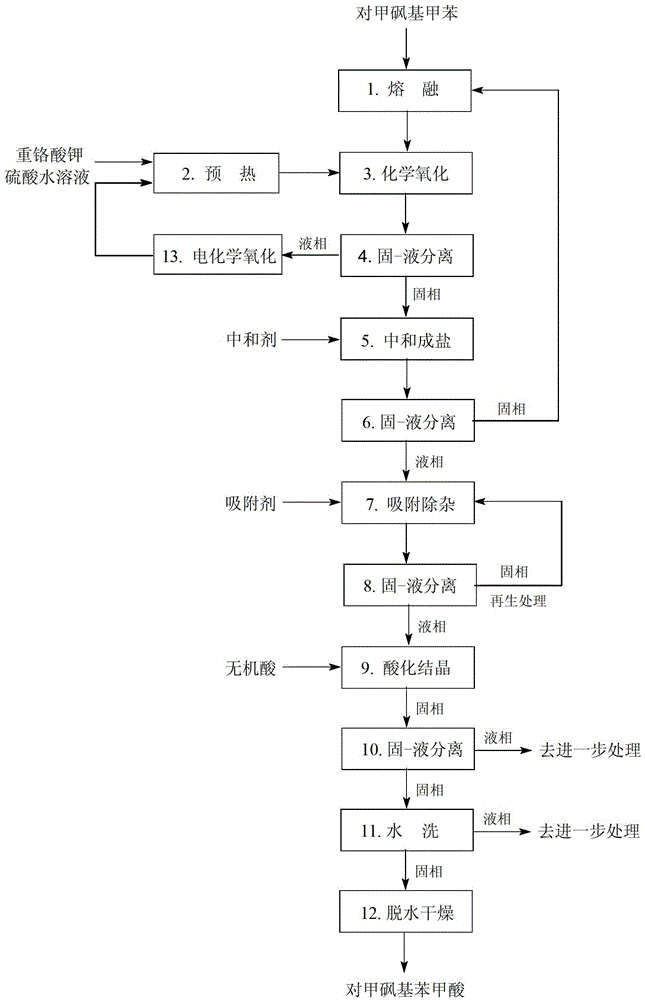

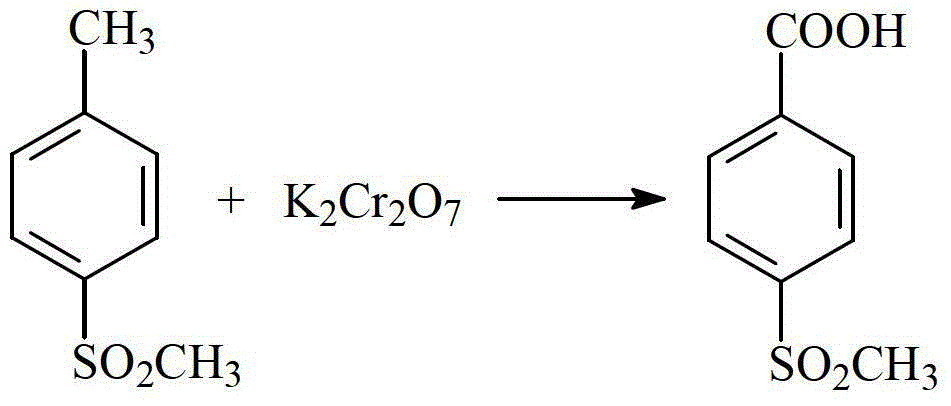

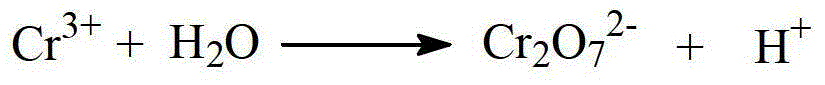

Preparation method of p-methylsulfonylbenzoic acid

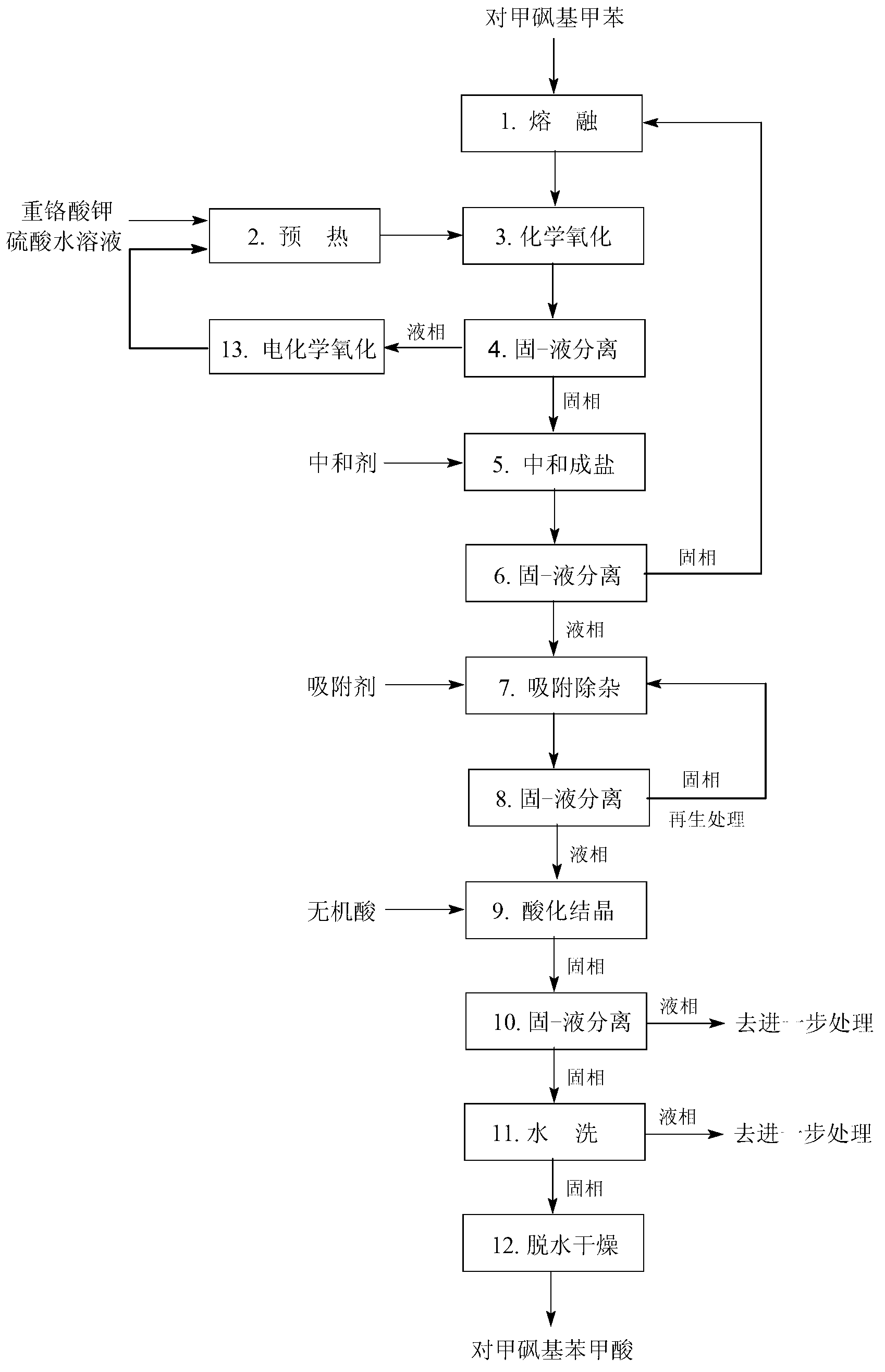

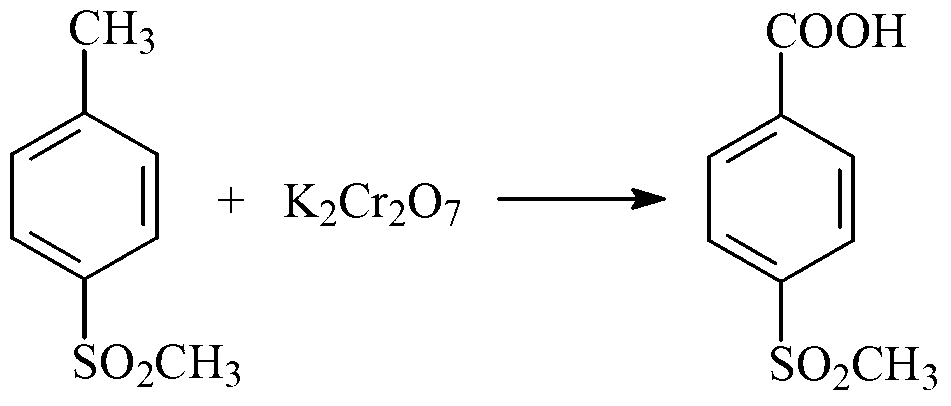

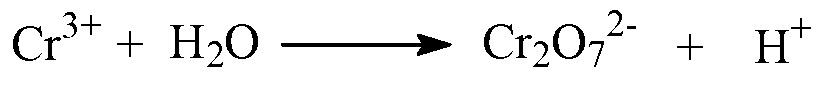

InactiveCN103319383AAchieve recyclingReduce pollutionOrganic chemistryOrganic compound preparationImpurityCleaner production

The invention relates to a preparation method of p-methylsulfonylbenzoic acid. The method provided by the invention mainly comprises the following steps: (1) fusing; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) neutralization for salt formation; (6) solid-liquid separation; (7) adsorption for removal of impurities; (8) solid-liquid separation; (9) acidification and crystallization; (10) solid-liquid separation; (11) washing; (12) dewatering and drying for obtaining a product p-methylsulfonylbenzoic acid; and (13) electrochemical oxidation. The preparation method provided by the invention is simple, has advantages of reasonable technology, low production cost, high product purity and safe process, is convenient to realize large-scale industrialization, and is a clean production technology which is used for preparing p-methylsulfonylbenzoic acid and accords with green chemical development requirements.

Owner:扬州德耀电气有限公司

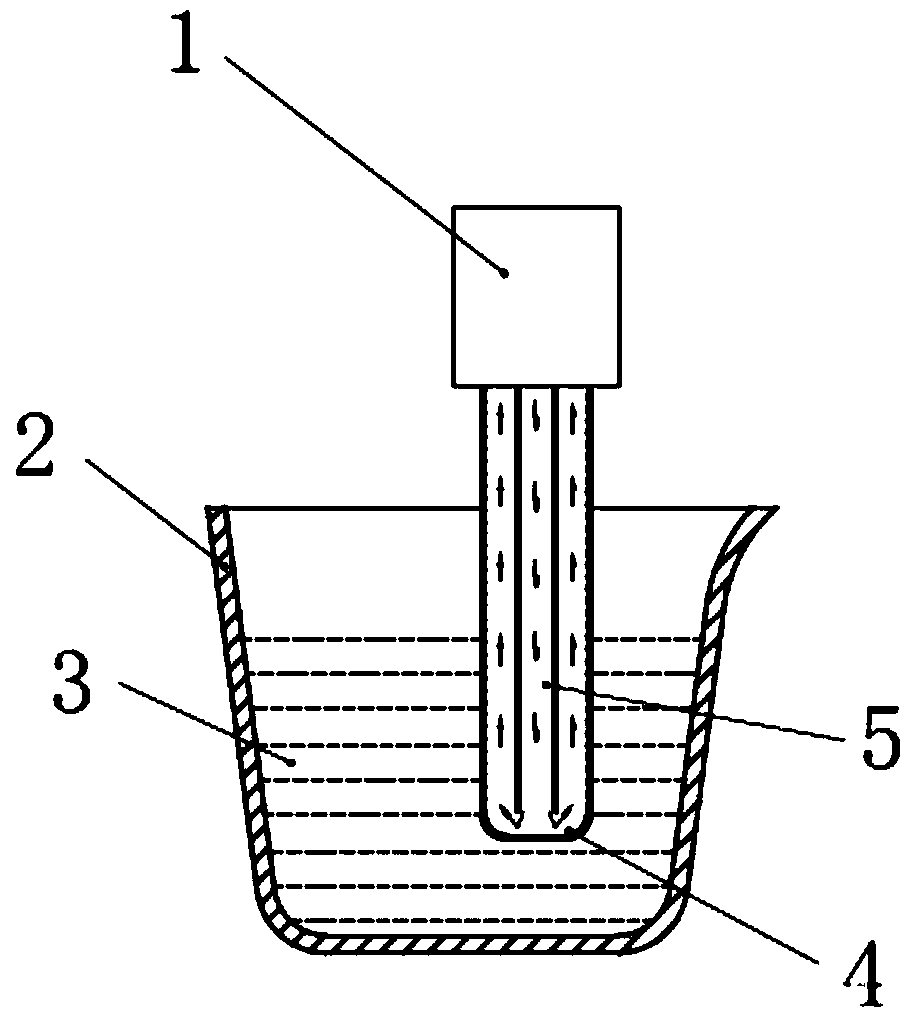

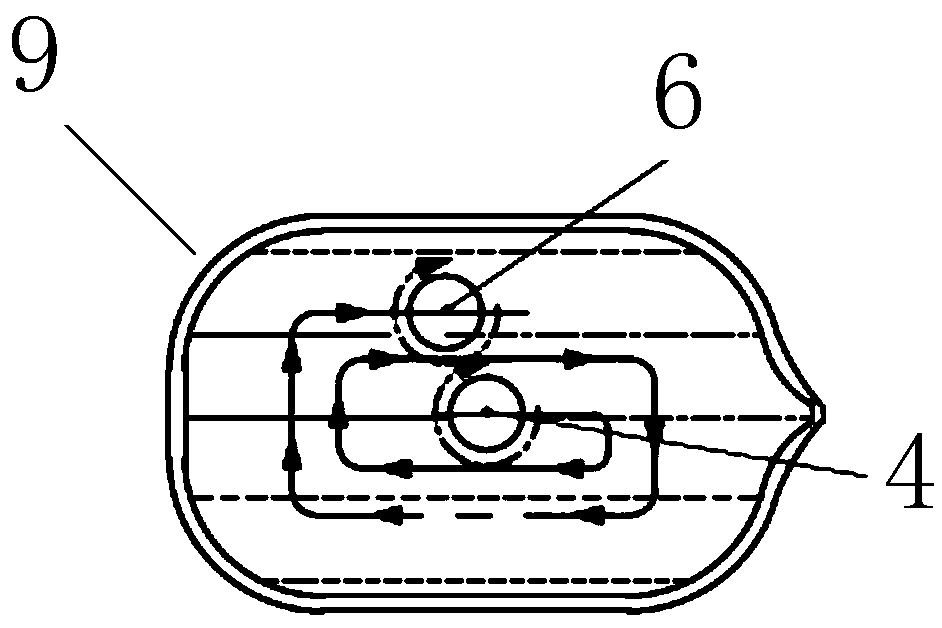

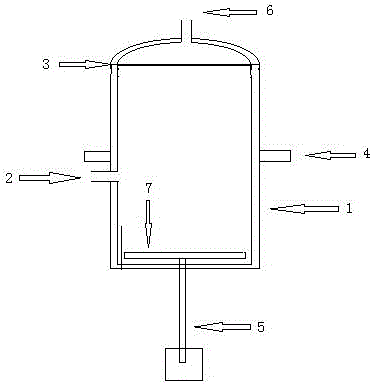

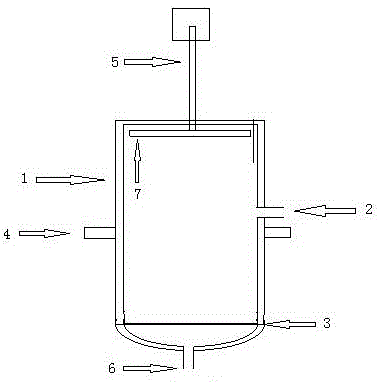

Semi-solid slurry pulping device

PendingCN109513886APromote growthUniform nucleationRotary stirring mixersTransportation and packagingSemi solidSlurry

The invention provides a semi-solid slurry pulping device comprising a rotor mixer (1) and a pulping tank (2). The rotor mixer (1) comprises a mixing drum (9) and a rotor mixing rod (4) extending fromthe mixing drum (9) to the interior of the pulping tank (2), and the mixing drum (9) is internally provided with a driving device used for driving the rotor mixing rod (4) to rotate by itself. The end face, facing the pulping tank (2), of the mixing drum (9) is provided with a transmission gear (6), the rotor mixing rod (4) is connected with the transmission gear (6) in an engaged manner, the transmission gear (6) is provided with n teeth, the spacing between the adjacent front and rear teeth is a, and the tooth width of each tooth is b; and the end, connected with the transmission gear (6),of at least one rotor mixing rod (4) is provided with engaged teeth matched with the transmission gear (6), each rotor mixing rod (4) comprises m engaged teeth, the spacing between the adjacent frontand rear engaged teeth is b, and the tooth width of each engaged tooth is a.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

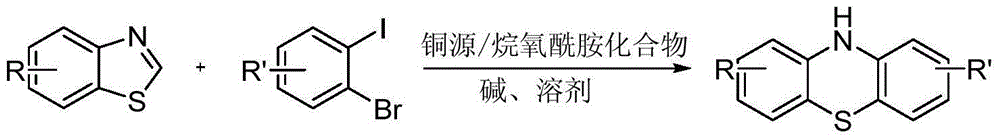

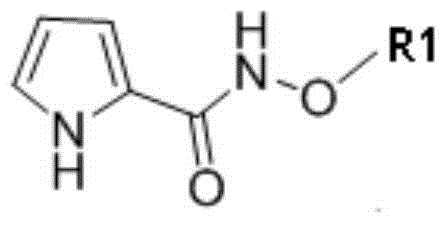

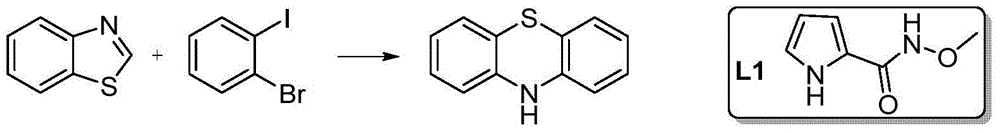

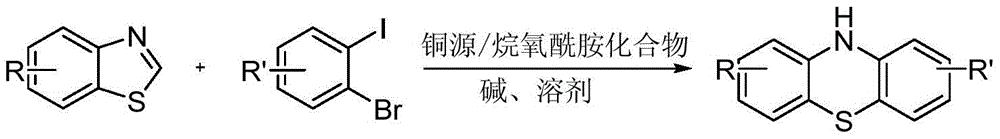

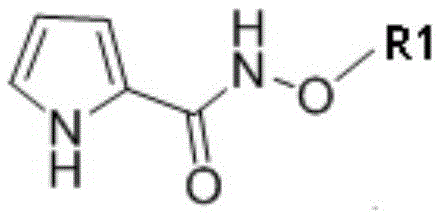

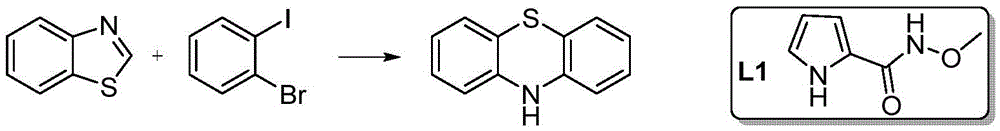

Novel method for synthesizing phenothiazine compounds

The invention develops a method for synthesizing phenothiazine compounds by using benzothiazole and derivatives thereof as well as 1-bromo-2-iodobenzene and derivatives thereof as raw materials and copper or copper salt / N-alkoxy-1H-pyrrolic amide system as a copper catalyst. The method is a brand-new method for synthesizing phenothiazine compounds. The method has the characteristics of low temperature, short reaction time, low solvent toxicity and wide substrate adaptability, and has wide application prospects in the aspect of preparation of medicines, pesticides and materials.

Owner:SUN YAT SEN UNIV

Green water-phase synthesis method of primary arylamine

InactiveCN102557958AEasy to operateSolve the pollution problemOrganic compound preparationAmino compound preparationEnvironmental resistancePollution

The invention provides a rapid, simple and convenient synthesis method of primary arylamine which is implemented in a water phase, utilizes a green ligand, and completely satisfies the requirements of green development. An aryl halide and ammonia water are used as raw materials, water is used as a solvent, and the carbonates, fluorides, phosphates and hydroxides of alkaline metals or alkaline-earth metals are used as alkali and the temperature condition is 50-150 DEG C. The synthesis method is characterized in that primary amine is formed by catalyzing an aromatic halide or a nitrogenous heterocyclic aromatic halide and the ammonia water in a green system in which a copper source catalyst is used, a carbohydrate is used as a ligand, and polyethylene glycol is taken as a surfactant. The synthesis method of primary arylamine provided by the invention has the advantages of being simple in operation, simple in products, easy in separation of products, green and environment-friendly, etc. Compared with similar reactions reported in research papers, the synthesis method meets the requirements of green chemical development since all used solvents and reagents are green and environment-friendly; the problem of pollution is solved from the source; and a wide application prospect is achieved in the aspect of high-throughput preparation of natural products, medicines and pesticides.

Owner:SUN YAT SEN UNIV

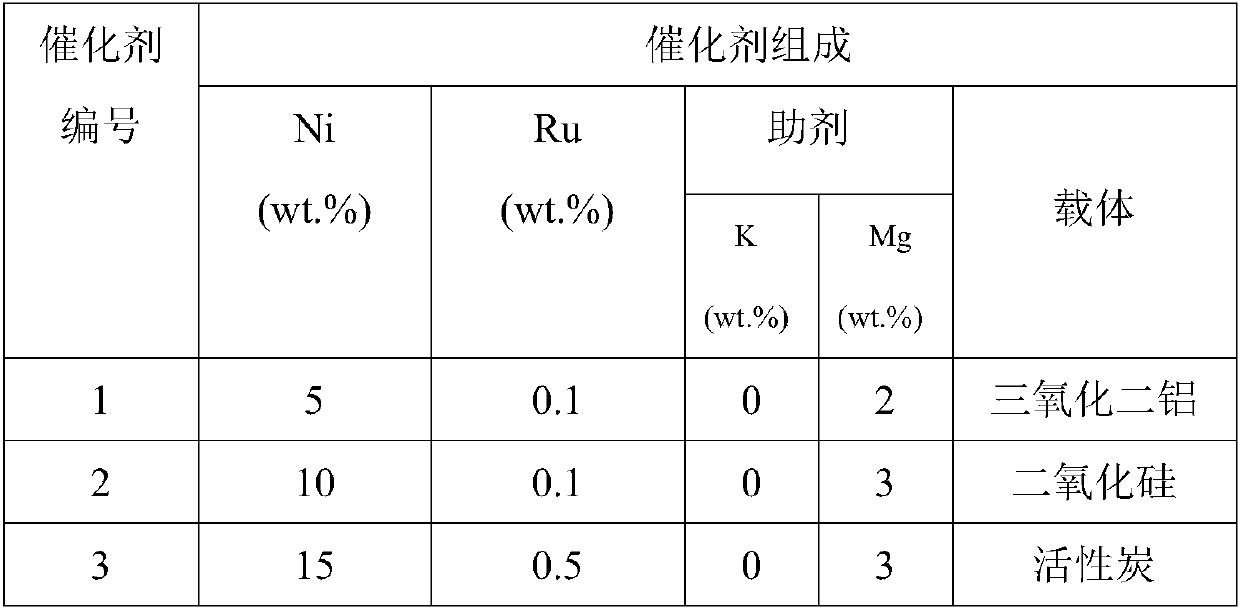

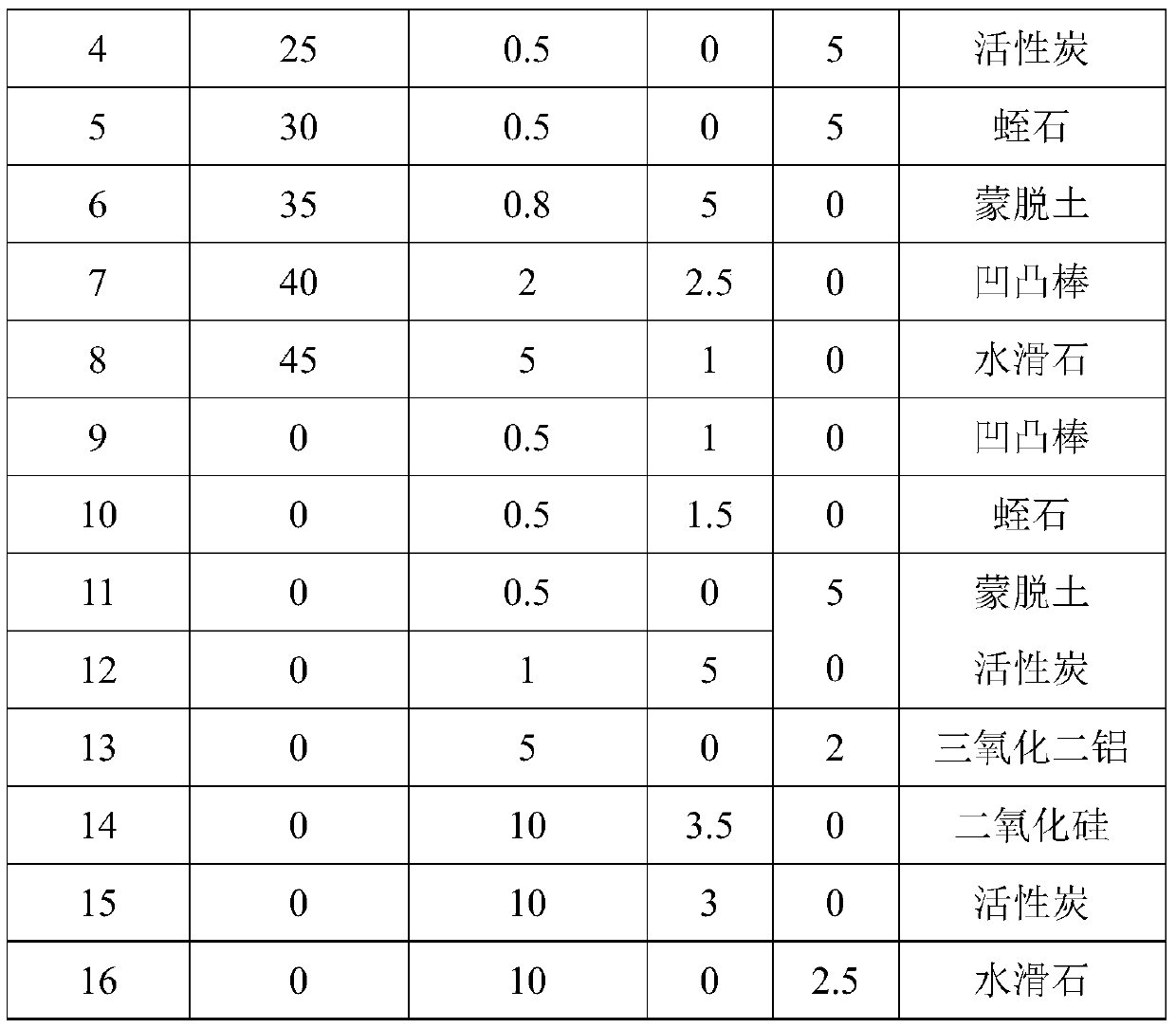

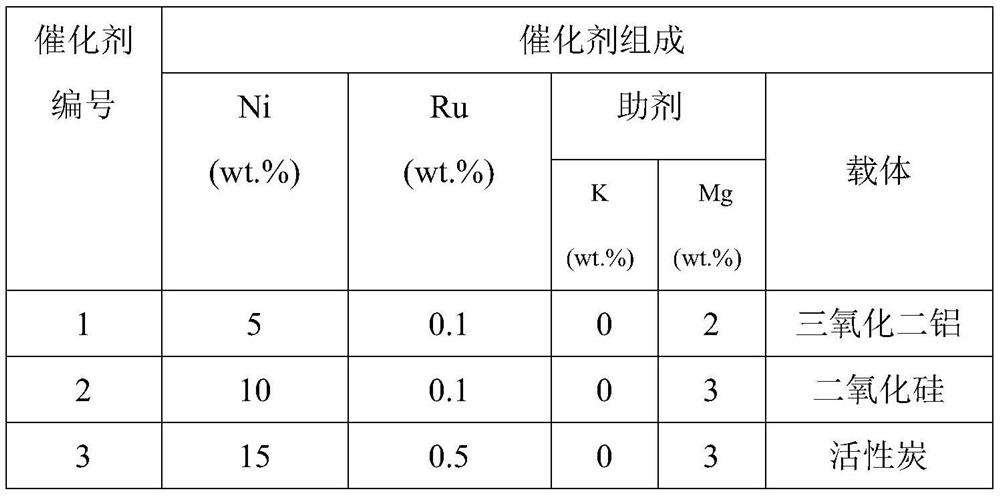

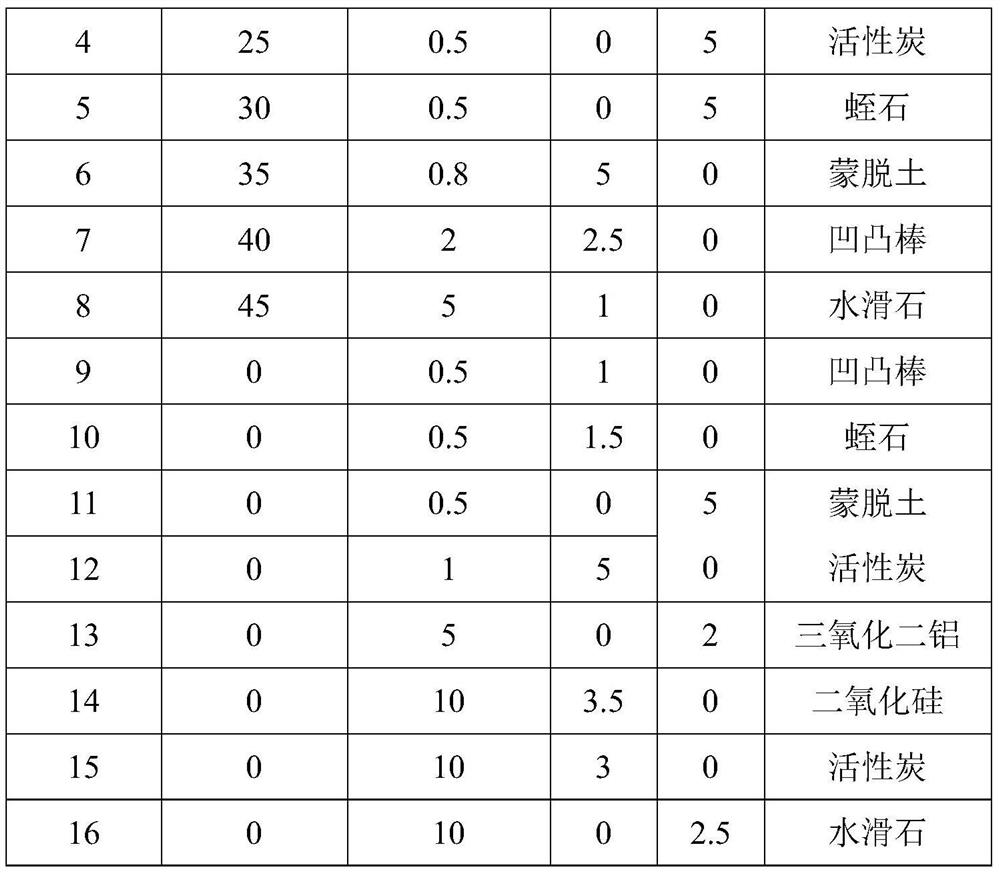

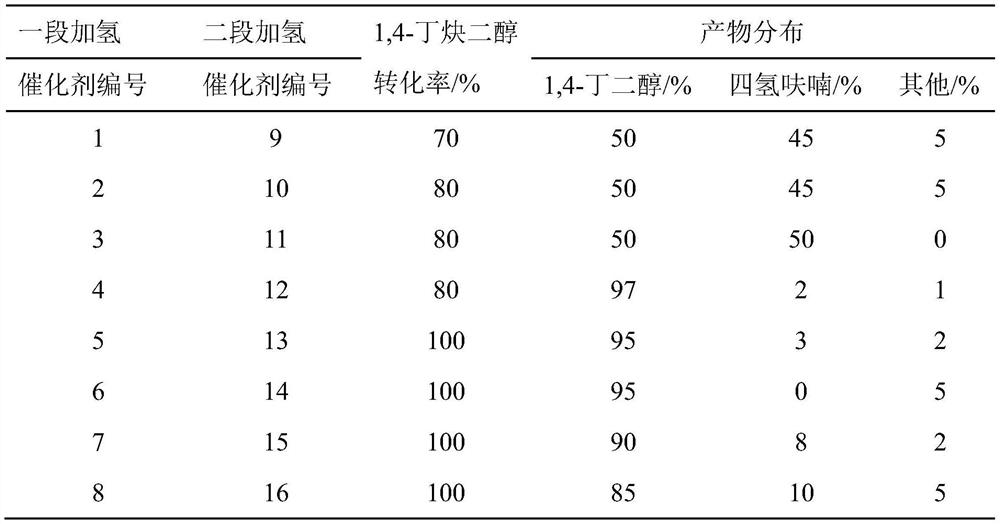

Method for synthesizing 1,4-butanediol by hydrogenating 1,4-butynediol

ActiveCN110483242AReduce distributionReduce typesOrganic compound preparationPreparation by hydrogenation1,4-ButanediolActive component

The invention discloses a method for synthesizing 1,4-butanediol through hydrogenation of 1,4-butynediol. The method comprises the following steps: 1,4-butynediol is subjected to a hydrogenation reaction in a first-stage hydrogenation reactor on a modified Ni-based catalyst, and pressure relief and separation is performed, so that a first-stage hydrogenation product is obtained, wherein the activecomponent of the modified Ni-based catalyst is Ni, and the auxiliary agent is at least one of Ru, K or Mg; then a second-stage hydrogenation reaction is carried out on the obtained first-stage hydrogenation product and a Ru-based catalyst in a second-stage hydrogenation reactor, and pressure relief and separation is performed to obtain the 1,4-butanediol, wherein the active component of the Ru-based catalyst is Ru. According to the method, the modified Ni-based catalyst and the Ru-based catalyst are combined, so that the conversion rate of the 1,4-butynediol reaches 100%, the selectivity of the 1,4-butanediol reaches 98%, and the method has the advantages of being good in catalytic activity, high in selectivity, mild in reaction condition, few in by-product variety and easy to separate.

Owner:LINGNAN NORMAL UNIV

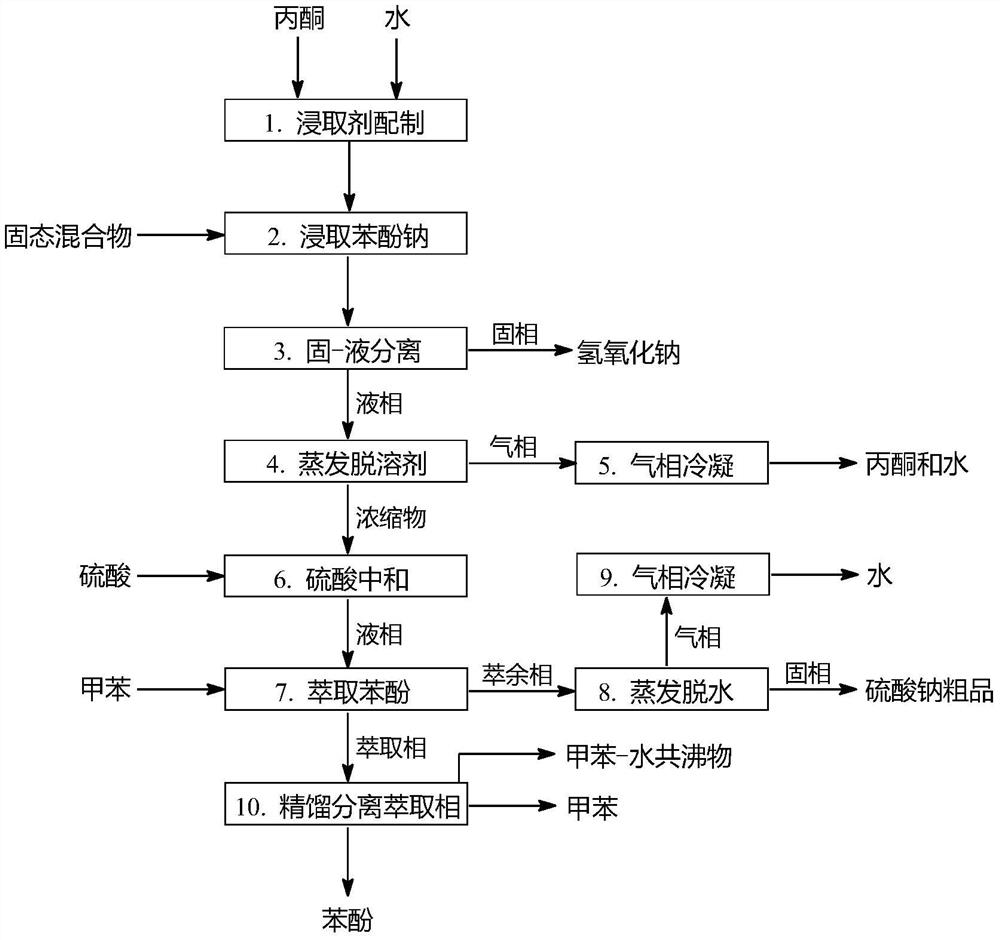

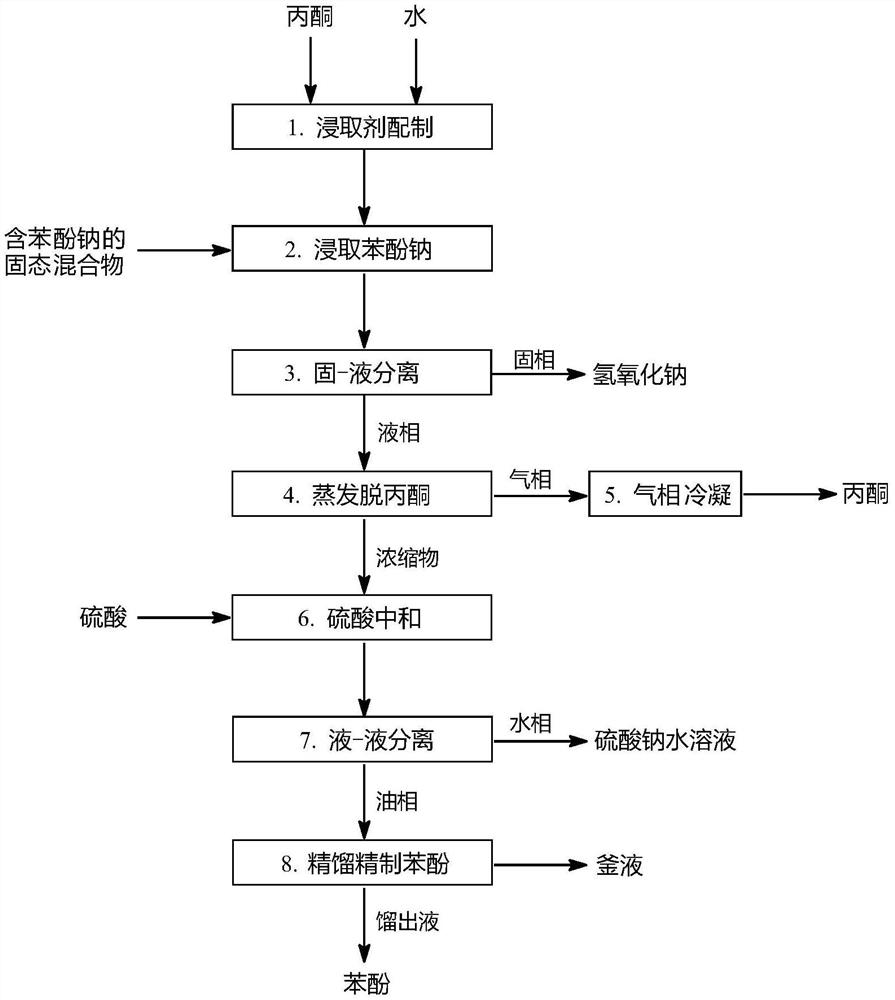

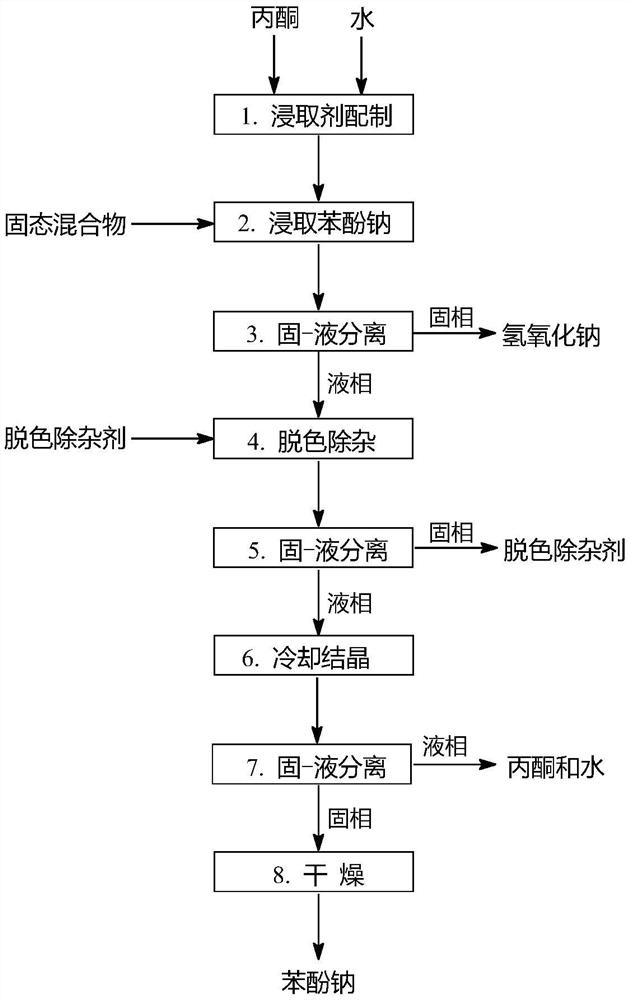

Method for separating sodium phenolate and sodium hydroxide solid mixture and recovering phenol by toluene extraction separation

ActiveCN111777495ANo lossEmission reductionOrganic chemistryOrganic compound preparationChemical industrySodium Phenolate

The invention relates to a method for separating a sodium phenolate and sodium hydroxide solid mixture and recovering phenol by toluene extraction separation. Particularly, an acetone-water mixed solvent is used as a leaching agent, methyl benzene is used as an extracting agent, a leaching-extraction-rectification coupled technology is adopted for separating and recovering phenol, and cyclic utilization of sodium hydroxide, the leaching agent and the extracting agent is achieved while phenol is obtained through separation. The separation method fully utilizes the characteristics of a separatedmaterial system and the characteristics of the separation process, is simple and feasible in separation operation, low in operation cost, high in material utilization rate, clean and environment-friendly, and is a clean production method meeting the development requirements of green chemical industry.

Owner:YANGZHOU UNIV

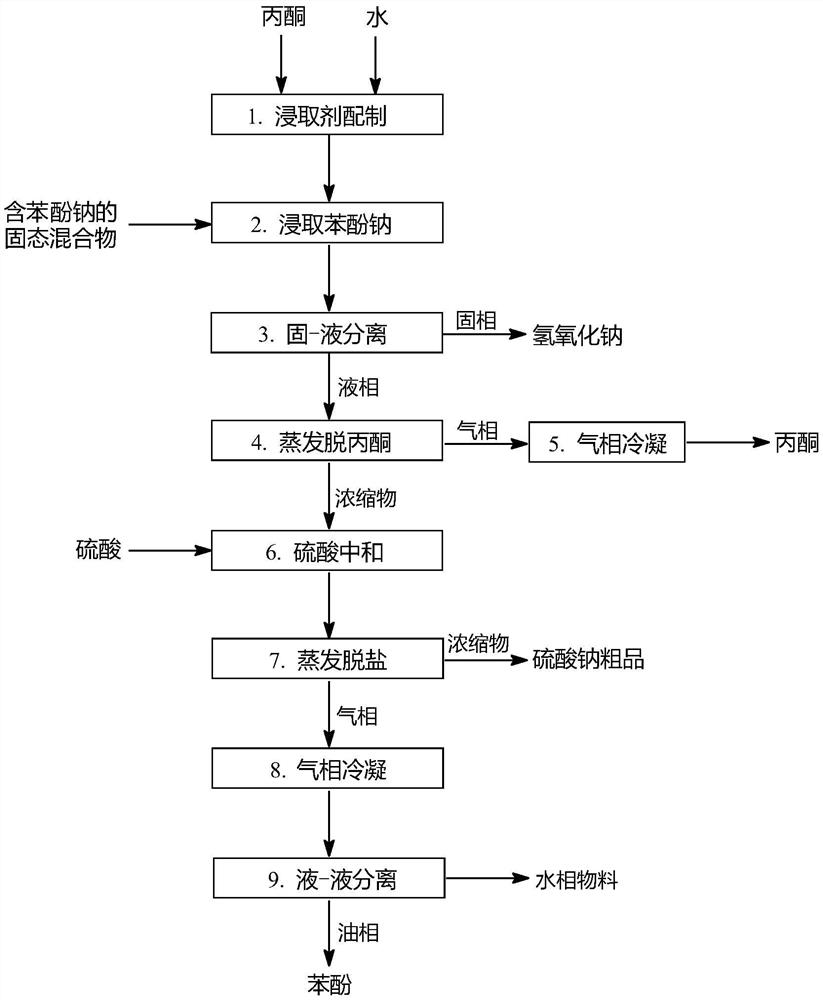

A kind of concentration process for preparing fatty alcohol ether carboxylic acid from fatty alcohol ether carboxylate

ActiveCN108658749BImprove dehydration effectDehydration process safetyPreparation from carboxylic acid saltsOrganic compound preparationChemical industryFluid phase

The invention discloses a concentration process for preparing fatty alcohol ether carboxylic acid from fatty alcohol ether carboxylate: in acidification reactor, add fatty alcohol ether carboxylate and acid prepared by oxidation method, acidification reaction occurs to generate acid form Fatty alcohol ether carboxylate, obtains the liquid phase product; In the layering equipment, the liquid phase product obtained in the previous step is left to stand for stratification, and the material that has been layered enters the next step; in the liquid-liquid separation equipment, the The material separated from the standing stratification obtained in the previous step obtains the lower aqueous phase and the upper layer material, and the upper layer material obtained after separation is concentrated to obtain the concentrated material; in the solid-liquid separation equipment, the concentrated material obtained in the previous step is subjected to solid-liquid separation. Liquid separation, the obtained solid phase material is used for recovery, and the obtained liquid phase material is once concentrated as the product. The invention not only has simple technological process and low operating cost, but also has safe and reliable process, high resource utilization and low energy consumption, and is a clean production process meeting the development requirements of green chemical industry.

Owner:SHANGHAI FINE CHEM CO LTD

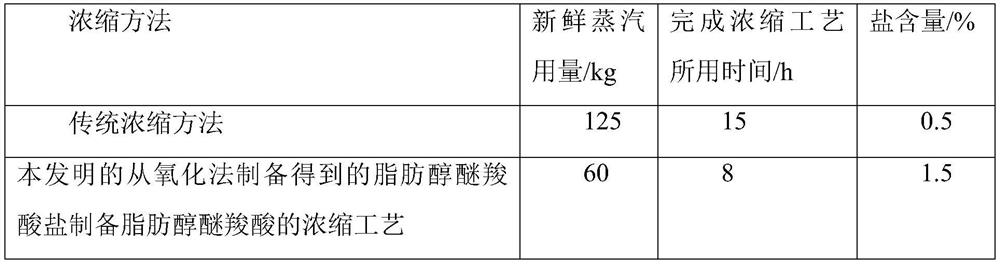

A method of leaching-evaporation-phase separation coupled separation and recovery of phenol

ActiveCN111635296BImprove solubilitySeparation is feasibleOrganic chemistryOrganic compound preparationSocial benefitsSodium Phenolate

The invention relates to a method for leaching-evaporation-phase separation coupled separation and recovery of phenol, in particular using acetone-water mixed solvent as the leaching agent to leaching and separating the solid mixture of sodium phenate and sodium hydroxide, and then evaporating, liquid-liquid Phase separation to obtain phenol, while sodium hydroxide, acetone, and water can be recycled. The separation method of the present invention makes full use of the characteristics of the separated species and the characteristics of the separation process. Not only is the separation operation simple and easy, and the operation cost is low, but also other materials can be recovered and utilized as resources while separating and obtaining phenol. The process technology not only has industrial application value, but also has significant economic and social benefits.

Owner:YANGZHOU UNIV

Preparation method of p-methylsulfonylbenzoic acid

InactiveCN103319383BReasonable workmanshipEasy to prepareOrganic chemistryOrganic compound preparationImpurityCleaner production

The invention relates to a preparation method of p-methylsulfonylbenzoic acid. The method provided by the invention mainly comprises the following steps: (1) fusing; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) neutralization for salt formation; (6) solid-liquid separation; (7) adsorption for removal of impurities; (8) solid-liquid separation; (9) acidification and crystallization; (10) solid-liquid separation; (11) washing; (12) dewatering and drying for obtaining a product p-methylsulfonylbenzoic acid; and (13) electrochemical oxidation. The preparation method provided by the invention is simple, has advantages of reasonable technology, low production cost, high product purity and safe process, is convenient to realize large-scale industrialization, and is a clean production technology which is used for preparing p-methylsulfonylbenzoic acid and accords with green chemical development requirements.

Owner:扬州德耀电气有限公司

Synthesizing method of phthaloyl-beta-alanine

The invention discloses a synthesizing method of phthaloyl-beta-alanine. In the synthesizing method, the phthaloyl-beta-alanine is prepared through grinding and microwave irradiation by taking beta-alanine and phthalic anhydride as raw materials and sodium carbonate and sodium chloride as mineralizers. The synthesizing method has the advantages of high selectivity, thorough reaction, high yield, low energy consumption, little pollution, suitability for industrial production and wide prospect.

Owner:石河子市郁茏生物科技有限公司

A method for synthesizing phenothiazine compounds

The invention develops a method for synthesizing phenothiazine compounds by using benzothiazole and derivatives thereof as well as 1-bromo-2-iodobenzene and derivatives thereof as raw materials and copper or copper salt / N-alkoxy-1H-pyrrolic amide system as a copper catalyst. The method is a brand-new method for synthesizing phenothiazine compounds. The method has the characteristics of low temperature, short reaction time, low solvent toxicity and wide substrate adaptability, and has wide application prospects in the aspect of preparation of medicines, pesticides and materials.

Owner:SUN YAT SEN UNIV

A kind of method for synthesizing 1,4-butanediol by hydrogenation of 1,4-butynediol

ActiveCN110483242BReduce distributionReduce typesOrganic compound preparationPreparation by hydrogenationPtru catalystHydrogenation reaction

The invention discloses a method for synthesizing 1,4-butanediol by hydrogenation of 1,4-butynediol. The method comprises the following steps: performing hydrogenation reaction on 1,4-butynediol in a first-stage hydrogenation reactor on a modified Ni-based catalyst, and separating under pressure to obtain a first-stage hydrogenation product; the modified Ni-based catalyst has an active group of It is divided into Ni, and the auxiliary agent is at least one of Ru, K or Mg; the obtained one-stage hydrogenation product and Ru-based catalyst are carried out in a two-stage hydrogenation reactor for a two-stage hydrogenation reaction, and pressure relief is separated to obtain 1, 4-Butanediol; the active component of Ru-based catalyst is Ru. In the present invention, the modified Ni-based catalyst and Ru-based catalyst are combined, so that the conversion rate of 1,4-butynediol reaches 100%, the selectivity of 1,4-butanediol reaches 98%, and the catalytic activity is good. , high selectivity, mild reaction conditions, less by-products, and easy separation.

Owner:LINGNAN NORMAL UNIV

Method for separating and refining phenol through leaching-phase separation-rectification coupling

ActiveCN111689839ANo lossEmission reductionOrganic chemistryOrganic compound preparationChemical industrySodium Phenolate

The invention relates to a method for leaching and separating a solid mixture of sodium phenolate and sodium hydroxide by taking an acetone-water mixed solvent as a leaching agent and separating and refining phenol through leaching-phase separation-rectification coupling, and sodium hydroxide and the leaching agent are recycled while phenol is obtained through separation and refining. The separation method provided by the invention fully utilizes the characteristics of the separated substance system and the characteristics of the separation process, is simple and feasible in separation operation, low in operation cost and high in valuable component utilization rate, and is a clean production method meeting the development requirements of green chemical industry.

Owner:YANGZHOU UNIV

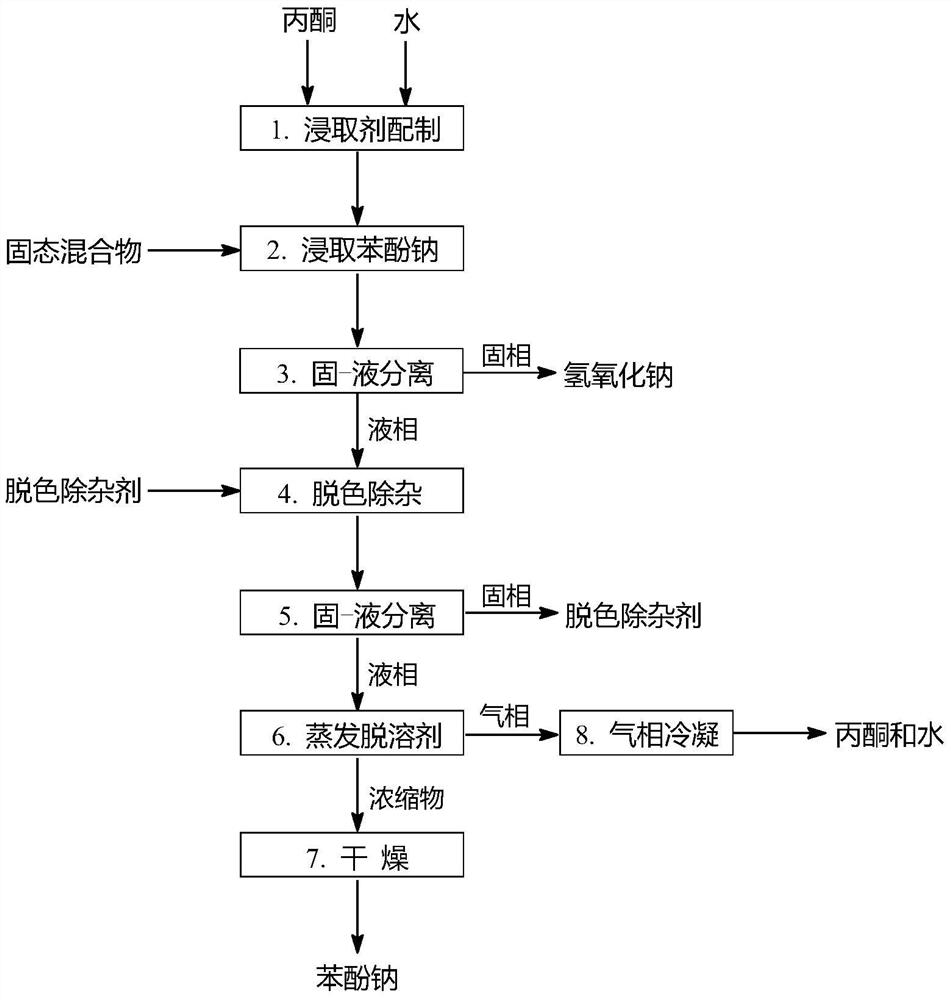

A kind of leaching separation method of sodium phenate and sodium hydroxide solid mixture

ActiveCN111777494BGo greenClean thoroughlyOrganic chemistryOrganic compound preparationChemical industrySodium Phenolate

The invention relates to a leaching and separation method for a solid mixture of sodium phenate and sodium hydroxide, in particular to a method of leaching, solid-liquid separation, and evaporation-desolvent coupling technology, using acetone-water mixed solvent as the leaching agent. In the separation method for separating the solid mixture of sodium phenate and sodium hydroxide, the leaching agent can also be recycled while the sodium phenate and sodium hydroxide are separated. The separation method of the present invention has the advantages of reasonable process, simple operation, low operation cost and high utilization rate of materials, and is a clean production method meeting the development requirements of green chemical industry.

Owner:YANGZHOU UNIV

MethyIsuIfino benzaldehyde preparation method

ActiveCN103360287BAchieve recyclingReduce pollutionOrganic chemistryOrganic compound preparationAlcoholBenzaldehyde

Owner:YANGZHOU UNIV

Preparation of glycollic acid from oxalaldehyde by intramolecular disproportionation method

ActiveCN101973870BHigh reaction yieldReduce pollutionPreparation from carboxylic acid saltsCarboxylic acid salt preparationEthylic acidBarium hydroxide

The invention relates to a preparation method of glycollic acid from oxalaldehyde by intramolecular disproportionation. The preparation method comprises the following steps of: 1) performing disproportionation on calcium hydroxide solution and aqueous solution of oxalaldehyde and preserving heat to obtain a suspended calcium hydroxyl-acetate precipitate mixture; 2) performing acidulation precipitation with sulfuric acid on the mixture to obtain glycollic acid and calcium sulfate precipitate, filtering, concentrating the filtrate until the filtrate contains no water, and then filtering again; and 3) diluting the filtrate in step 2) with water, completely removing SO4(2-) ions by adding barium acetate or barium hydroxide into the filtrate, filtering out barium sulfate precipitate and active carbon, and concentrating the filtrate to obtain the glycollic acid solution. The preparation method has the advantages of: 1) low environmental pollution; 2) no special requirement on equipment, simplicity of operation, comprehensive usage of by-products and capability of realizing clean production during disproportionation at a normal temperature and under a normal pressure; and 3) high selectivity of reaction, few product impurities and high purity. The method provides the preparation of high-purity glycollic acid crystal with convenient conditions.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

A kind of method for preparing β-carbonyl sulfone

ActiveCN110818600BImprove economySimple and fast operationSulfonyl/sulfinyl group formation/introductionOrganic compound preparationPotassium persulfatePtru catalyst

The invention discloses a method for preparing β-carbonyl sulfone. Using α-carbonyl diazonium compound and sodium aryl sulfinate as the reaction substrate, using cheap silver nitrate as the optimal catalyst, 1,10-phenanthroline as the ligand, and potassium persulfate as the oxidant, in acetonitrile and water A β-carbonyl sulfone compound is obtained through a coupling reaction in a mixed solvent. Compared with the prior art, the method of the invention has the following advantages: wide range of reaction substrates, short reaction time, relatively high reaction yield, mild reaction conditions and the like. The invention uses non-toxic and harmless reagents as reaction raw materials, has no harm to the environment, and meets the requirements of contemporary green chemistry development. The post-reaction treatment is relatively simple and convenient for separation and purification. In addition, this reaction can achieve gram-scale synthesis, laying the foundation for practical applications.

Owner:SUZHOU UNIV

Method of preparing 3-amino-2-thiocyano-alpha, beta-unsaturated compound

ActiveCN109232340AReduce usageAbundant resourcesGroup 5/15 element organic compoundsSteroidsFluoresceinSpins

The invention discloses a method of preparing a 3-amino-2-thiocyano-alpha, beta-unsaturated compound. The preparation method comprises the following steps of adding activated ketone, ammonium thiocyanate and dye fluorescein in acetonitrile as a solvent, performing driven reaction for 6-12h with visible light at the temperature of 25 DEG C, performing spin drying on reaction liquid to obtain a concentrate, and performing silica gel column chromatography on the concentrate to obtain a target compound. The method has the advantages of no use of additional oxidizing agent, low preparation cost, no toxic and side products emission and accords with the requirement for green chemical engineering development.

Owner:LANZHOU UNIVERSITY

A method for leaching-crystallization coupling separation of solid mixture of sodium phenate and sodium hydroxide

ActiveCN111792983BGo greenClean thoroughlyOrganic chemistryOrganic compound preparationChemical industrySodium Phenolate

The present invention relates to a method for leaching-crystallization coupling separation of sodium phenate and sodium hydroxide solid mixture, in particular to a method of using acetone-water mixed solvent as leaching agent, leaching-cooling crystallization coupling separation of sodium phenate and sodium hydroxide The method of the solid mixture, when the separation method separates and obtains sodium phenate and sodium hydroxide, the leaching agent is also recycled. The separation method of the present invention has the advantages of reasonable process, simple operation, low operation cost and high utilization rate of materials, and is a clean production method meeting the development requirements of green chemical industry.

Owner:YANGZHOU UNIV

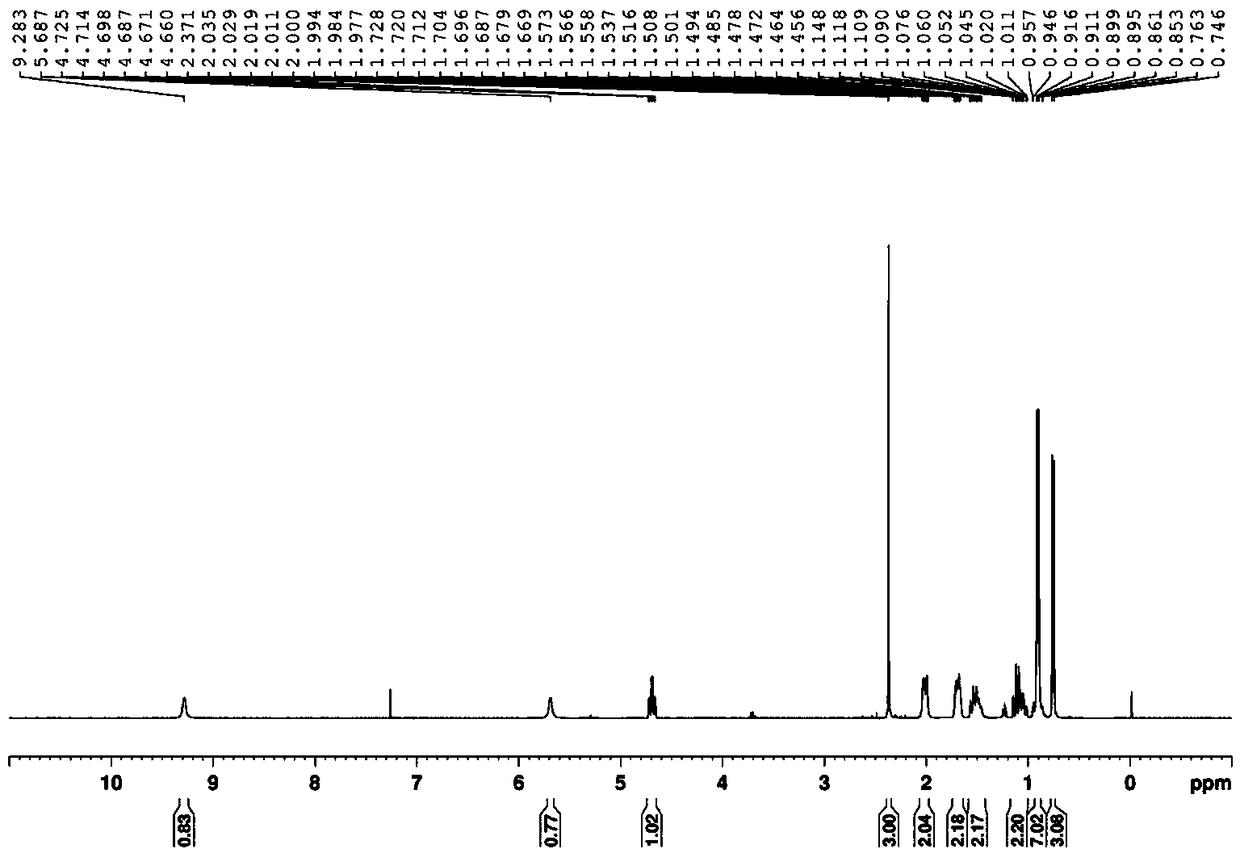

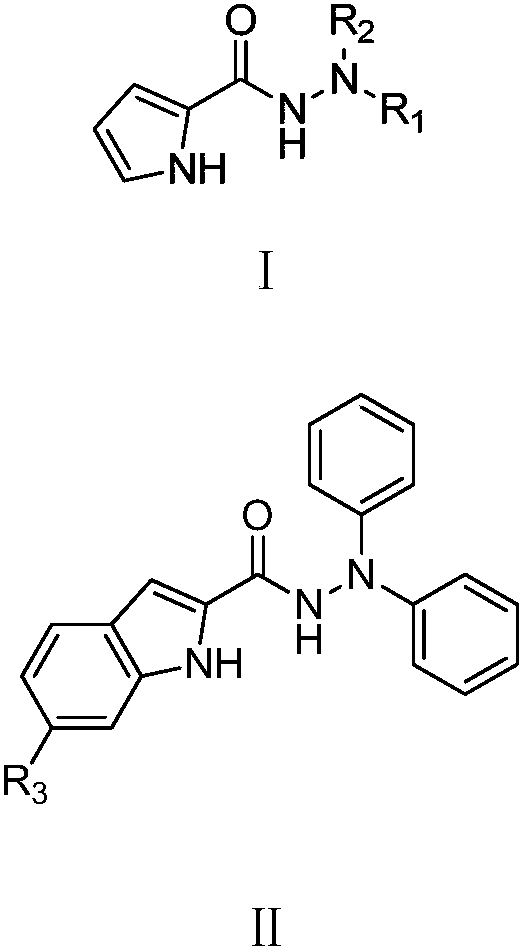

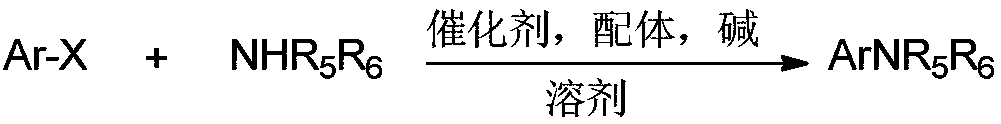

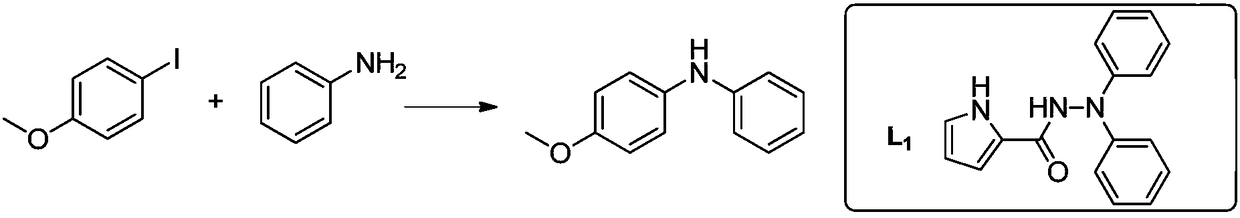

A copper-catalyzed c-n coupling method using n,n-disubstituted hydrazides as ligands

ActiveCN106883132BHigh yieldMild reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsStructural formulaSolvent

The invention discloses a copper-catalyzed C-N coupling method adopting N,N-disubstituted hydrazide as a ligand. The method comprises the steps of adopting aromatic halide and an amine compound as raw materials, adopting an alcohol compound as a solvent, adopting copper or a copper compound as a catalyst, adopting the N,N-disubstituted hydrazide with a structural formula as shown in a formula I or a formula II as the ligand, and under the existence of alkali, carrying out C-N coupling reaction at the temperature of 10 to 130 DEG C so as to generate an N-aryl compound. The copper-catalyzed C-N coupling method provided by the invention is mild in reaction conditions, high in chemoselectivity, wide in substrate application range, and simple to operate; a product is simple, easy to separate, green and environment-friendly; and the product yield is higher. According to the figure, R1 and R2 are selected from methyl, phenyl, 4-methoxyphenyl, 4-nitrobenzophenone, 2-methylphenyl, 2-isopropyl phenyl; R3 is hydrogen or methoxyl.

Owner:SUN YAT SEN UNIV

A method for synthesizing aromatic primary amines in a circulating aqueous phase system

ActiveCN103739417BImprove friendlinessEasy to separate and purifyOrganic compound preparationCarboxylic acid amides preparationAlkaline earth metalSynthesis methods

The invention discloses a method for synthesizing an aromatic primary amine in a circulating water phase system. According to the method, an aryl halide and ammonia water are taken as raw materials, water is taken as a solvent, a carbonate, a fluoride, a phosphate or a hydroxide of an alkali metal or an alkaline-earth metal or a compound which can be converted to a corresponding alkali in water is taken as the alkali, polyamine carboxylic acid and a salt type compound thereof are taken as ligands, and a copper source catalyst is adopted for catalyzing the formation of the aromatic primary amine from the aryl halide and the ammonia water. According to the method disclosed by the invention, the water is used as the solvent, any phase transfer of the catalyst is not required, and the catalyst, the ligands and the reaction solvent, namely the water, can be recycled, so that the environment-friendly property of reaction is effectively improved, the method is more in line with requirements of green chemical development, a substrate particularly has a wide range of applications, and the method further has broad prospects in the aspects of preparation of natural products, medicaments and pesticides.

Owner:SUN YAT SEN UNIV

Preparation method for silicofluoride-contained polyurethane water repellent finishing agent

The invention provides a preparation method for silicofluoride-contained polyurethane water repellent finishing agent, which is characterized in that the preparation method comprises the following specific steps that isocyanate and alcohol with fluoride are dissolved in a solvent, and the isocyanate and the alcohol with fluoride are mixed for reaction under protection of nitrogen; prepolymer R1 is obtained by adding at least one of polyether diol and polyester diol with a catalyst into the reaction system of the first step; organic oxosilane is dissolved in the solvent, the catalyst is added for obtaining organic oxosilane solution, and prepolymer R2 is obtained by adding the organic oxosilane solution into the prepolymer R1 which is obtained from the second step in a dropping way; and diol or diamine is used as chain extender to be added into the prepolymer R2 which is obtained from the third step, finally, small-molecule alcohol is added and mixed with isocyanate remained in the reaction system to be carried out reaction and end capping, and silicofluoride-contained polyurethane is obtained. The silicofluoride-contained polyurethane provided by the invention can be used as fabric finishing agent, leather coating agent, self-cleaning paint additive and the like, and has the advantages of remarkable finishing properties of water and oil repelling.

Owner:DONGHUA UNIV

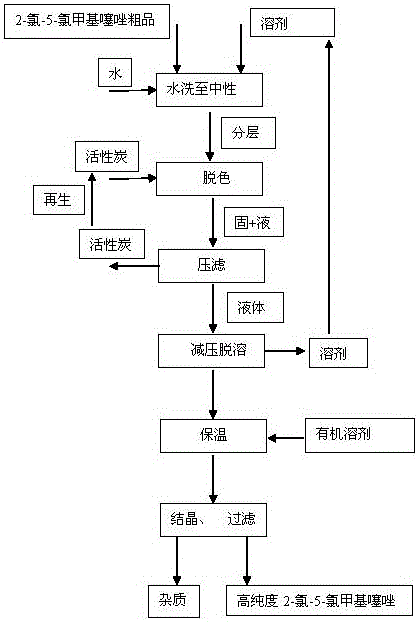

A kind of separation and purification method of 2-chloro-5-chloromethylthiazole

ActiveCN103755661BLow melting pointReduce energy consumptionOrganic chemistryChemical industryPurification methods

The invention relates to a separating and refining method of 2-chloro-5-chloromethylthiazole. High-purity 2-chloro-5-chloromethylthiazole is prepared through a crystallization method by taking crude 2-chloro-5-chloromethylthiazole as a raw material. The method comprises the following steps: (1) washing with water; (2) performing adsorbing and color-removing; (3) performing pressure filtration; (4) desolventizing; (5) adding an organic solvent; (6) crystallizing with a crystallization device, heating and melting; collecting to obtain high-purity 2-chloro-5-chloromethylthiazole. High-purity 2-chloro-5-chloromethylthiazole is prepared through the crystallization method of the self-made crystallization device according to the characteristics of low melting point of 2-chloro-5-chloromethylthiazole and high melting point of impurities. The separating method is simple, the production purity is high, the quality is stable, the energy consumption is low, the three-waste output is low, and the green chemical industry development requirements are met.

Owner:SHANDONG ACADEMY OF PESTICIDE SCI +1

Spinning glue preparation method for dissolving animal hair and vinylon by ionic liquid

PendingCN114737273AGreen dissolveEffective dissolutionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention relates to a spinning glue-making method by dissolving animal hair and vinylon with an ionic liquid, which comprises the following steps: cleaning the animal hair with water, soaking with ethanol or acetone to degrease for 1-12 hours, drying at 60-90 DEG C, crushing into fine powder by a crusher, adding the treated animal hair and polyvinyl butyral into a container filled with the ionic liquid, and uniformly stirring to obtain the spinning glue-making method. The preparation method comprises the following steps: dissolving keratin in an oil bath at 120 DEG C until a transparent glue solution is formed to obtain a keratin solution, and then defoaming the keratin solution in a vacuum environment of-0.95 MPa to obtain a spinning glue solution after vacuum defoaming; according to the method, keratin and vinylon can be dissolved in a green and efficient mode, degradation of the keratin is controlled to obtain regenerated keratin with large molecular weight, the strength of keratin spinning is greatly improved, keratin molecules are made into filaments independently, the application range of the keratin spinning is widened, meanwhile, pollution to the environment is avoided, and the method is suitable for industrial production. The requirements of modern green chemical development are met.

Owner:LUOYANG CHANGLONG CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com