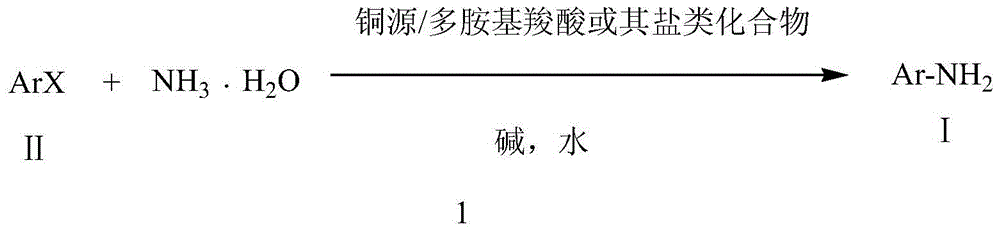

A method for synthesizing aromatic primary amines in a circulating aqueous phase system

A technology of aromatic primary amines and circulating water, applied in the chemical field, can solve problems such as non-circularity, and achieve the effects of improving environmental friendliness, process economy, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the synthesis of 4-methoxyaniline

[0027] 187mg (1mmol) 4-bromoanisole, 1mL ammonia water (25-28%, 13.3mmol), 8mg (0.1mmol) CuO, 58mg (0.2mmol) EDTA, 112mg (2mmol) KOH, 1mL H 2 Add O into a 10mL reaction tube, seal it, and react at 100°C for 12h. After the reaction stopped, extracted with ethyl acetate, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 98 mg of 4-methoxyaniline, with a yield of 80% .

[0028] 1 H NMR (300MHz, CDCl 3 )δ6.75(d,J=7.8Hz,2H),6.65(d,J=8.2Hz,2H),3.75(s,3H),3.37(brs,2H). 13 C NMR (75MHz, CDCl 3 )δ: 153.0, 140.2, 116.6, 115.1, 56.1. ESI-MS: m / z=124[M+H] + .

Embodiment 2

[0029] Embodiment 2: the synthesis of p-nitroaniline

[0030] 202mg (1mmol) 4-nitrobromobenzene, 1mL ammonia water (25-28%, 13.3mmol), 6mg (0.1mmol) Cu, 79mg (0.2mmol) diethylenetriaminepentaacetic acid, 80mg (2mmol) NaOH, 1mL h 2 Add O into a 10mL reaction tube, seal it, and react at 100°C for 2h. After the reaction stopped, it was extracted with ethyl acetate, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 60 mg of 4-methoxyaniline, with a yield of 44%. .

[0031] 1 H NMR (300MHz, DMSO) δ8.05(d, J=8.9Hz, 2H), 6.62(d, J=8.9Hz, 2H), 4.39(s, 2H). 13 CNMR (75MHz, CDCl 3 )δ: 156.3, 136.3, 127.0, 113.0.MS (EI + ):m / z=138[M + ].

Embodiment 3

[0032] Embodiment 3: the synthesis of 4-methylaniline

[0033] 170mg (1mmol) 4-bromotoluene, 1mL ammonia water (25-28%, 13.3mmol), 28mg (0.2mmol) Cu 2 O, 67 mg (0.2 mmol) EDTA disodium salt, 112 mg (2 mmol) KOH, 1 mL H 2 Add O into a 10mL reaction tube, seal it, and react at 130°C for 12h. After the reaction stopped, it was extracted with ethyl acetate, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 80 mg of 4-methylaniline with a yield of 80%.

[0034] 282mg (1mmol) 4-iodotoluene, 1mL ammonia water (25-28%, 13.3mmol), 8mg (0.1mmol) CuO, 79mg (0.2mmol) diethylenetriaminepentaacetic acid, 112mg (2mmol) KOH, 1mL H 2 Add O into a 10mL reaction tube, seal it, and react at 100°C for 6h. After the reaction stopped, it was extracted with ethyl acetate, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com