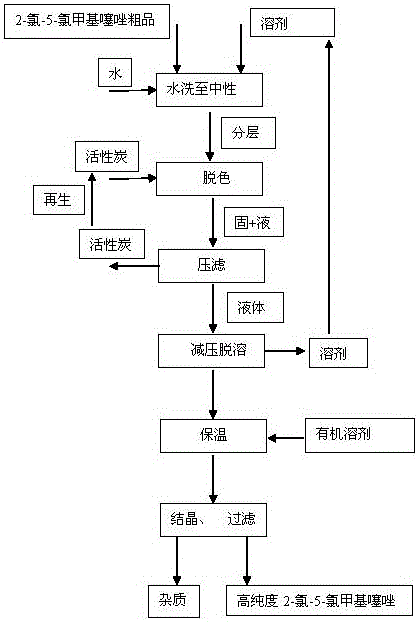

A kind of separation and purification method of 2-chloro-5-chloromethylthiazole

A technology of chloromethylthiazole and a purification method, applied in the direction of organic chemistry and the like, can solve the problems of high difficulty and high cost of dilute acid recovery and treatment, and achieve the effects of small amount of three wastes, stable quality and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

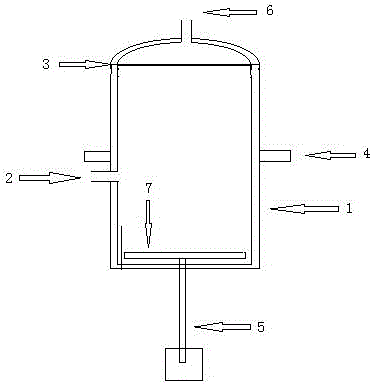

[0043] (1) Washing: In a washing kettle, dissolve 400kg of crude 2-chloro-5-chloromethylthiazole in 300kg of dichloroethane, add 900kg of water in batches for washing, and the pH value of the organic phase of washing is 6~ 7. After washing with water, separate the lower organic phase;

[0044] (2) Adsorption and color removal: Add 50kg of activated carbon to the material obtained in step (1), and stir at 40°C for 3 hours until the color of the mother liquor changes from dark yellow to light yellow;

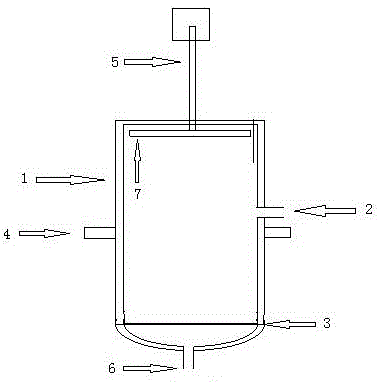

[0045] (3) Pressure filtration: transfer the material obtained in step (2) to a pressure filter kettle for pressure filtration, and the light yellow material obtained by pressure filtration enters the collection tank;

[0046](4) Precipitation: Transfer the material in the collection tank of step (3) to the precipitator, and distill dichloroethane at 50-60°C under a pressure of -0.06 to -0.07 bar to obtain dichloroethane It can be directly applied to step (1) as a dissolving solv...

Embodiment 2

[0050] (1) Washing: In a washing kettle, dissolve 400kg of crude 2-chloro-5-chloromethylthiazole in 150kg of toluene, add 900kg of water in batches for washing, the pH value of the organic phase of washing is 6-7, wash with water After completion, separate the lower organic phase;

[0051] (2) Adsorption and color removal: Add 25kg of macroporous adsorption resin to the material obtained in step (1), and stir at 35°C for 3 hours until the color of the mother liquor changes from dark yellow to light yellow;

[0052] (3) Pressure filtration: transfer the material obtained in step (2) to a pressure filter kettle for pressure filtration, and the light yellow material obtained by pressure filtration enters the collection tank;

[0053] (4) Desolventization: Transfer the material in the collection tank of step (3) to the desolventization kettle, and distill the toluene at 65-75°C under the pressure of -0.08 to -0.095 bar, and the obtained toluene can be directly applied to the step ...

Embodiment 3

[0057] (1) Washing: In a washing kettle, dissolve 400kg of crude 2-chloro-5-chloromethylthiazole in 150kg of toluene, add 900kg of water in batches for washing, the pH value of the organic phase of washing is 6-7, wash with water After completion, separate the lower organic phase;

[0058] (2) Adsorption and color removal: add 30kg of activated carbon to the material obtained in step (1), and stir at 45°C for 3 hours until the color of the mother liquor changes from dark yellow to light yellow;

[0059] (3) Pressure filtration: transfer the material obtained in step (2) to a pressure filter kettle for pressure filtration, and the light yellow material obtained by pressure filtration enters the collection tank;

[0060] (4) Desolventization: Transfer the material in the collection tank of step (3) to the desolventization kettle, and distill the toluene at 65-75°C under the pressure of -0.08 to -0.095 bar, and the obtained toluene can be directly applied to the step ( 1) As a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com