Preparation method of p-methylsulfonylbenzoic acid

A technology of methylsulfonyl benzoic acid and p-methylsulfonyl benzoic acid is applied in the field of preparation of p-methylsulfonyl benzoic acid, and can solve the problems of low selectivity, low conversion rate and yield, difficult control of reaction degree, difficulty in separation and purification, and the like, To achieve the effect of simple preparation method, convenient large-scale industrialization and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Main process equipment: stirred tank reactor, flat plate electrochemical reactor, sedimentation solid-liquid separator, melting equipment, preheating equipment, washing equipment, crystallization equipment, drying equipment, etc.

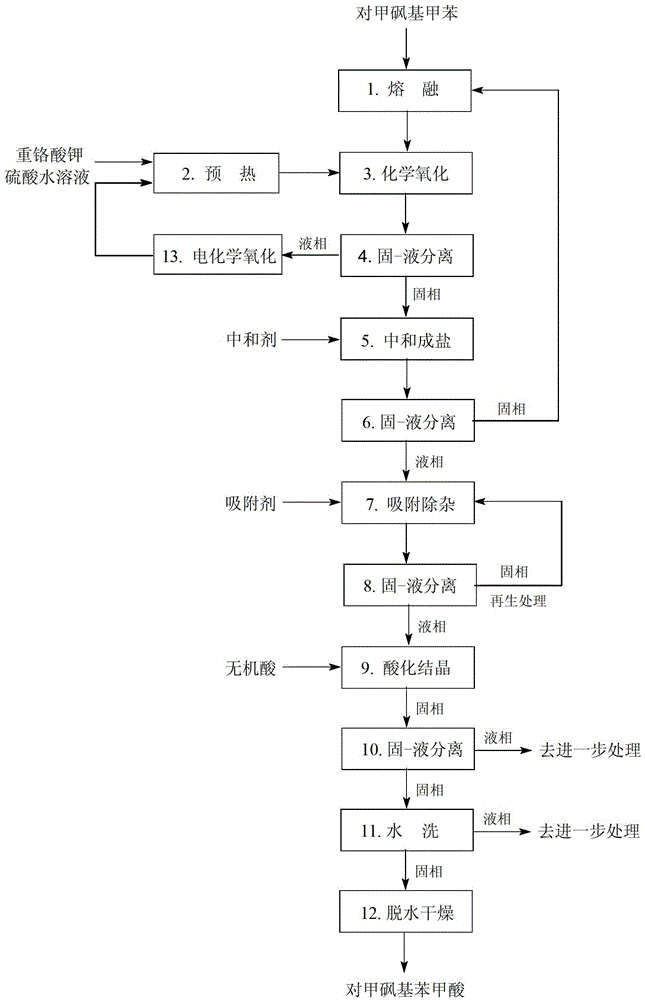

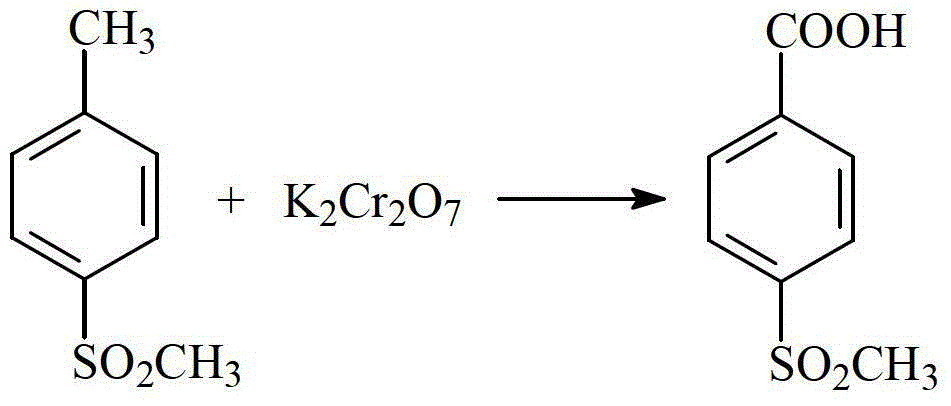

[0051] Such as figure 1 Shown, a kind of preparation method of thiamphenicol benzoic acid is to carry out selective oxidation to prepare the method for thiamphenicol benzoic acid with p-thiamphenicol toluene as raw material, and its steps are as follows:

[0052] (1) Melting: in a stirred tank, p-thiamphenicol toluene is heated up to 90° C., and the p-thiamphenicol toluene that is solid at room temperature is melted into a liquid material;

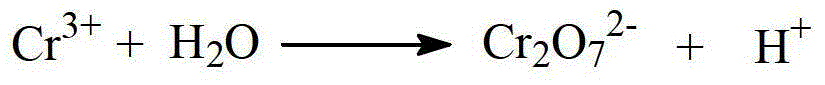

[0053] (2) Preheating: In the stirred tank, add sulfuric acid aqueous solution and oxidant potassium dichromate, heat up to 90°C, the concentration of potassium dichromate in the system is 0.5mol / L, the concentration of sulfuric acid is 0.1mol / L, The system is in a liquid state when the material is mixed...

Embodiment 2

[0066] Main process equipment: static mixing reactor, three-dimensional electrochemical reactor, filter solid-liquid separator, melting equipment, preheating equipment, washing equipment, crystallization equipment, drying equipment, etc.

[0067] Proceed as follows:

[0068] (1) Melting: In the falling film melting equipment, p-thiamphenicol is heated up to 150° C., so that the solid p-thiamphenicol at room temperature is melted into a liquid material;

[0069] (2) Preheating: In the stirred tank, add sulfuric acid aqueous solution and oxidant potassium dichromate, heat up to 120°C, the concentration of potassium dichromate in the system is 3.0mol / L, the concentration of sulfuric acid is 8.0mol / L, The system is in a liquid state when the material is mixed with the raw material p-thiamphenicol by heating the temperature;

[0070] (3) Chemical oxidation: In the static mixing reactor, the sulfuric acid aqueous solution of potassium dichromate preheated in the previous step is mi...

Embodiment 3

[0082] Main process equipment: static mixing reactor, flat plate electrochemical reactor, centrifugal solid-liquid separator, melting equipment, preheating equipment, washing equipment, crystallization equipment, drying equipment, etc.

[0083] Proceed as follows:

[0084] (1) Melting: in a stirred tank, p-thiamphenicol toluene is heated up to 120° C., and the p-thiamphenicol toluene that is solid at room temperature is melted into a liquid material;

[0085] (2) Preheating: In the stirred tank, add sulfuric acid aqueous solution and oxidant potassium dichromate, heat up to 100°C, the concentration of potassium dichromate in the system is 2.0mol / L, the concentration of sulfuric acid is 4.0mol / L, The system is in a liquid state when the material is mixed with the raw material p-thiamphenicol by heating the temperature;

[0086] (3) Chemical oxidation: In the static mixing reactor, the sulfuric acid aqueous solution of potassium dichromate preheated in the previous step is mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com