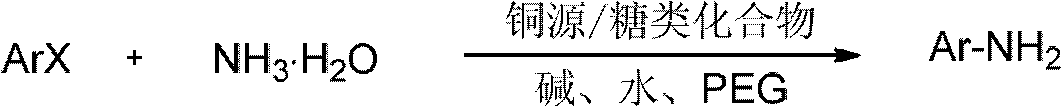

Green water-phase synthesis method of primary arylamine

A green technology for aromatic primary amines, applied in the field of color-water phase synthesis of aromatic primary amines, can solve environmental pollution and other problems, achieve simple operation, solve pollution problems, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the synthesis of 4-methoxyaniline

[0023] 187mg (1mmol) 4-bromoanisole, 150uL (2mmol) ammonia water, 25mg (0.1mmol) CuSO 4 ·5H 2 O, 90mg (0.5mmol) fructose, 138mg (1mmol) K 2 CO 3 , 1.5g PEG-400, 1mL H 2 Add O into a 10mL reaction tube, seal it, and react at 110°C for 8h. After the reaction stopped, extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 98 mg of 4-methoxyaniline, the yield 80%.

[0024] 234mg (1mmol) 4-iodoanisole, 650uL (8mmol) ammonia water, 6.4mg (0.1mmol) Cu, 171mg starch, 138mg (1mmol) K 2 CO 3 , 1g PEG-300, 1mL H 2Add O into a 10mL reaction tube, seal it, and react at 90°C for 10h. After the reaction stopped, extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, the f...

Embodiment 2

[0027] Embodiment 2: the synthesis of 4-methylaniline

[0028] 171mg (1mmol) 4-bromotoluene, 950uL (12mmol) ammonia water, 16mg (0.2mmol) CuO, 144mg (0.8mmol) glucose, 28mg (0.5mmol) KOH, 1g PEG-300, 1mL H 2 O was added to a 10mL reaction tube, sealed, and reacted at 90°C for 18h. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 80 mg of 4-methylaniline with a yield of 75 %.

[0029] With 218mg (1mmol) 4-iodotoluene, 1500uL (20mmol) ammonia water, 28.6mg (0.2mmol) Cu 2 O, 144mg (0.8mmol) fructose, 28mg (0.5mmol) KOH, 1g PEG-200, 1.5mL H 2 O was added to a 10mL reaction tube, sealed, and reacted at 80°C for 15h. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous...

Embodiment 3

[0031] Embodiment 3: the synthesis of 4-ethylaniline

[0032] With 185mg (1mmol) 4-bromoethylbenzene, 400uL (5mmol) ammonia water, 12mg (0.05mmol) Cu(NO 3 ) 2 ·3H 2 O, 103mg (0.3mmol) sucrose, 978mg (3mmol) Cs 2 CO 3 , 1.5g PEG-1000, 0.5mL H 2 Add O into a 10mL reaction tube, seal it, and react at 130°C for 14h. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography to obtain 60 mg of 4-ethylaniline with a yield of 50 %.

[0033] MS (ESI + ): m / z: 122 ([M+H] + ); 1 H NMR (300MHz, CDCl 3 )δ7.09-7.01(m, 2H), 6.71-6.64(m, 2H), 3.55(brs, 2H), 2.61(q, J=7.6Hz, 2H), 1.27(t, J=7.6Hz, 3H ). 13 C NMR (75MHz, CDCl 3 )δ144.3, 134.6, 128.8, 115.5, 28.4, 16.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com