Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Meet scientific research" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

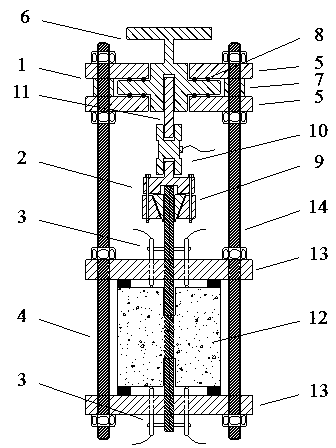

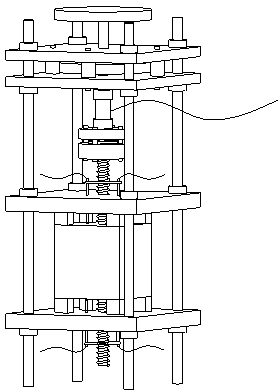

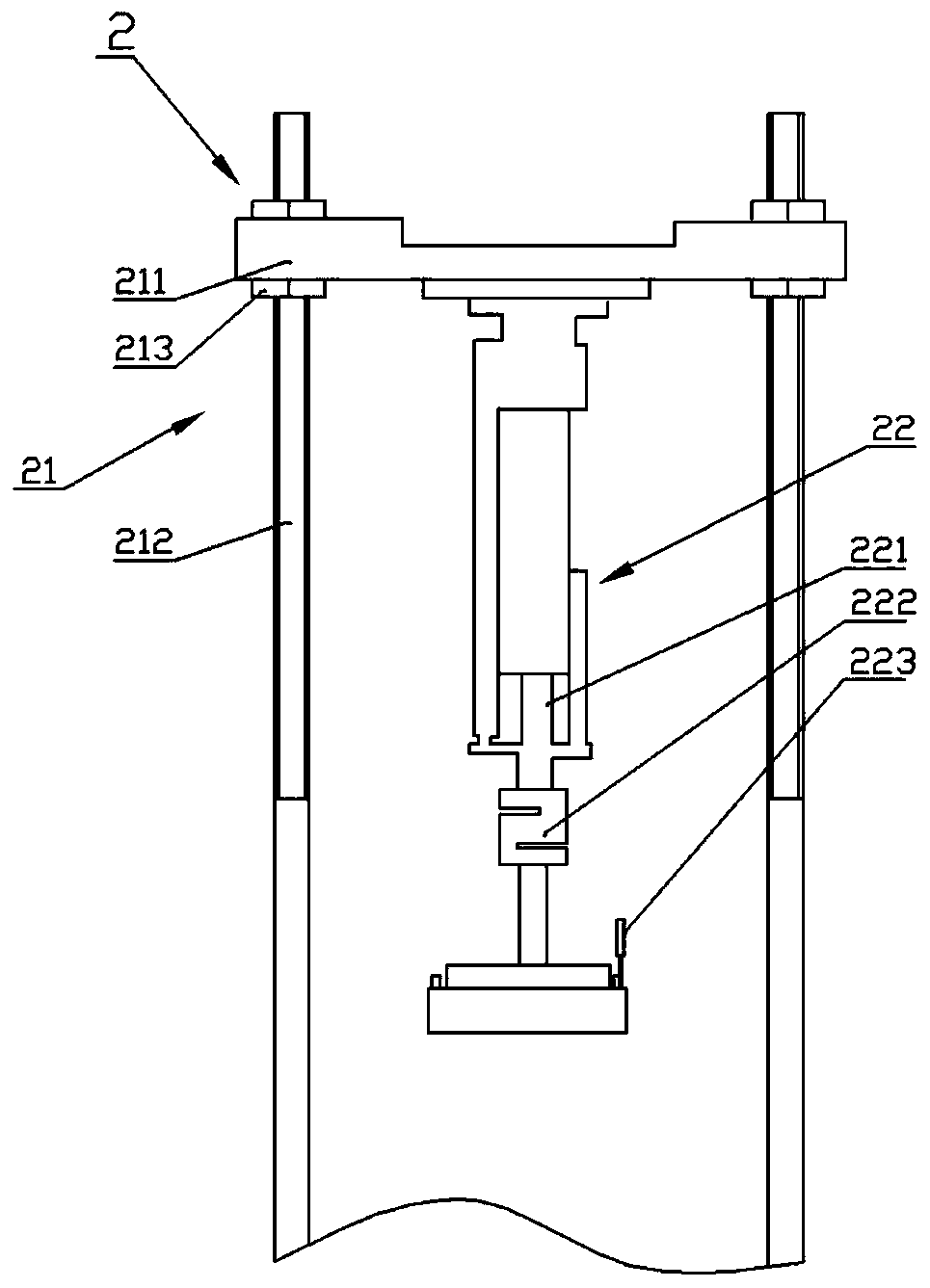

Multifunctional portable bonding anchorage performance detection device

ActiveCN103837471AClear principleSimple structureUsing mechanical meansMaterial analysisClassical mechanicsField tests

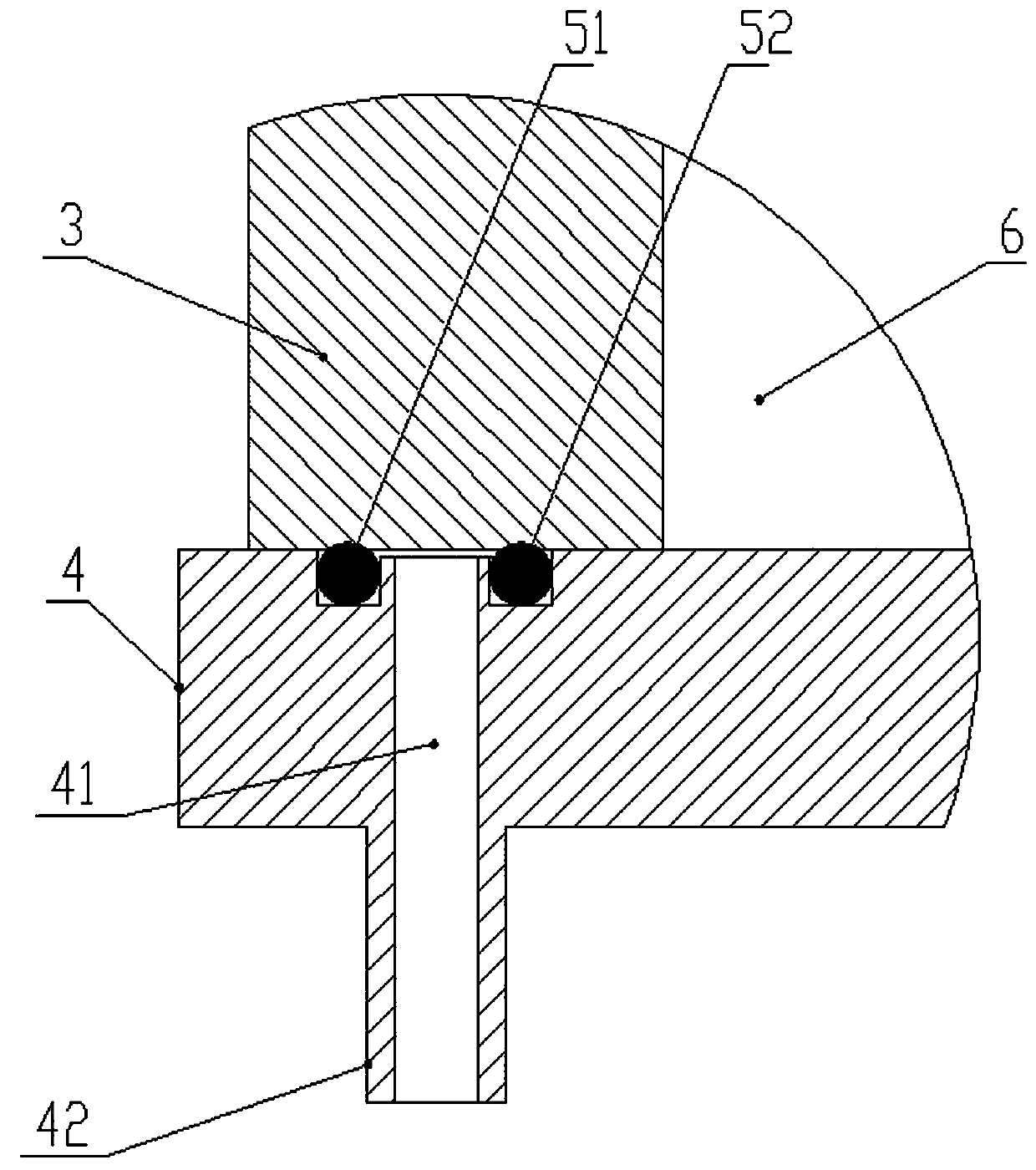

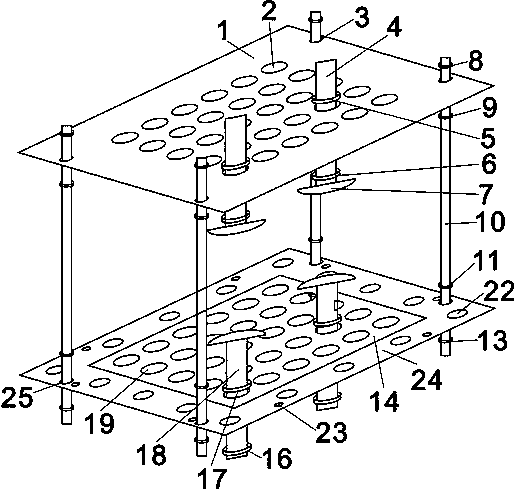

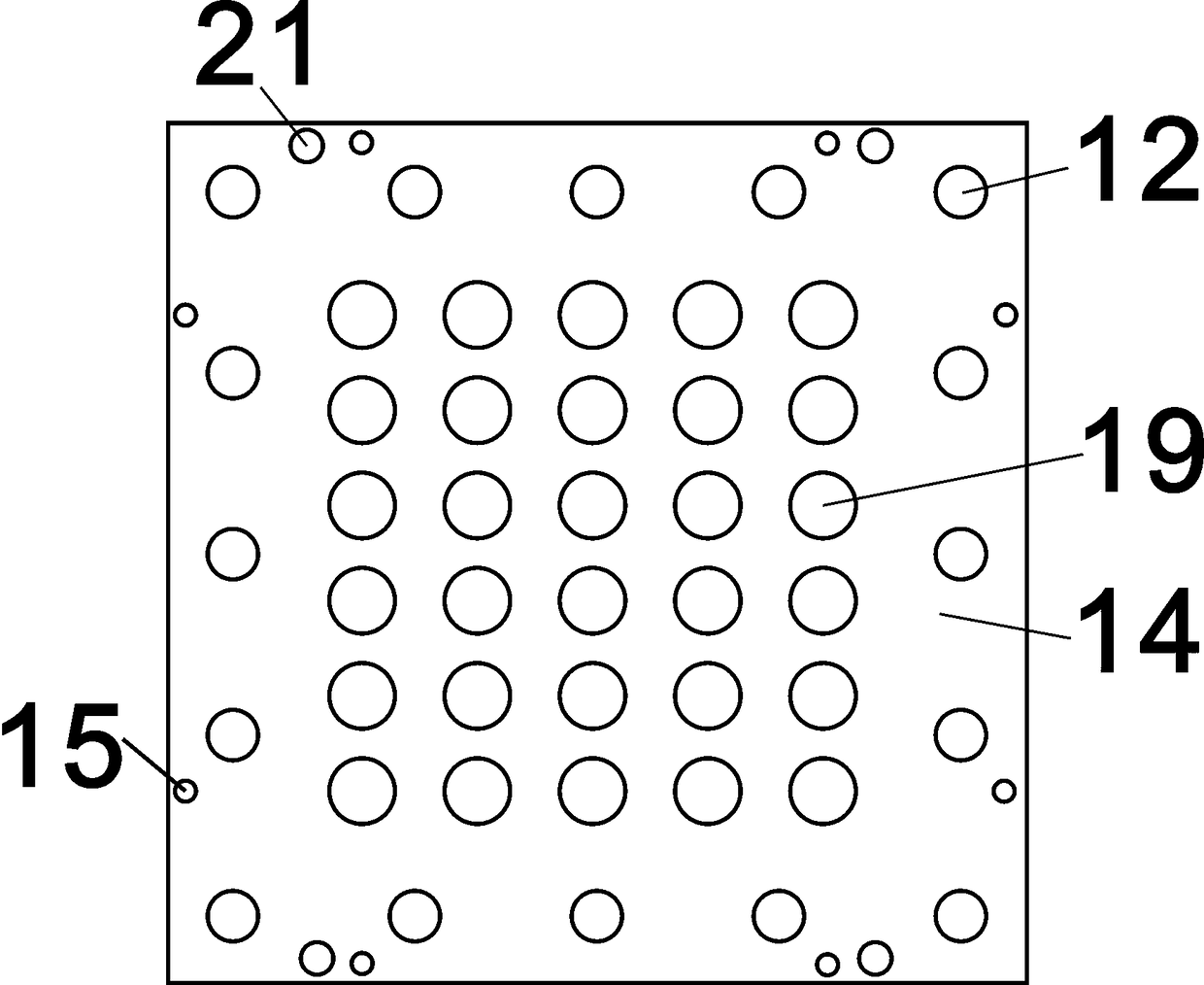

The invention discloses a multifunctional portable bonding anchorage performance detection device which comprises an assembled rotary table, a clamp piece type assembled anchorage device, a displacement sensor, a frame assembly and four through steel threaded rods, wherein the upper ends of the steel threaded rods are connected with the assembled rotary table, and the lower ends of the steel threaded rods are connected with the frame assembly; the clamp piece type assembled anchorage device is arranged between the assembled rotary table and a part to be tested, the lower end of the clamp piece type assembled anchorage device is closely connected with the end of the part to be tested, and the upper end of the clamp piece type assembled anchorage device is closely connected with the assembled rotary table; one end of the displacement sensor is fixed on rib material of the part to be tested, and the other end of the displacement sensor passes through the frame assembly and is contacted with the part to be tested. The multifunctional portable bonding anchorage performance detection device is simple in structure, easy to be assembled and convenient to carry, can be used for detecting the bonding anchorage performance of a reinforcing steel bar (or a complex fiber rib) between monotonic load, repeated load or especially low frequency cyclic load and concrete substrate, and has the detection ways including center tensile compression, eccentric tensile compression, two-end relative tensile compression and the like, thus meeting the demands of scientific research or field test.

Owner:WUHAN UNIV

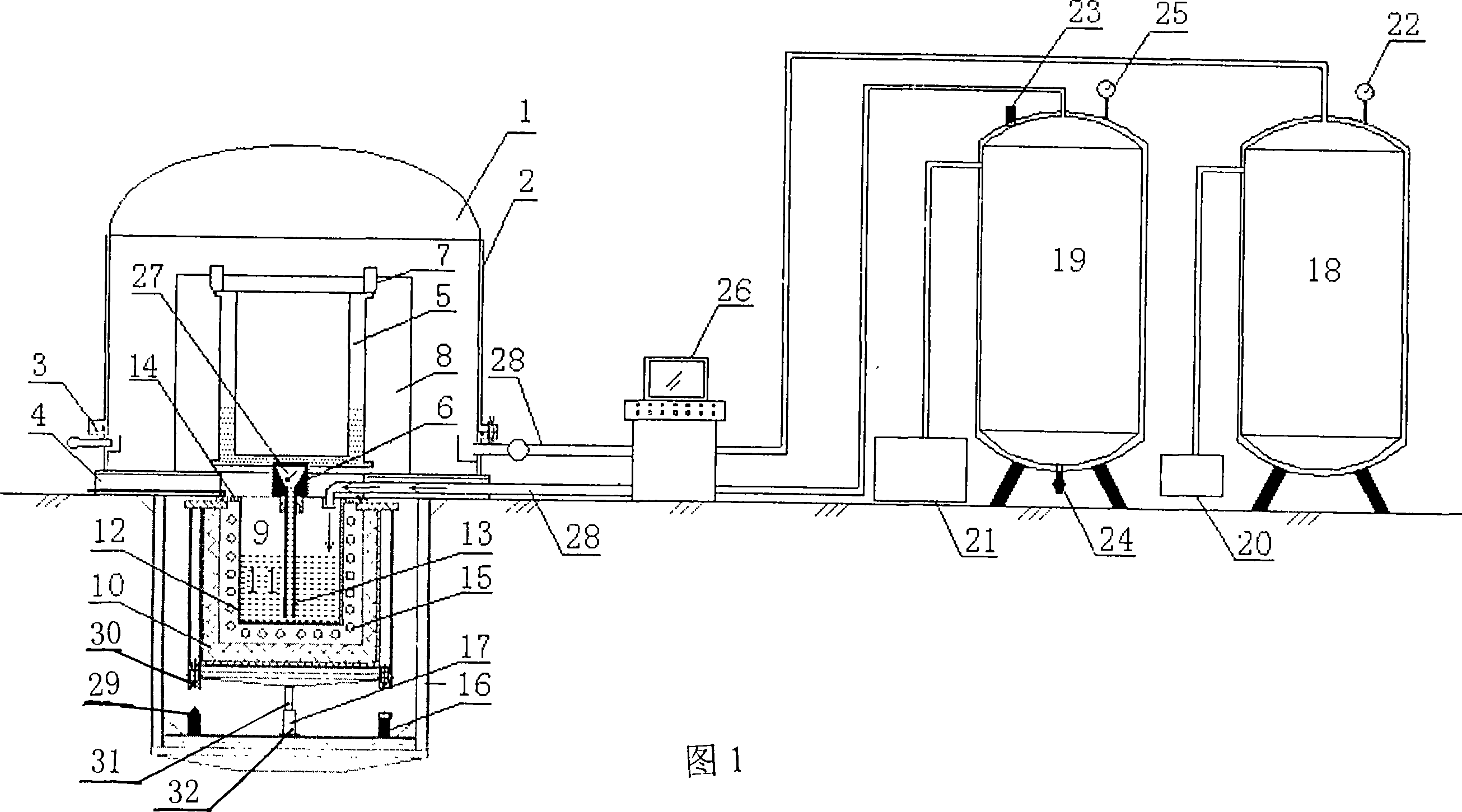

Vacuum differential pressure pressurization casting method and device

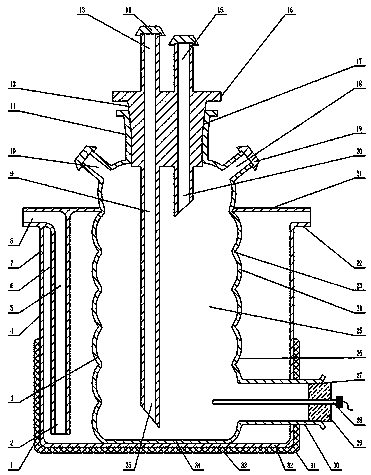

The invention provides a supercharging casting method with vacuum difference pressure, which comprises that (1) a mould after being mold-matched, located and mounted is arranged on an upper-deck cabin, (2) a lower-deck cabin filled with molten metal and the upper-deck cabin are in butt joint, the pouring channel mouth and throat on the bottom of the upper-deck cabin mould aligns the upper mouth of a water raising pipe of the lower-deck cabin and seal the edge, thereby leading the upper-deck cabin and the lower-deck cabin to form a passage via the pouring channel mouth, throat and the water raising pipe, (3) the upper-deck cabin and the lower-deck cabin are evacuated and simultaneously the sub-atmospheric pressure balance of the two cabins are kept, (4) a vacuum valve is closed and the vacuum-pumping is stopped, (5) an air inlet valve of the lower-deck cabin is opened and the pressure which step by step leads the two cabins to produce pressure difference which forces the molten metal of the lower-deck cabin to lift to the upper-deck cabin is increased, then the air inlet valve of the lower-deck cabin is closed, (6) the throat is closed, and an air inlet valve of the upper-deck cabin is opened and the pressure starts being added to the upper-deck cabin, keeping for 5 to 15 minutes after the pressure reached 0.2 to 2 Pa until the molten metal of the upper-deck cabin is all solidified. The invention further provides a supercharging casting device with vacuum difference pressure. The invention is capable of improving compactness degree and quality of the casting products, effectively produces 'flawless casting products', and effectively and reliably meets the requirement of scientific researches, military and high-quality casting products.

Owner:李泽奇

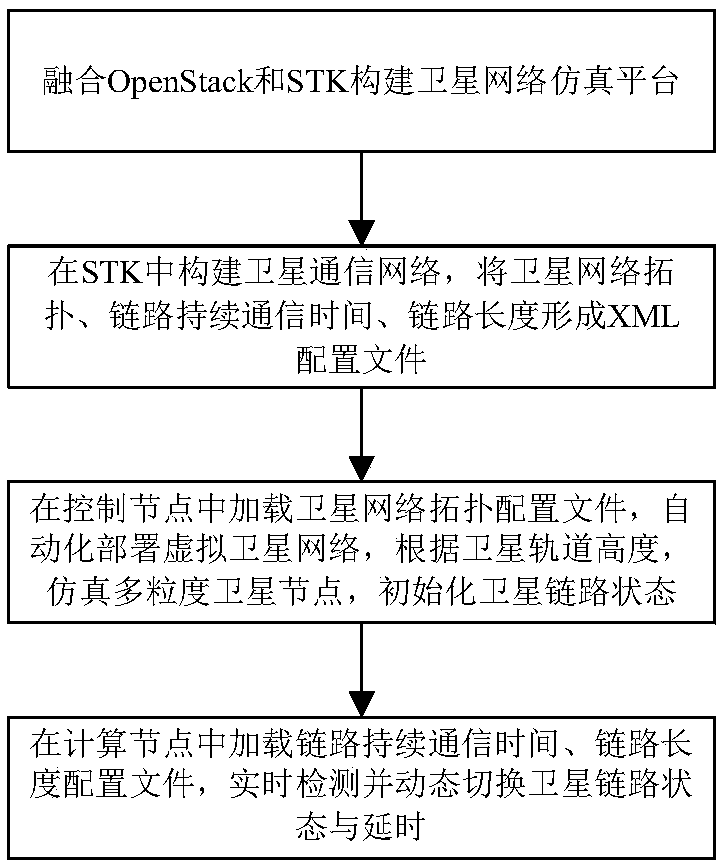

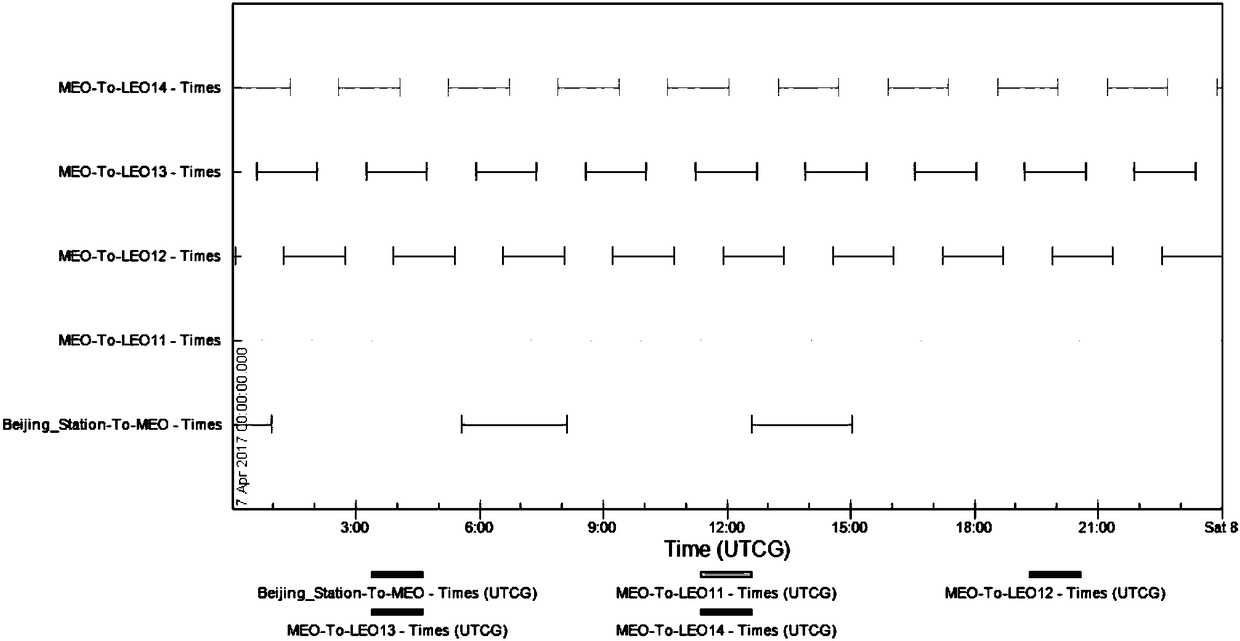

Satellite link intermittent and delay simulation method

ActiveCN108737141ASolve the problem of not being able to simulate real network trafficQuick configurationRadio transmissionData switching networksGranularitySatellite orbit

The invention discloses a satellite link intermittent and delay simulation method, which relates to the technical field of network simulation and effectively solves the problem of intermittent and delay simulation of satellite links in satellite network simulation. The method includes the following steps: integrating OpenStack and an STK to construct a satellite network simulation platform; constructing a satellite communication network in the STK, and enabling the satellite network topology, the continuous communication time of the link and the link length to form an XML configuration file; loading a satellite network topology configuration file in a control node, automatically deploying a virtual satellite network, simulating a multi-granularity satellite node according to the height ofa satellite orbit, and initializing the satellite link state; and loading the configuration file of the continuous communication time of the link and the link length in a computing node, and real-timely detecting and dynamically switching the satellite link state and delay. The invention provides the satellite link intermittent and delay simulation method, which can be used for scientific researches of different satellite network scenarios.

Owner:JIANGNAN UNIV

Neural stem cell culture amplification method and used culture medium

InactiveCN102839154AAchieving Amplification EfficiencyMeet scientific researchNervous system cellsCulture fluidAntibiotic Y

The invention discloses a neural stem cell culture amplification method, which comprises the following steps of culturing different sources of neural stem cells with a culture solution, adding a nutritional supplement solution, replacing a fresh culture solution, selecting a certain size of neurospheres for passage and the like. A formula of a relative culture solution, the nutritional supplement solution and other compositions is also provided. The method obviously improves the proliferation efficiency of neural stem cells under static culture, no antibiotics are used, and the cost is lower. The method is suitable for industrial production.

Owner:SHANGHAI ANGECON BIOTECH

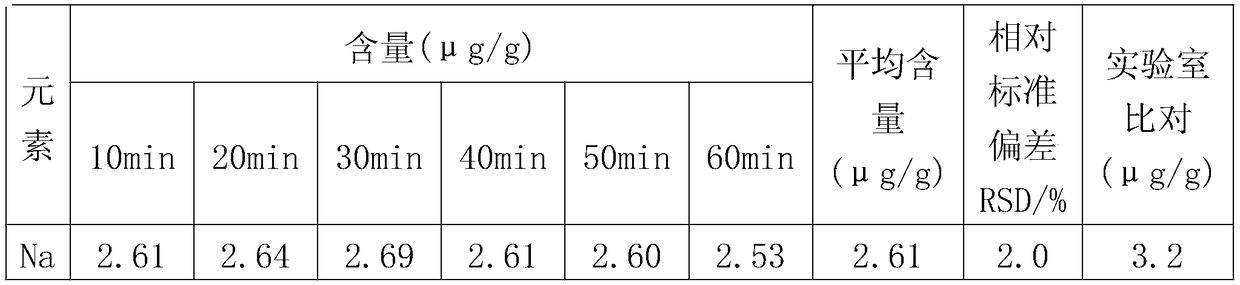

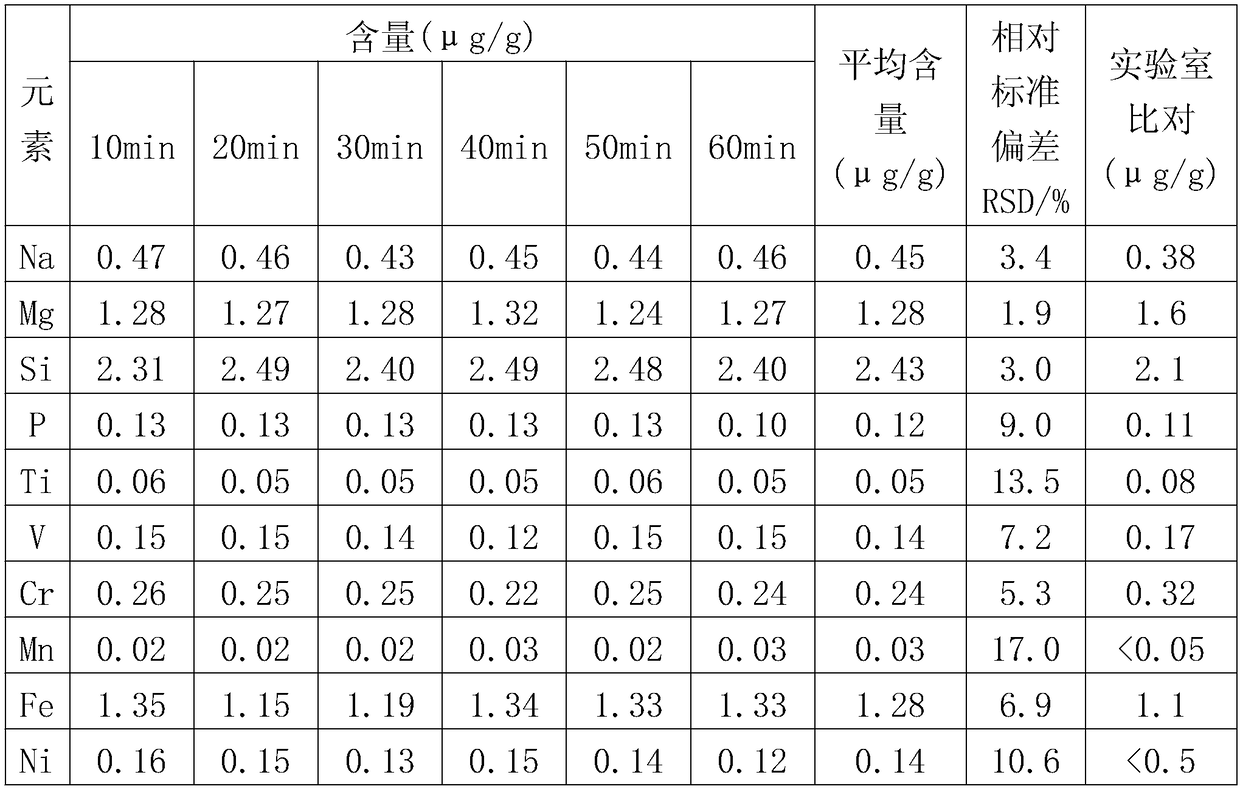

Method for determining trace impurity elements in high purity alumina polycrystalline material

InactiveCN109239179ASolve the problem that GD-MS analysis cannot be performed directly due to non-conductivityAvoid interferenceParticle separator tubesMaterial analysis by electric/magnetic meansSpectrometerAg element

The invention relates to a method for determining trace impurity elements in the high purity alumina polycrystalline material. The invention provides a method for determining trace impurity elements in the high purity alumina polycrystalline material, comprising the following steps of: (1) breaking the block high purity alumina polycrystalline material sample into polycrystalline particles; (2) placing the polycrystalline particles between two high purity enamel sheets, pressing, and mosaicing on the surface of the high purity enamel sheets; (3) putting the high purity enamel sheets into a GD-MS sample holder, and the side with the high purity alumina polycrystalline material is the detection surface; (4) evacuating an ion source, and adjusting a discharge voltage and a discharge currentin a pulse mode; (5) performing a pulsed glow discharge mass spectrometer analysis under the conditions set in step (4), collecting the signal intensity of the element to be tested, and calculating the mass fraction of the impurity to be tested. The determining method avoids the influence of irregularity or surface roughness of the alumina polycrystalline sample on the discharge and the detectionresult, and can be directly used for the determination of impurities of the high purity alumina polycrystalline material.

Owner:XINJIANG JOINWORLD CO LTD

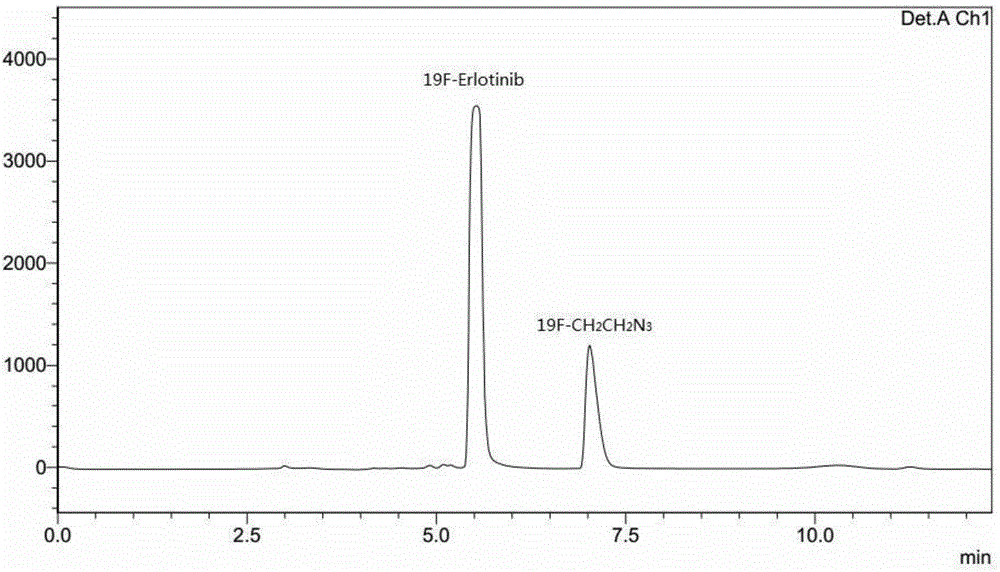

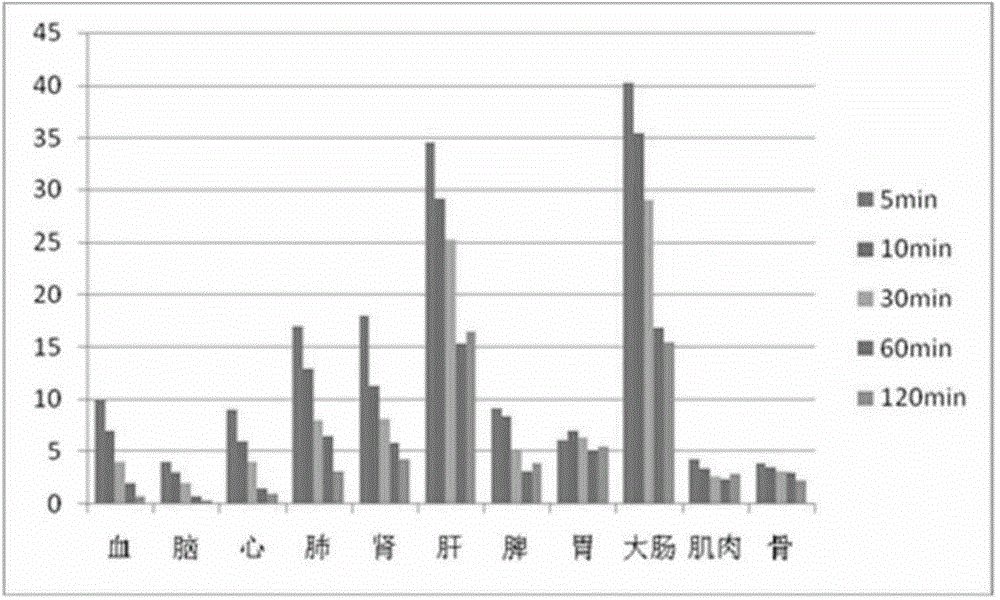

EGFR positron tracer, preparation method and application thereof

InactiveCN104817542AGood tracer effectStrong specificityOrganic chemistryRadioactive preparation carriersErlotinibStructural formula

The invention discloses an EGFR positron tracer, a preparation method and application thereof. The structural formula of the EGFR positron tracer is shown as the specification. The EGFR positron tracer has good tracing effect, and compared with 18F-FDG that is the most common in clinical practice at current, the tracer has very good specificity, can achieve positive identification of epidermal growth factor receptor (EGFR) high expression tumors. The preparation method is convenient, simple and fast, can realize fully automatic production, and can meet scientific research and clinical demands. In the aspect of application, the PET imaging of 18F-Erlotinib not only can be used for screening of clinical anticancer drug Erlotinib sensitive individuals, and also has very good application prospects in detection of EGFR expression level and screening of small molecule EGFR inhibitors in the pharmaceutical industry.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV +1

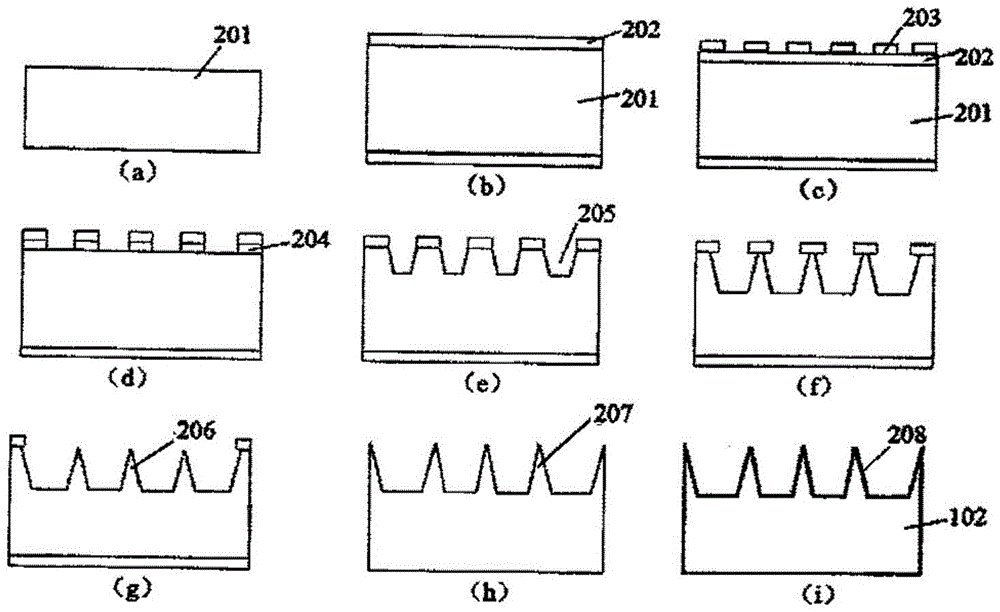

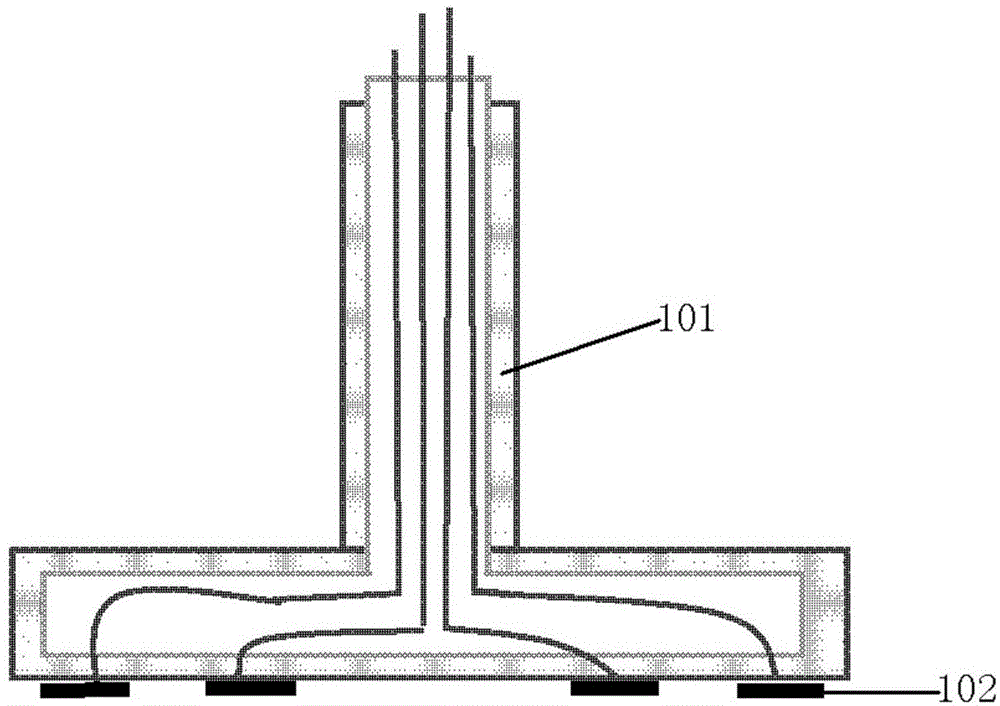

Muscle impedance handheld electrode based on microneedle arrays and preparation method

ActiveCN104523273AAvoid repeated taggingEasy to detectDecorative surface effectsDiagnostic recording/measuringImpedance testingPhysics

The invention relates to a muscle impedance handheld electrode based on microneedle arrays. The muscle impedance handheld electrode comprises a hollow T-shaped handle and four microneedle array electrode plates; and the four microneedle array electrode plates are fixed to the bottom of the handle and connected with an external impedance testing device through four wires. The handheld electrode is used for intrusively detecting the muscle impedance in a painless manner; operation is easy and convenient; and the detection sensitivity is high.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

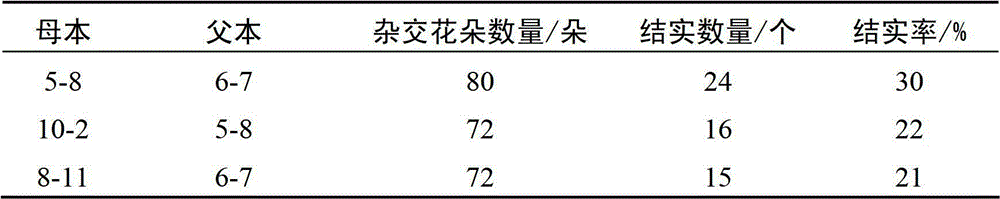

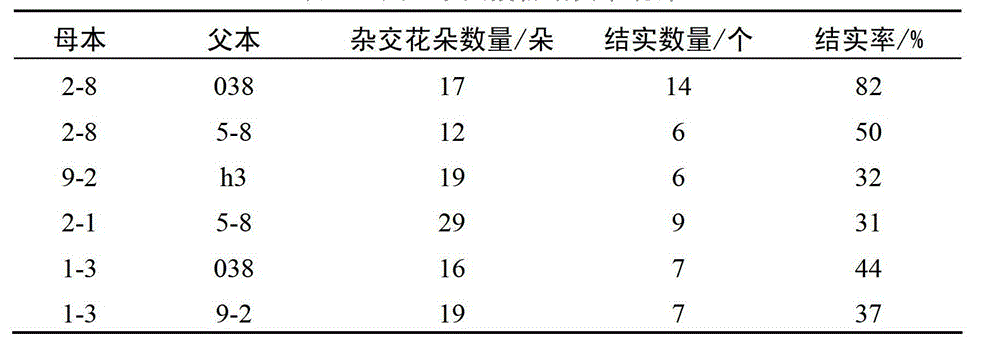

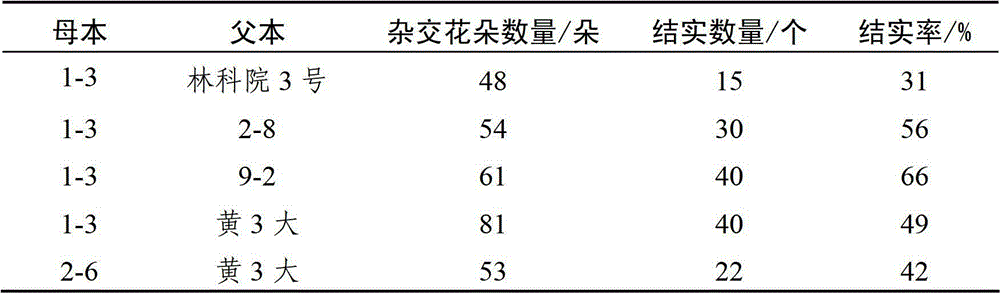

Method for performing artificial crossbreeding without removing stamen from catalpa bungei and application thereof

The invention provides a method for performing artificial crossbreeding without removing stamen from catalpa bungei. The method particularly comprises the following steps: (1) collecting pollen: collecting anther before the anther of the catalpa bungei is mature and does not crack, drying the anther indoors at the room temperature of 20 to 22 DEG C and collecting pollen after the anther cracks; and (2) performing artificial pollination: when the stamen of each flower of catalpa bungei is mature, the stigma is opened in a reverse V shape and the surface has milk white luster, lightly touching with hands or shaking catkin and quickly closing to perform artificial pollination. By the method, the artificial pollination is properly performed by selecting the optimum pollination time at the appropriate air temperature and under the clear, windless or breeze condition, so that a seed tree can be fertilized successfully and fructify a large number for fruits, and the requirements of scientific research and production can be met.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

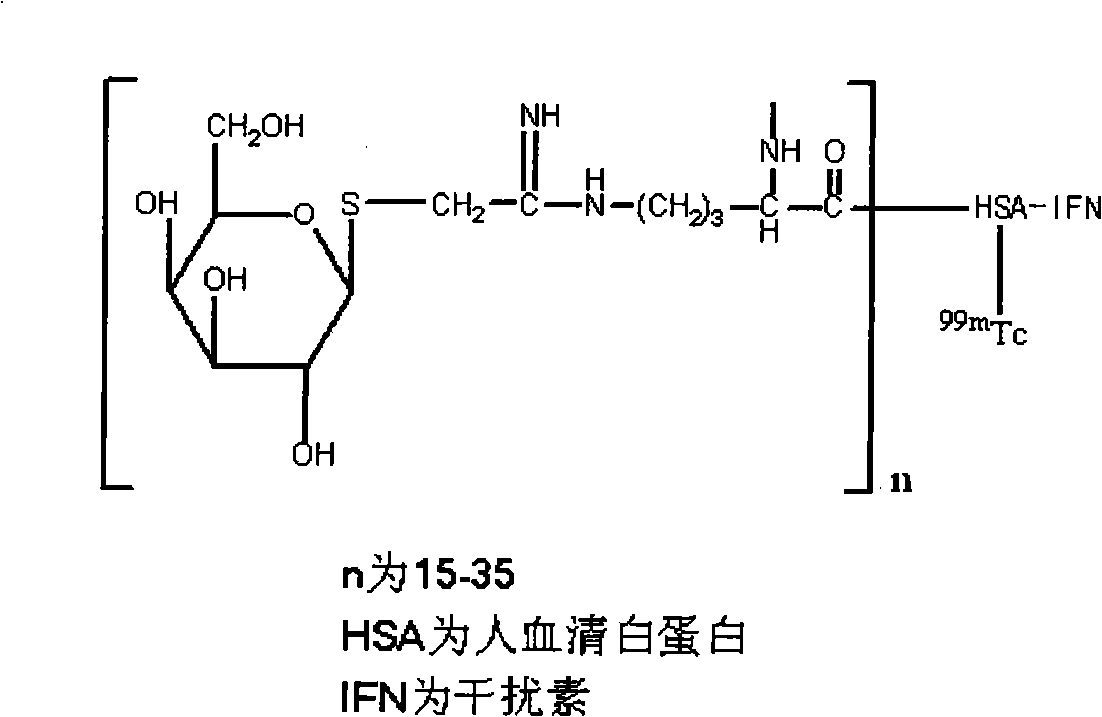

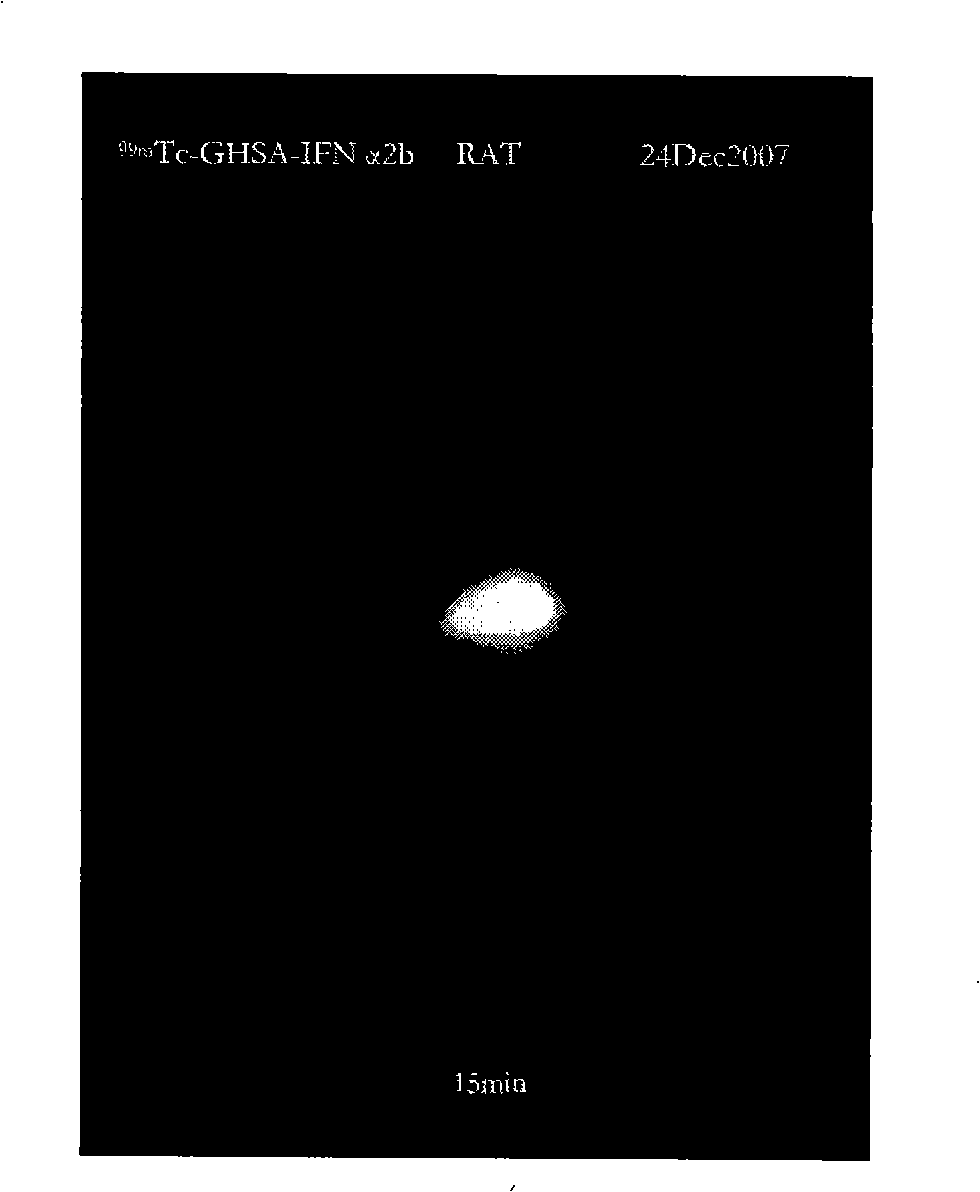

Preparation of <99m>Tc galactosyl human serum albumin fusion interferon of liver receptor developer and uses thereof

InactiveCN101333259AClear imagingMeet scientific researchIn-vivo radioactive preparationsPeptide/protein ingredientsDiseaseImaging agent

Disclosed are a preparation method for hepatic receptor imaging agent 99mTc-galactosyl-human serum albumin fusion interferon and the application of the albumin fusion interferon, belonging to the nuclear medicine technical field. The invention adopts a stannous reduction method for the radioactive technetium tagging of the hepatic receptor imaging agent 99mTc-galactosyl-human serum albumin fusion interferon GHSA-IFN; upon polyamide-66 thin layer chromatography analysis, the radiochemical purity of the prepared 99mTc-GHSA-IFN is more than 90% and can be stabilized for more than 6 hours at room temperature, in line with the requirements of scientific research and clinical use. The distribution in mice and the imaging results of rats show that the 99mTc-GHSA-IFN can be incepted by liver in a specific way, and the liver imaging is very clear within 10-30 minutes which is the best time for liver imaging. Therefore, the 99mTc-GHSA-IFN is a good new liver receptor function SPECT imaging agent and can be used to evaluate the liver receptor functions, diagnose liver diseases and evaluate the liver disease treatment drug efficacy; at the same time, the 99mTc-GHSA-IFN is also used to prepare liver targeted therapy drugs and the treatment drugs for viral hepatitis.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

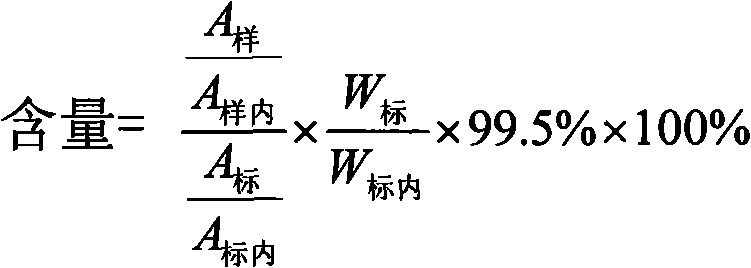

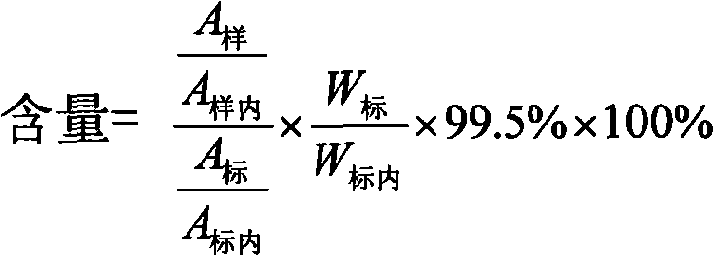

Method for measuring low-concentration methylcyclopentadienyl manganese tricarbonyl by gas chromatography internal standard method

InactiveCN101581708ARapid determinationA Fast Method for Determination of Low Concentration Methylcyclopentadiene Manganese TricarbonylComponent separationPreparing sample for investigationOrganic solventGas phase

The invention relates to a method for measuring a low-concentration methylcyclopentadienyl manganese tricarbonyl by a gas chromatography internal standard method, comprising the following specific measurement processes of: selecting a high-purity methylcyclopentadienyl manganese tricarbonyl (MMT) standard substance and the internal standard substance of a high-purity ferrocene; dissolving the high-purity ferrocene in a refined organic solvent to prepare an internal standard liquid; dissolving the high-purity MMT standard substance in the internal standard liquid to prepare a standard solution; dissolving an industrial-grade MMT in the internal standard liquid to prepare a liquid to be measured; and analyzing the standard solution and the liquid to be measured under the same gas chromatography condition. The method is quick, convenient and exact, the analysis testing has low cost, the result measured by the method is equivalent to the result measured by an atomic absorption spectrometry when being converted into manganese content by calculation, and the method can meet the requirements of scientific research and industrial production.

Owner:江西昌宁化工有限责任公司

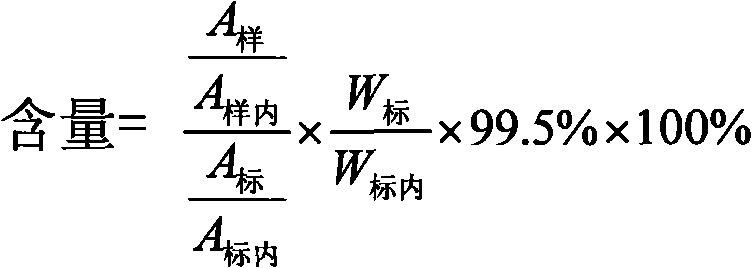

Shale fluid-retaining closed coring device and method

ActiveCN110700781AReduce desorption rateGuaranteed calculation accuracyCore removalRock coreShale gas

The invention discloses a shale fluid-retaining closed coring device and method. The shale fluid-retaining closed coring device comprises a coring drill bit, an outer cylinder and a drill rod joint which are connected in sequence, wherein the drill rod joint can drive the outer cylinder and the coring drill bit to rotate; a ball valve assembly, an inner cylinder, a plurality of fluid collecting tanks connected in series and a measurement-while-drilling device are connected in sequence and are arranged in the outer cylinder; the plurality of fluid collecting tanks are used for collecting natural gas in a rock core; the measurement-while-drilling device is used for measuring the temperature and pressure of the natural gas in the fluid collecting tanks; the shale fluid-retaining closed coringdevice further comprises a suspension assembly, one end of the suspension assembly is connected with the outer cylinder, and the other end of the suspension assembly is connected with the measurement-while-drilling device, the plurality of fluid collecting tanks and the inner cylinder, so that when the outer cylinder rotates, the inner cylinder does not rotate. When the core is taken and the drill is lifted, the ball valve assembly is closed, and the gas in the fluid collecting tanks is not lost, so that the shale sample and the lost gas content of the closed coring can be effectively obtained, the reliability and economic evaluation of the shale gas content and the shale gas reservoir reserve are improved, and the requirements of scientific research and production are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

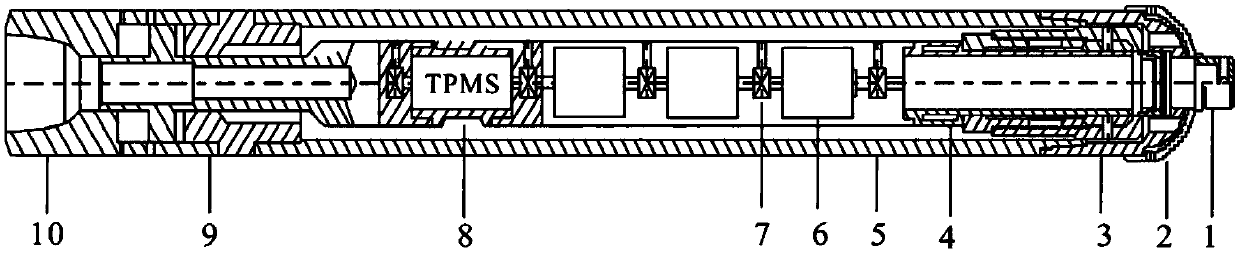

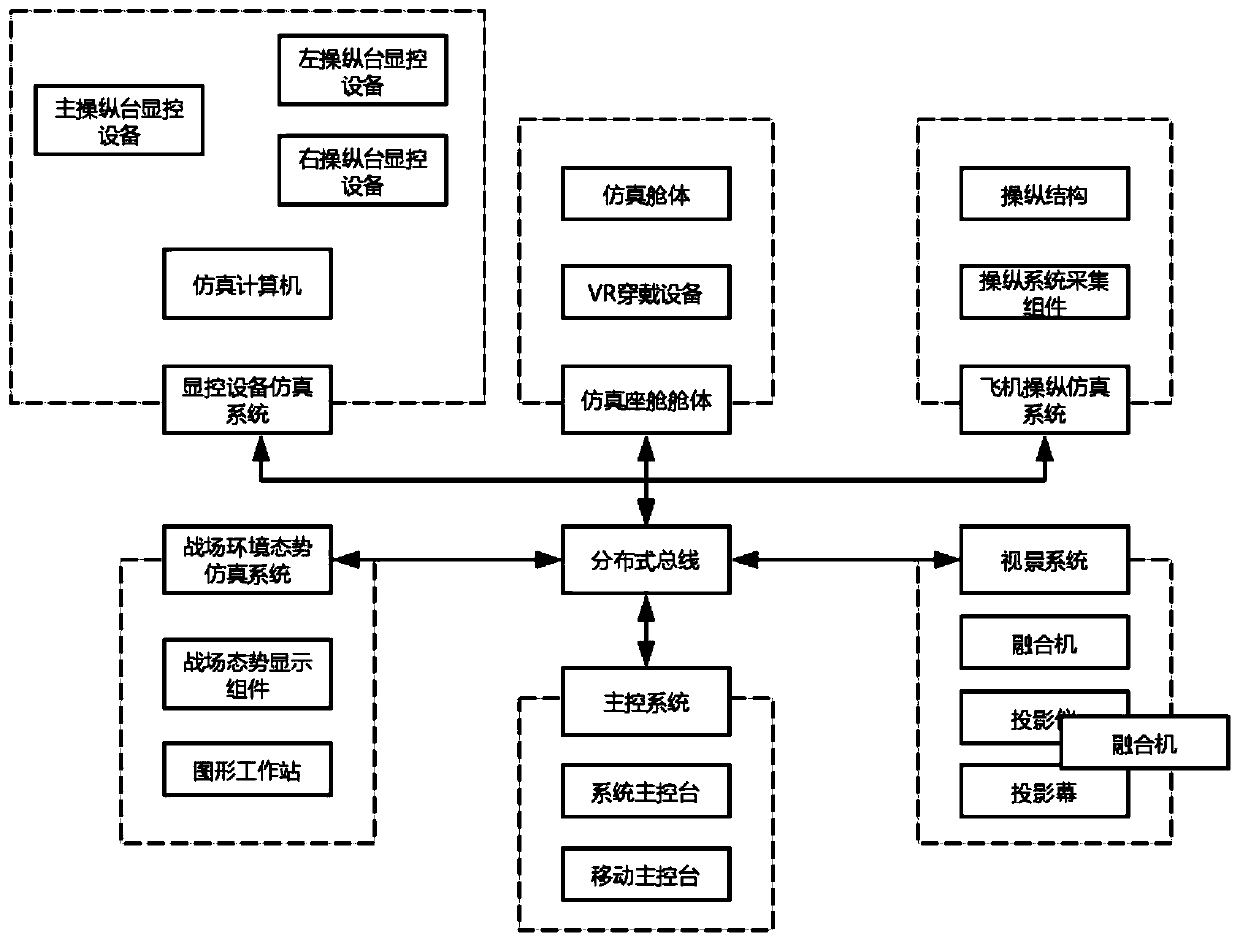

Simulation driving system of military fighter aircraft

InactiveCN109920300AMeet teachingMeet scientific researchCosmonautic condition simulationsSimulatorsJet aeroplaneControl system

The invention discloses a simulation driving system of a military fighter aircraft. The simulation driving system of the military fighter aircraft comprises a simulation cockpit body, an aircraft control simulation system, a display control equipment simulation system, a scene system, a battlefield environment situation simulation system and a main control system. The simulation driving system ofthe military fighter aircraft, disclosed by the invention, has the beneficial effects that firstly, the simulation driving system of the fighter aircraft comprises a flight simulation system, a flightposture system and a flight scene system; an integral complete simulation system is formed; an internal layout environment and an external scene of the military fighter aircraft in a process of executing a flight task through flying by a pilot can be restored from multiple angles; the requirements of teaching, scientific research and experiments can be met; secondly, modular design are adopted for hardware and software of the simulation driving system of the fighter aircraft; a single module can be replaced; the secondary development, upgrade and maintenance requirements are supported; all systems are connected through distributed buses; data is managed and dispatched in a unified way by the main control system; and the flight simulation task can be efficiently completed.

Owner:SHANGHAI KASUO AVIATION TECH

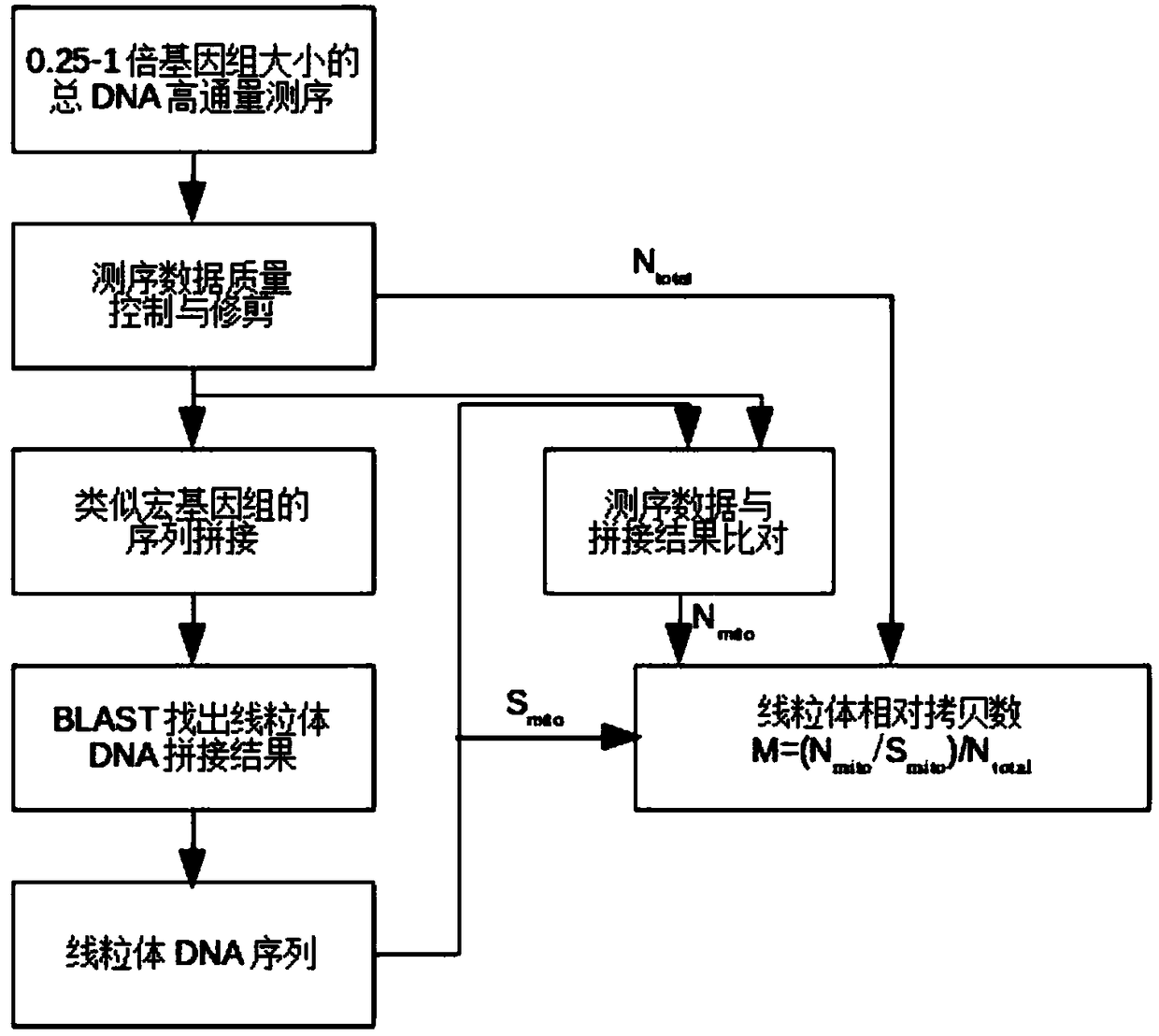

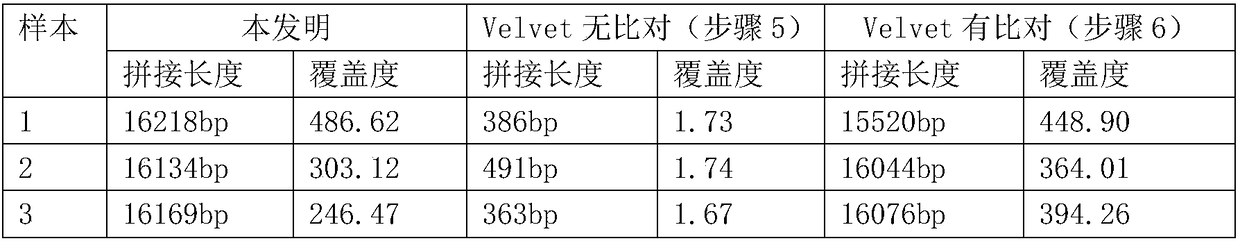

Mitochondria sequence splicing and copy number measuring method based on high-throughput sequencing

ActiveCN108733974AMaintain mitochondrial DNA content informationLower quality requirementsSpecial data processing applicationsGenomicsQuality control

The invention belongs to the technical field of the genomics, and specifically relates to a method for directly measuring eucaryon mitochondria sequence and copy number by using the high-throughput sequencing (the next generation of sequencing, the second generation of sequencing, and the depth sequencing). The method comprises the following steps: performing high-throughput sequencing on the total DNA; performing quality control on the sequencing data; performing sequence splicing based on similar metagenome; and computing the mitochondria content. Through the method disclosed by the invention, the mitochondria assembling is performed by using less sequencing data in the premise of not performing the mitochondria enrichment operation, and the method has the advantages of being simple in experiment, low in sample quality requirement, good in splicing integrity, and capable of measuring the relative content of the mitochondria. And the scientific research and application demand can be satisfied to a certain degree.

Owner:沈阳中科赛尔生物科技有限公司

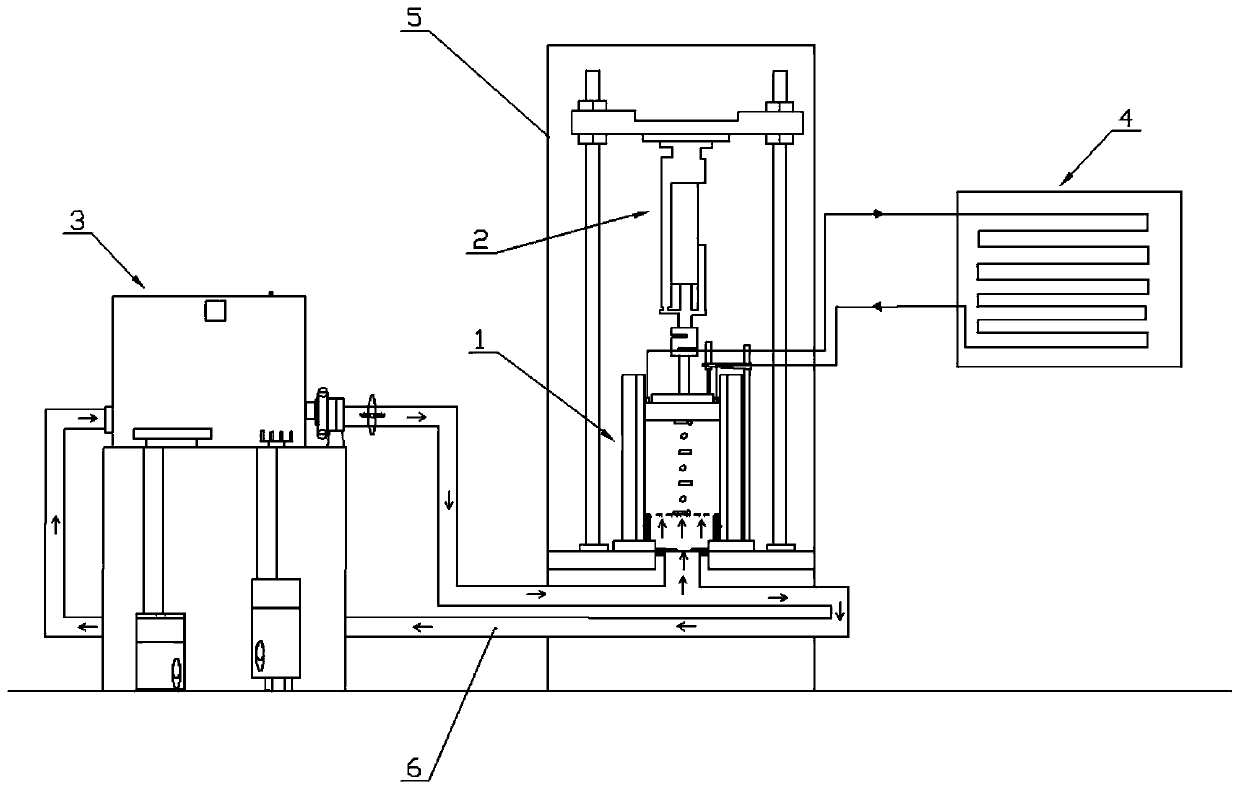

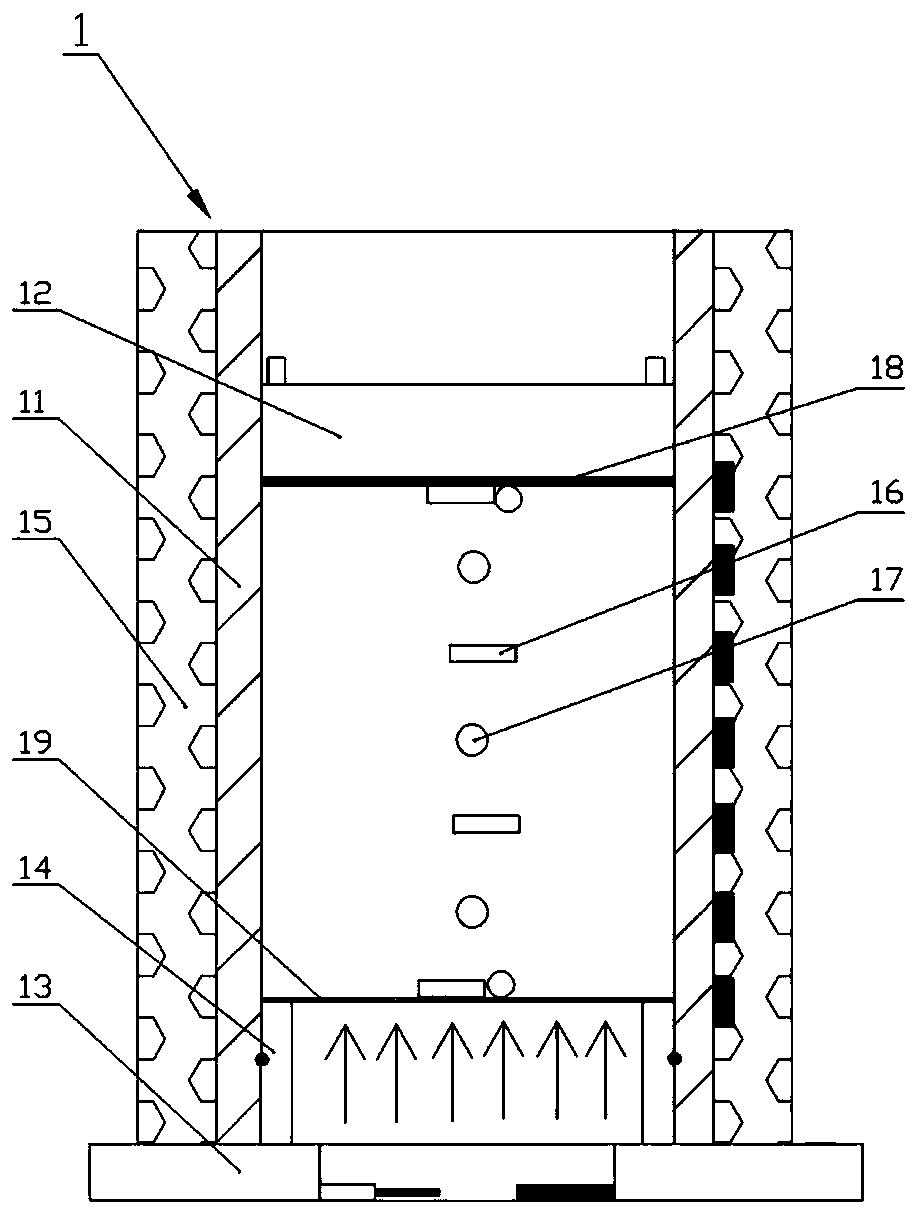

Multi-loading-mode unsaturated soil frost heaving instrument and frost heaving amount testing method

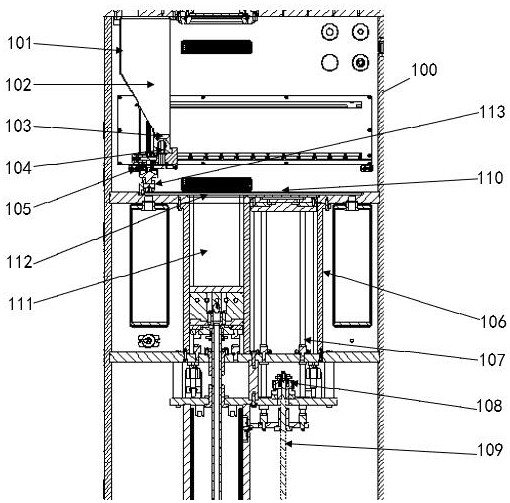

ActiveCN110954573ARelieve stressApplicable frost heave characteristicsMaterial thermal analysisTemperature controlControl system

The invention discloses a multi-loading-mode unsaturated soil frost heaving instrument and a frost heaving amount testing method. The frost heaving instrument comprises a sample storage system, a loadcontrol system, a humidity control system, a temperature control system and a thermostat, the sample storage system comprises a sample cylinder and a temperature disc, an air inlet is formed in the bottom end of the sample cylinder, a cavity is formed in the temperature disc, a water-proof and air-proof film is arranged outside the cavity bottom, a liquid inlet and a liquid outlet are formed in the cavity top, the temperature disc is arranged in the top end of the sample cylinder, and the sample cylinder is arranged in the constant-temperature box; the load control system comprises a counter-force frame and a load control mechanism, the load control mechanism is arranged in the counter-force frame, the counter-force frame is erected in the thermostat, and the load control mechanism is arranged in the counter-force frame and connected with the temperature disc; the humidity control system is communicated with an air inlet of the sample cylinder; an output port of the temperature control system is communicated with a liquid inlet in the temperature disc, and an outlet of the temperature control system is communicated with a liquid outlet in the temperature disc. Frost heaving testsin multiple loading modes can be carried out, gaseous water supply can be achieved, and frost heaving of coarse-grained soil is induced.

Owner:CENT SOUTH UNIV

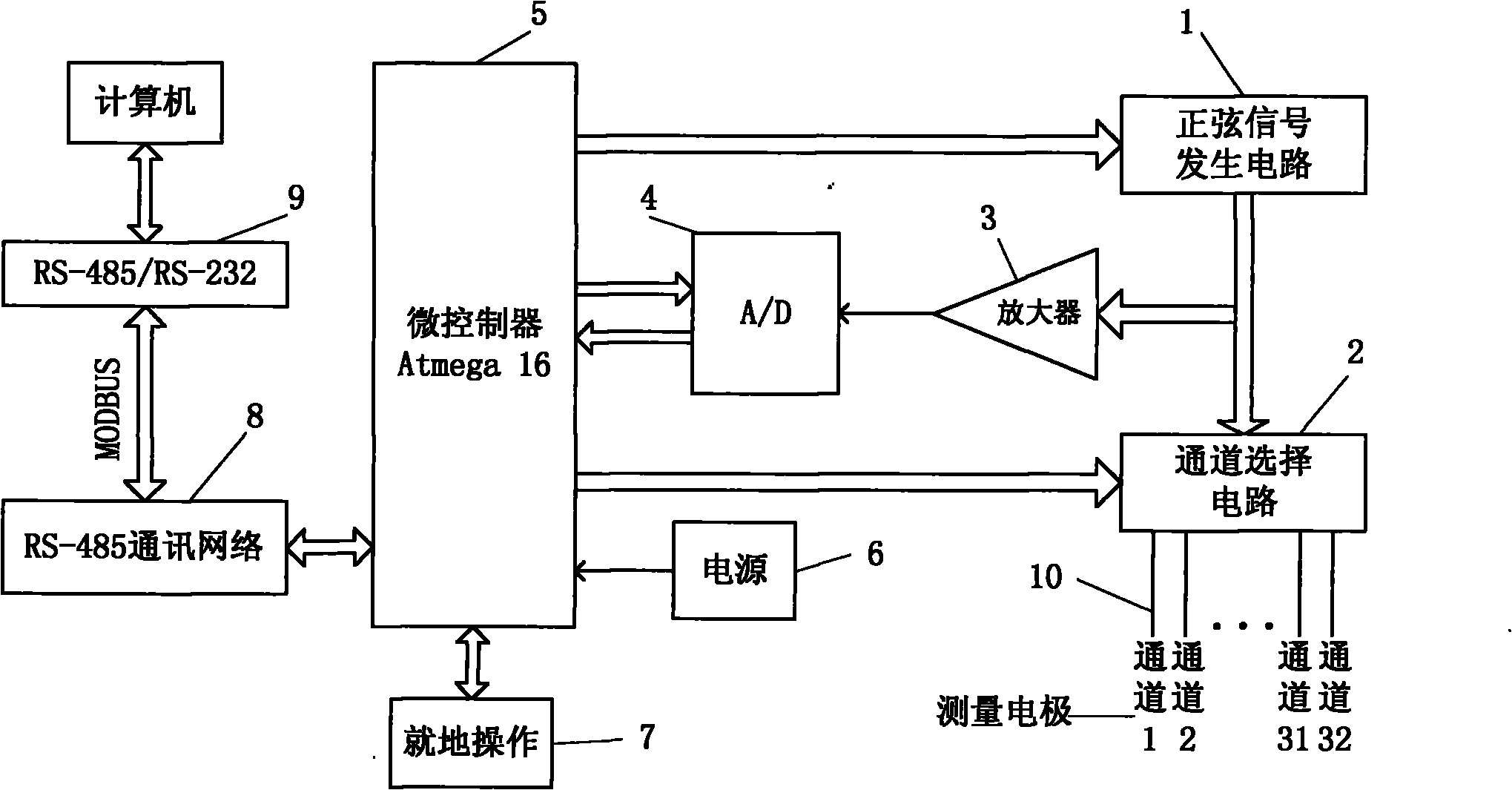

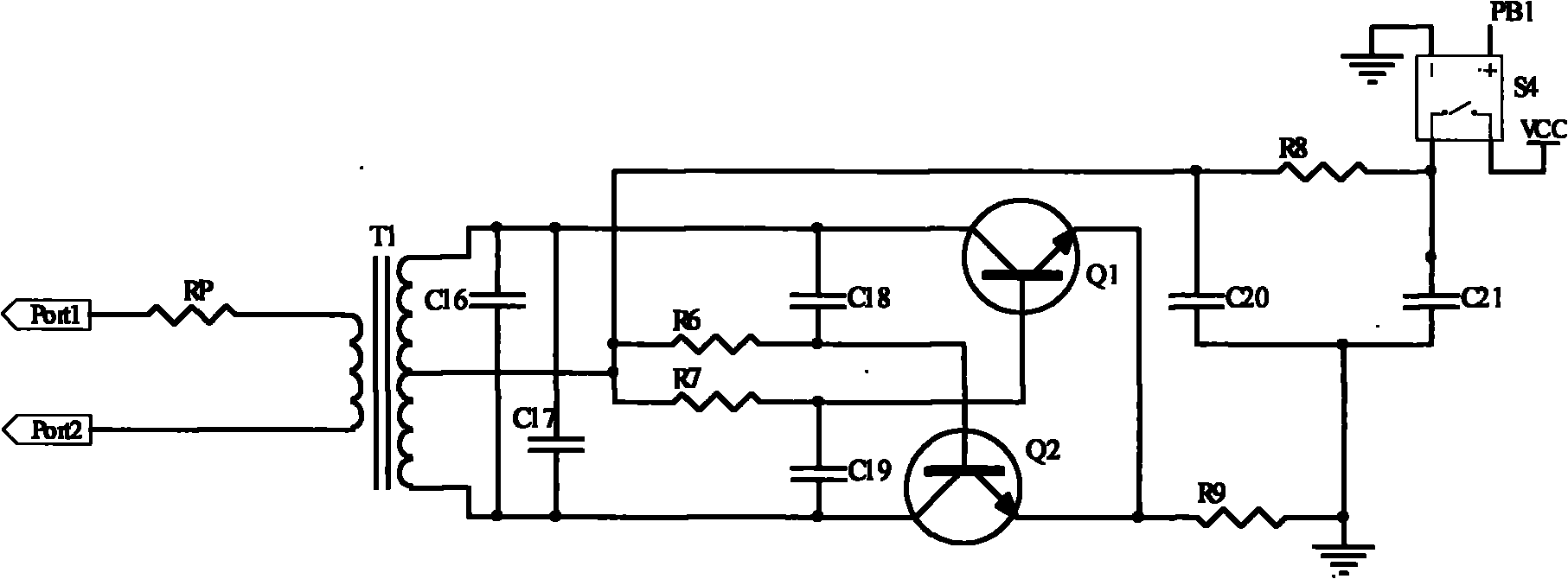

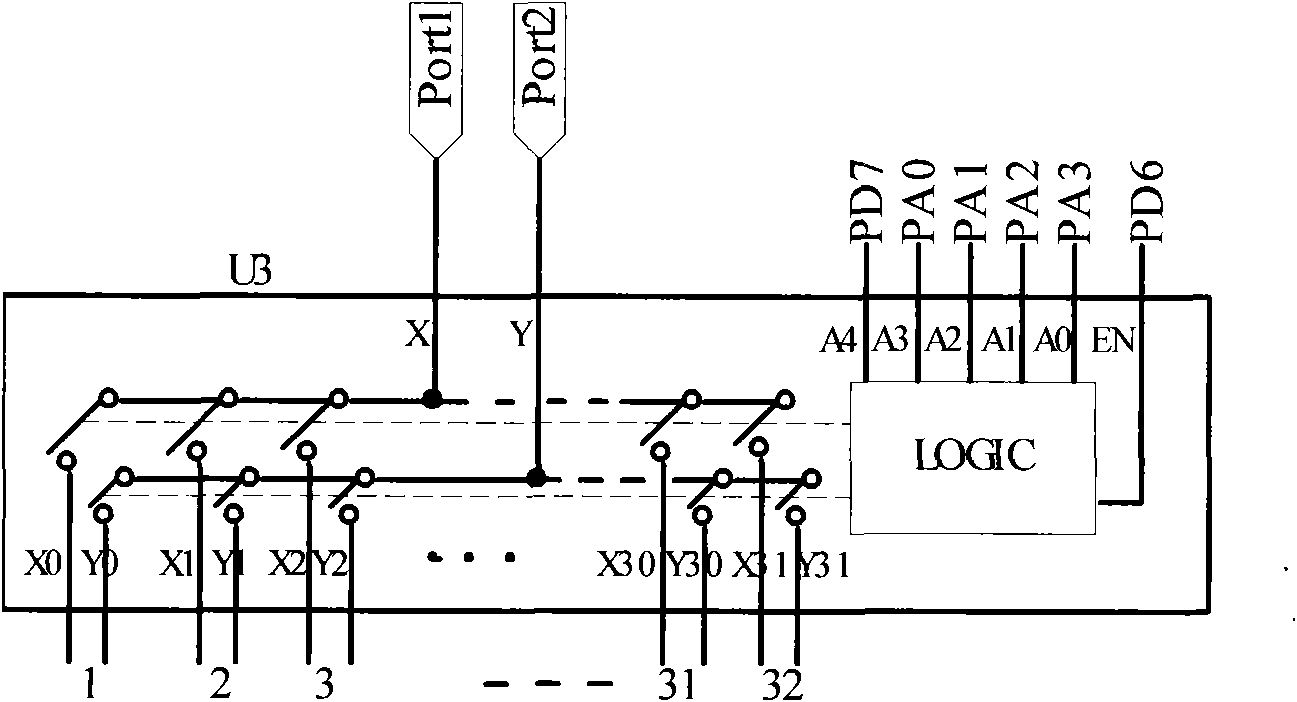

Multi-channel salinity online measuring system

InactiveCN101788526AOvercome the disadvantage that it can only be used for single-point measurementSolve multi-point measurement problemsMaterial electrochemical variablesMicrocontrollerFull wave

The invention relates to a multi-channel salinity online measuring system, belonging to the technical field of automatic detection. The automatic measuring system capable of simultaneously measuring multi-point salinity comprises a sinusoidal signal generating circuit, a channel selection circuit, measuring electrodes, a signal collection conversion circuit, a microcontroller circuit, a remote communication circuit and computer application software. Full-wave sampling is carried out on measuring signals, and the area of a region encapsulated by the wave period is derived by a microcontroller and is in direct proportion to the salinity to realize high-precision salinity measurement. Multi-point salinity measurement is realized by the unique channel selection circuit, the measuring signal is remotely transferred by the remote communication circuit, data and drawing curves are automatically stored by the application software, and the influence on the flow field of a fluid to be measured is greatly lessened by the designed ultrafine measuring electrodes. The multi-point salinity measuring system has low cost and high precision and can be widely applied to scientific research and experiments.

Owner:闫瑞杰 +2

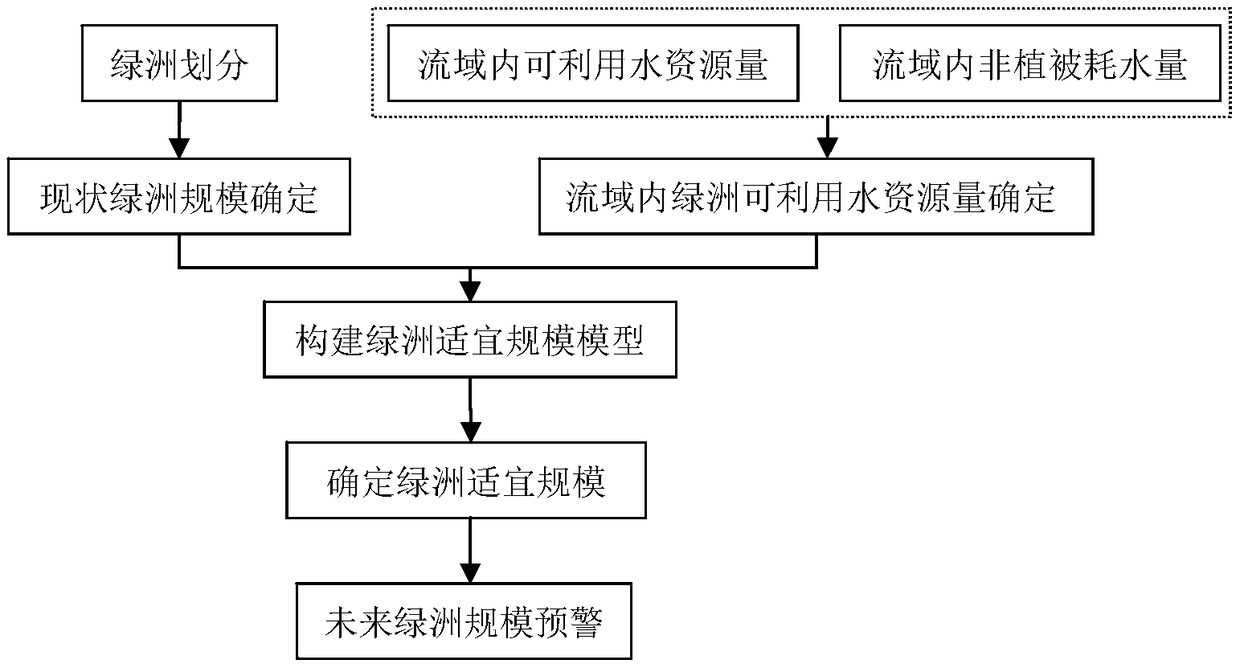

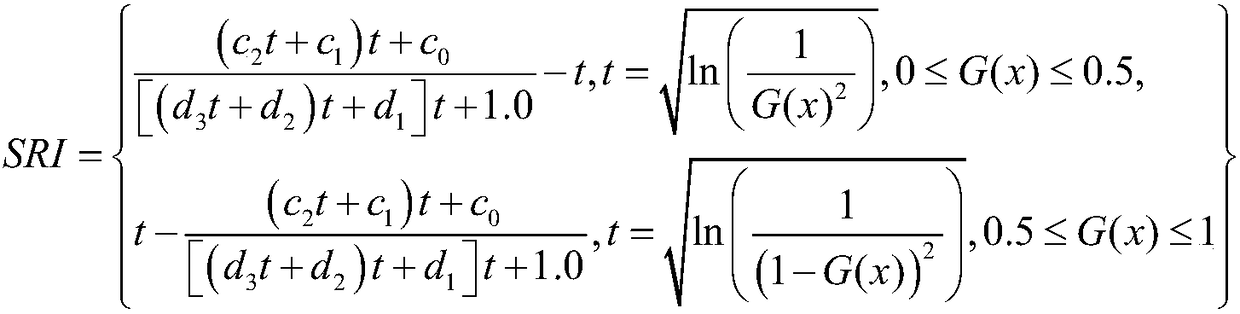

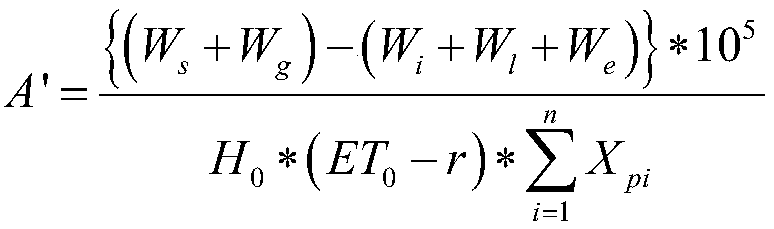

A method for calculating the suitable scale and stability of an oasis in an inland river basin

PendingCN109345054AImprove the accuracy of automatic recognitionMeet scientific researchClimate change adaptationCharacter and pattern recognitionAridScale model

The invention discloses a method for calculating the suitable scale and stability of an oasis in an inland river basin, which is characterized by mainly comprising the following steps of 1) determining the scale of the present oasis; 2) dividing abundant and dry water resources; 3) constructing the suitable scale model of the oasis in the inland river basin; 4) carrying out the stability assessment of oasis in inland river basin. In accordance with that prior art, the outstanding advantages of the invention are that by constructing the calculation formula of the suitable scale of the oasis, and combining with the current satellite remote sensing technology, the long-term drought in the inland river basin has been solved, the problems that the suitable area and stability of oasis in semi-arid area can not be determined accurately is solved, and technical support is provided for the stable development of the oasis safety, and the method has stronger practical value for the control and planning of the oasis area. Meanwhile, the method is simple in calculation and reasonable in result, plays an important role in the oasis management and social and economic benefits in arid and semi-arid areas of inland river basin, and can be used in practical projects.

Owner:SHIHEZI UNIVERSITY

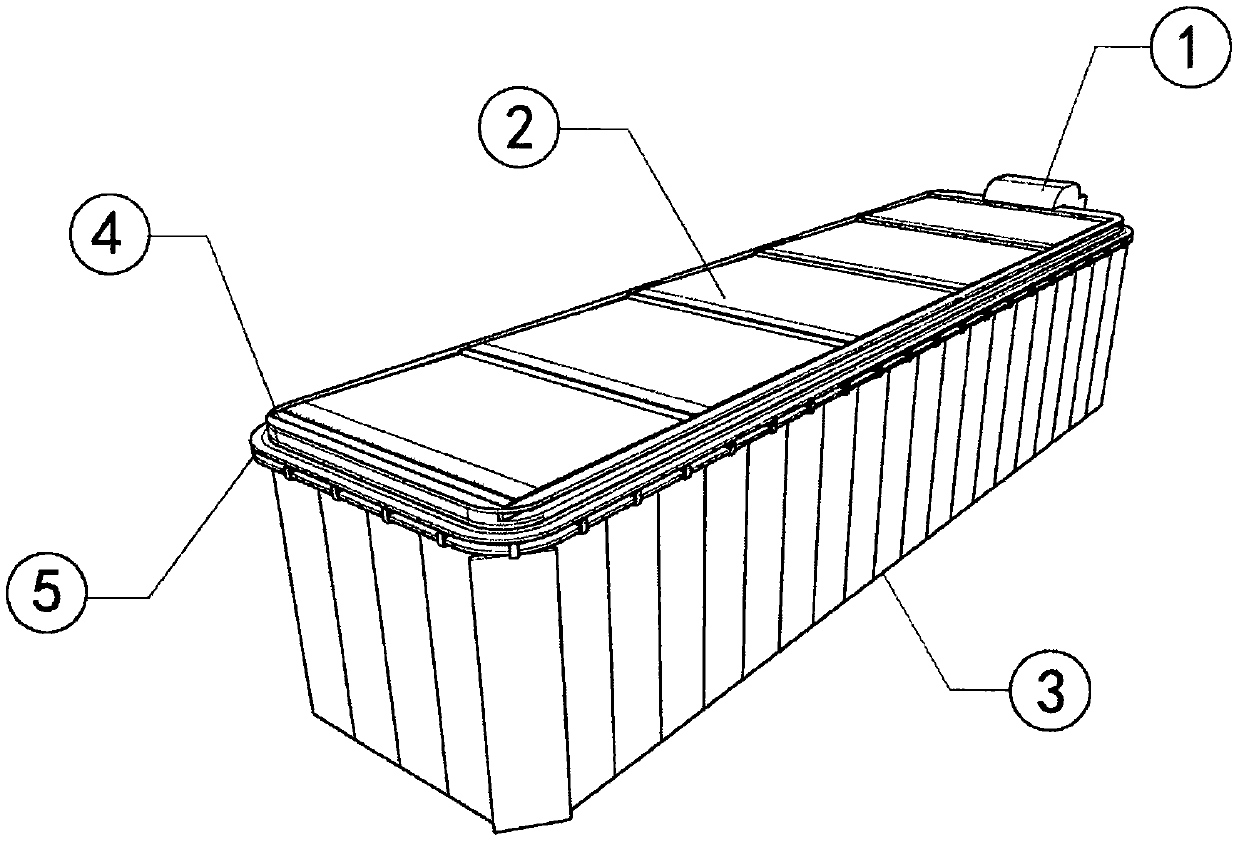

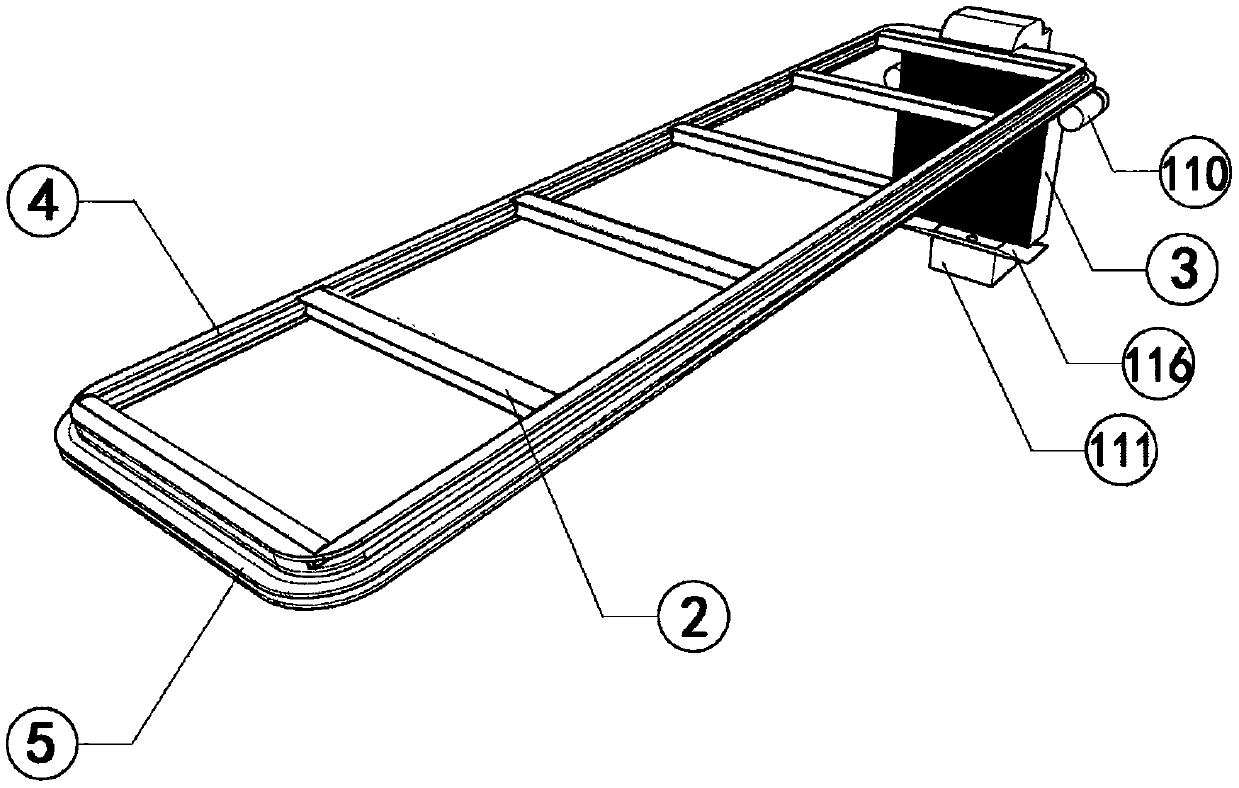

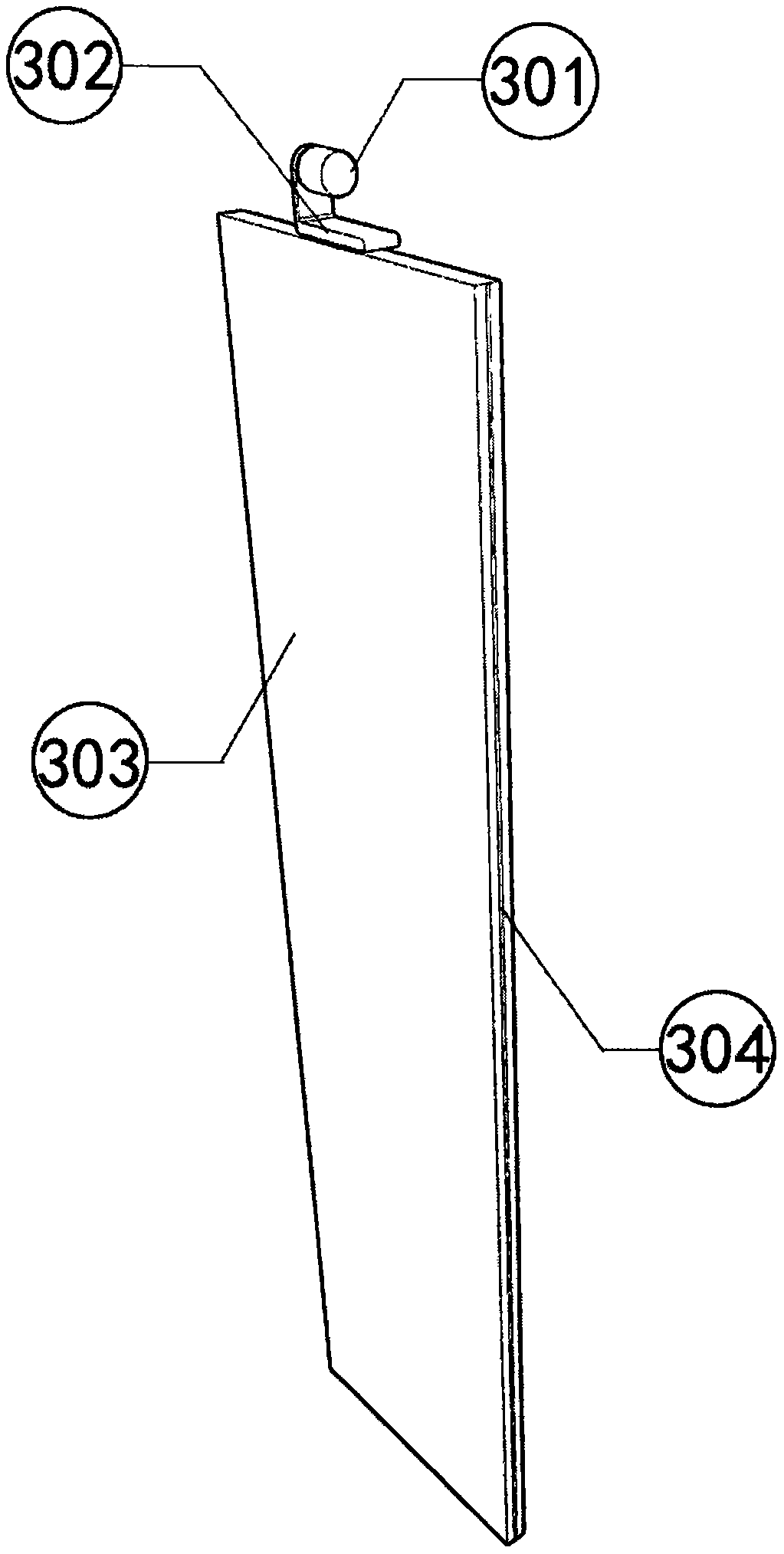

Automatic moving greenhouse capable of realizing rainwater recycling and suitable for rain sheltering experiments of crops

PendingCN110506544AHigh degree of opennessHigh precisionGeneral water supply conservationGreenhouse cultivationInformation transmissionWireless transmission

The invention discloses an automatic moving greenhouse capable of realizing rainwater recycling and suitable for rain sheltering experiments of crops and belongs to the technical field of agriculturalequipment. The greenhouse mainly consists of a side plate track, a top plate track, a top plate module, a head module and a side plate module. The top of the head module is fixedly mounted with the side plate track, the side plate module is mounted on the side plate track through side plate sliding wheels, the top plate track is fixedly mounted on the side plate track, and the top plate module ismounted on the top plate track. The head module is internally provided with a circuit assembly which is connected with a side plate circuit assembly through information transmission between a first wireless transmission module and a second wireless transmission module. According to the greenhouse, the demands of automated experiments are met, and the problems of high construction cost and monotonous test conditions in the prior art are solved.

Owner:江西省赣抚平原水利工程管理局

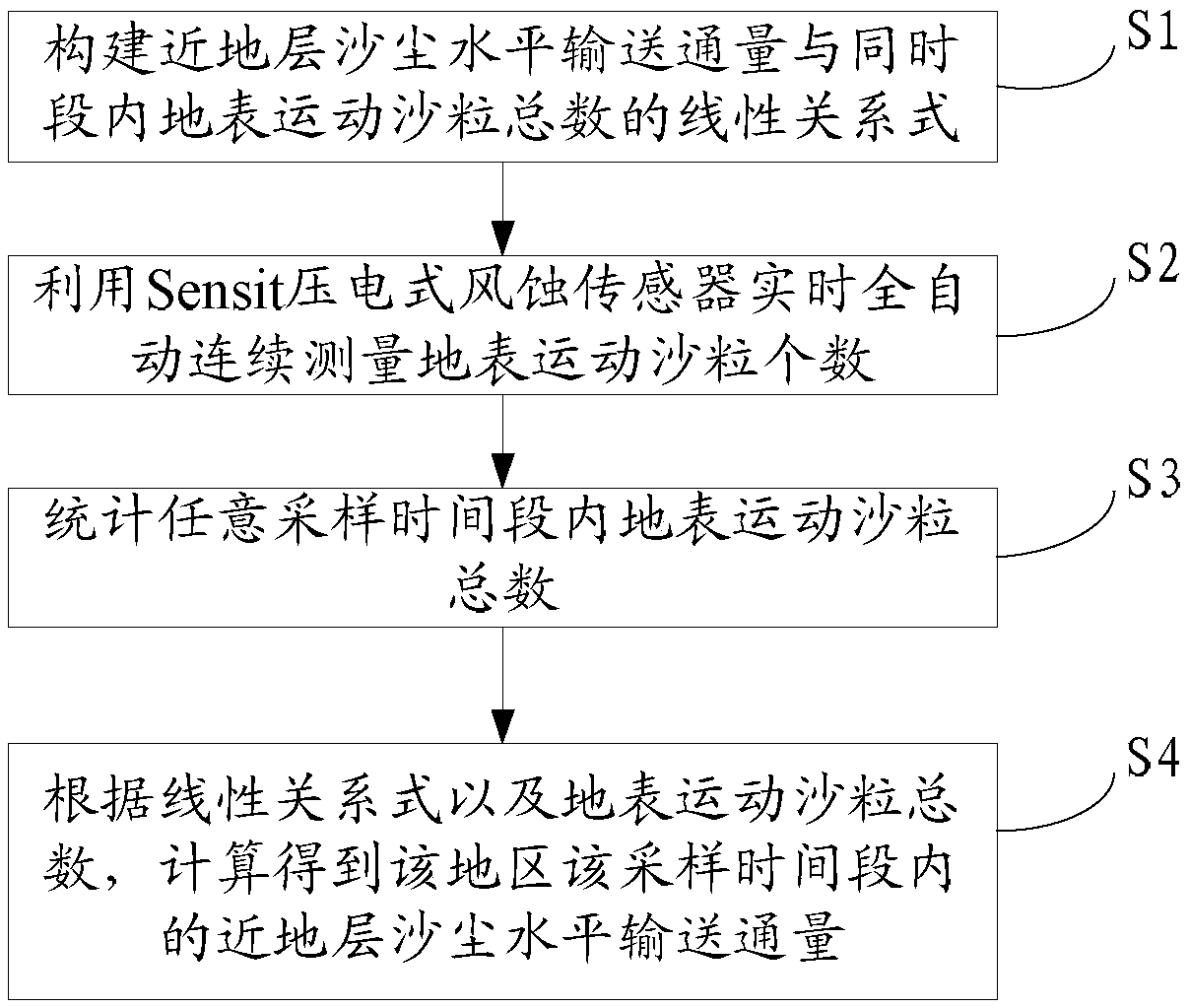

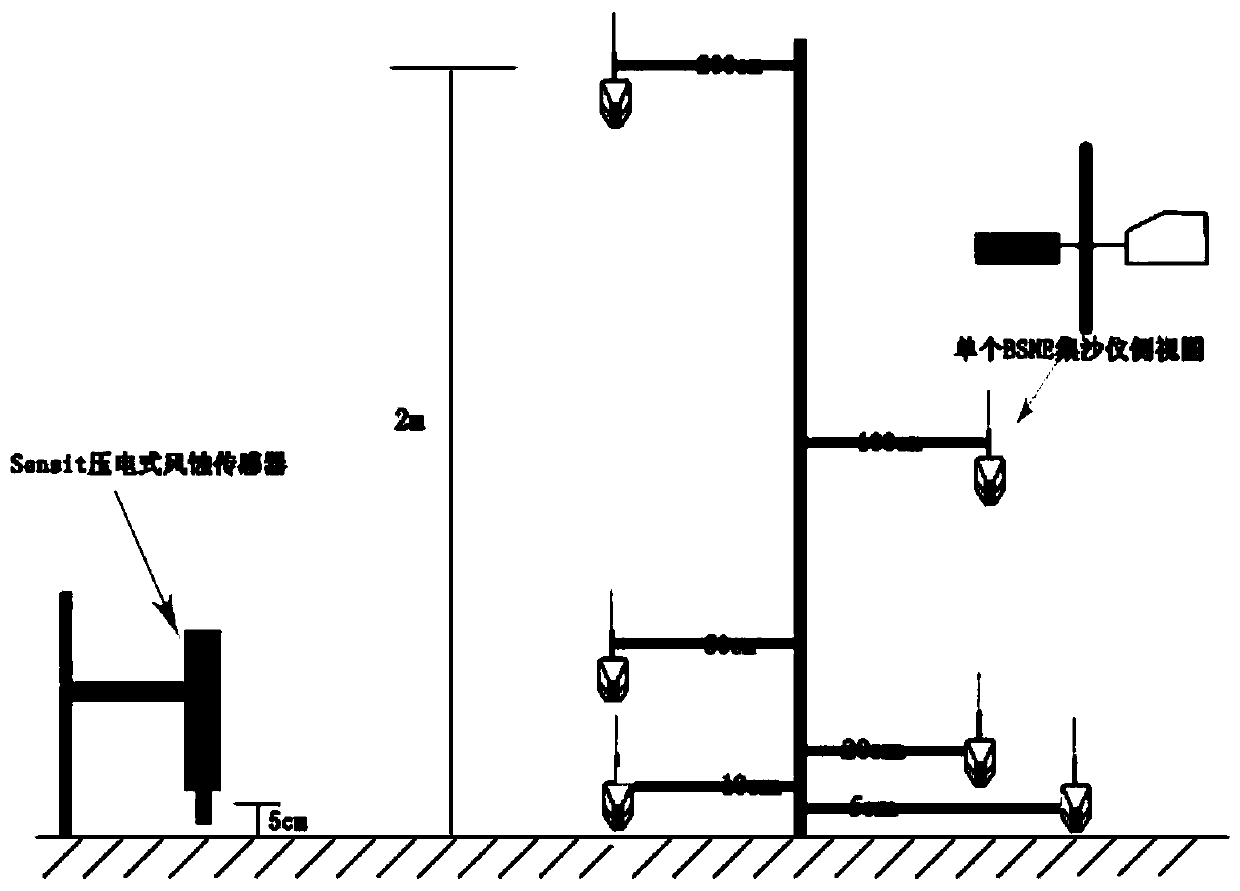

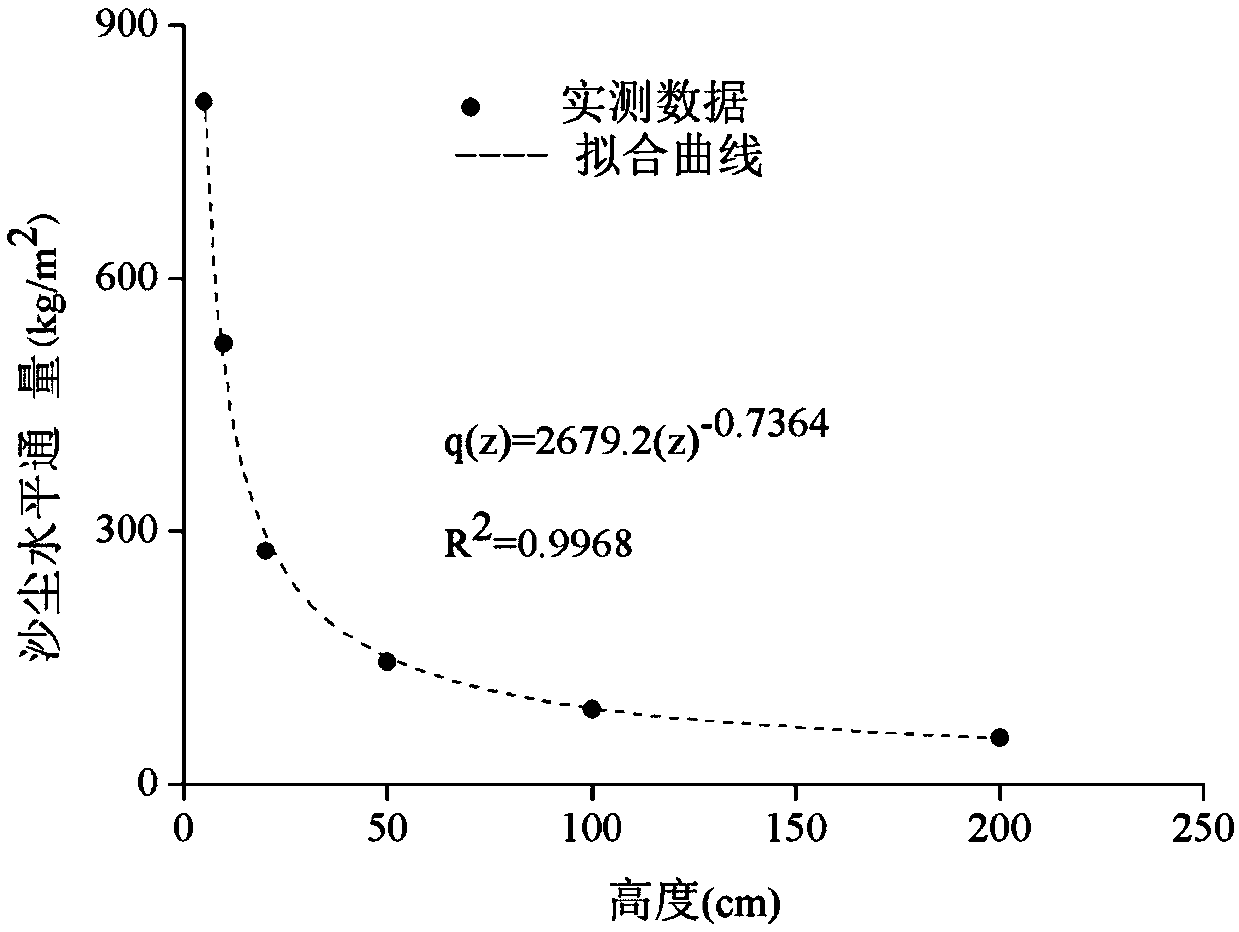

Method for acquiring sand horizontal moving flux in surface layer

The invention discloses a method for acquiring the sand horizontal moving flux in the surface layer, and relates to the technical field of stratum sand monitoring. According to the method, the numberof the sand moving in the surface layer is measured in real time, fully automatically, and continuously by a Sensit piezoelectric wind erosion sensor, so that the total number of the sand moving in the surface layer in any sampling time period can be obtained. By establishing a linear relation between the sand horizontal moving flux in the surface layer and the total number of the sand moving in the surface layer in the same time period, and utilizing the linear relation and the total number of the sand moving in the surface layer in any sampling time period, the sand horizontal moving flux inthe surface layer of any measurement time step in a certain area can be rapid estimated. Therefore, the acquisition of the sand horizontal moving flux parameter in the surface layer of a certain areais more convenient and rapid. Compared with the acquisition method in the prior art, the labor cost can be greatly reduced; the sand horizontal moving flux data in the surface layer can be acquired in a higher frequency; and the requirement for scientific research or business application is met.

Owner:INST OF DESERT METEOROLOGY CMA URUMQI

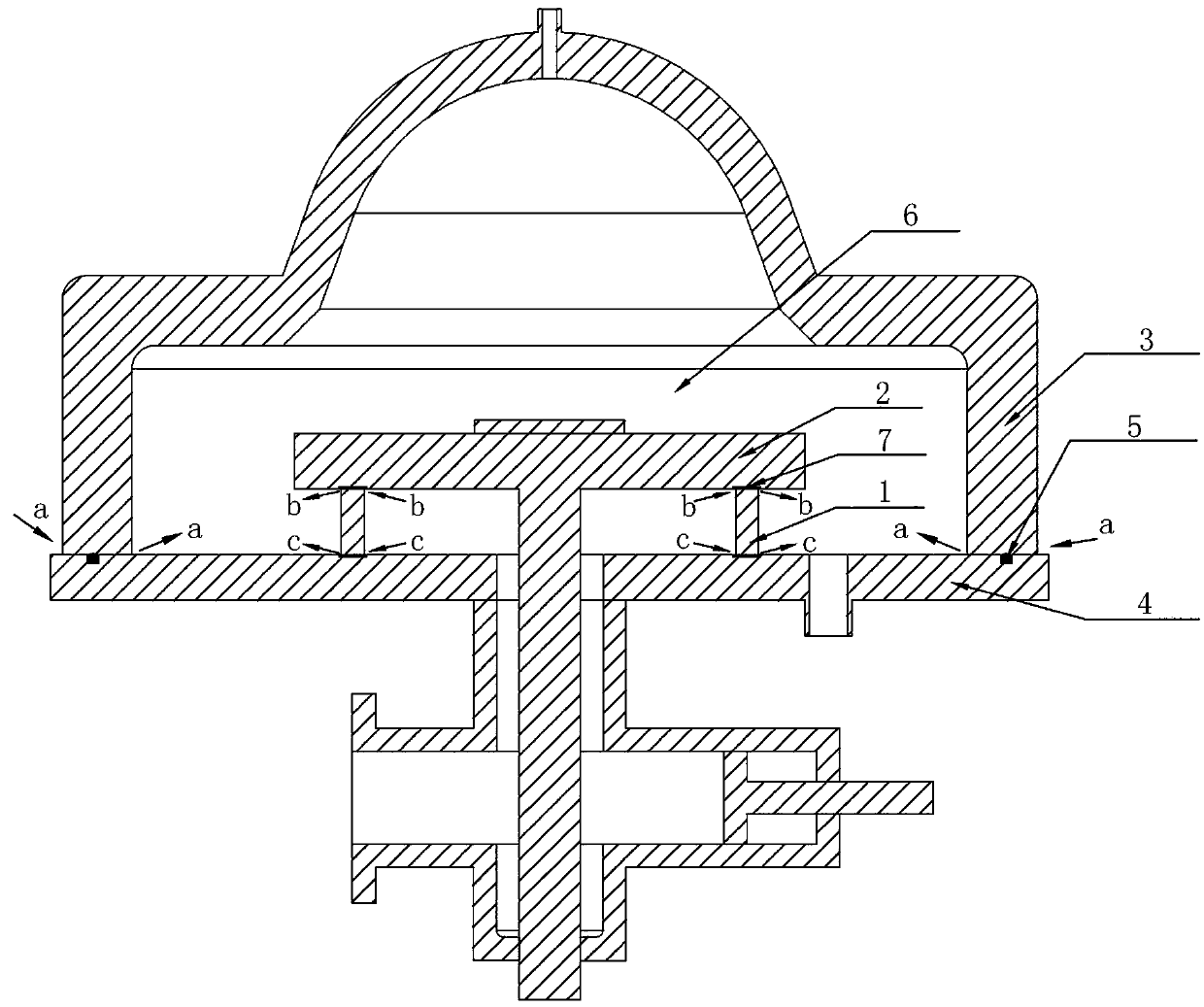

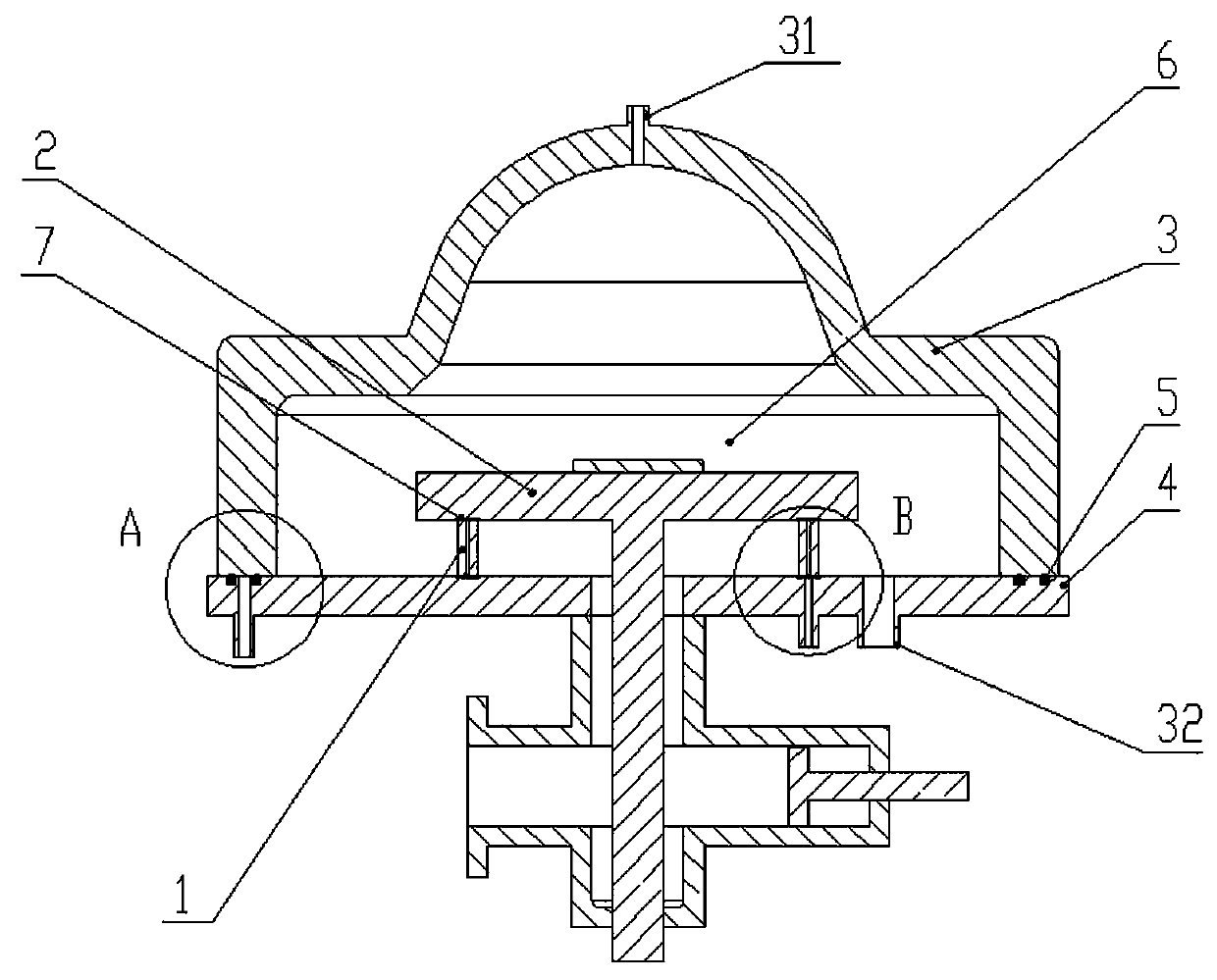

Microwave plasma diamond film deposition equipment

ActiveCN109778138AReduce vacuum leak rateQuality improvementChemical vapor deposition coatingGas-discharge lampMicrowave

The invention relates to the technical field of microwave plasma chemical vapor deposition, and specifically discloses microwave plasma diamond film deposition equipment. The top and the bottom of a microwave quartz window are in sealing connection with a deposition table and a bottom plate through a sealing gasket group separately; the sealing gasket group comprises an outer-ring sealing gasket and an inner-ring sealing gasket; gas discharge gaps are formed between the outer-ring sealing gasket and the inner-ring sealing gasket; the gas discharge gaps in the top and the bottom are communicated through second ventilation holes; third ventilation holes in the bottom plate are used for communicating the gas discharge gaps with a second exhaust pipe; and the second exhaust pipe is connected with a vacuumizing device. The microwave plasma diamond film deposition equipment is capable of effectively isolating external air, so that a vacuum working environment in a reaction cavity is maintained, and the vacuum leakage rate of MPCVD equipment of the type is effectively lowered; and effective isolation for the reaction cavity from external air is finally realized, so that a beneficial guarantee is provided for preparation for a high-quality product, the quality of the microwave plasma chemical vapor deposition product is improved, and the scientific research and industrialized production needs are met.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Convenient-to-use intestinal static replacement experimental device

The invention provides a convenient-to-use intestinal static replacement experimental device. The device comprises an intestinal assembly simulating the large intestine shape of a human or animal, wherein an intestinal cavity bottom plate of the intestinal assembly is connected with a dome-shaped intestinal wall provided with a plurality of protruding quasi-ring bags and quasi-ring folds, the dome-shaped intestinal wall is provided with a gas inlet connector for nitrogen injection, a gas discharging opening discharges oxygen to from an oxygen-free environment, an edged bottle cover is installed on an intestinal cavity upper opening of the dome-shaped intestinal wall in a matched mode, the edged bottle cover is provided with a sample feeding pipeline and a sample taking pipeline for fillingan experimental sample into or sucking the experimental sample out of the intestinal assembly, a sample-discharging lower opening and a lower opening rubber plug provided with multiple probes are installed on the lower edge of the dome-shaped intestinal wall, a temperature control water sleeve provided with a water bath sealed bin is arranged around the intestinal assembly in a wrapping mode, temperature is controlled in the way that a water bath inlet and a water bath outlet are connected with a water pump and a water heater outside, and the outer surface of the temperature control water sleeve is tightly wrapped in a thermal insulation soft pad. The device has the advantages that an in-vivo experiment can be replaced with a convenient-to-perform and fast in-vitro static replacement experiment on the digestion function in intestines with low cost and high efficiency, and the requirements for standard scientific research and application are met.

Owner:TIANJIN HOPE IND & TRADE

Method for improving stability of carbon dioxide detection reagent

ActiveCN103698500AReduce exposureImprove stabilityBiological testingParaffin oilsSurface-active agents

The invention provides a method for improving the stability of a carbon dioxide detection reagent; after the method is adopted, the stability and the biological activity of the carbon dioxide detection reagent can be maintained for a long time and the biological activity of the carbon dioxide detection reagent can be maintained after the carbon dioxide detection reagent is decapped. According to the method, an organosilicon polymer, mineral oil or light paraffin oil, a surface active agent and a pH value regulator are used for reducing the contact between carbon dioxide in outside air and the reagent, so that the stability of the carbon dioxide biochemical reagent can be remarkably improved. After the method for improving the stability of the carbon dioxide detection reagent is adopted, a carbon dioxide detection kit has the relatively excellent stability, so that the demands of scientific research and medical examination can be relatively well met.

Owner:上海执诚生物科技有限公司

Device and method for testing shielding effectiveness of curved surface electromagnetic shielding fabric

ActiveCN108107275ASolve the problem that the shielding effectiveness of electromagnetic shielding fabrics with curved surfaces cannot be testedSolve the shielding effectElectromagentic field characteristicsFixed frameElectromagnetic shielding

The invention provides a device and a method for testing shielding effectiveness of a curved surface electromagnetic shielding fabric. The device comprises a fabric fixing frame, a curved surface adjusting rod and an edge fixing device, wherein the fabric fixing frame comprises a main board and an auxiliary board, the main board and the auxiliary board are connected through a connecting rod, curved surface adjusting rods are arranged on the main board and the auxiliary board, and the edge fixing device comprises a pressing plate arranged on the main plate. The problem that the shielding effectiveness of the curved surface form electromagnetic shielding fabric cannot be tested currently is solved. An important basis is provided for design, production and evaluation of the electromagnetic shielding clothing and the shielding covers, and a theoretical foundation is laid for related research of the electromagnetic shielding fabric. The device is simple to operate, accurate in testing effect, low in cost, and is practical and novel.

Owner:ZHONGYUAN ENGINEERING COLLEGE

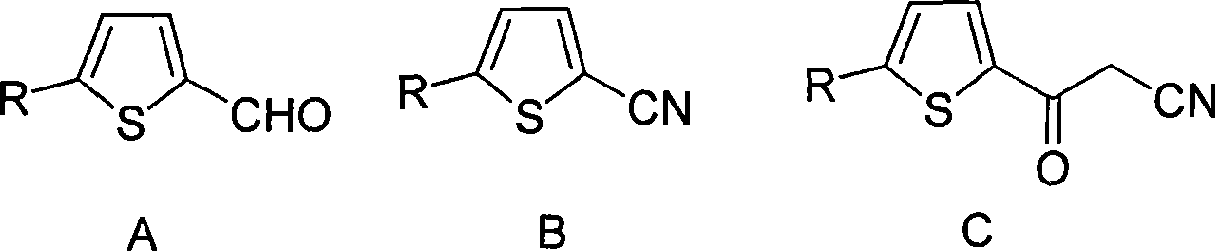

Method for preparing 2-cyanoacet-5-substituted thiophenes compound

The invention discloses a method for preparing 2-oxopropionitrile-5-substituted thiophene compounds as shown in the formula C. The method includes the following steps: (1) 5-substituted thiophene formaldehyde , iodin and ammonia shown in the formula A are led to react in an inertia organic solution at the temperature of 0 to 60 DEG C to obtain the 5-substituted thiophenecarbonitrile shown in the formula B; (2) the 5-substituted thiophenecarbonitrile shown in the formula B is led to react with acetonitrile in the inertia organic solution, with the existence of alkali and at the temperature of minus 80 to 0 DEG C; wherein, R represents H, F, Cl, Br, I or CH3. The 2-oxopropionitrile-5-substituted thiophene compounds prepared by the method of the invention have high purity reaching above 98 percent (HPLC purity) and meet the requirements of scientific researches and pharmacy industry. The method provided by the invention is simple; the operation is convenient; the yield is high; the method is suitable for large-scale industrial production, with comparatively high industrial application value.

Owner:CHINA GATEWAY PHARMA DEV CO LTD

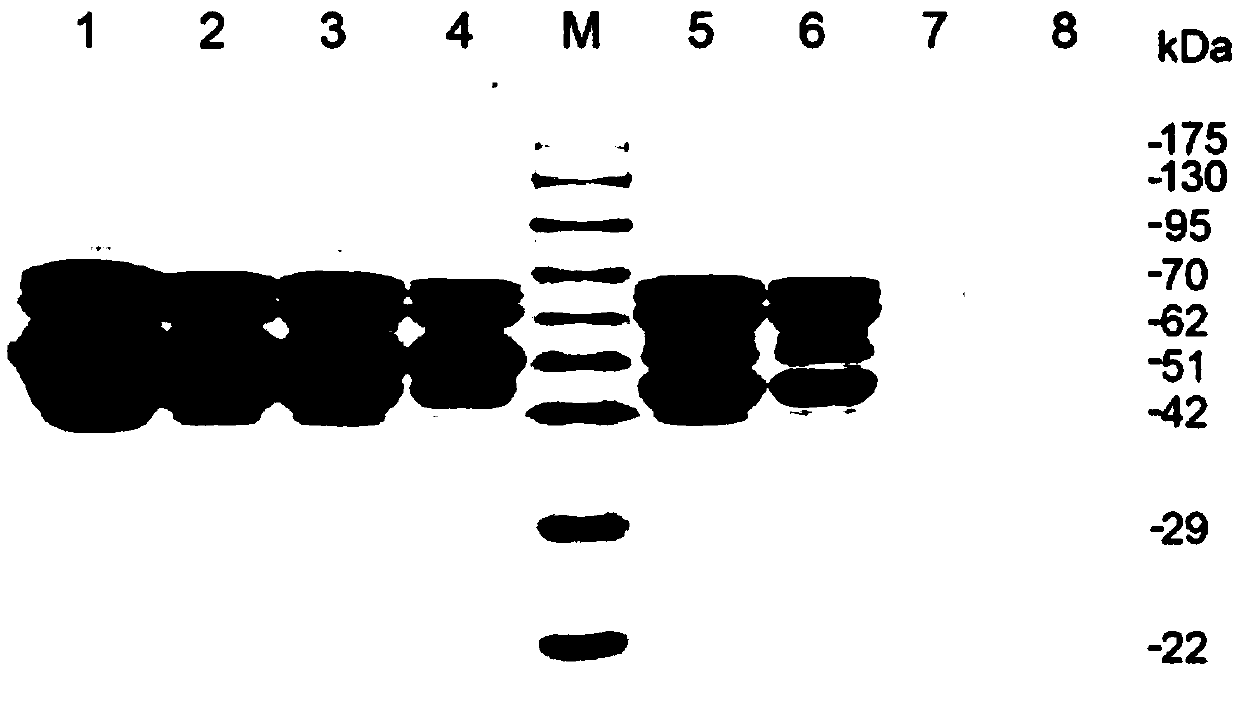

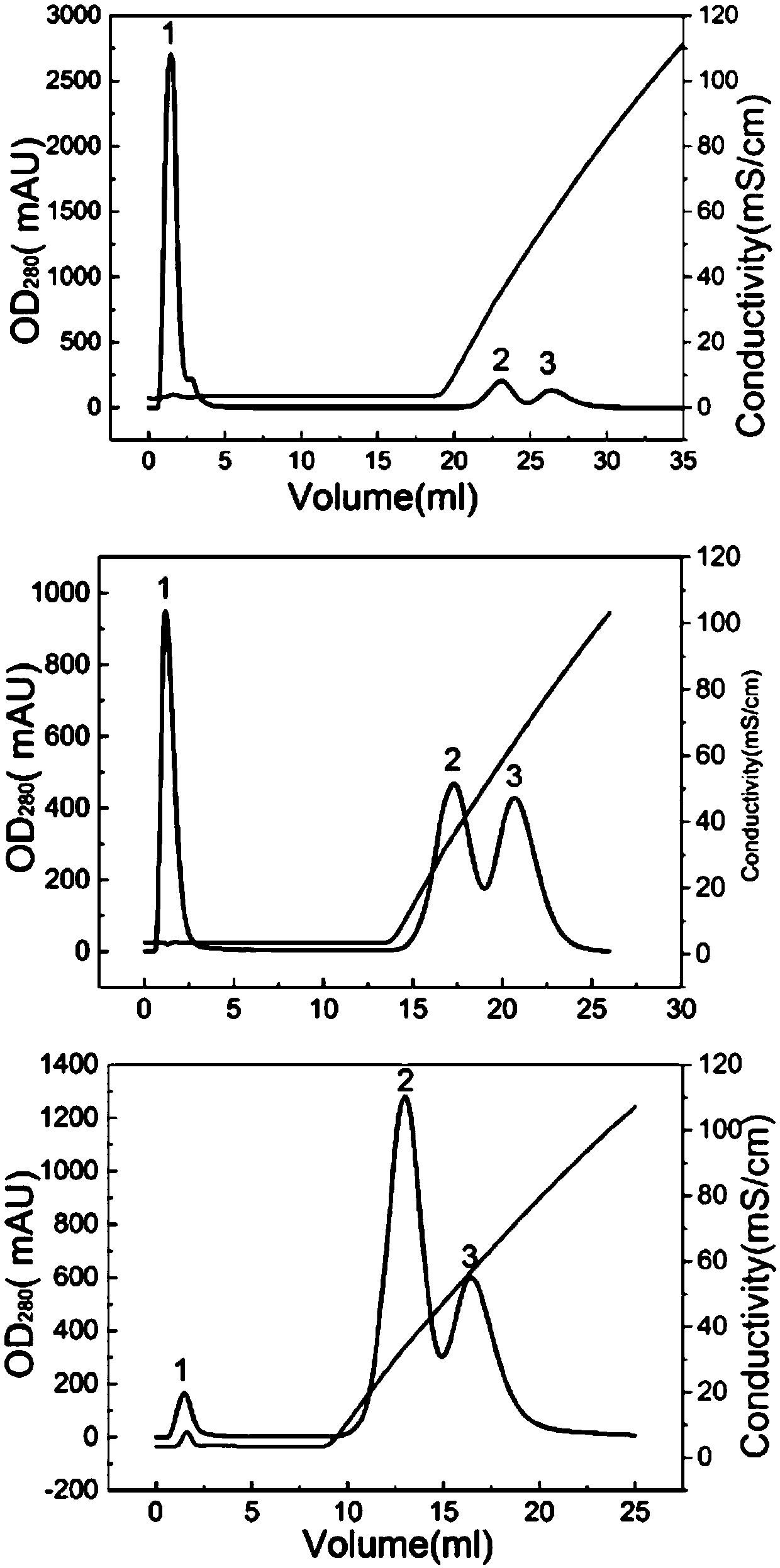

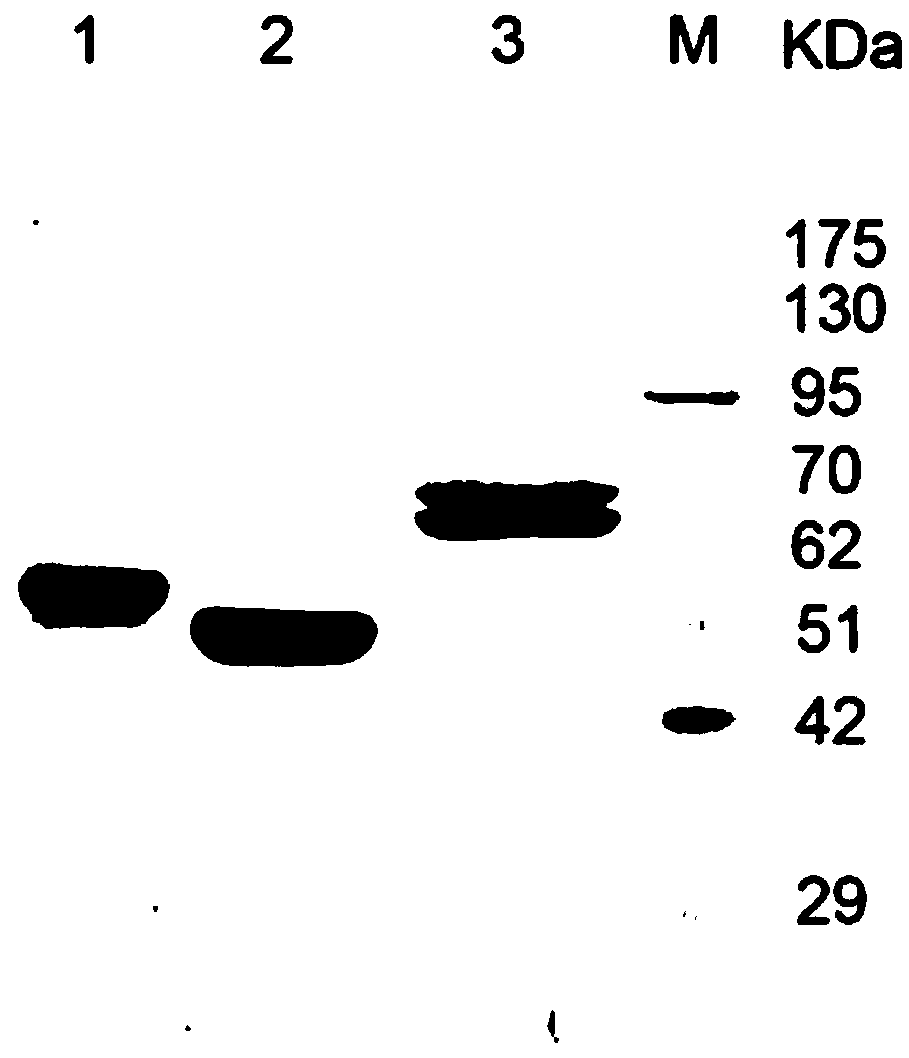

Method for increasing yield of major proteins 2 and 3 in royal jelly by liquid chromatography purification

ActiveCN109535239AIncrease productionIncrease abundancePeptide preparation methodsAnimals/human peptidesCentrifugationUltrafiltration

The invention provides a method for increasing yield of major proteins 2 and 3 in royal jelly by liquid chromatography purification. The method comprises steps as follows: royal jelly is dissolved inan extraction buffer solution, the mixture is mixed uniformly and centrifuged, a supernatant is taken, saturated ammonium sulfate is added to the supernatant for precipitation, a supernatant is takenafter centrifugation, filtering is performed by a filter membrane, and a sample buffer solution is obtained; the sample buffer solution is replaced with a buffer solution A with pH being 7.0 by an ultrafiltration centrifuge tube; a royal jelly sample is loaded to a pre-assembled weak cationic chromatographic column balanced by the buffer solution A; the column is subjected to gradient elution by amixed solution of the buffer solution A and a buffer solution B, the ratio of the buffer solution B is gradually increased from 0 to 100%, and major proteins 2 and 3 in the royal jelly are separatedand purified in sequence. According to the method for increasing the yield of the major proteins 2 and 3 in the royal jelly by liquid chromatography purification, abundance of the major proteins 2 and3 in the royal jelly is increased, yield of the major proteins 2 and 3 in the royal jelly is increased, repeatability is good, the yield is high, and the major proteins 2 and 3 in the royal jelly canbe produced on a large scale.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

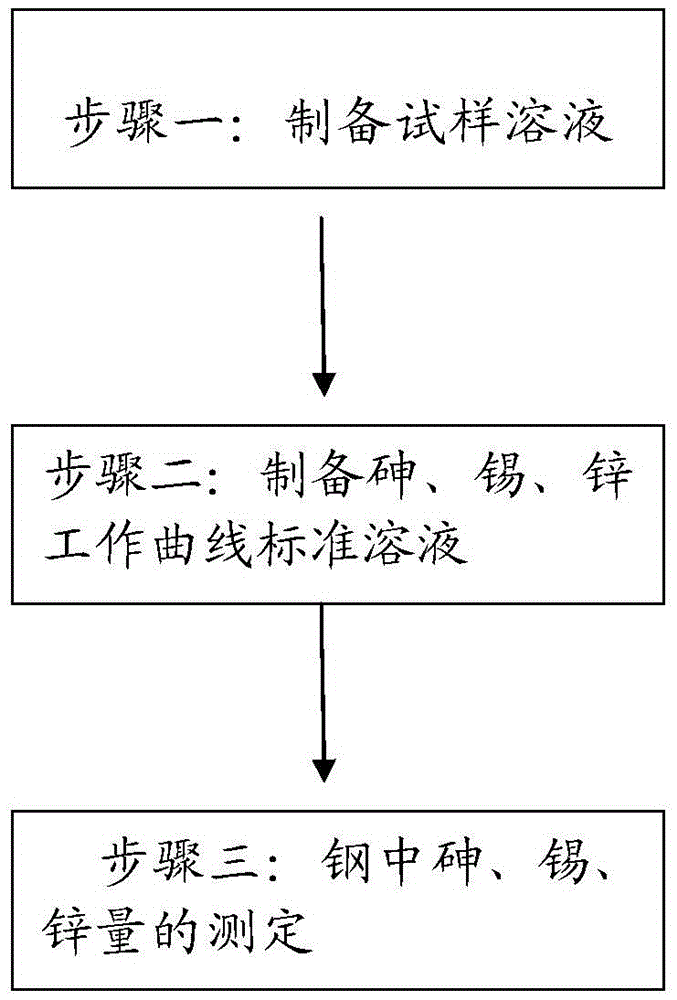

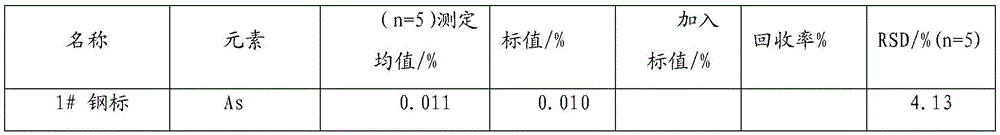

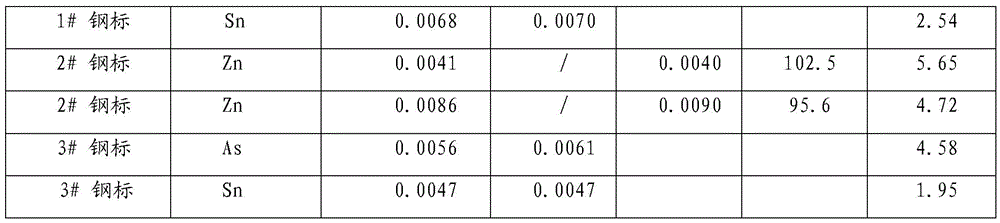

Determination method for content of arsenic, tin and zinc in steel

InactiveCN105548330ALow detection limitAnalysis method is simple and fastPreparing sample for investigationMaterial analysis by electric/magnetic meansMetallurgical assayInterference factor

Belonging to the field of metallurgical analysis methods, the invention discloses a determination method for the content of arsenic, tin and zinc in steel, and aims to solve the disadvantages of unable simultaneous determination of the content of arsenic, tin and zinc three elements in steel, a lot of use of chemical reagents, harm to the environment and human body, many interference factors, slow analysis speed, and low accuracy in the prior art. The determination method comprises the steps of: 1. preparation of a sample solution, 2. preparation of an arsenic, tin, zinc working curve standard solution, and 3. determination of the content of arsenic, tin and zinc in steel. The method provided by the invention has the characteristics of low detection limit of 0.10ng / ml, simple and fast analysis method, few reagent, little interference, fast analysis speed, good precision, and high accuracy, and is suitable for simultaneous determination of the content of arsenic, tin and zinc three elements in steel.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

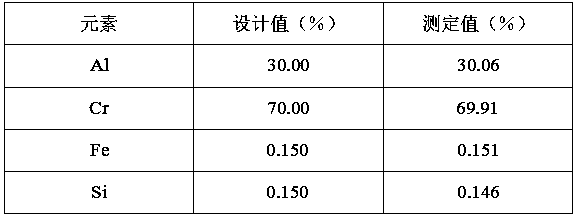

Analytical method for simultaneously determining percentages of aluminum, chromium, iron and silicon in aluminum chromium alloy

InactiveCN108896535AEasy to operateEasy to masterPreparing sample for investigationAnalysis by thermal excitationFerrochromeChromium Alloys

The invention relates to an analytical method for simultaneously determining percentages of aluminum, chromium, iron and silicon in an aluminum chromium alloy. The analytical method comprises the following steps: establishing a corresponding working curve according to an emission line intensity value and a concentration value of a standard solution for a plurality of working curves and acquiring amethod linear equation; determining a to-be-detected aluminum chromium alloy solution and acquiring the intensities of all the emission lines; adopting an inductively coupled plasma atomic emission spectrometer for automatically calculating the percentages of aluminum, chromium, iron and silicon in the aluminum chromium alloy according to the working curve. The analytical method provided by the invention solves the problems that the existing international standard and current journal method cannot simultaneously determine the contents of aluminum, chromium, iron and silicon in the aluminum chromium alloy and have more analytical steps, more reagent materials for analysis, long analysis period and low efficiency, also solves the problem that an internal standard method-inductively coupledplasma atomic emission spectroscopy analytical method for simultaneously determining aluminum, chromium, iron and silicon in the aluminum chromium alloy does not exist at present, and provides a reference basis for the production control and application of the aluminum chromium alloy.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

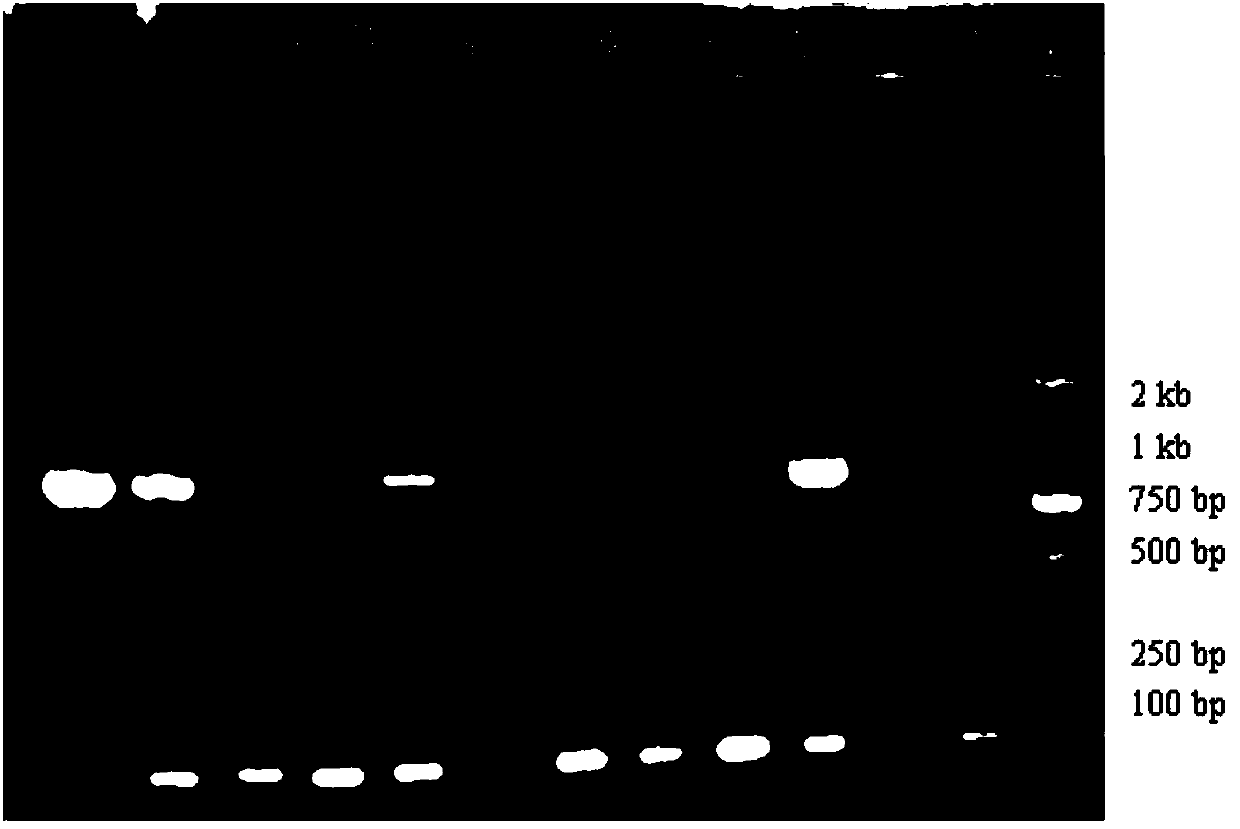

Molecular identification primer and identification method of angular leaf spot bacteria of tobacco

ActiveCN104212896AFast and reliable detectabilityFast and reliable identificationMicrobiological testing/measurementDNA/RNA fragmentationMolecular identificationAgricultural science

The invention discloses a molecular identification primer and an identification method of angular leaf spot bacteria of tobacco. The molecular identification primer of the angular leaf spot bacteria of tobacco is as shown in SEQ ID NO: 1-SEQ ID NO: 2, wherein the sequence as shown in the SEQ ID NO: 1 is an upstream primer for identifying the angular leaf spot bacteria of tobacco and the sequence as shown in the SEQ ID NO: 2 is a downstream primer for identifying the angular leaf spot bacteria of tobacco. The molecular identification primer disclosed by the invention can be applied in specific identification of the angular leaf spot bacteria of tobacco. In addition, the invention also provides a reliable, strong-specificity and high-sensitivity rapid molecular identification method of the angular leaf spot bacteria of tobacco.

Owner:中国烟草总公司黑龙江省公司烟草科学研究所

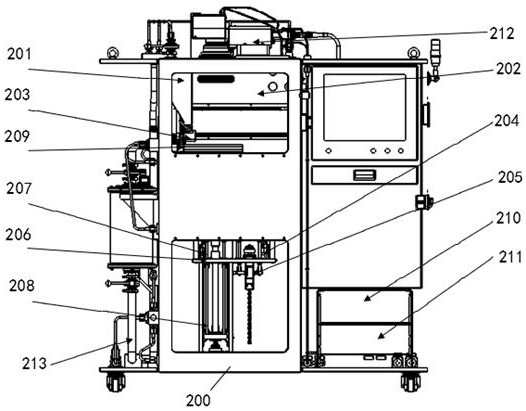

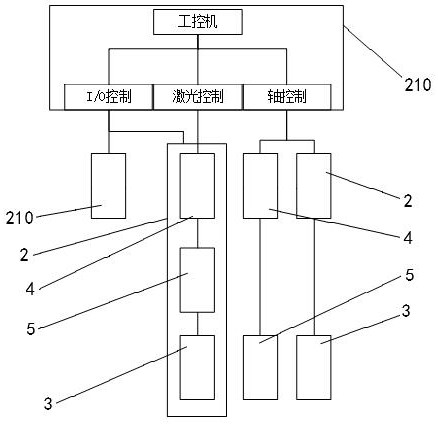

Gradient functional material synthesis and additive manufacturing integrated mechanism

PendingCN113147029AImprove molding efficiencyImprove molding qualityAdditive manufacturing apparatus3D object support structuresMaterial synthesisGalvanometer

The invention belongs to the technical field of additive manufacturing, and particularly relates to a gradient functional material synthesis and additive manufacturing integrated mechanism. According to the technical scheme, the gradient functional material synthesis and additive manufacturing integrated mechanism comprises a support, a shell, a powder feeding cabin servo driving system, a powder feeding cabin lifting mechanism, a forming cabin servo driving system, a forming cabin lifting mechanism, a galvanometer control card, a galvanometer, a laser device, a CNC system, a servo driving system, a laser system and an atmosphere system, wherein a powder feeding and powder laying mechanism is fixedly installed on the support. The gradient functional material synthesis and additive manufacturing integrated mechanism has the beneficial effects that gradient control over the powder feeding amount, the powder laying layer thickness, the laser heating source temperature and the like each time is synchronously and consistently achieved in a fusion manner till FGM material synthesis and additive manufacturing integrated forming is achieved, the forming efficiency and quality are improved, and the technical problems of gradient function integration type and FGM material synthesis are solved; and the technical problems of FGM material synthesis and additive manufacturing integration and integration process preparation are further solved.

Owner:西安高商智能科技有限责任公司

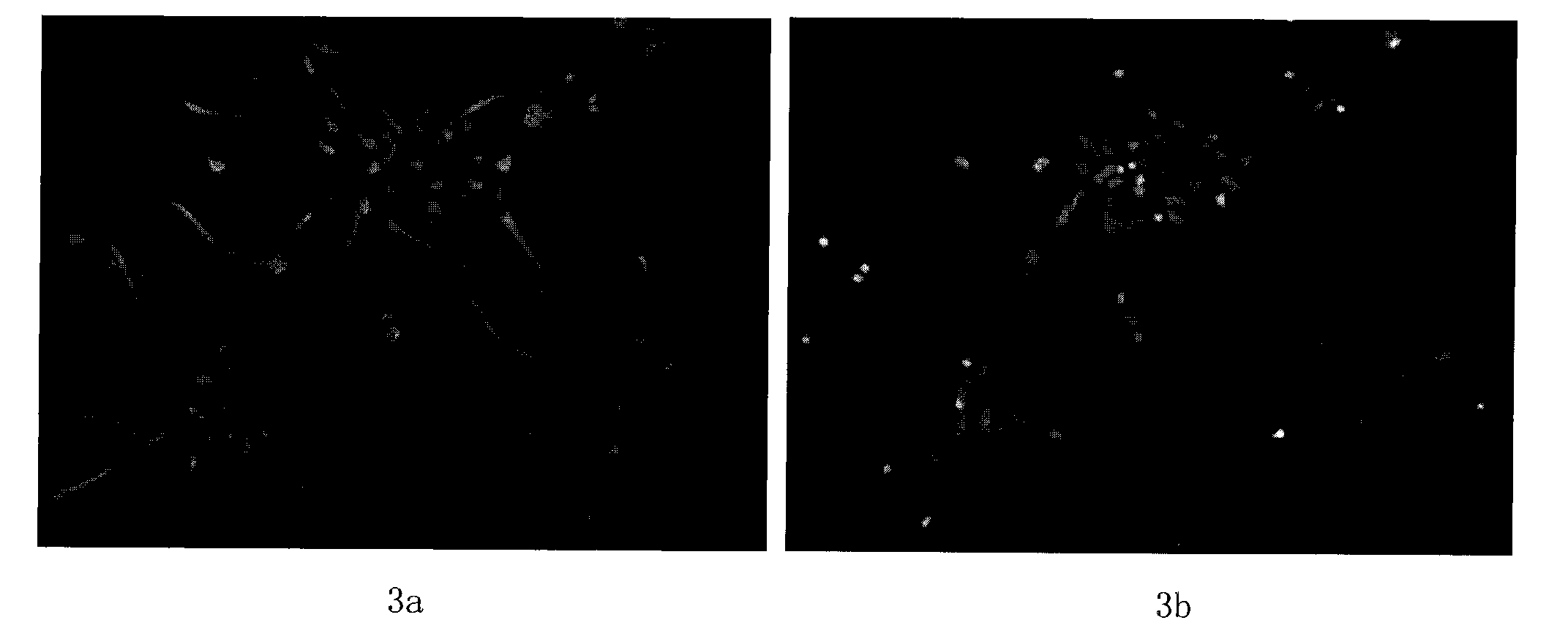

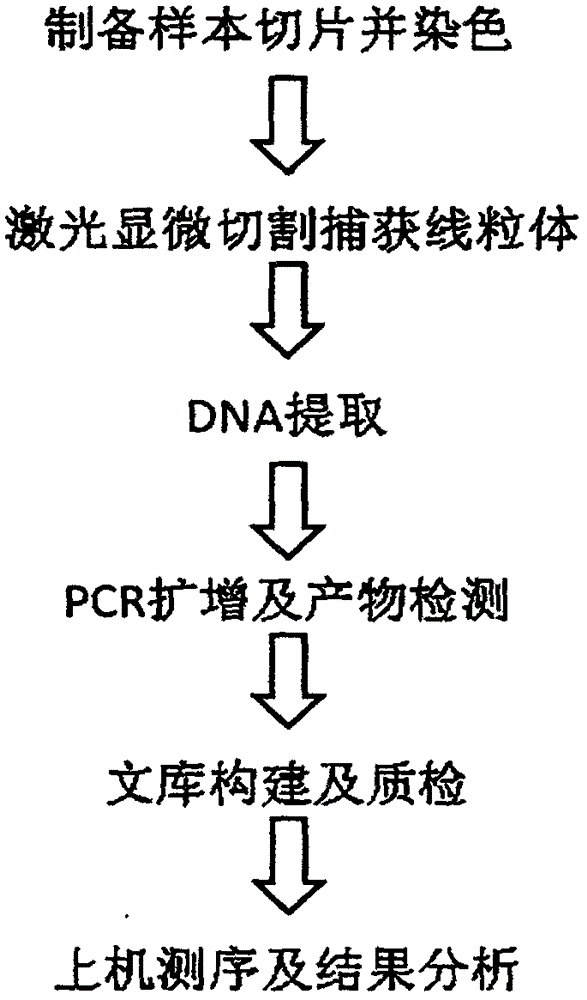

Next generation sequencing platform-based noninvasive target mitochondrion sequencing method

InactiveCN106520945ARealize detectionHelp in correct diagnosisMicrobiological testing/measurementMitochondrion organizationDNA extraction

The invention discloses a next generation sequencing platform-based noninvasive target mitochondrion sequencing method. The method comprises the following steps of preparing a sample slice and performing staining; capturing mitochondria through laser microdissection, wherein the number of mitochondrion tissues captured through the laser microdissection is 1-200; performing DNA extraction; performing PCR amplification and product detection; performing library construction and quality inspection; and performing computer sequencing and result analysis. Through a specific staining technology, the mitochondrion tissues are stained; by utilizing a laser microdissection technology, mitochondrial DNAs are obtained in a targeted way; through micro DNA extraction and amplification technologies, the mitochondrial DNAs are obtained and used for downstream library construction and detection; and the experimental design is rigorous, the experimental process is simple, a detection result is accurate and reliable, the scientific research and clinical detection demands can be met to varying degrees, the method is suitable for quick detection of mitochondrion-related mutation in scientific research and clinic, and correct diagnosis and classification of clinical diseases are facilitated.

Owner:JIANGSU SUPERBIO LIFE SCI CO LTD

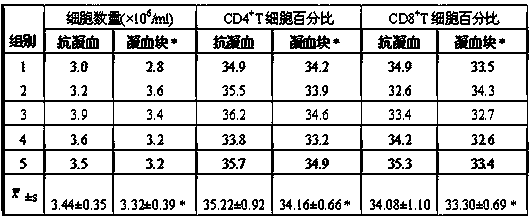

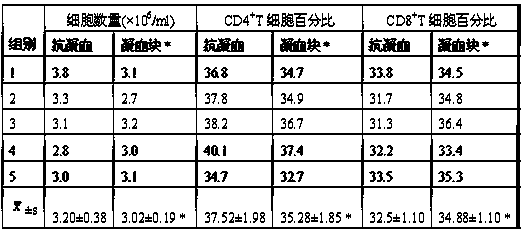

Method for extraction of white blood cells from blood clot

InactiveCN103820388AEnoughFunction increaseBlood/immune system cellsPeripheral blood mononuclear cellRed blood cell

The invention provides a method for extraction of white blood cells from a blood clot, comprising the following steps: covering a 100 mesh filter screen onto a beaker or plate; stripping the blood clot and transferring it onto the filter screen; grinding the blood clot in the core of a glass syringe and dropping normal saline to wash simultaneously; gathering blood cells which pass through the filter screen and collect in the beaker or plate; adding hemolysin to crack red blood cells in blood cells and obtaining white blood cells; or separating blood cells by lymphocyte stratified fluid to obtain peripheral blood mononuclear cells. The invention is applicable to the field of scientific experiments or clinical tests in which both serum and white blood cells are needed according to the same blood sample.

Owner:SHANXI MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com