Method for determining trace impurity elements in high purity alumina polycrystalline material

A high-purity alumina and determination method technology, which is applied in the field of determination of trace impurity elements in high-purity alumina polycrystalline materials, can solve problems such as glow discharge interference, difficult to grasp the mixing ratio, and influence on measurement results, and achieve Simplified sample pretreatment steps, easy to stabilize signal stability, simple sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

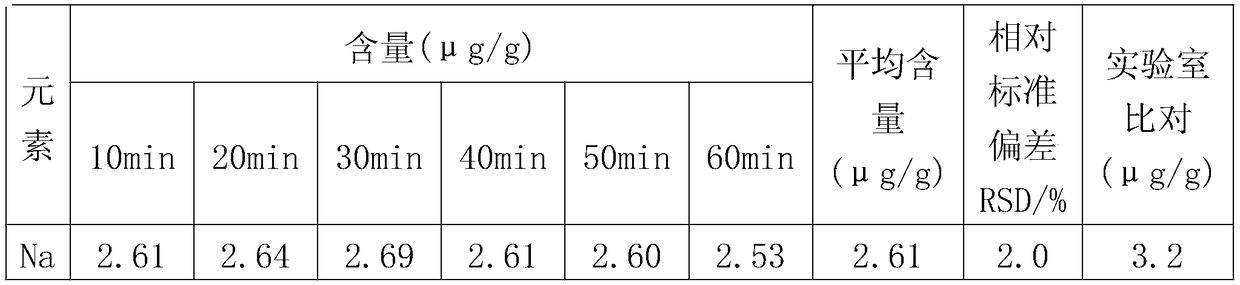

Embodiment 1

[0041] (1) Break the sample AP1# of massive high-purity alumina polycrystalline material to be tested, and process it into a particle sample with a diameter of 2-4mm; avoid pollution caused by the operation process during sample processing.

[0042] (2) First corrode the high-purity tantalum sheet with a mixed solution of nitric acid and hydrofluoric acid with a volume ratio of 3:1, then wash it with pure water, wash it with absolute ethanol, and dry it;

[0043] Take a 2.5mm high-purity alumina polycrystalline particle and place it on two cleaned high-purity tantalum sheets (thickness 0.5mm, purity ≥ 99.999%, and Na, Mg, Si, Ca, Ti, V, Cr, Mn , Fe, Ni, Cu, Zn, Ga single impurity element content should not be greater than 0.05μg / g; length × width = 25mm × 25mm); under the pressure of about 2KN, use SYP-30TS manual tablet press (Shanghai Xinnuo instrument) to inlay polycrystalline particles onto the surface of high-purity tantalum sheets.

[0044] Introduce a high-purity tanta...

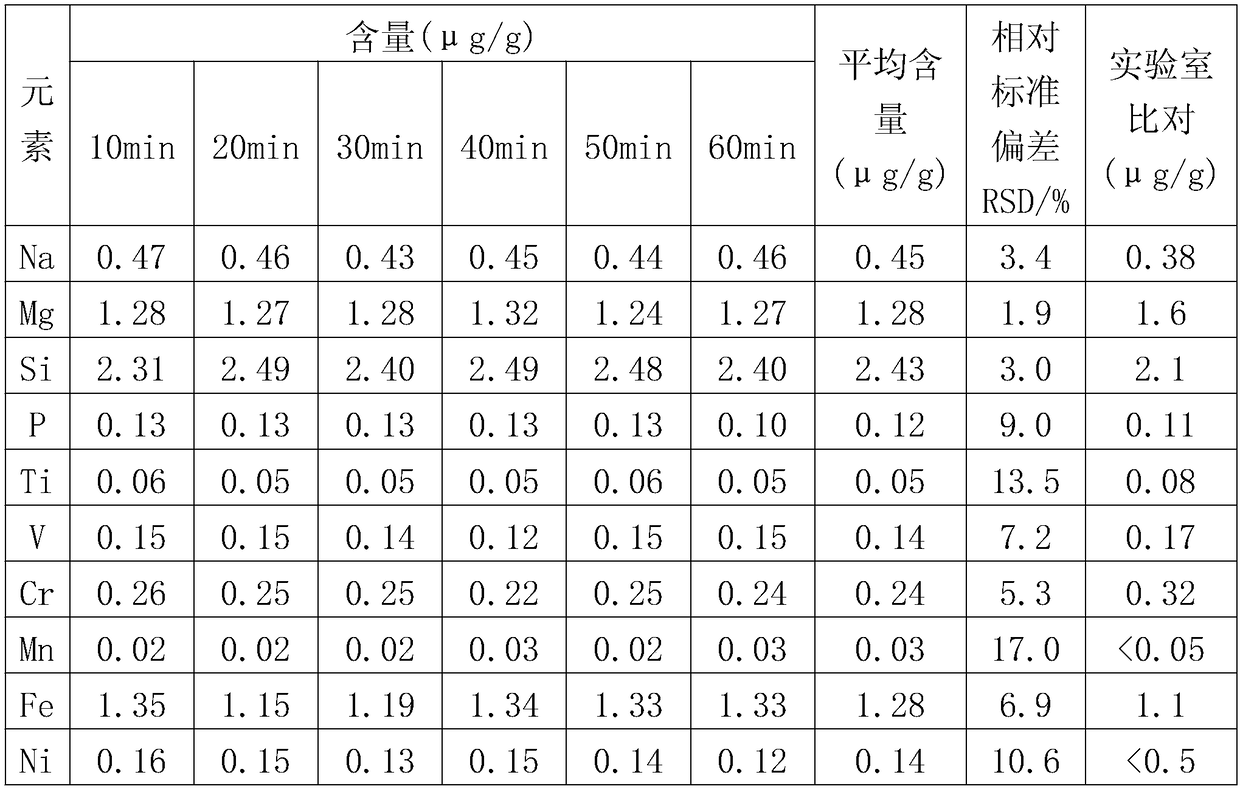

Embodiment 2

[0056] The specific operation steps are as follows:

[0057] (1) Break AP2# of the massive high-purity alumina polycrystalline material sample to be tested, and process it into a particle sample with a diameter of 2-4mm; during the sample processing process, avoid pollution caused by the operation process.

[0058] (2) First corrode the high-purity tantalum sheet with a mixed solution of nitric acid and hydrofluoric acid with a volume ratio of 3:1, then wash it with pure water, wash it with absolute ethanol, and dry it;

[0059] Take a 3.5mm high-purity alumina polycrystalline particle on two cleaned high-purity tantalum sheets (thickness 8mm, purity ≥ 99.999%, and Na, Mg, Si, Ca, Ti, V, Cr, Mn, Fe , Ni, Cu, Zn, Ga single impurity element content should not be greater than 0.05μg / g, length × width = 25mm × 25mm); under the pressure of about 2KN, use SYP-30TS manual tablet press (Shanghai Xinnuo Instrument) , so that polycrystalline particles are embedded on the surface of hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com