Analytical method for simultaneously determining percentages of aluminum, chromium, iron and silicon in aluminum chromium alloy

A technology of aluminum-chromium alloy and percentage content, which is applied in the field of chemical composition determination, can solve the problems such as the inability to measure the composition range, and achieves the effect of good application effect, accurate result and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of the iron standard solution is as follows: accurately pipette the iron standard stock solution in step 1 and place it in a volumetric flask, add water to the volumetric flask after adding hydrochloric acid to make it constant, and set it aside;

[0031] Silicon standard stock solution: mix silicon dioxide and anhydrous sodium carbonate into a platinum crucible and put it in a high-temperature furnace to melt, and keep melting in the platinum crucible for 15 to 20 minutes, cool, soak in warm water, wash the crucible and beaker with water for at least Transfer three times and set the volume to 1000mL to prepare a silicon standard stock solution containing 0.5mg / mL of silicon, store it in a polyethylene bottle, and wait for use;

[0032] The preparation of the silicon standard solution is as follows: use a pipette to accurately pipette the silicon standard stock solution in step 1 and place it in a volumetric flask, add hydrochloric acid, add water to the ...

Embodiment 1

[0040] Step 1, preparing iron standard stock solution, silicon standard stock solution, working curve blank solution, working curve standard solution and aluminum-chromium alloy liquid to be tested, wherein the specific preparation method of iron standard stock solution and silicon standard stock solution is as follows:

[0041] Iron standard stock solution: Weigh 1.0000g of high-purity metal iron into a 250mL beaker, rinse the beaker wall with water, add 100mL of hydrochloric acid with a mass concentration of 36.0% to 38.0%, heat and dissolve, place it at room temperature, and transfer the solution to 1000mL Make up to volume in a volumetric flask. Prepare an iron standard stock solution containing 1 mg / mL of iron for use;

[0042] The preparation of the iron standard solution is as follows: use a pipette to accurately pipette 5.00mL of 1.00mg / mL iron standard stock solution into a 100mL volumetric flask, add 10.00mL of hydrochloric acid with a mass concentration of 36.0% to ...

Embodiment 2

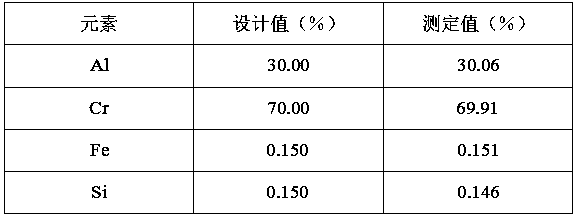

[0052] Adopt the method in embodiment 1 to measure Al, Cr, Fe, Si content in the aluminum-chromium alloy sample, and measured value is compared with design value, as shown in table 1:

[0053] Table 1 Determination of aluminum, chromium, iron and silicon content

[0054]

[0055] As shown in Table 1, the analysis errors of Al, Cr, Fe, and Si are all within the allowable error range of analysis, which shows that the detection method has accurate results and good application effect.

[0056] Can obviously observe by above-mentioned analysis, assay method of the present invention is mixed with working curve blank solution, working curve standard solution a, working curve standard solution by adding a certain amount of high-purity aluminum, high-purity chromium, iron standard solution, silicon standard solution b. Working curve standard solution c, under the premise of determining the working parameters of the inductively coupled plasma atomic emission spectrometer, select the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com