Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Low formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

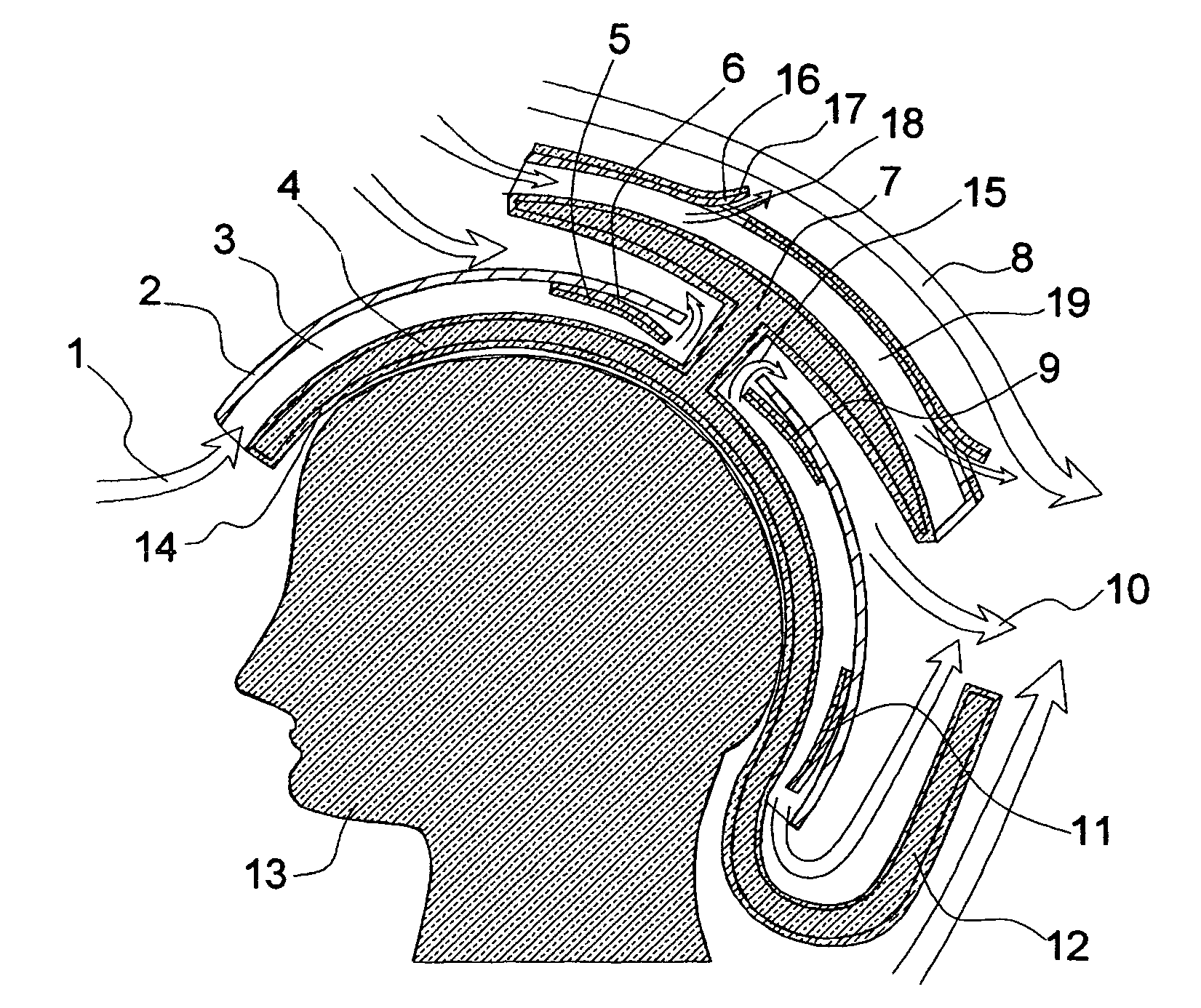

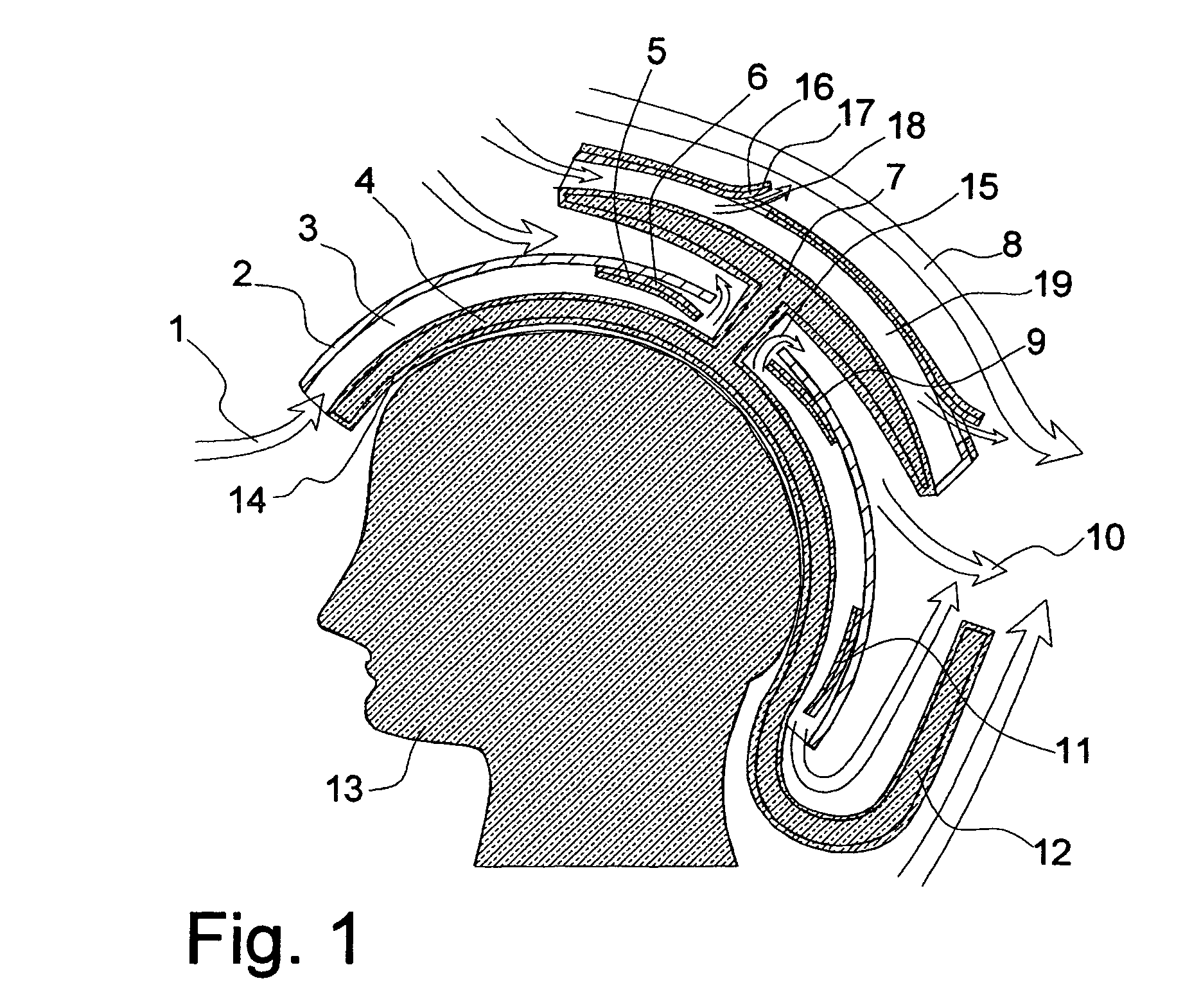

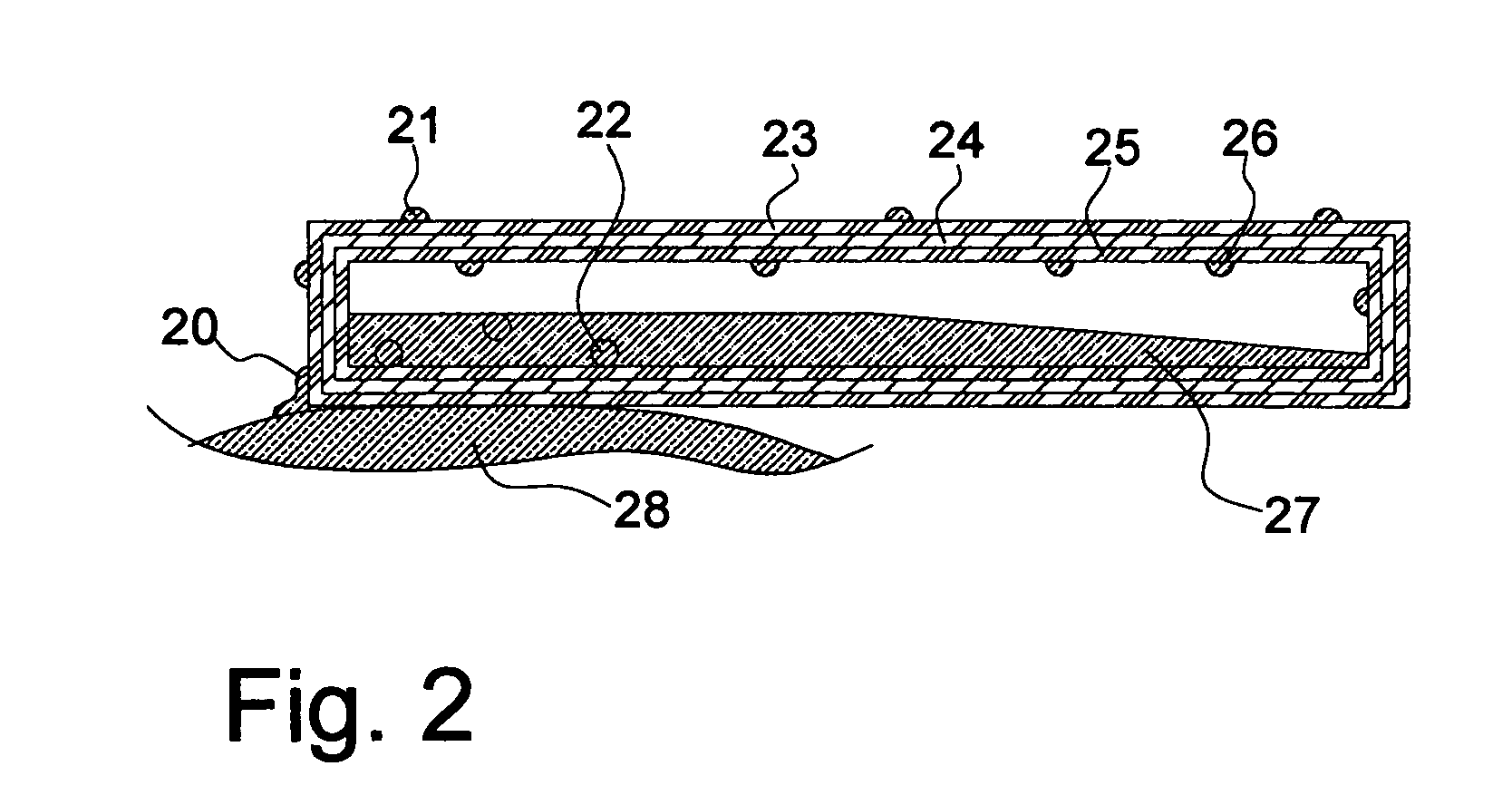

Helmet and body armor actuated ventilation and heat pipes

ActiveUS8156570B1Reduce heat transferInterfere with efficient wickingSpecial paperPaper/cardboardBiological growthHeat flow

The lack of air flow under body armor, helmets, and thick garments can lead to excessive moisture build up and discomfort on the wearers body due to lack of heat removal and effective evaporation of sweat. By incorporating wick covered heat pipes or thermal conductors with air flow channels in the apparel contact area between the garments, helmets, and body armor the effectiveness air flow cooling and evaporation of sweat can be restored. Humidity or temperature auto-actuated bi-material valves are used to control this air-moisture-heat flow to achieve a controlled comfortable humidity-temperature environment and avoid excessive cooling. Supplementary air pumps, filters, dehydrators, fluid pumps, heating fluids, and cooling fluids may be incorporated to enhance the effectiveness. Biocides and hydrophilic materials are also incorporated on the wick coverings to avoid biological growth and maintain performance to achieve a healthy environment for the wearer.

Owner:HOCKADAY ROBERT G

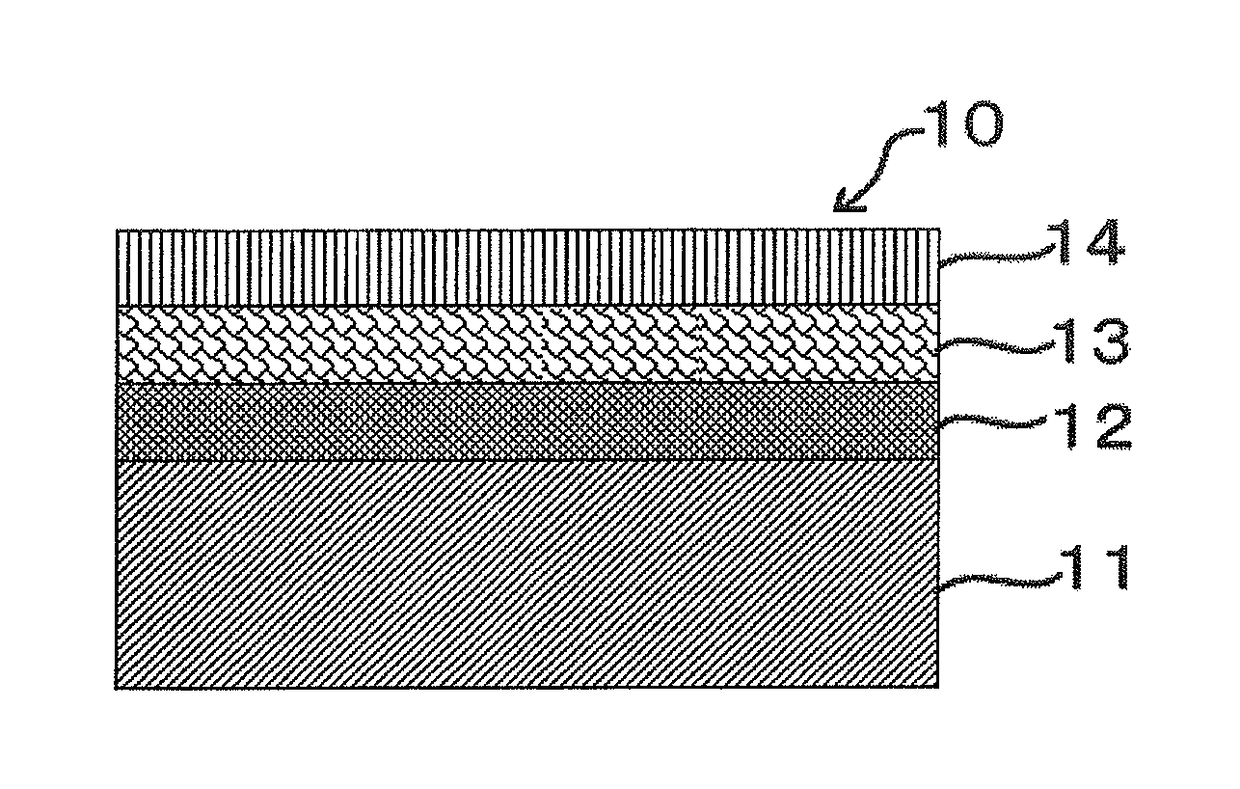

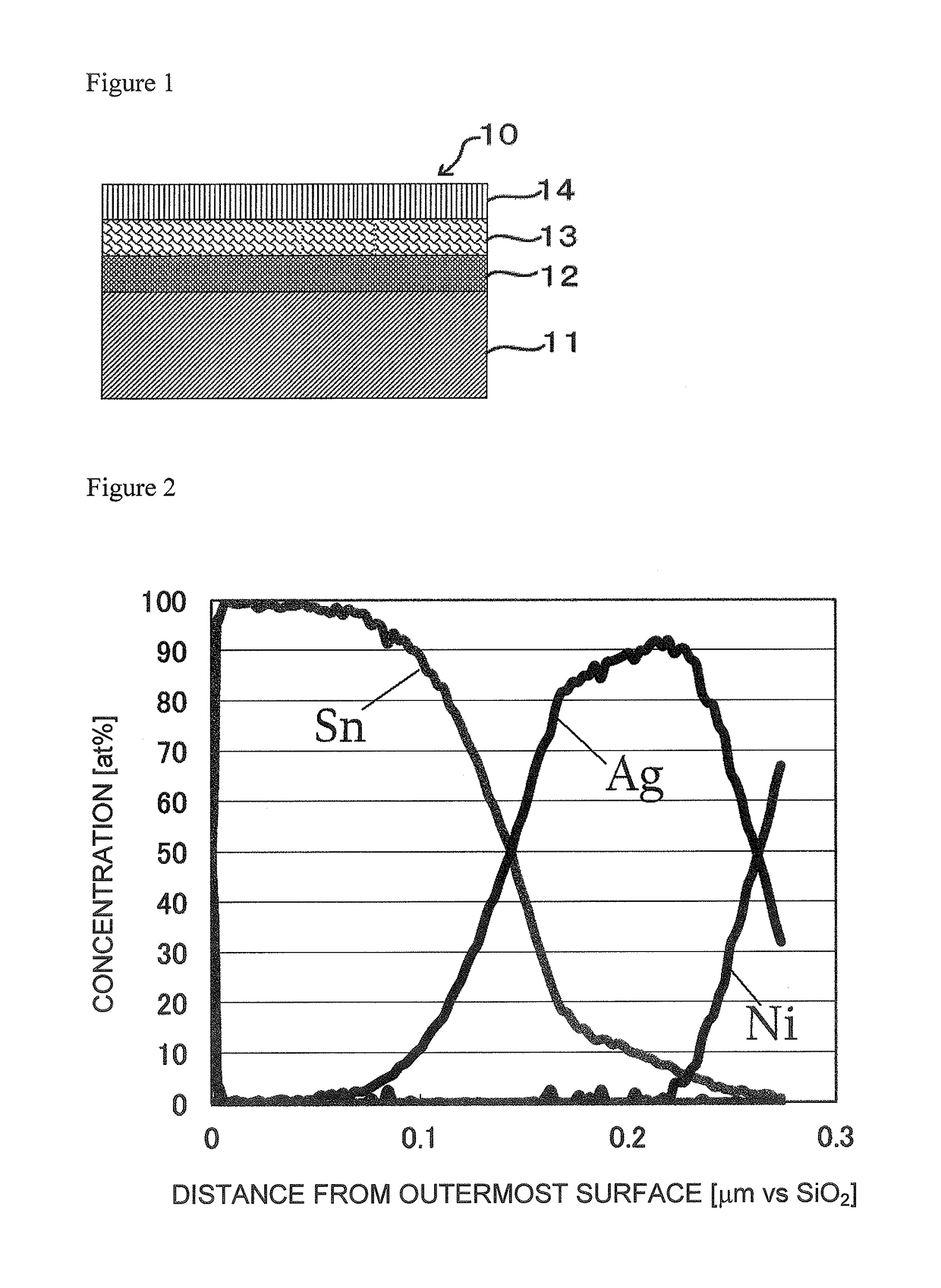

Electronic component metal material and method for manufacturing the same

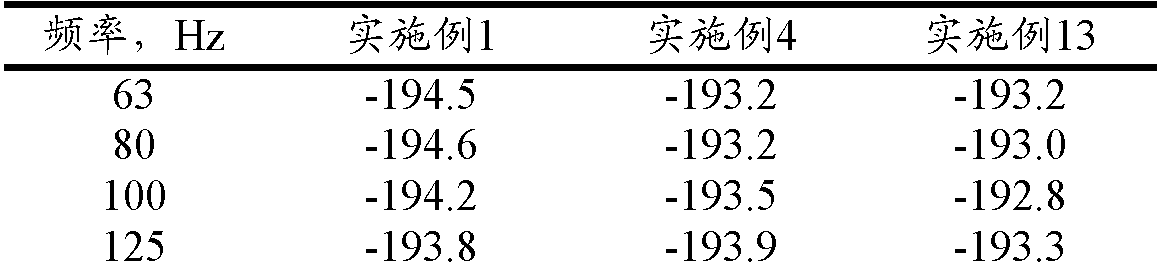

ActiveUS20150295333A1Low insertability/extractabilityIncreased durabilityElectrically conductive connectionsCoupling contact membersSurface layerMetallic materials

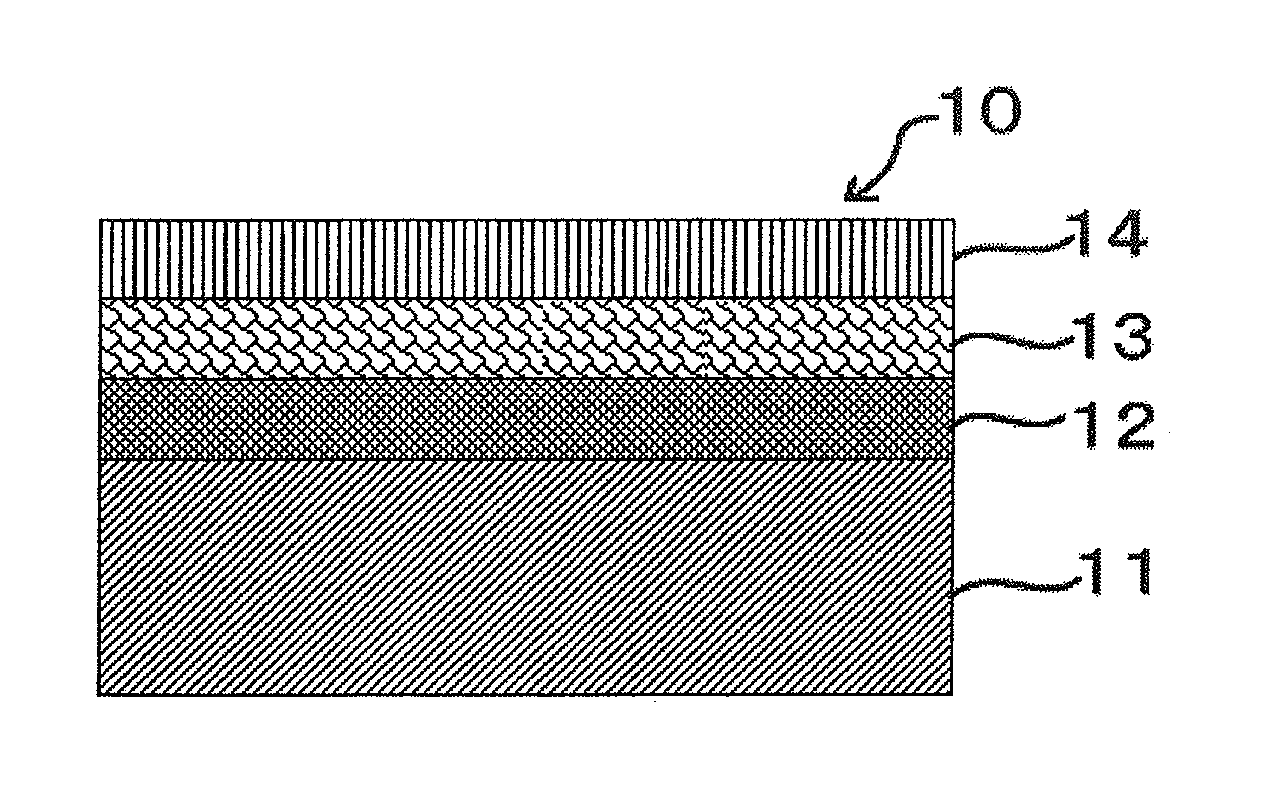

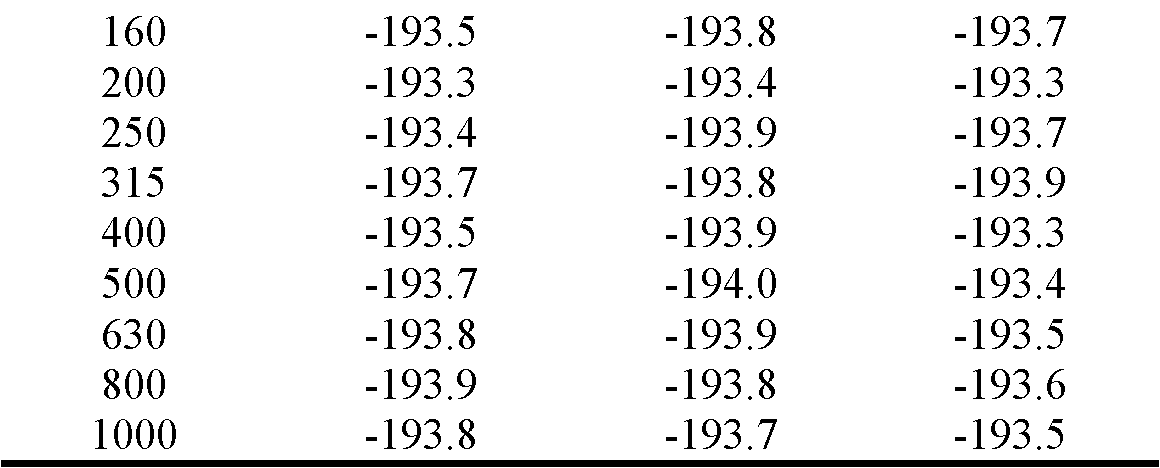

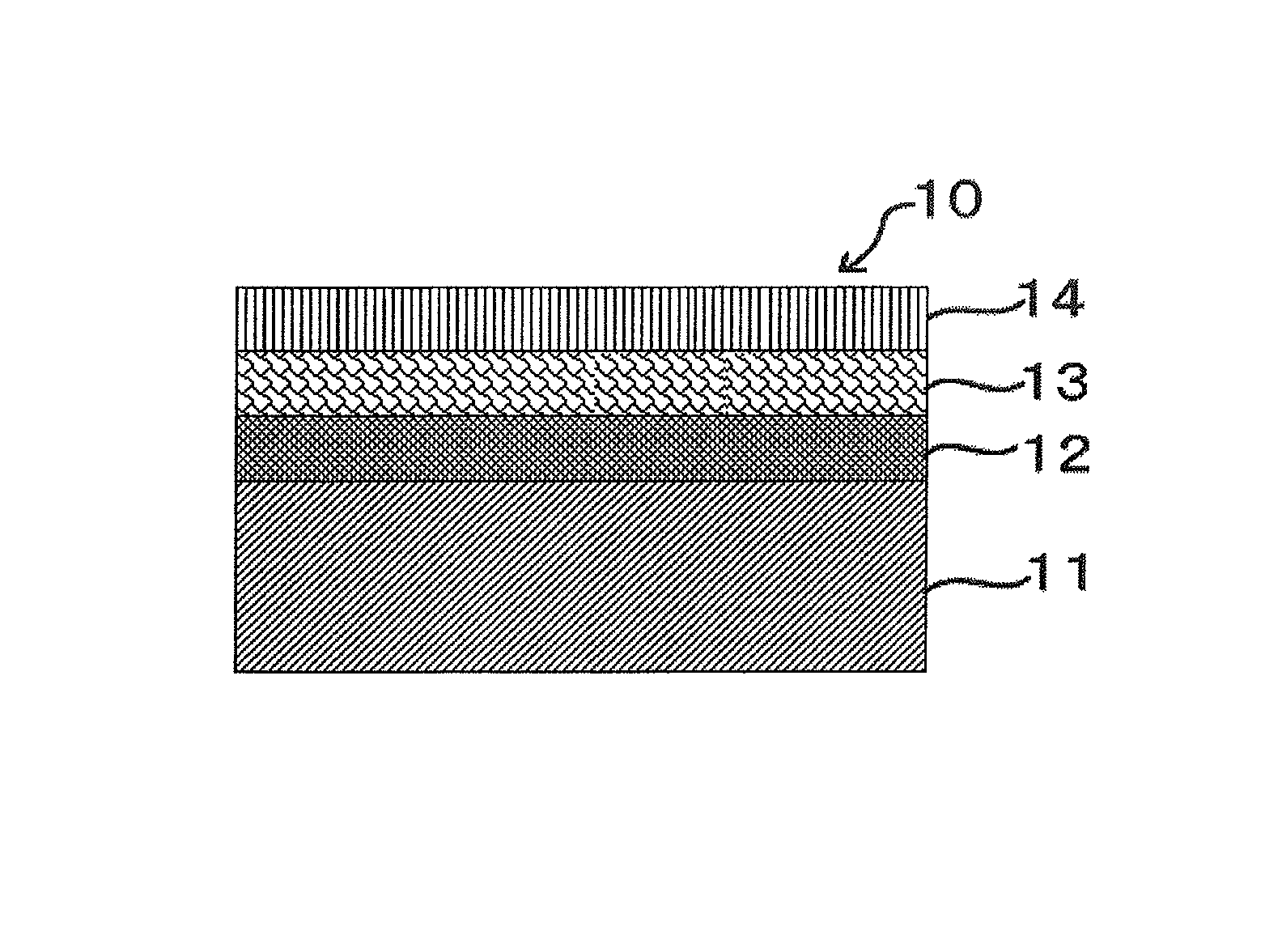

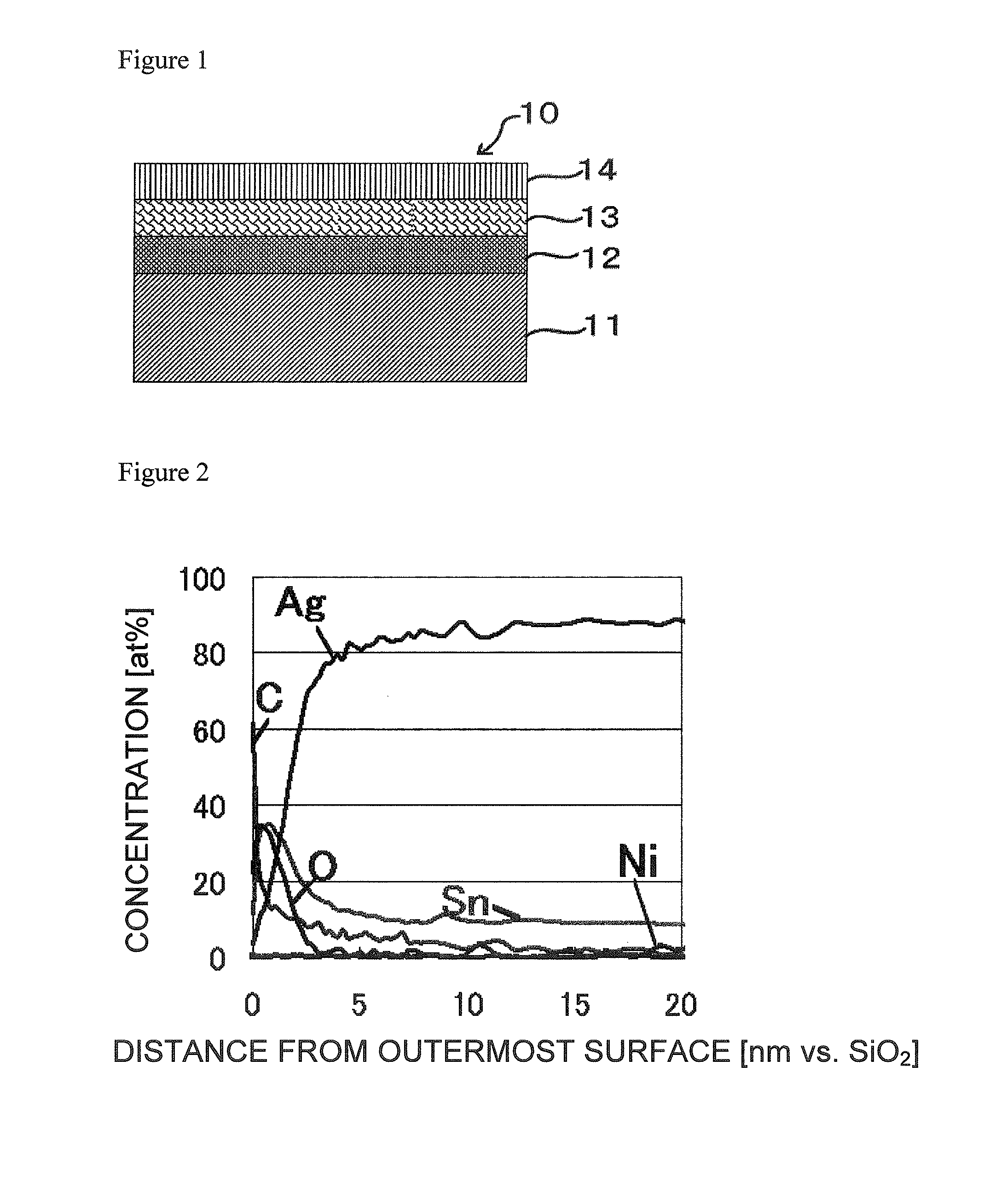

There are provided an electronic component metal material which has low insertability / extractability, low whisker formability, and high durability, and a method for manufacturing the metal material. The electronic component metal material 10 includes a base material 11, an A layer 14 constituting an outermost surface layer on the base material 11 and formed of Sn, In or an alloy thereof, and a B layer 13 constituting a middle layer provided between the base material 11 and the A layer 14 and formed of Ag, Au, Pt, Pd, Ru, Rh, Os, Ir or an alloy thereof, wherein the outermost surface layer (A layer) 14 has a thickness of 0.002 to 0.2 μm, and the middle layer (B layer) 13 has a thickness larger than 0.3 μm.

Owner:JX NIPPON MINING& METALS CORP

Epoxy plastic cement and preparing method thereof

InactiveCN1528852AReduce melt viscosityLow formabilityOther chemical processesSemiconductor/solid-state device detailsFirming agentAbsorption rate

The invention refers to a kind of new epoxy plastic sealed materials for integrated circuit sealing and the manufacturing method. The materials include liquid crystal epoxy resin 100 shares, 0-15 shares of ortho-aminotoluene phenolic aldehyde epoxy resin, 30-200 shares of firming agent, 700-1100 shares of inorganic fillers, 0.1-0.5 shares of firming accelerator. The method mixes the ingredients evenly, then the materials are melted and mixed through rubber mixing machine or double screw stem extruder under 90-220deg.C, and cooled to solid piece material, finally the method crushes the piece into powder, and presses and forms them under 60-90deg.C, 0.3-1MPa. The invention has high rigidity and flexibility, low heat expansion parameter and humidity absorption rate, high heat resistance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

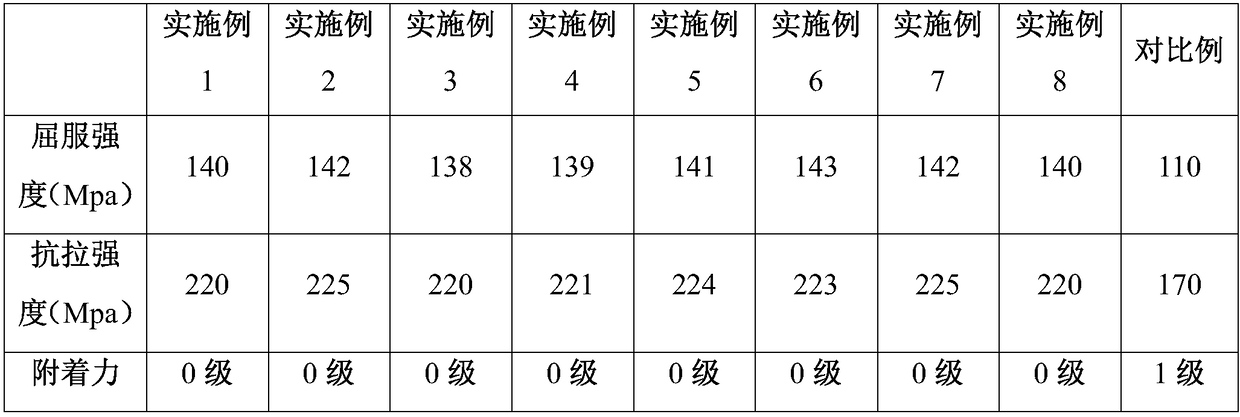

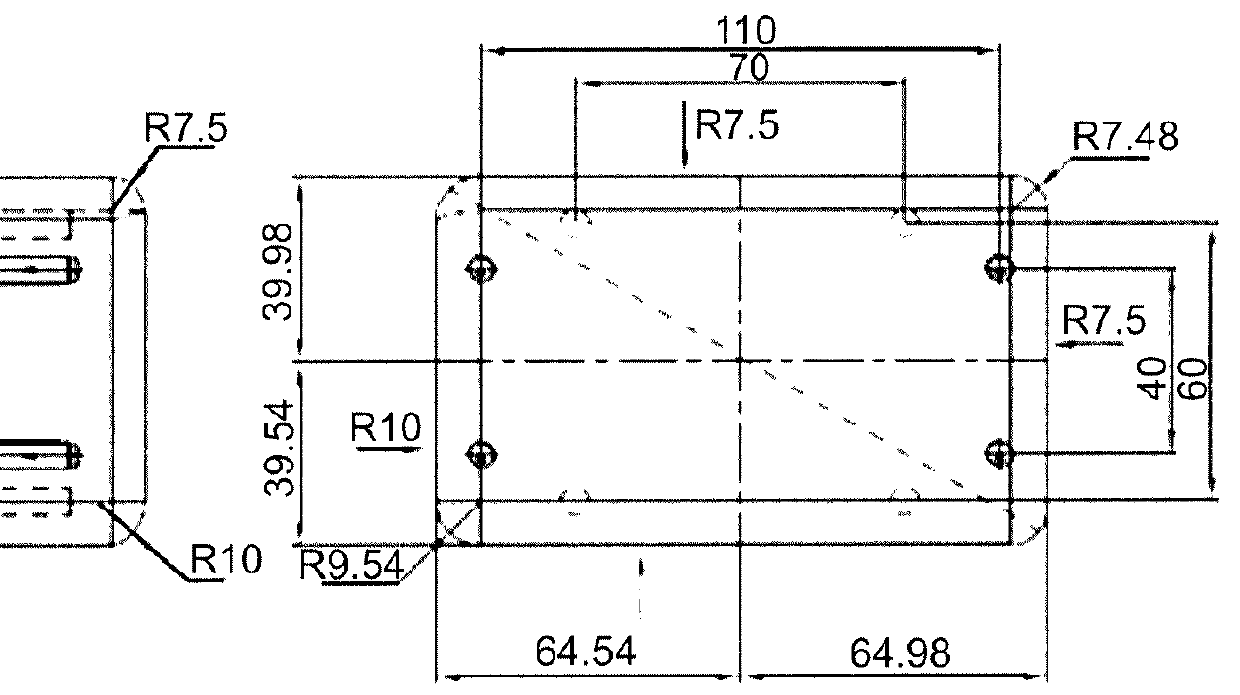

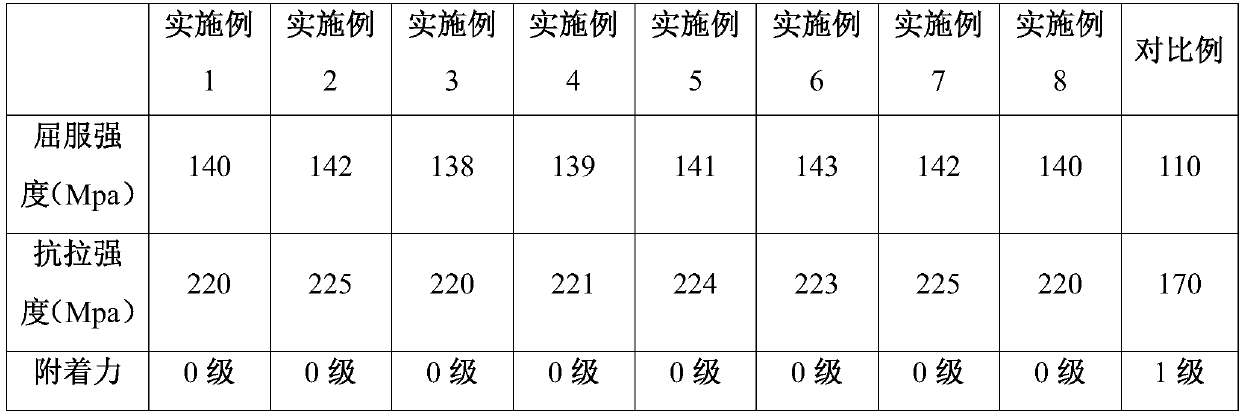

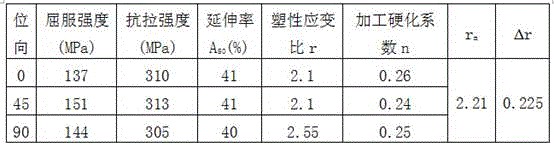

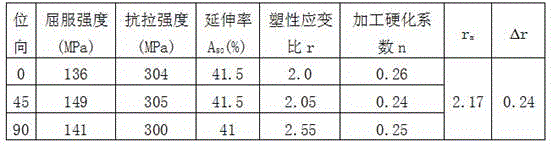

Aluminum alloy plate with high bake hardenability and preparation method thereof

The invention belongs to the field of manufacturing of aluminum alloy plates, and relates to an aluminum alloy plate with high bake hardenability and a preparation method thereof. The aluminum alloy plate with the high bake hardenability is prepared from, by weight, 0.4-0.9% of Mg, 0.6-1.4% of Si, 0.008-0.12% of Ti, 0.0005-0.04% of B, no more than 0.3% of Fe, 0.06-1.5% of Zn, 0.3-0.8% of Cu, 0.03-0.25% of Sn, no more than 0.15% of impurities and the balance Al, wherein the content of each the impurity is no more than 0.05%. By adoption of the aluminum alloy plate with the high bake hardenability and the preparation method thereof, the problem that MgO is likely to be formed on the surface of an aluminum alloy plate adopted by an automobile body covering part in the prior art, and consequentially, the binding property and corrosion resistance after painting of the automobile body covering part are poor is solved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Magnesium-aluminum-zinc environment-friendly stabilizer special for U-PVC calendered sheet

The invention discloses a special environment-friendly stabilizer for U-PVC calendered sheet, which is prepared from the following components in weight ratio: 260-300 kg of magnesium-aluminum-zinc composition, 50-150 kg of zinc stearate, and 1010-15-15 kg of antioxidant. 20kg, calcium acetylacetonate 40~68kg, tris(2-hydroxyethyl) isocyanurate 80~130kg, oxidized polyethylene wax 50~250kg, polyethylene wax 30~100kg. The stabilizer of the invention is suitable for continuous calendering and extrusion production of U-PVC sheet, and has moderate dosage, low cost, good production process stabilization effect, good rolling effect, smooth processing, smooth sheet surface, good plasticization, and satisfactory mechanical properties. The requirements of the national standard also have the advantages of non-toxicity and high environmental protection performance; the U-PVC sheet prepared by the stabilizer of the present invention has stable chemical properties, no rust, good impact resistance, and good transparency. Good insulation and low thermal conductivity; good formability and colorability, and low processing cost; the PVC sheet produced conforms to GB / T15267 "PVC Rigid Sheets and Films for Food Packaging" and conforms to YBB00212005 Polyethylene Vinyl chloride solid medicinal tablet.

Owner:广东森德利环保新材料科技有限公司

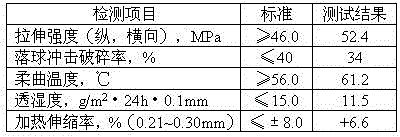

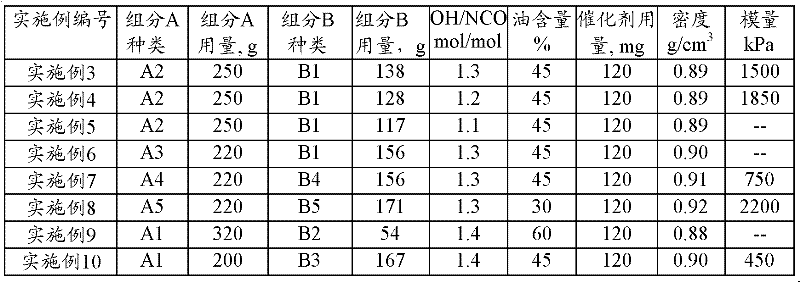

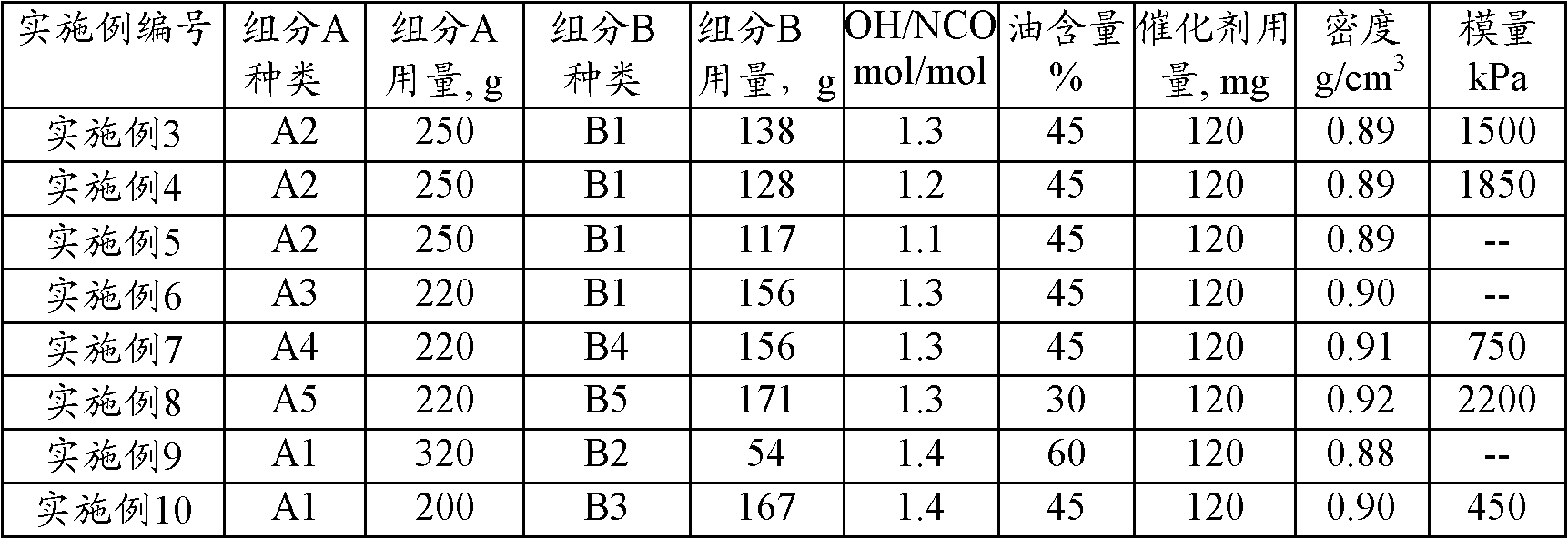

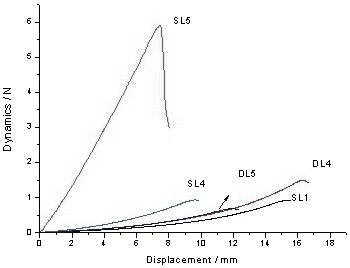

Polyurethane gel for marine exploration streamer and preparation method for same

ActiveCN102643409AAdjustment of mechanical propertiesHigh modulusSeismology for water-covered areasSonarPolymer science

The invention discloses a low-density and low-modulus polyurethane gel capable of being used as a filling material for a marine exploration streamer and a preparation method for the same. The polyurethane gel disclosed by the invention is formed by mixing and filling hydroxyl-terminated polybutadiene polyurethane prepolymer, polyether polyol and solvent oil under the action of a catalyst, whereinthe density of the polyurethane gel is lower than 0.92 g / cm<3>, and the modulus of the polyurethane gel is lower than 5 MPa. The low-density and low-modulus polyurethane gel disclosed by the invention has good cohesive property, high extensibility and self-healing property, and excellent sound transmission performance; and can be used as a filling material for a marine exploration streamer for realizing the suspension, sound transmission and sonar signal acquisition of the exploration streamer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

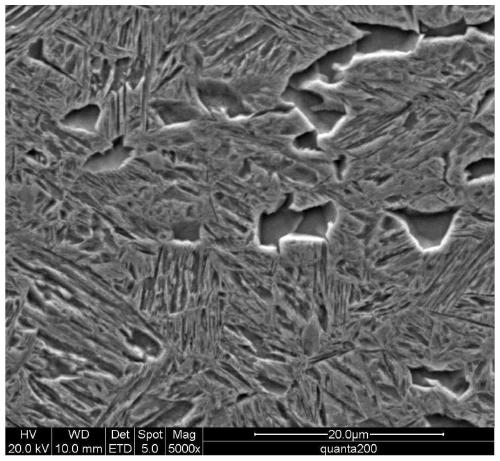

Martensite-ferrite-austenite complex-phase abrasion-resistant steel plate with low yield ratio and manufacturing method thereof

The invention provides a martensite-ferrite-austenite complex-phase abrasion-resistant steel plate with a low yield ratio and a manufacturing method thereof. The manufacturing method of the steel plate comprises the steps of smelting different alloy components; manufacturing a steel billet through continuous casting; and carrying out heating, controlled rolling, controlled cooling, thermal treatment, and the like. The martensite-ferrite-austenite complex-phase abrasion-resistant steel plate is characterized in that (1) the manufactured steel plate is of a martensite-ferrite-austenite multi-phase composite structure; (2) the yield ratio of the manufactured steel plate is greatly decreased compared with that of a traditional abrasion-resistant steel plate, the yield ratio is smaller than orequal to 0.75, and the manufactured steel plate has excellent formability; (3) the hardness of the manufactured steel plate is 300 HB to 420 HB, and acquisition of good abrasion resistance is guaranteed; and (4) the abrasion resistance is excellent, and the abrasion resistance of the obtained abrasion-resistant steel plate is doubled or above compared with that of a single-martensite abrasion-resistant steel plate with the same hardness. The martensite-ferrite-austenite complex-phase abrasion-resistant steel plate has good welding performance and higher low-temperature impact toughness, and isparticularly applicable to manufacturing of devices or parts like concrete stirring tank rollers, dump truck carriages and pipelines for channel dredging.

Owner:NORTHEASTERN UNIV

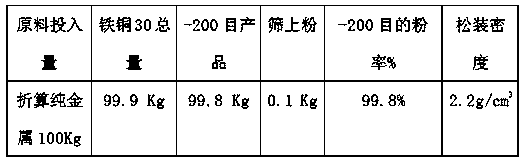

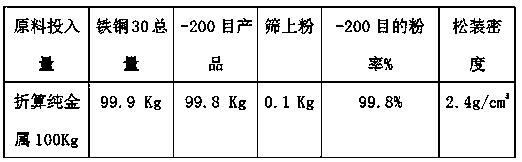

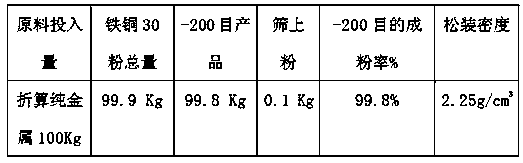

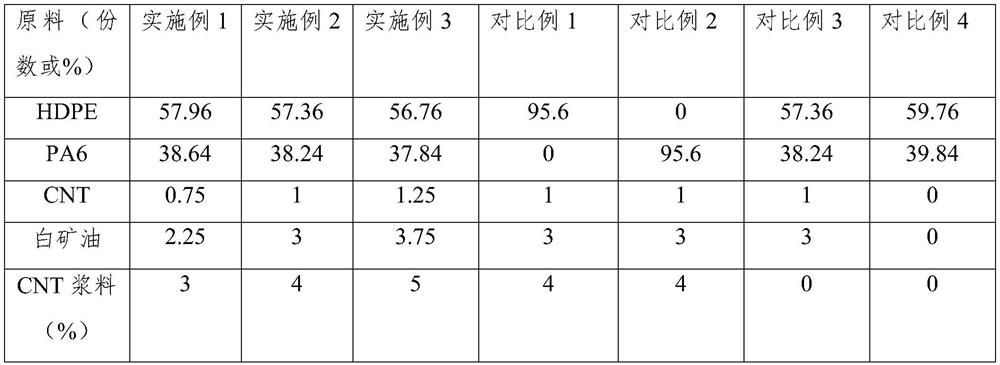

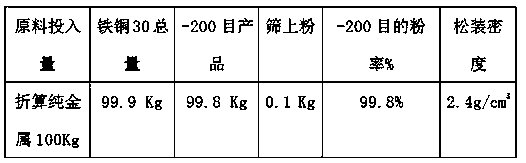

Production method for copper-iron diffusion powder

The invention belongs to the field of powder metallurgy manufacturing and discloses a production method for metal diffusion powder. The production method comprises the steps that cupric oxide powder with -300 meshes is selected, industrial machine oil is selected as binders, or mixed powder of reduced iron powder with -300 meshes and nickel powder with -300 meshes is selected; the cupric oxide powder and the industrial machine oil are mixed, the reduced iron powder or the mixed powder of the reduced iron powder and the nickel powder is loaded in a three-dimensional blender mixer, and then thecupric oxide powder is added into the three-dimensional blender mixer; material mixing is started, the mixed powder is added into an iron powder reducing furnace, a reducing atmosphere is added, temperature rise continues after reducing is finished, high temperature diffusion is started, a beater is utilized to scatter the powder discharged from the furnace, and then iron-copper diffusion powder or copper-iron-nickel diffusion powder with -200 meshes is screened out. The product produced by the method has the beneficial effects that ingredients are even, almost no segregation occurs, the apparent density of the product is low, and the formability is good, and has broad popularization value.

Owner:JINCHUAN GROUP LIMITED

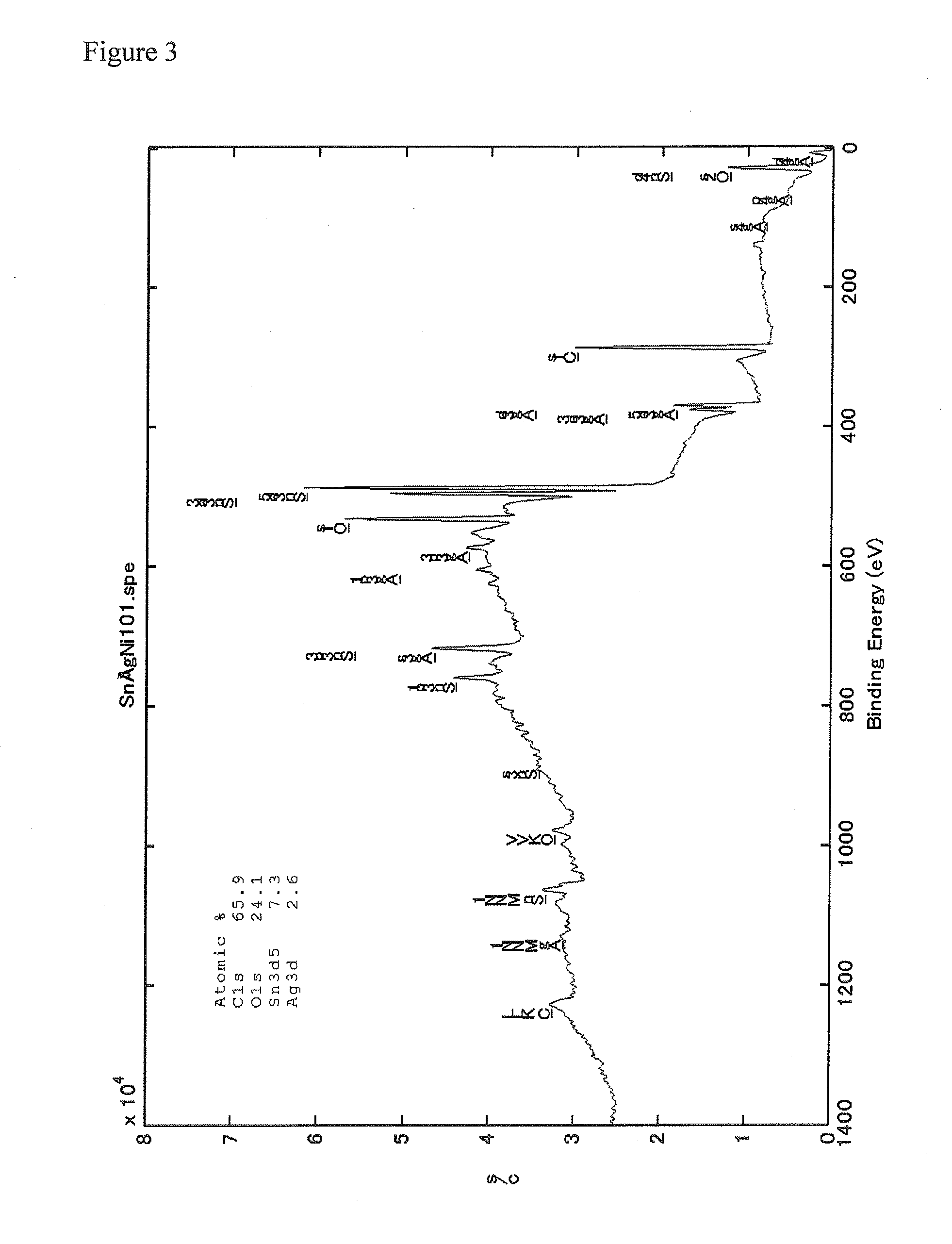

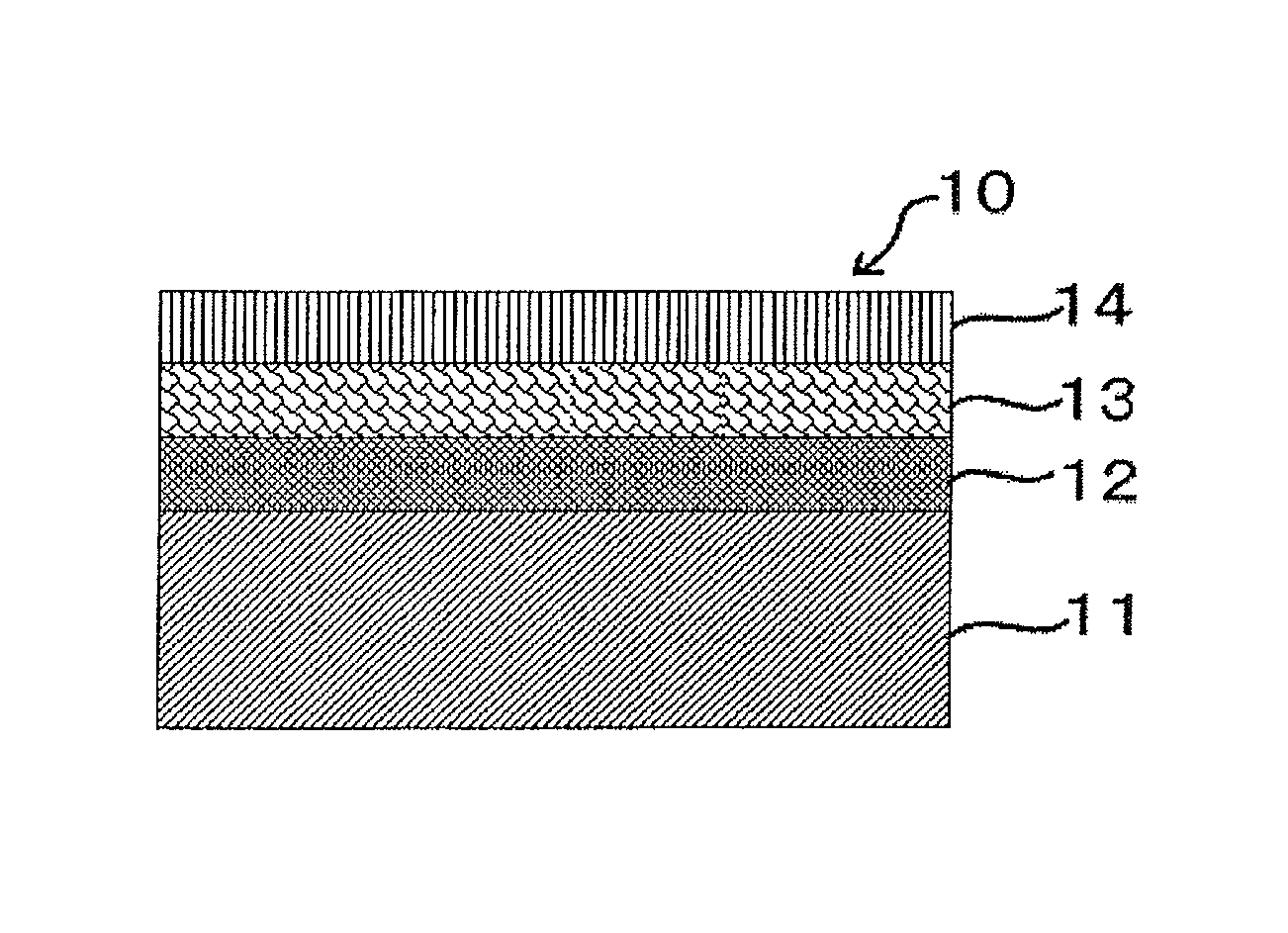

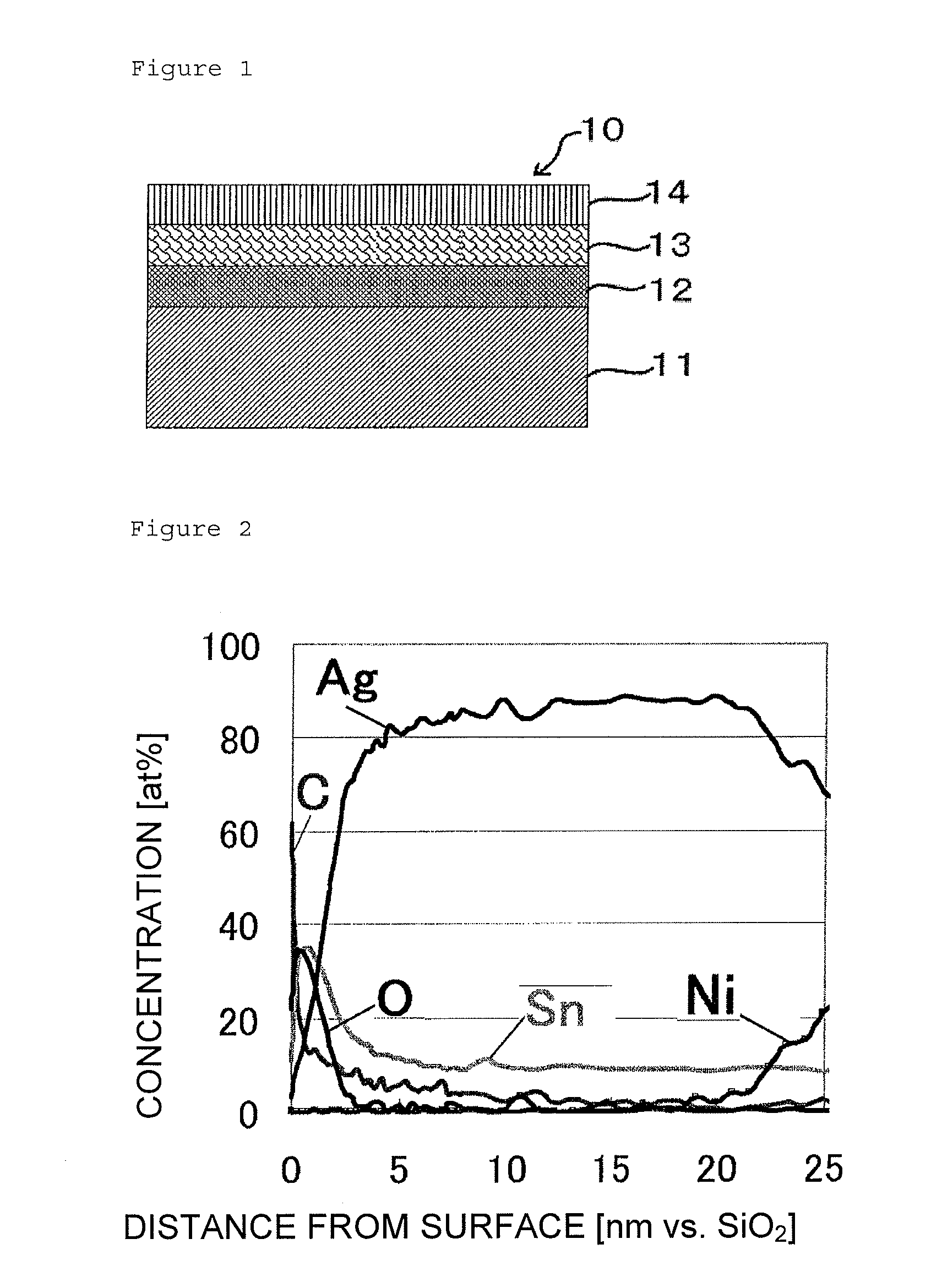

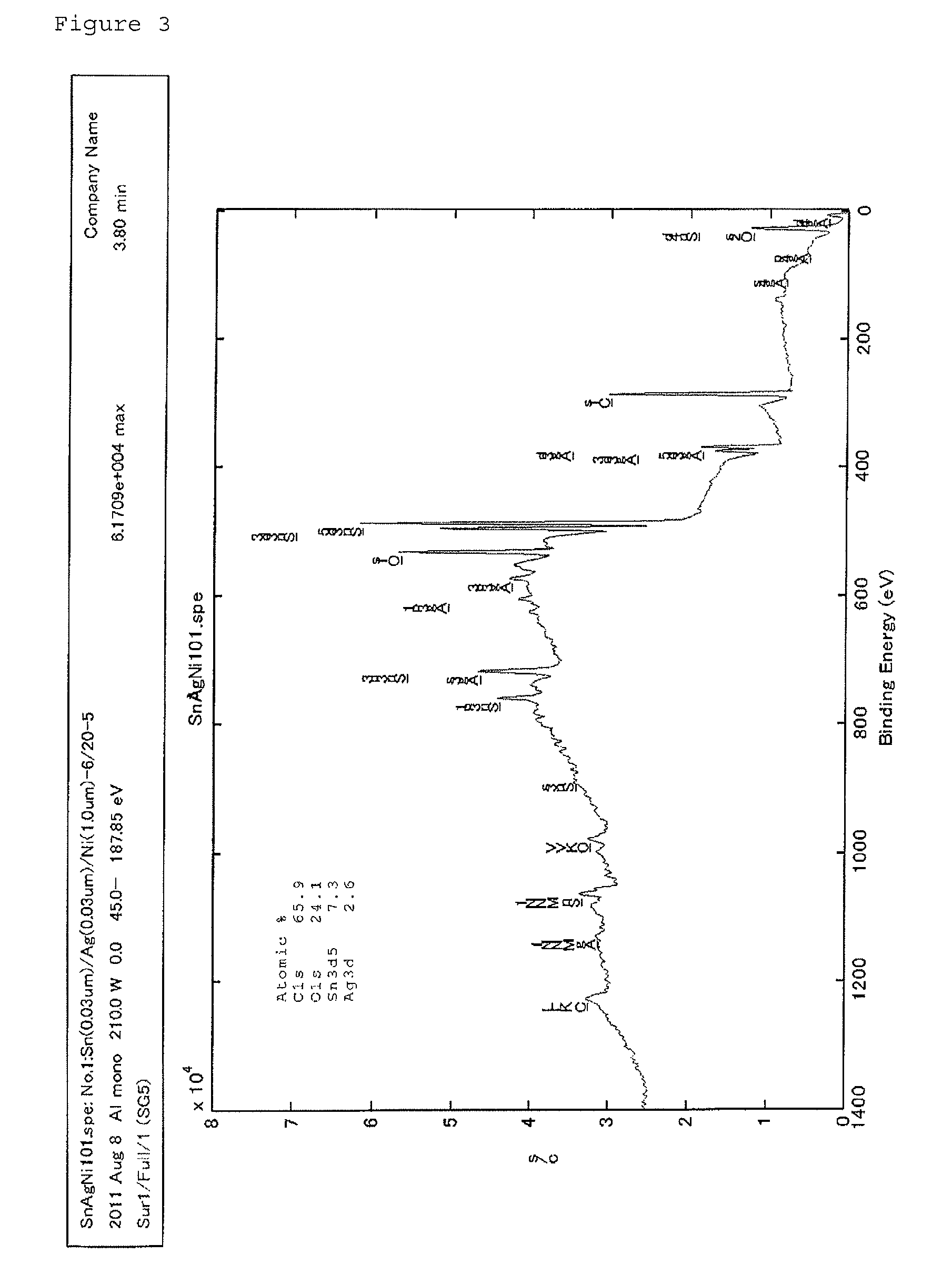

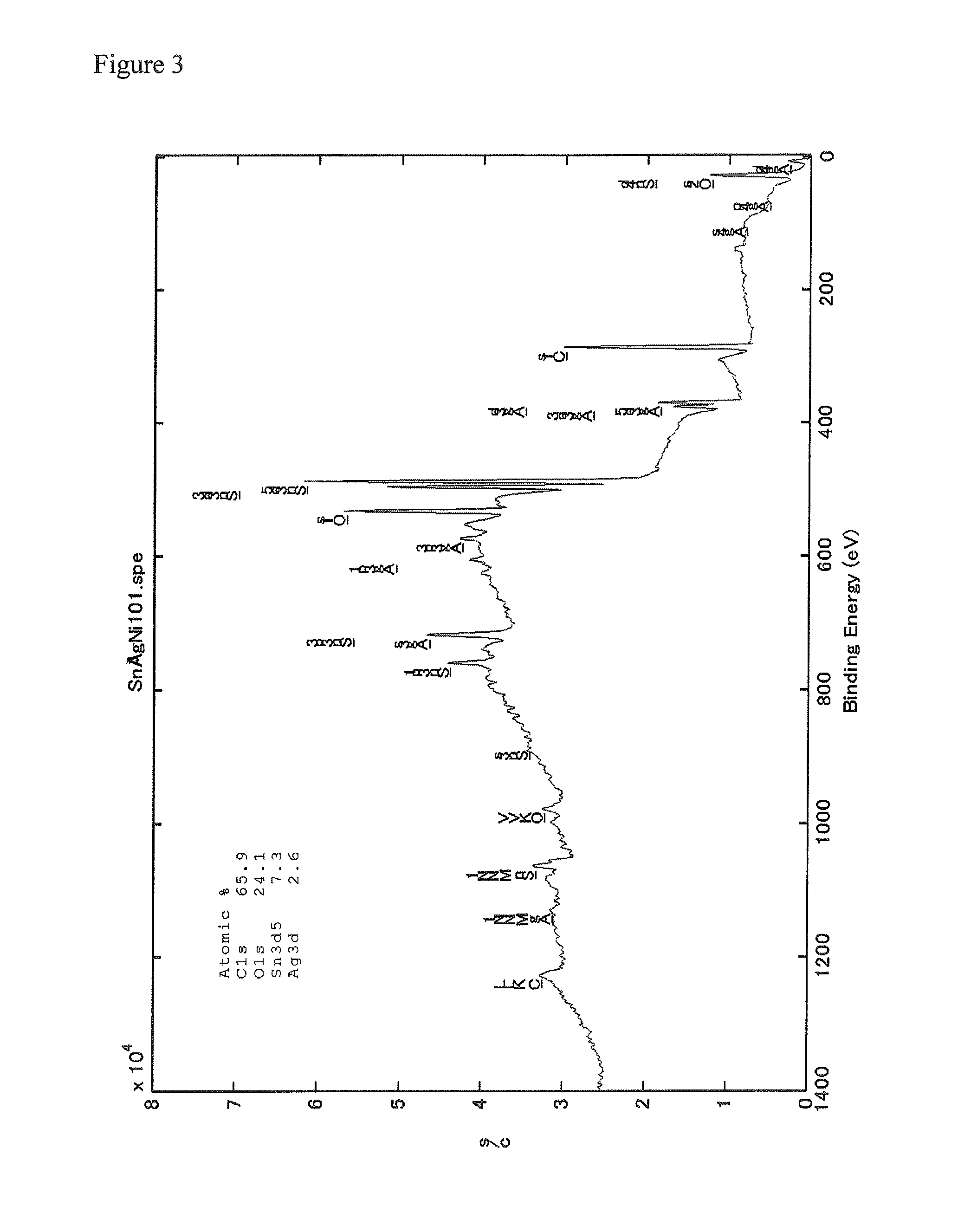

Metal material for electronic component and method for manufacturing the same

ActiveUS9576693B2Low insertability/extractabilityIncreased durabilityPrinted circuit aspectsCoupling contact membersMetallic materialsAlloy

There are provided a metal material for electronic component which has low insertability / extractability, low whisker formability, and high durability, and a method for manufacturing the metal material. The metal material 10 for electronic components has a base material 11, an A layer 14 constituting a surface layer on the base material 11 and formed of Sn, In or an alloy thereof, and a B layer 13 constituting a middle layer provided between the base material 11 and the A layer 14 and formed of Ag, Au, Pt, Pd, Ru, Rh, Os, Ir or an alloy thereof, wherein the surface layer (A layer) 14 has a thickness of 0.002 to 0.2 μm, and the middle layer (B layer) 13 has a thickness of 0.001 to 0.3 μm.

Owner:JX NIPPON MINING & METALS CORP

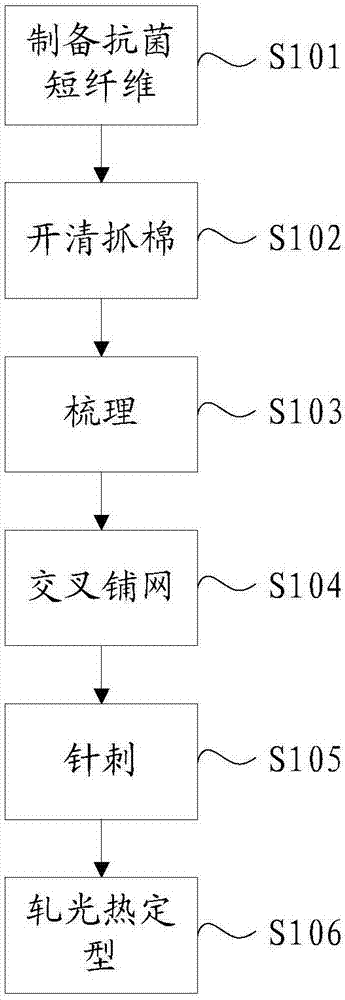

Antibacterial nonwoven cloth and production method thereof

InactiveCN107245809ALow fatigue resistanceLow wear resistanceNon-woven fabricsArtifical filament manufacturePolyesterPunching

The invention discloses antibacterial nonwoven cloth and a production method thereof; the production method of the antibacterial nonwoven cloth comprises the steps of producing antibacterial fiber, opening, cleaning, picking, carding, performing cross laying, needle-punching, and performing calendering and thermal setting. Polypropylene fiber has low melting point and good formability, and post-processing is facilitated; polyester staple fiber is resistant to creep, fatigue and abrasion and good in size stability, and has high hardness and low cost; viscose fiber has good moisture absorbability, and features smoothness and coolness, breathability, electrostatic resistance, bright dyed color and the like; therefore, the antibacterial nonwoven cloth made by mixing any two or three of antibacterial polypropylene fiber, antibacterial polyester fiber and antibacterial viscose fiber has advantages of various fibers, defects of the fibers can be complemented, the better product is formed, and all the three fibers are antibacterial fibers so that it is possible to effectively inhibit bacteria and purify air for a long time.

Owner:ZHAOQING JOFO WEBFORMA CO LTD

Electronic component metal material and method for manufacturing the same

ActiveUS9979110B2Low insertability/extractabilityIncreased durabilityCoupling contact membersThin material handlingMetallic materialsAlloy

There are provided an electronic component metal material having low insertability / extractability, low whisker formability and high durability, and a method for manufacturing the electronic component metal material. The electronic component metal material 10 includes a base material 11, an A layer 14 constituting an outermost surface layer on the base material 11 and formed of Sn, In or an alloy thereof, and a B layer 13 constituting a middle layer provided between the base material 11 and the A layer 14 and formed of Ag, Au, Pt, Pd, Ru, Rh, Os, Ir or an alloy thereof, wherein the outermost surface layer (A layer) 14 has a thickness larger than 0.2 μm, and the middle layer (B layer) 13 has a thickness of 0.001 μm or larger.

Owner:JX NIPPON MINING & METALS CORP

Polyurethane gel for marine exploration streamer and preparation method for same

ActiveCN102643409BAdjustment of mechanical propertiesHigh modulusSeismology for water-covered areasSelf-healingExtensibility

The invention discloses a low-density and low-modulus polyurethane gel capable of being used as a filling material for a marine exploration streamer and a preparation method for the same. The polyurethane gel disclosed by the invention is formed by mixing and filling hydroxyl-terminated polybutadiene polyurethane prepolymer, polyether polyol and solvent oil under the action of a catalyst, wherein the density of the polyurethane gel is lower than 0.92 g / cm<3>, and the modulus of the polyurethane gel is lower than 5 MPa. The low-density and low-modulus polyurethane gel disclosed by the invention has good cohesive property, high extensibility and self-healing property, and excellent sound transmission performance; and can be used as a filling material for a marine exploration streamer for realizing the suspension, sound transmission and sonar signal acquisition of the exploration streamer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Electronic component metal material and method for manufacturing the same

ActiveUS9580783B2Low insertability/extractabilityIncreased durabilityMetal layered productsSurface layerMetallic materials

There are provided an electronic component metal material which has low insertability / extractability, low whisker formability, and high durability, and a method for manufacturing the metal material. The electronic component metal material 10 includes a base material 11 , an A layer 14 constituting an outermost surface layer on the base material 11 and formed of Sn, In or an alloy thereof, and a B layer 13 constituting a middle layer provided between the base material 11 and the A layer 14 and formed of Ag, Au, Pt, Pd, Ru, Rh, Os, Ir or an alloy thereof, wherein the outermost surface layer (A layer) 14 has a thickness of 0.002 to 0.2 μm, and the middle layer (B layer) 13 has a thickness larger than 0.3 μm.

Owner:JX NIPPON MINING & METALS CORP

Synthesis method and application of unsaturated hyperbranched polyimide resin

The invention discloses a synthesis method and application of an unsaturated hyperbranched polyimide resin. The synthesis method comprises the following steps: 1) preparing a monomer, namely uniformlymixing raw materials, namely aromatic tertiary amine A3 and a dianhydride compound B2, adding a high-melting point solvent, and performing a reaction under a set condition so as to obtain an A2B typefunctional monomer; 2) performing a polymerization reaction, namely putting a catalyst into the A2B type functional monomer prepared in the step 1), performing a self-polycondensation reaction so asto obtain a yperbranched resin at the tail end of amino, further adding a free radical polymerization inhibitor and an end-capping reagent, performing a quenching reaction, controlling a branching degree, and performing reduced pressure distillation, thereby obtaining the unsaturated hyperbranched polyimide resin HP-PI. The polyimide resin prepared by using the synthesis method is relatively low in viscosity, good in solubleness, capable of effectively reducing the amount of diluents in the process that an insulating impregnating varnish is prepared, the cost can be reduced, and the toxicity can be degraded.

Owner:CENT SOUTH UNIV

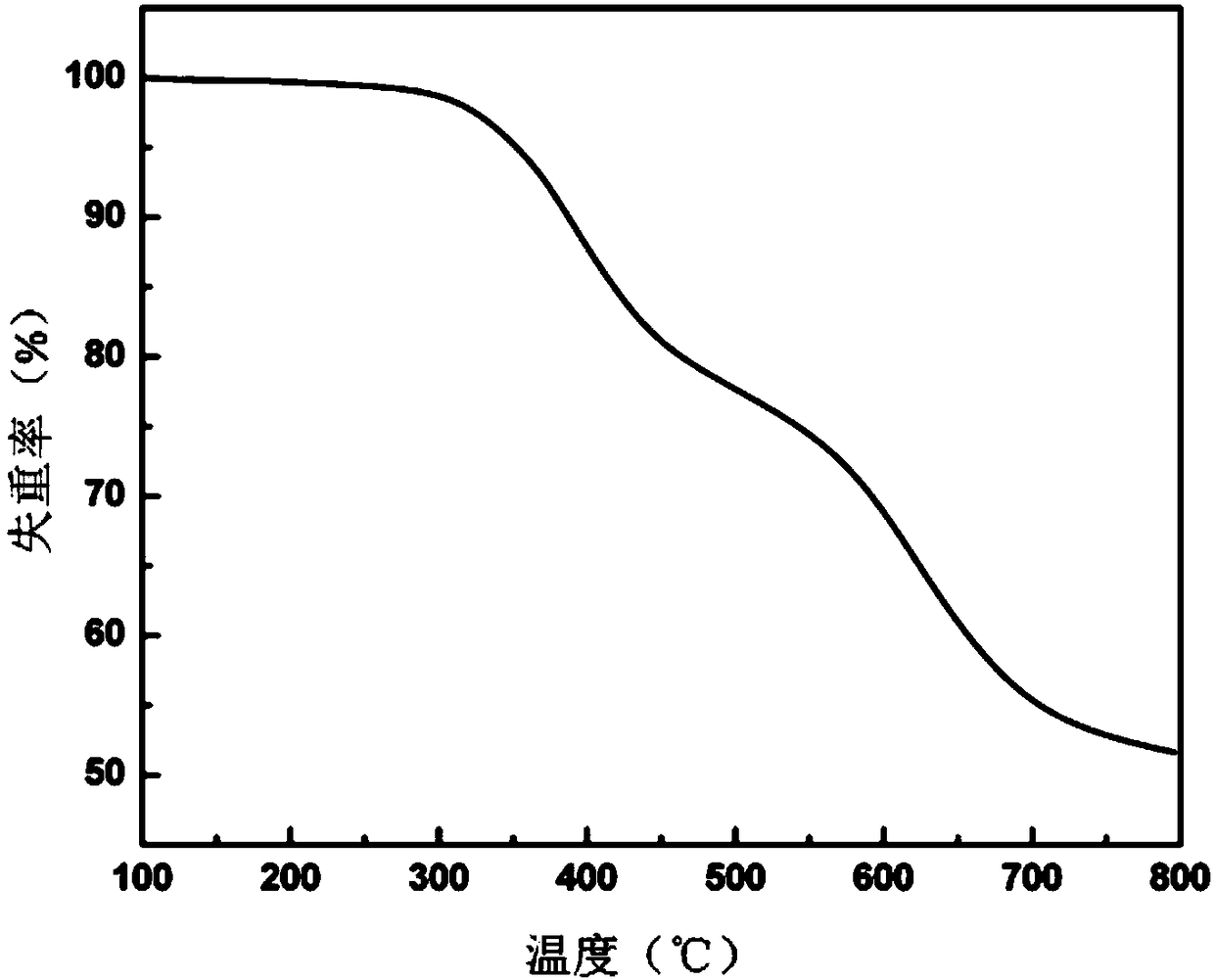

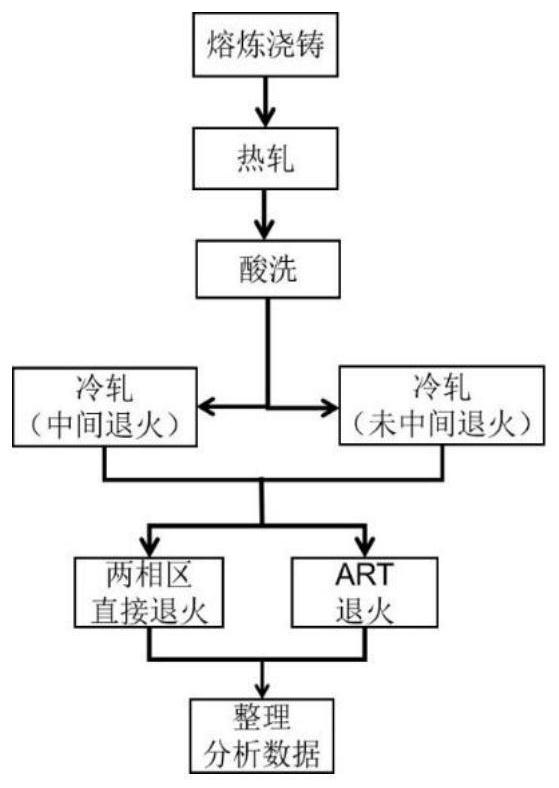

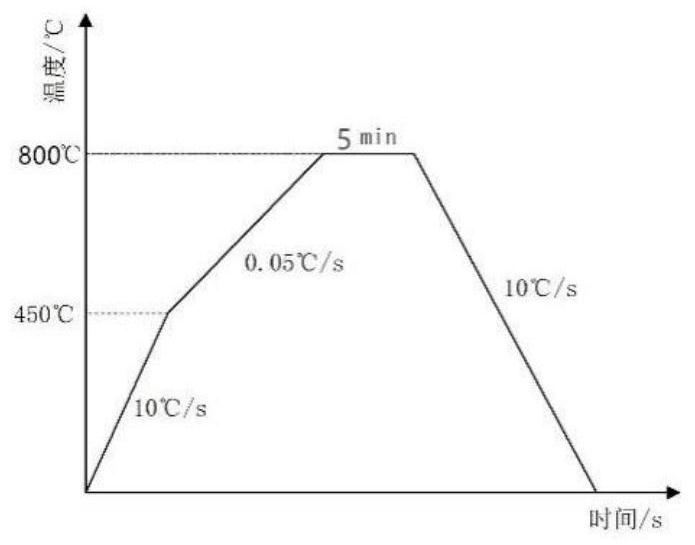

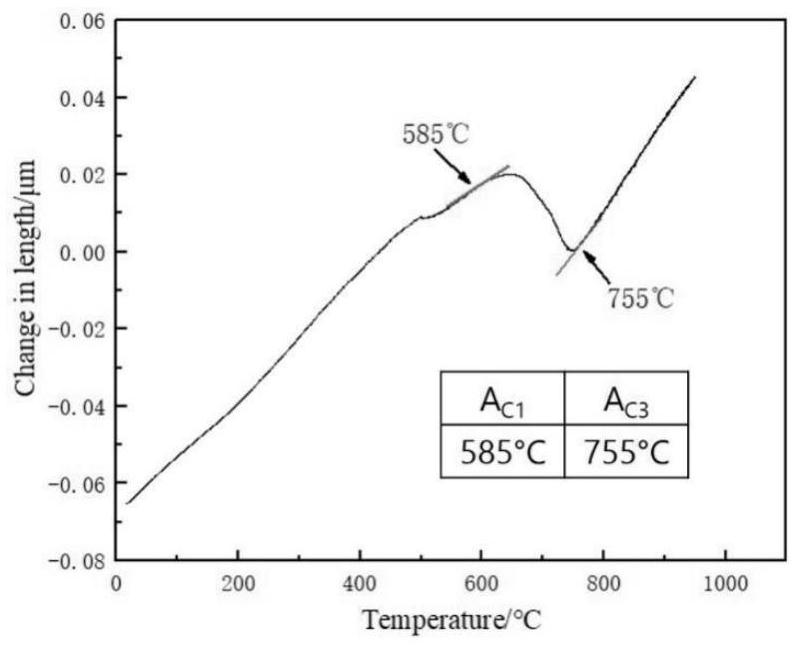

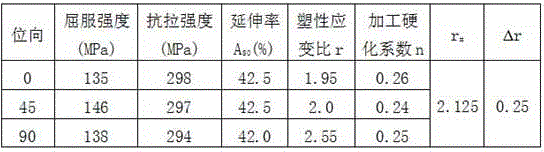

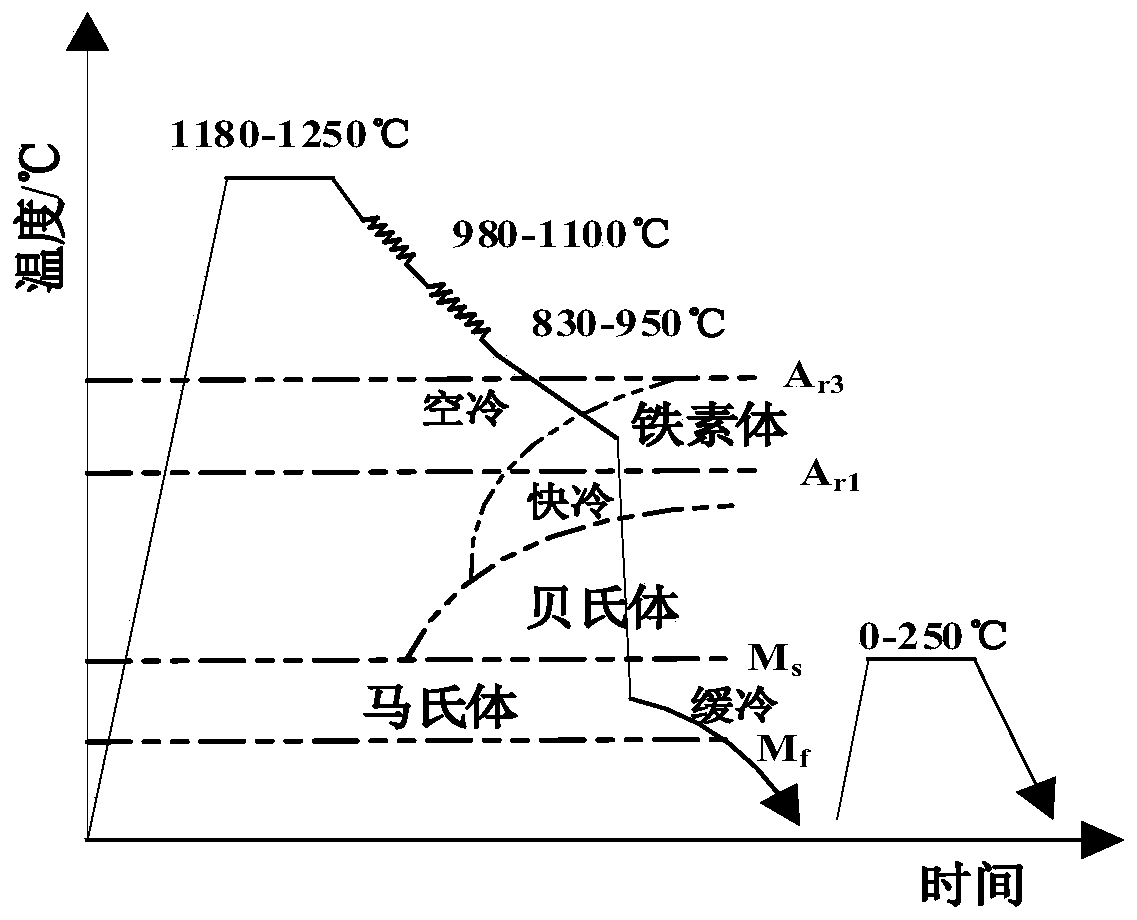

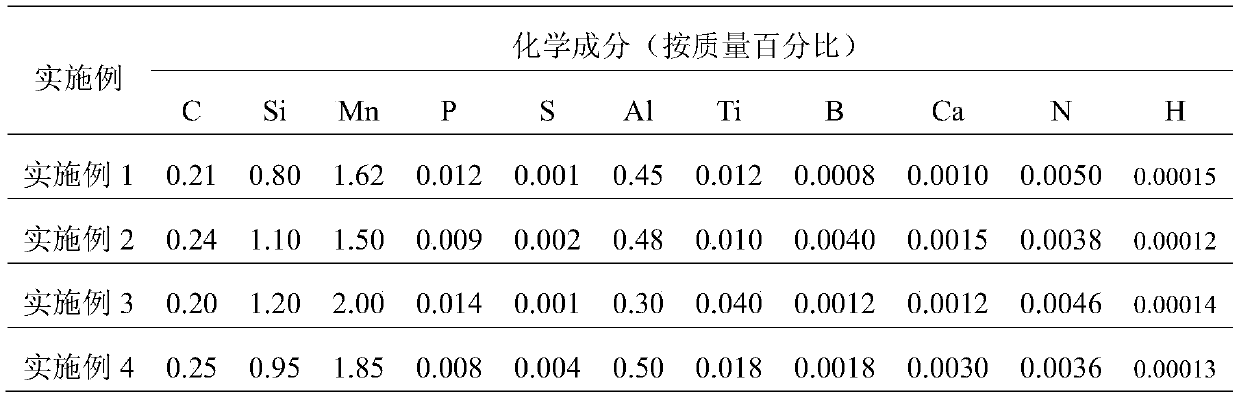

Low-cost third-generation automobile steel processing technology

The invention discloses a low-cost third-generation automobile steel processing technology. The low-cost third-generation automobile steel processing technology comprises the following steps of carrying out smelting and casting, specifically, placing a medium manganese steel raw material in a vacuum induction furnace for smelting and casting so as to obtain a blank; carrying out hot rolling, specifically, placing the blank in a double-roller hot rolling mill for rolling so as to obtain a hot-rolled blank; carrying out acid pickling, specifically, placing the hot-rolled blank in acid liquor to be washed to be bright white, then washing the acid liquor on the surface of the hot-rolled blank clean with water and blow-drying the surface of the hot-rolled blank, and finally carrying out oiling treatment to obtain an acid-pickled blank; carrying out cold rolling, specifically, carrying out cold rolling on the acid-pickled blank through a straight-pull type four-roller reversible cold rolling mill so as to obtain cold-rolled third-generation automobile steel; and carrying out annealing, specifically, annealing the cold-rolled third-generation automobile steel so as to obtain the low-cost third-generation automobile steel. The third-generation automobile steel produced through the processing technology has the advantages of being low in cost, good in plasticity, good in forming performance, high in product of strength and elongation and the like, it is guaranteed that forming is facilitated while the mechanical property is not reduced, the whole processing technology is simple in process, and the production difficulty is low.

Owner:INNER MONGOLIA UNIV OF TECH

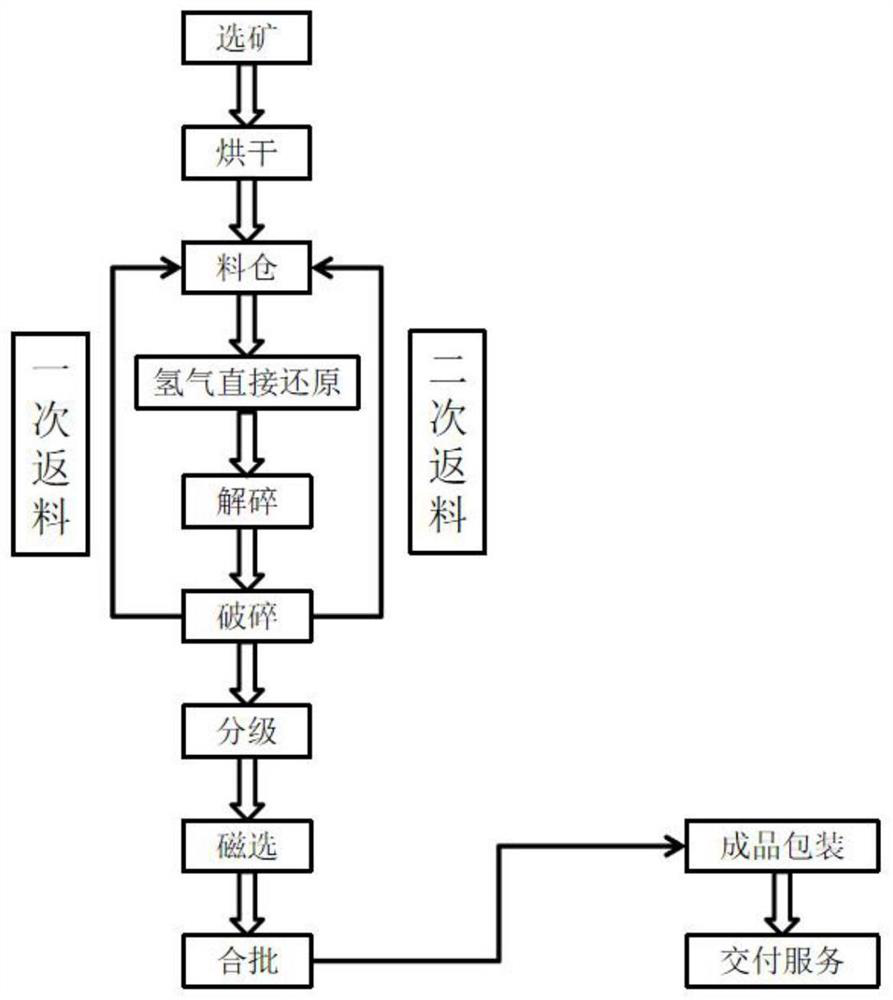

Reduction method of iron ore powder

PendingCN112974825AUniform particle size distributionImprove the annealing effectIron powderHydrogen atmosphere

The invention belongs to the technical field of production of reduced iron powder, and particularly relates to a reduction method of iron ore powder. The reduction method of the iron ore powder comprises the following steps that under the hydrogen atmosphere, the iron ore powder is sequentially subjected to first-stage reduction, second-stage reduction and third-stage reduction, and reduced iron powder is obtained; the temperature of the first-stage reduction is 810-830 DEG C; the temperature of the second-stage reduction is 920-940 DEG C; and the temperature of the third-stage reduction is 945-960 DEG C. According to the reduction method of the iron ore powder, the hydrogen atmosphere is used as a reduction medium, the temperature in the production process is low, the whole reduction process is environmentally friendly, resources are saved, and the production cost is low.

Owner:安徽马钢粉末冶金有限公司

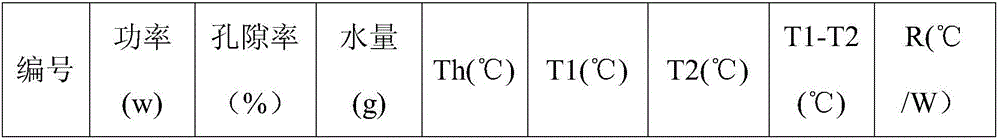

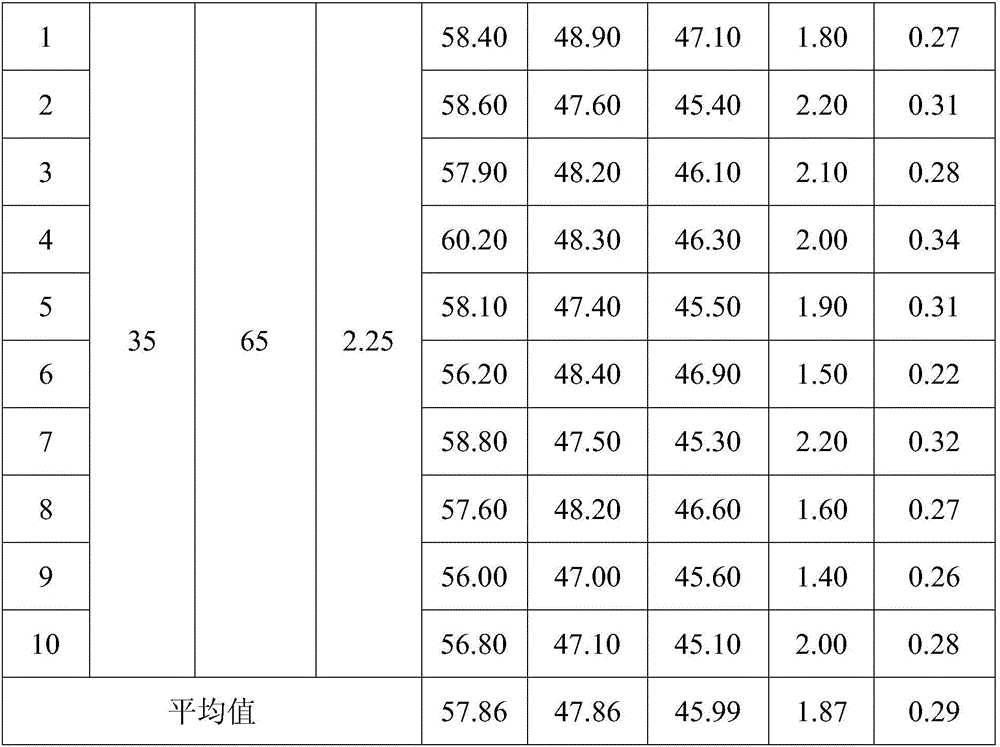

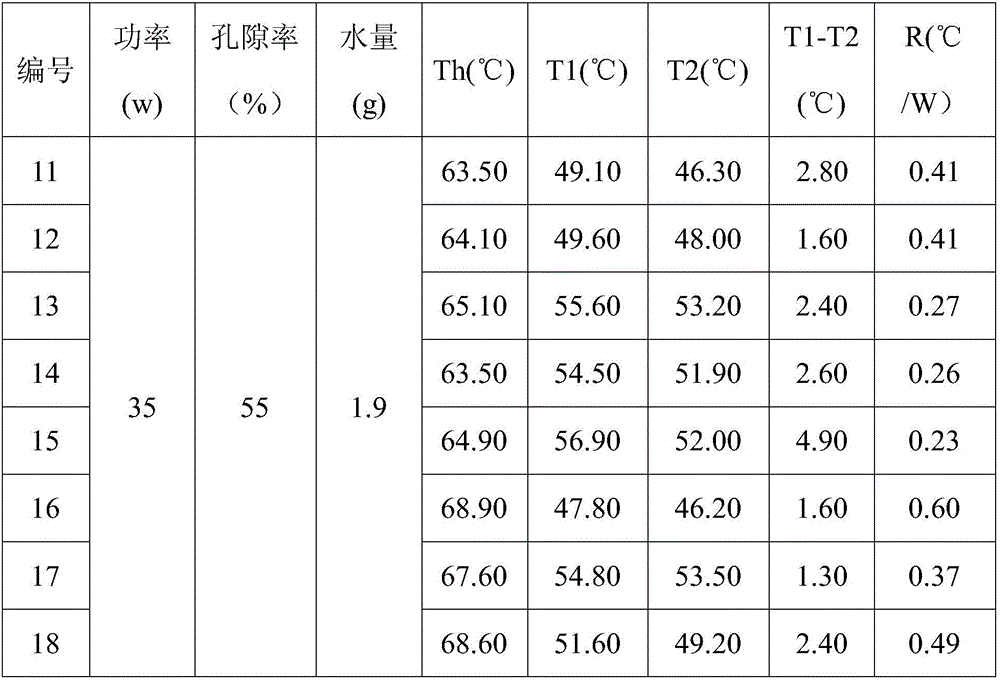

Heat pipe and preparation method thereof

InactiveCN106323062AImprove manufacturabilityHigh porosityIndirect heat exchangersPorosityHeat conducting

The invention discloses a heat pipe and a preparation method thereof, and relates to the technical field of heat pipes. The heat pipe comprises a liquid suction core, and the liquid suction core is prepared from, by weight, 20-50% of water-atomized copper powder and 50-80% of foamy copper powder. The micro shape of the water-atomized copper powder is irregular, the oxygen content is low, the forming property is good, the process performance is stable, and the water-atomized copper power has fast capillary force. The foamy copper powder is a novel functional material formed by evenly distributing a large number of communicating or non-communicating holes in a copper substrate; and the electrical conductivity and the ductility of the foamy copper powder are good, the porosity is relatively high, and the heat-conducting property is good. By adjusting the ratio of the water-atomized copper powder to the foamy copper powder, the porosity and the moisture content of the prepared liquid suction core can be effectively controlled, and the prepared heat pipe can be made low in heat resistance and high in porosity and moisture content. Meanwhile, the preparation method of the heat pipe provided by the invention is simple in process and suitable for industrial heat pipe production.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

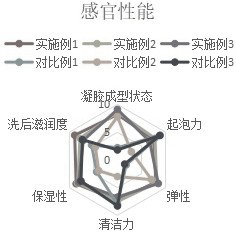

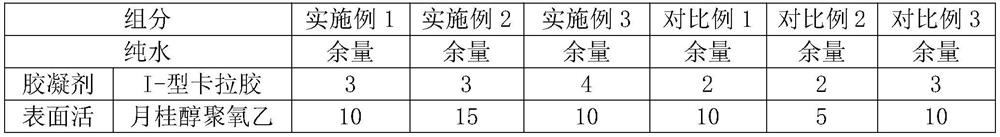

Novel jelly bath soap and preparation method thereof

InactiveCN111920692AModerate gel strengthReduce water yieldCosmetic preparationsToilet preparationsPolyolAlcohol

The invention belongs to the field of daily chemicals. The invention discloses novel jelly bath soap which comprises the following components in percentage by mass: 0.5 to 5 percent of gelatinizing agent, 5 to 30 percent of surfactant, 10 to 60 percent of polyhydric alcohol, 0.01 to 3 percent of cross-linking agent, 0.01 to 5 percent of additive and the balance of pure water. The gelatinizing agent is prepared from gelatinizing agent consisting of 1, 3-alpha-D-galactopyranose and 1, 4-beta-D-galactopyranose. The novel jelly bath soap disclosed by the invention is proper in PH, mild, non-irritant, good in cleaning performance and moisturizing capacity, low in water yield and capable of presenting formability with various textures.

Owner:OPAL COSMETICS HUIZHOU

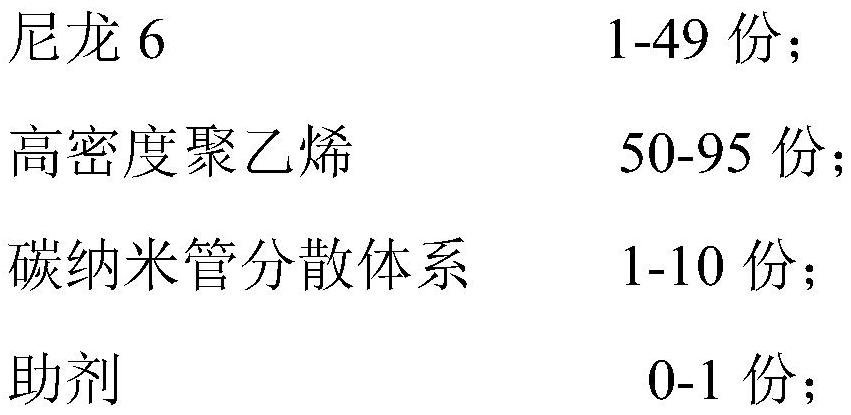

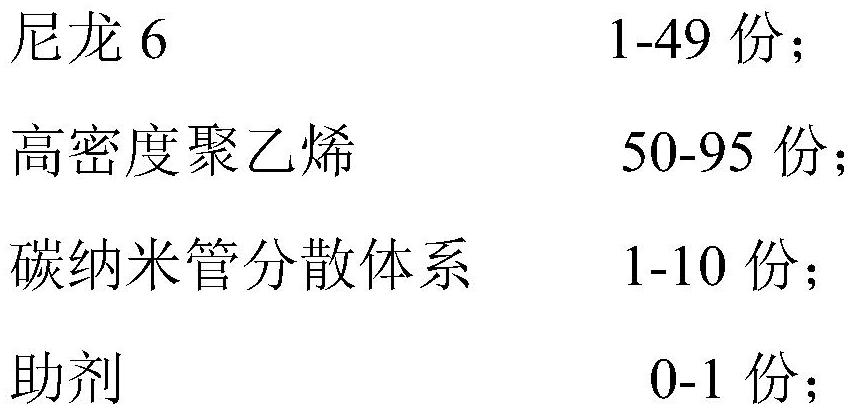

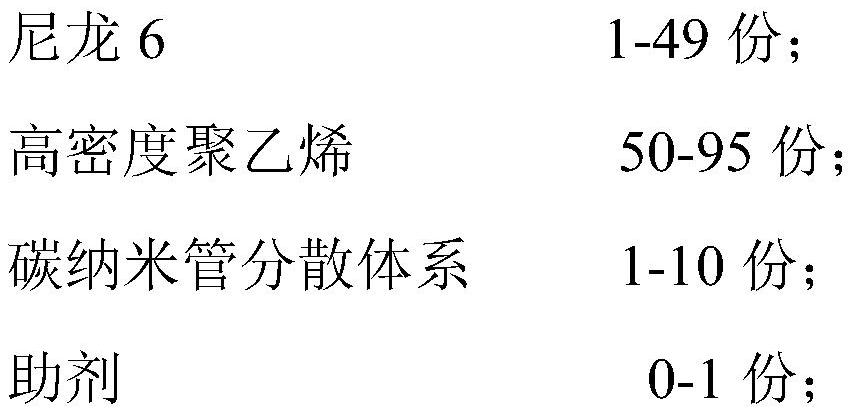

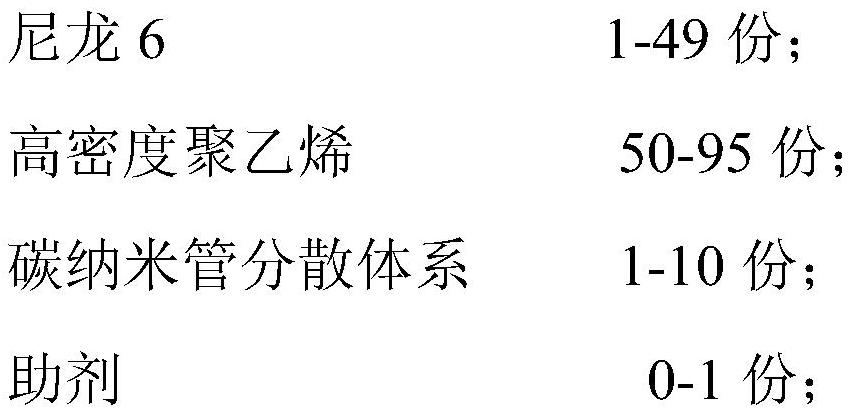

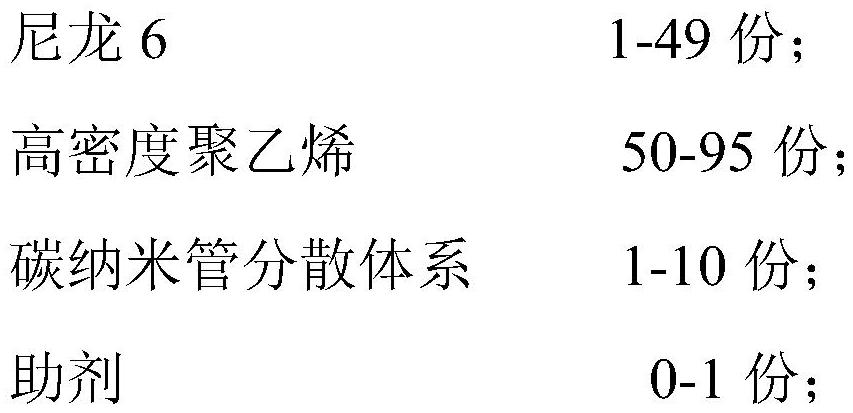

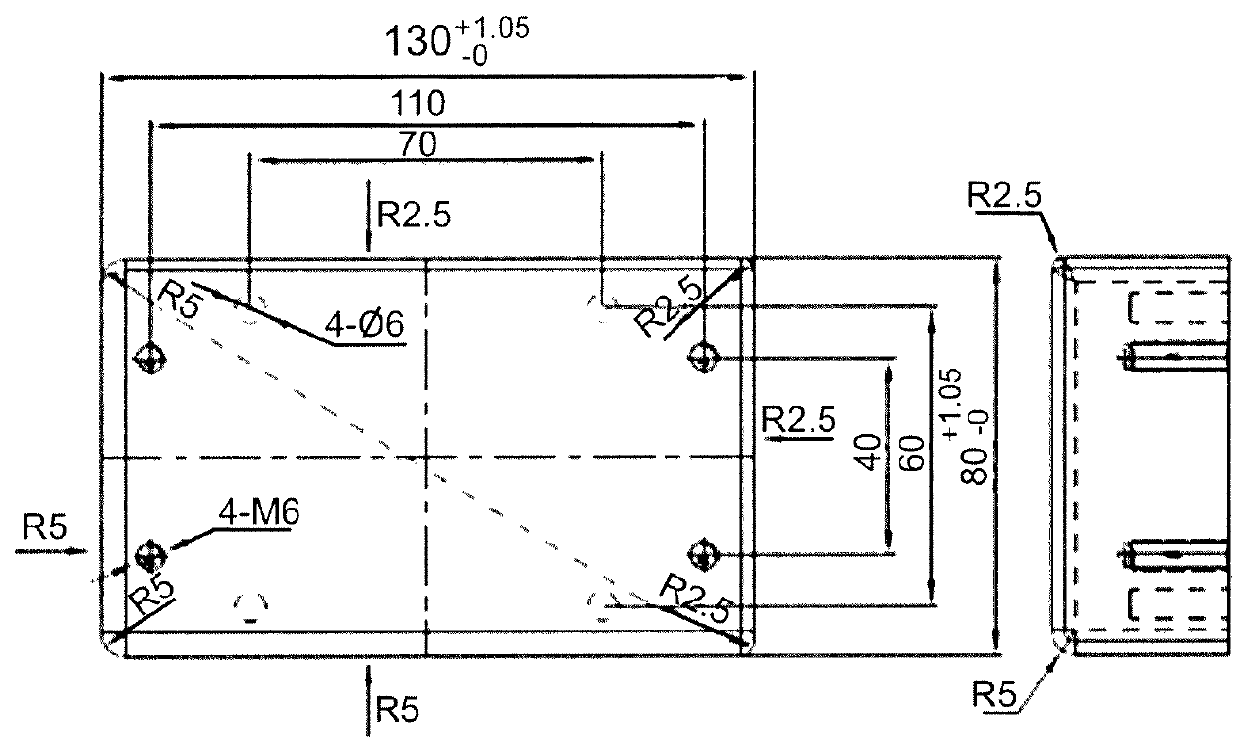

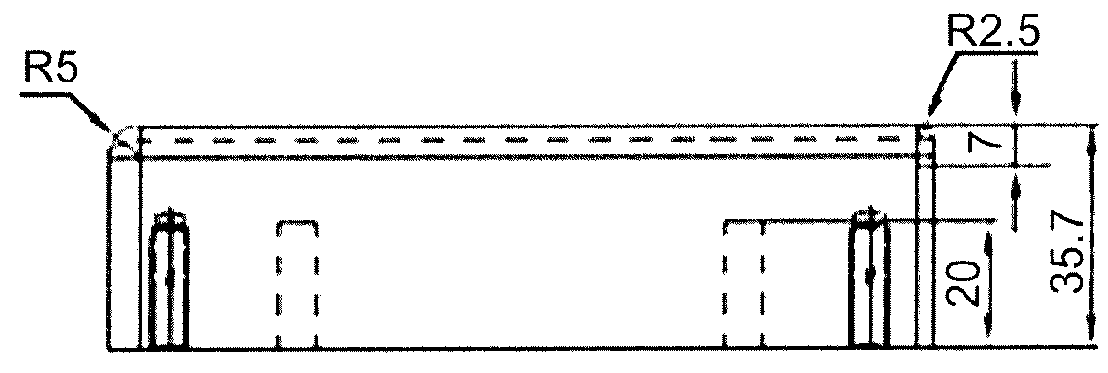

Composite resin material for pressure gas storage container and preparation method thereof

The application belongs to the technical field of composite resin materials, and in particular relates to a composite resin material used for a pressure gas storage container and a preparation method thereof. The method for preparing a composite resin material for a pressure gas storage container provided by the present application includes the following steps: mixing carbon nanotubes and dispersed oil to prepare carbon nanotube slurry; mixing nylon 6 and high-density polyethylene to form Resin mixture; after the resin mixture is melted in a twin-screw extruder, the carbon nanotube slurry is added, and the composite resin material is prepared by extrusion and granulation. The preparation method provided by the present application can improve the dispersibility of carbon nanotubes in the matrix resin, thereby improving the low temperature performance of the composite material and improving the heat dissipation performance.

Owner:SHENZHEN XIWAN TECH CO LTD

A kind of production method of copper-iron diffusion powder

The invention belongs to the field of powder metallurgy manufacturing and discloses a production method for metal diffusion powder. The production method comprises the steps that cupric oxide powder with -300 meshes is selected, industrial machine oil is selected as binders, or mixed powder of reduced iron powder with -300 meshes and nickel powder with -300 meshes is selected; the cupric oxide powder and the industrial machine oil are mixed, the reduced iron powder or the mixed powder of the reduced iron powder and the nickel powder is loaded in a three-dimensional blender mixer, and then thecupric oxide powder is added into the three-dimensional blender mixer; material mixing is started, the mixed powder is added into an iron powder reducing furnace, a reducing atmosphere is added, temperature rise continues after reducing is finished, high temperature diffusion is started, a beater is utilized to scatter the powder discharged from the furnace, and then iron-copper diffusion powder or copper-iron-nickel diffusion powder with -200 meshes is screened out. The product produced by the method has the beneficial effects that ingredients are even, almost no segregation occurs, the apparent density of the product is low, and the formability is good, and has broad popularization value.

Owner:JINCHUAN GROUP LIMITED

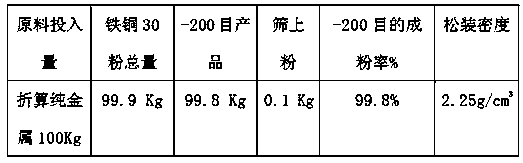

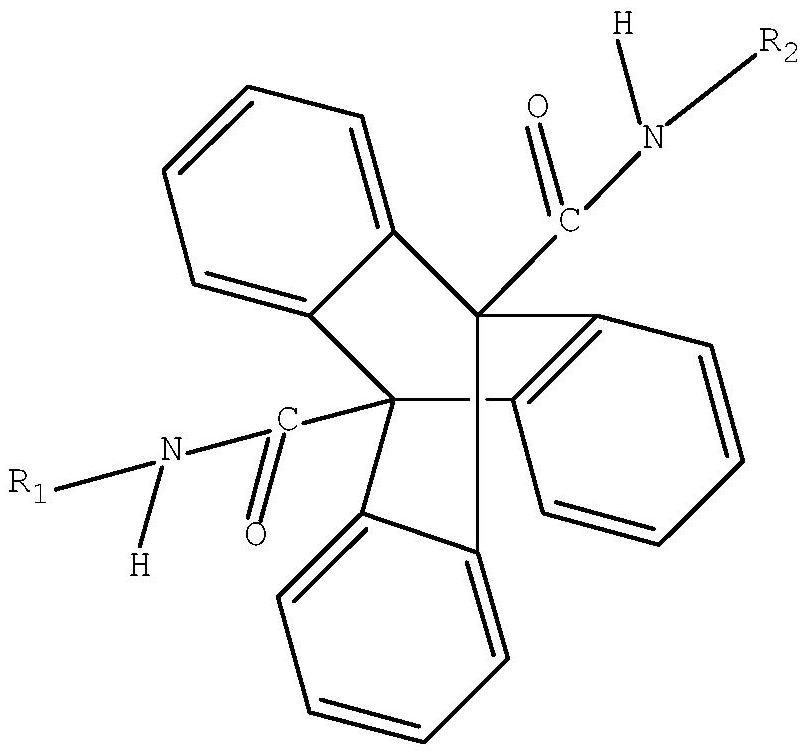

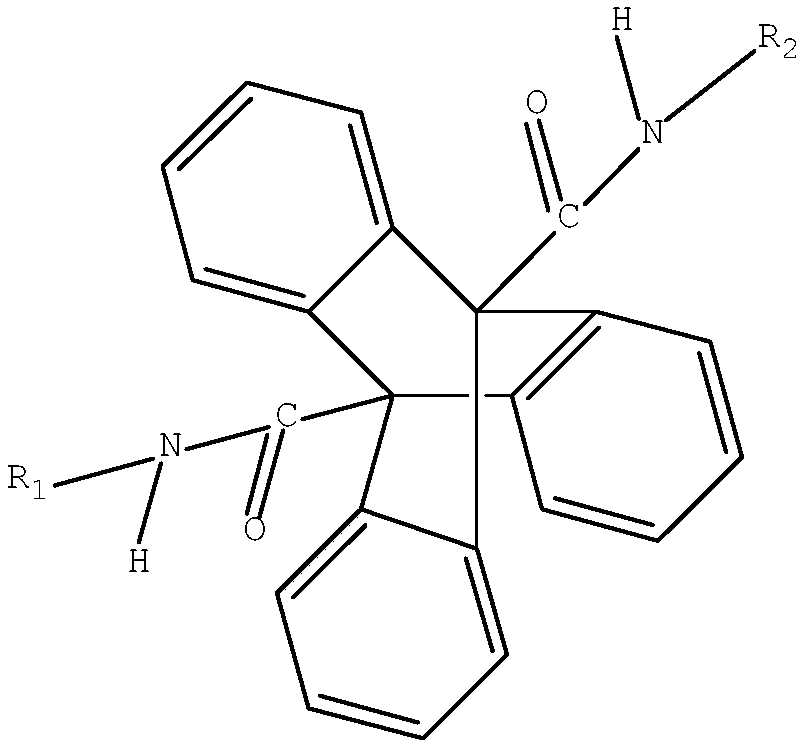

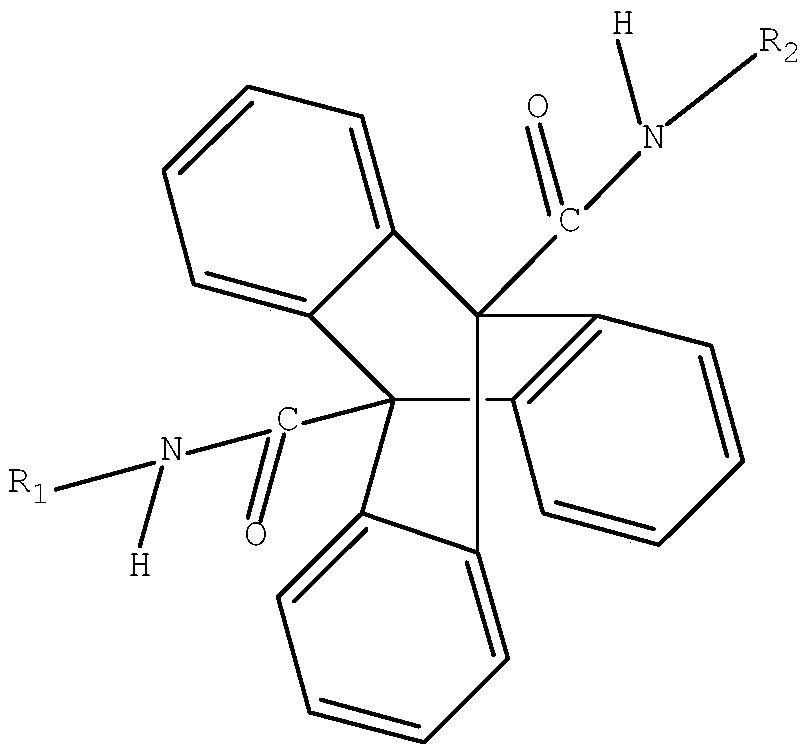

A low-hardness thermoplastic polyurethane elastomer with fast transparent molding and preparation method thereof

The invention belongs to the technical field of polyurethane elastomer preparation, and in particular relates to a low-hardness thermoplastic polyurethane elastomer with fast transparent molding and a preparation method thereof. The present invention uses triptycene derivatives with a special structure as chain extenders. The derivatives have H connected to N atoms and C connected to O atoms in the structure, which helps to form hydrogen bonds between molecular chains. It is helpful for the rapid and orderly arrangement of hard segments, and finally makes the product have better crystallization ability; in addition, due to the large steric hindrance of triptycene derivatives, the crystallization is destroyed to a certain extent, and the use of lower molecular weight Polyol is used as the soft segment, which makes the final product-thermoplastic polyurethane elastomer have lower hardness, better formability and good transparency.

Owner:MIRACLL CHEM

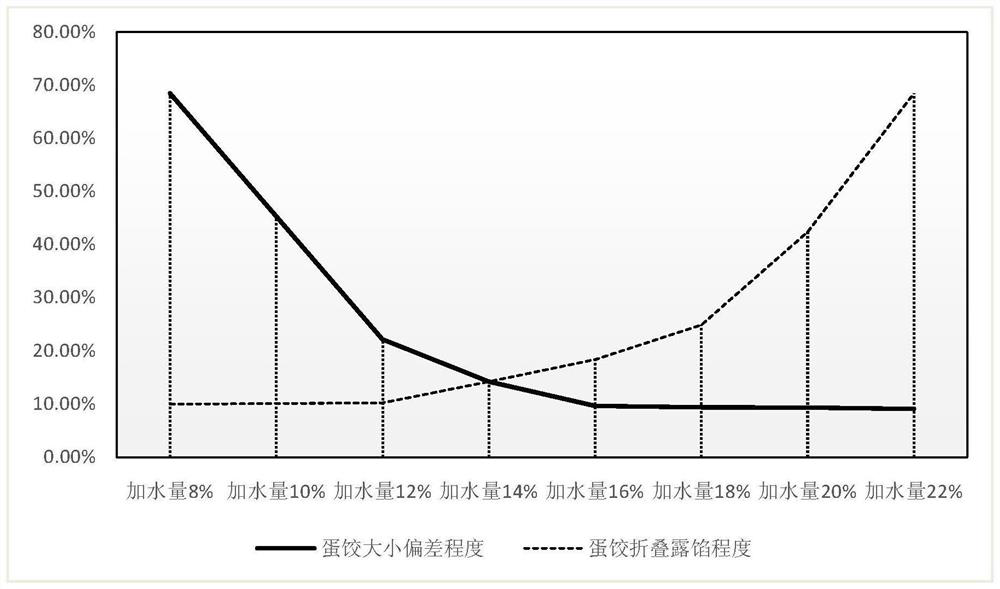

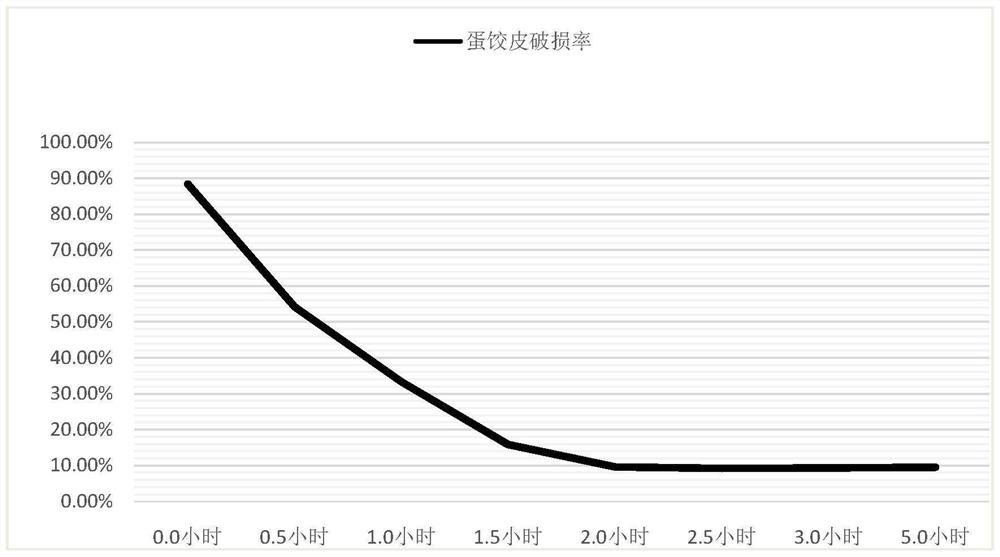

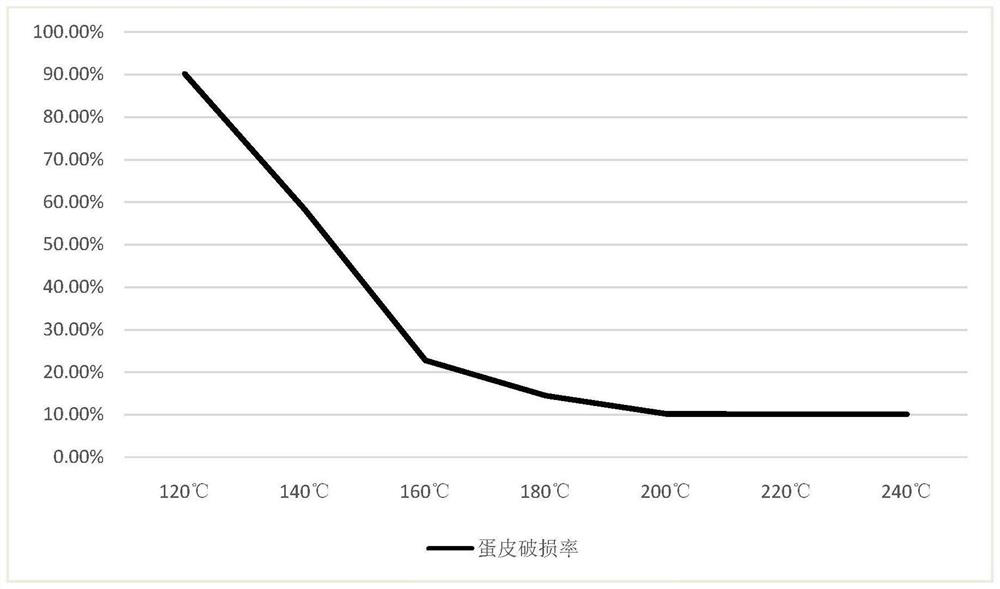

Prepackaged large egg dumpling and processing method thereof

The invention discloses a prepackaged large egg dumpling and a processing method thereof. The average weight of the size is about 60 grams. The processing method mainly includes the processing steps of raw and auxiliary materials, standing and refrigerating the egg liquid, blending and mixing the meat stuffing, forming and cooking, and quick-freezing. , product packaging, the processing method of the present invention overcomes the poor forming degree of traditional large egg dumplings, the adhesion between the egg skins is not high, the egg skins are easy to break, and cannot meet the limitations of batch production, and basically restores the traditional egg dumplings. The taste, color and appearance of dumplings also solved the problem of red meat and water loss rate caused by the destruction of tissue in the high-temperature engineering of traditional crafts, and obtained a large dumpling with beautiful appearance, excellent taste and high market acceptance. Egg dumplings.

Owner:鸿海(苏州)食品科技股份有限公司

Composite resin material for pressure gas storage container and preparation method thereof

The invention belongs to the technical field of composite resin materials, and particularly relates to a composite resin material for a pressure gas storage container and a preparation method thereof. The preparation method of the composite resin material for a pressure gas storage container, provided by the invention, comprises the following steps of: mixing carbon nanotubes and dispersed oil to prepare carbon nanotube slurry; mixing nylon 6 and high-density polyethylene to form a resin mixture; and melting the resin mixture in a twin-screw extruder, adding the carbon nanotube slurry, and carrying out extrusion granulation to obtain the composite resin material. According to the preparation method provided by the invention, the dispersity of the carbon nanotubes in the matrix resin can be improved, so that the low-temperature performance of the composite material is improved, and the heat dissipation performance is improved.

Owner:SHENZHEN XIWAN TECH CO LTD

Formable hard coated PC/PMMA coextruded films

ActiveUS9994718B2High pencil hardnessModerate formabilitySynthetic resin layered productsCoatingsMethacrylateOligomer

The present invention provides a formable hard coating composition, comprising a binder, comprising at least one acrylate oligomer and at least one monofunctional acrylate monomer and a crosslinking agent, comprising at least one multifunctional acrylate or methacrylate monomer. Furthermore, the present invention provides a coated film comprising a coextruded PC / PMMA film and a coating obtained by coating with the hard coating composition, wherein the coating has a dry film thickness according to ASTM B499 in the range of from ≥1 to ≤6 μm and preferably a crosslink density in the range of from ≥2·10−3 to ≤13·10−3. The coated films exhibit a combination of good formability and pencil hardness, solvent and chemical resistance which makes it particular useful for applications such as in-mold decoration processes.

Owner:COVESTRO DEUTSCHLAND AG

A kind of soft magnetic metal powder and preparation method thereof

ActiveCN114582580BGood molding effectLow formabilityTransportation and packagingMetal-working apparatusCopper wireSlurry

The invention discloses a soft magnetic metal powder and a preparation method thereof. Two kinds of gas atomized iron-nickel-molybdenum alloy powders with large particle size and carbonyl iron powder with small particle size are mixed to form the main body of the magnetic powder, and then binary pickling is performed, and acid washing is carried out. After washing, the powder is subjected to high-temperature composite phosphating treatment. After the powder is dried, the prepared coating slurry is mixed, stirred evenly, and then granulated. The obtained granules are baked at 70-90° C. for 60-80 minutes, and cooled to After mixing with lubricant at room temperature, sieving through 50-270 mesh to obtain soft magnetic metal powder. The powder prepared by the invention has the characteristics of high magnetic permeability and low loss, and the integrally formed inductor pressed by the powder has the advantages of low loss, low heat generation, high efficiency, low DC resistance, and cost saving of copper wire.

Owner:TDG HLDG CO LTD

A high baking hardenability aluminum alloy plate and its preparation method

The invention belongs to the field of manufacturing of aluminum alloy plates, and relates to an aluminum alloy plate with high bake hardenability and a preparation method thereof. The aluminum alloy plate with the high bake hardenability is prepared from, by weight, 0.4-0.9% of Mg, 0.6-1.4% of Si, 0.008-0.12% of Ti, 0.0005-0.04% of B, no more than 0.3% of Fe, 0.06-1.5% of Zn, 0.3-0.8% of Cu, 0.03-0.25% of Sn, no more than 0.15% of impurities and the balance Al, wherein the content of each the impurity is no more than 0.05%. By adoption of the aluminum alloy plate with the high bake hardenability and the preparation method thereof, the problem that MgO is likely to be formed on the surface of an aluminum alloy plate adopted by an automobile body covering part in the prior art, and consequentially, the binding property and corrosion resistance after painting of the automobile body covering part are poor is solved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

A kind of seawater corrosion-resistant copper alloy containing zirconium and its preparation method

The invention provides seawater-corrosion-resistant copper alloy containing zirconium. The seawater-corrosion-resistant copper alloy containing zirconium is prepared from, by mass percent, 63%-75% of Cu, 0.05%-1.5% of Al, 1.91%-3.5% of Si, 0.26%-2.0% of P, 0.0008%-0.006% of Zr and the balance Zn, and the copper alloy is in a single alpha phase. The invention further provides a preparation method of the copper alloy. By mass percent, the reaction substances are weighed, wherein Cu, Al, Zr, Si and Zn are elementary substances, and P is added in the manner of Cu-P intermediate alloy; and the above substances are added into a reaction vessel, smelting is performed for 2-5 hours at the temperature of 1000-1200 DEG C, and the seawater-corrosion-resistant copper alloy is obtained after cooling. The seawater-corrosion-resistant copper alloy is resistant to long-time corrosion of seawater, meanwhile, other performance of brass is not damaged, and the alloy has the beneficial effects of being high in strength, good in machining performance, high in hardness and resistant to seawater scouring.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Production method of ultra-low carbon interstitial-free mild steel

The invention discloses a production method of ultralow-carbon interstitial free soft steel, which comprises the following steps: hot rolling, cold rolling and cover annealing. The casting blank adopted by the hot rolling comprises the following components in percentage by weight: at most 50 ppm of C, at most 0.15% of Mn, at most 0.010% of S, at most 0.020% of P, greater than or equal to 0.10% and less than or equal to 0.20% of Si, at most 0.070% of Ti, 200-500 ppm of Als, at most 25 ppm of Ca, at most 50 ppm of N and the balance of Fe. In the hot rolling, a forepart cooling process is adopted, the finishing temperature is 900+ / -20 DEG C, and the coiling temperature is 700+ / -20 DEG C. In the cold rolling, the reduction in cold rolling is greater than or equal to 70%. In the cover annealing, an all-hydrogen cover annealing furnace is adopted, the dew point is lower than -50 DEG C, the hot-spot temperature is 740+ / -10 DEG C, the cold-point temperature is 720+ / -10 DEG C, and the holding time is 20-25 hours. By improving the steel grade components, improving the production process by Si alloying and enhancing the processability of the finished product, the method has the advantages of simple technique and no additional increase of cost; the experimental production is performed to obtain the expected effect; and the production process is stable, and the finished product has excellent performance.

Owner:HEBEI IRON AND STEEL

A low yield ratio martensite-ferrite-austenite composite wear-resistant steel plate and its manufacturing method

The invention provides a low yield ratio martensite-ferrite-austenite composite phase wear-resistant steel plate and a manufacturing method thereof. The steel plate manufacturing method is: selecting different alloy components for smelting, continuous casting into steel billets, and manufacturing through processes such as heating, controlled rolling, controlled cooling, and heat treatment. Its characteristics are: (1) The structure of the manufactured steel plate is a martensite-ferrite-austenite multi-phase composite structure; (2) The yield strength of the manufactured steel plate is significantly lower than that of traditional wear-resistant steel plates, and the yield-strength ratio ≤0.75, with excellent formability; (3) The hardness of the manufactured steel plate is between 300 and 420HB, which provides guarantee for obtaining good wear resistance; (4) The wear resistance is excellent, and the wear-resistant steel plate obtained by the present invention is the same as The wear resistance of martensitic wear-resistant steel plate with single hardness is more than doubled. The above-mentioned steel plates have good welding performance and higher low-temperature impact toughness, and are especially suitable for the manufacture of equipment or parts such as concrete mixing tank drums, dump truck compartments and pipes for channel dredging.

Owner:NORTHEASTERN UNIV LIAONING

Transparent fast- forming low-hardness thermoplastic polyurethane elastomer and preparation method thereof

The invention belongs to the technical field of polyurethane elastomer preparation, and particularly relates to a transparent fast- forming low-hardness thermoplastic polyurethane elastomerand a preparation method thereof. According to the invention, a triptycene derivative with a special structure is adopted as a chain extender, the derivative has H connected with N atom and C connected with O atom in the structure, the structure is helpful for forming hydrogen bonds between molecular chains, is helpful for fast and orderly arrangement of hard segments, and finally the structure enables the product to have better crystallization capability. In addition, due to the large steric hindrance of the triptycene derivative, crystallization is destroyed to a certain extent, and a polyol with lowermolecular weight is used as a soft segment, so that the final product-thermoplastic polyurethane elastomer has lower hardness, better formability and good transparency.

Owner:MIRACLL CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com