Composite resin material for pressure gas storage container and preparation method thereof

A composite resin and gas storage container technology, applied in the field of composite resin materials, can solve the problems affecting the performance of plastic liner, poor performance, increasing the risk of hydrogen leakage due to material failure, etc., to reduce the linear expansion coefficient, improve the overall performance, and improve the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

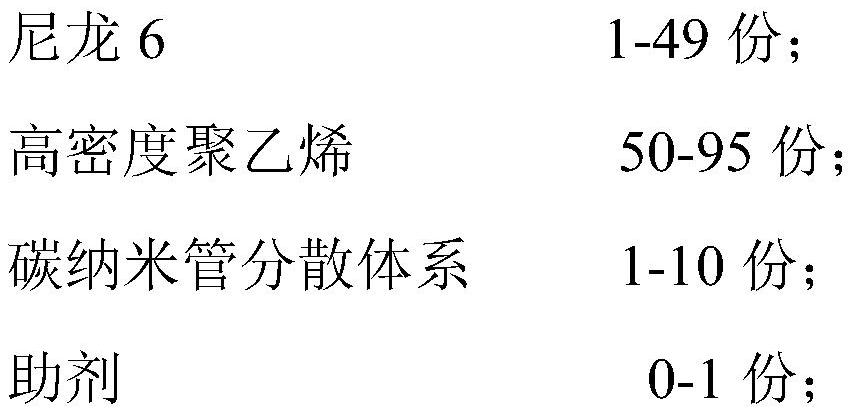

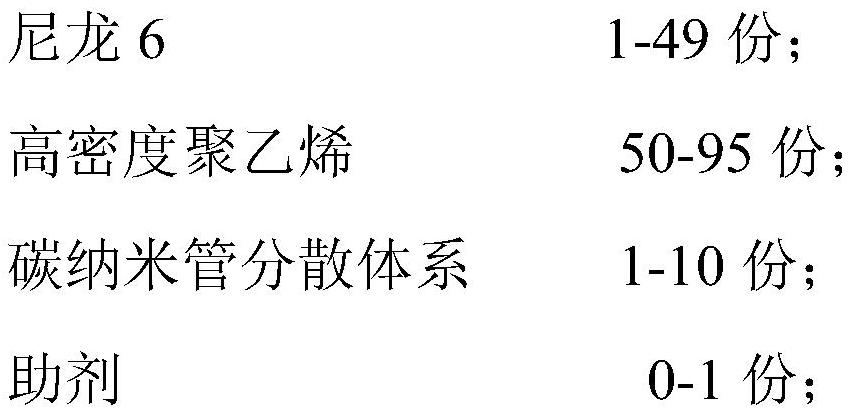

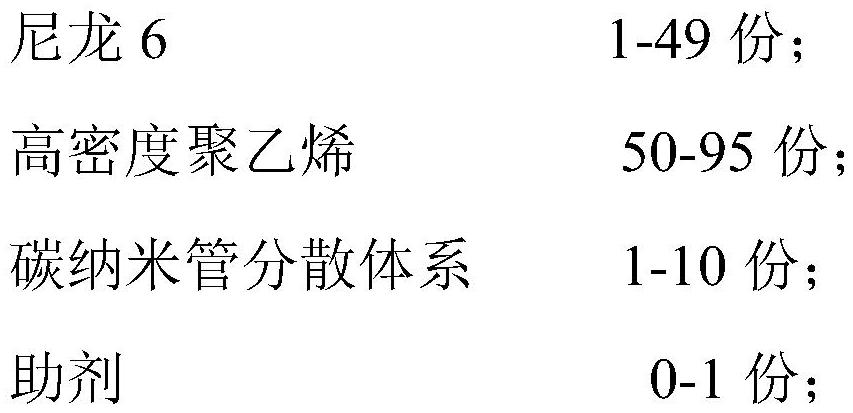

[0049] In the second aspect, the present application provides a method for preparing a composite resin material for a pressure gas storage container, comprising the steps of:

[0050] S01. Mixing carbon nanotubes and dispersion oils, configuring carbon nanotube slurry;

[0051] S02. Mixing nylon 6 and high density polyethylene forming a resin mixture;

[0052] S03. After melting the resin mixture in a twin screw extruder, a carbon nanotube slurry, extruded granulation, and preparing a composite resin material.

[0053] The preparation method of a composite resin material for pressure gas storage container is provided, using a dispersion oil as a dispersion medium of carbon nanotubes, and the carbon nanotube slurry is prepared by two dispersion to increase carbon nanotubes. Dispersing properties in dispersion oil, on this, the carbon nanotube slurry is added to the molten resin mixture, and the dispersion uniformity of carbon nanotubes in the resin melt is improved to enhance the c...

Embodiment 1

[0072] A composite resin material as a high-pressure hydrogen storage bottle, and the content of each raw material is shown in Table 1 Example 1. The composite resin material was prepared by the following method:

[0073] The carbon nanotubes were stitched with carbon nanotubes under stirring, and the carbon nanotubes were slowly added to the white ore oil while stirring, wherein the mass ratio of carbon nanotubes and white ore oil was 1: 3, and the stirring velocity was 500 rpm. After the carbon nanotubes were added, stirring was stirred for 20 minutes to obtain a carbon nanotube / white ore oil premixed slurry.

[0074] The premixed slurry was poured into a homogeneous dispersion, and the carbon nanotube dispersion slurry was obtained under pressure at 40 MPa conditions.

[0075] HDPE, PA6, 1010, and 168 were mixed by mechanically stirring, and HDPE / PA6 mixture was obtained, and the HDPE / PA6 mixture was stirred by a twin-screw extruder under temperature of 230-250 ° C; a compo...

Embodiment 2

[0077] A composite resin material as a high-pressure hydrogen storage bottle, and the content of each raw material is shown in Table 1 Example 2. The composite resin material was prepared by the following method:

[0078] The carbon nanotubes were stitched with carbon nanotubes under stirring, and the carbon nanotubes were slowly added to the white ore oil while stirring, wherein the mass ratio of carbon nanotubes and white ore oil was 1: 3, and the stirring velocity was 500 rpm. After the carbon nanotubes were added, stirring was stirred for 20 minutes to obtain a carbon nanotube / white ore oil premixed slurry.

[0079] The premixed slurry was poured into a homogeneous dispersion, and the carbon nanotube dispersion slurry was obtained under pressure at 40 MPa conditions.

[0080] HDPE, PA6, 1010, and 168 were mixed by mechanically stirring, and HDPE / PA6 mixture was obtained, and the HDPE / PA6 mixture was stirred by a twin-screw extruder under temperature of 230-250 ° C; a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com