Composite resin material for pressure gas storage container and preparation method thereof

A composite resin and gas storage container technology, applied in the field of composite resin materials, can solve the problems of affecting the performance of plastic liner, increasing the risk of hydrogen leakage due to material failure, poor performance, etc., to reduce the coefficient of linear expansion, improve the strength, and improve the overall performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

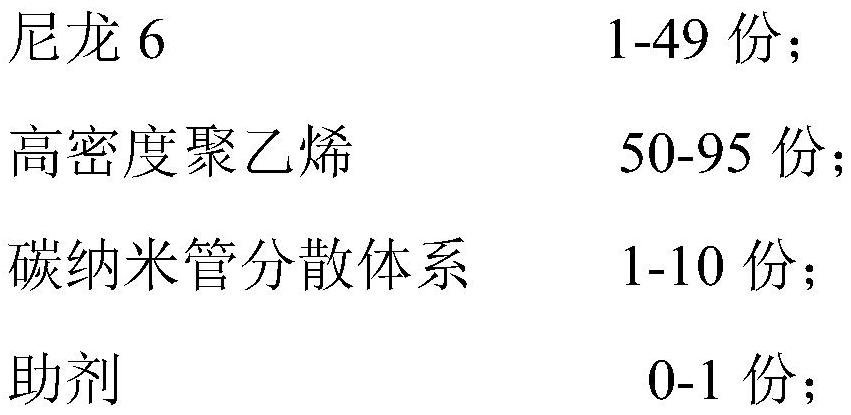

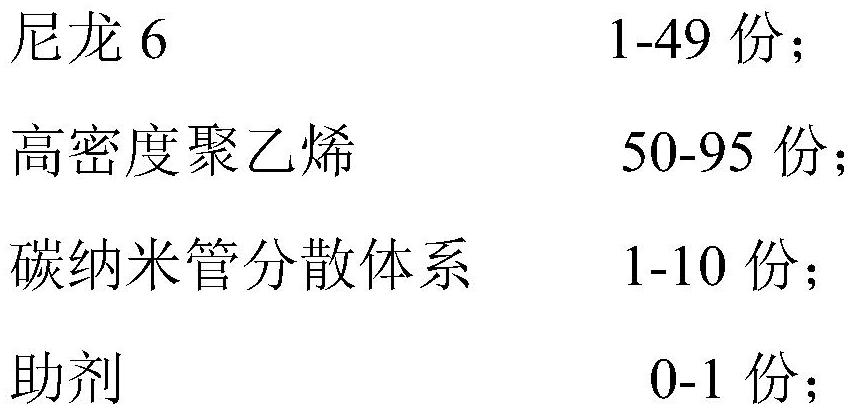

Method used

Image

Examples

preparation example Construction

[0049] In a second aspect, an embodiment of the present application provides a method for preparing a composite resin material for a pressure gas storage container, comprising the following steps:

[0050] S01. Mixing carbon nanotubes and dispersing oil to configure carbon nanotube slurry;

[0051] S02. Mix nylon 6 and high-density polyethylene to form a resin mixture;

[0052] S03. After the resin mixture is melted in a twin-screw extruder, carbon nanotube slurry is added, and extruded and pelletized to obtain a composite resin material.

[0053] The preparation method of the composite resin material for the pressure gas storage container provided in the embodiment of the present application adopts dispersing oil as the dispersion medium of carbon nanotubes, and prepares the carbon nanotube slurry through two dispersion treatments, so as to improve the carbon nanotubes in the carbon nanotubes. Dispersion performance in dispersing oil. On this basis, carbon nanotube slurry is...

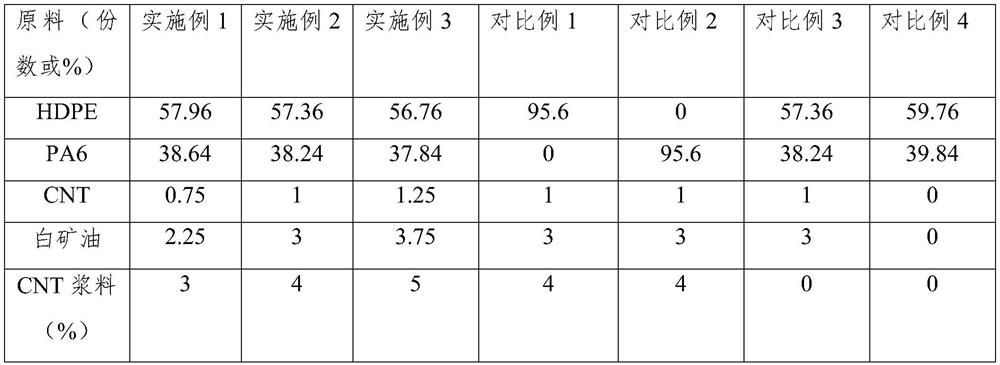

Embodiment 1

[0072] A composite resin material used as a high-pressure hydrogen storage bottle liner material, the content of each raw material is shown in Example 1 of Table 1. The composite resin material is prepared by the following method:

[0073] Weigh the carbon nanotubes under the stirring condition of the stirring disperser, and slowly add the carbon nanotubes to the white mineral oil while stirring, wherein the mass ratio of the carbon nanotubes to the white mineral oil is 1:3, and the stirring speed is 500rpm. After the carbon nanotubes are added, continue stirring for 20 minutes to obtain a carbon nanotube / white mineral oil premixed slurry.

[0074] The above-mentioned premixed slurry was poured into a homogenizer, and dispersed for 12 hours under the condition of a pressure of 40 MPa to obtain a carbon nanotube dispersion slurry.

[0075] Mix HDPE, PA6, 1010 and 168 through mechanical stirring to obtain HDPE / PA6 mixture; melt and stir the HDPE / PA6 mixture through a twin-screw e...

Embodiment 2

[0077] A composite resin material used as a high-pressure hydrogen storage bottle liner material, the content of each raw material is shown in Example 2 of Table 1. The composite resin material is prepared by the following method:

[0078] Weigh the carbon nanotubes under the stirring condition of the stirring disperser, and slowly add the carbon nanotubes to the white mineral oil while stirring, wherein the mass ratio of the carbon nanotubes to the white mineral oil is 1:3, and the stirring speed is 500rpm. After the carbon nanotubes are added, continue stirring for 20 minutes to obtain a carbon nanotube / white mineral oil premixed slurry.

[0079] The above-mentioned premixed slurry was poured into a homogenizer, and dispersed for 12 hours under the condition of a pressure of 40 MPa to obtain a carbon nanotube dispersion slurry.

[0080] Mix HDPE, PA6, 1010 and 168 through mechanical stirring to obtain HDPE / PA6 mixture; melt and stir the HDPE / PA6 mixture through a twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com