Reduction method of iron ore powder

A technology of iron ore powder and reduction furnace, which is applied in the field of iron ore powder reduction, can solve the problems of high energy consumption, cumbersome process, and high production cost, and achieve the effects of uniform particle size distribution, green environmental protection resources, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

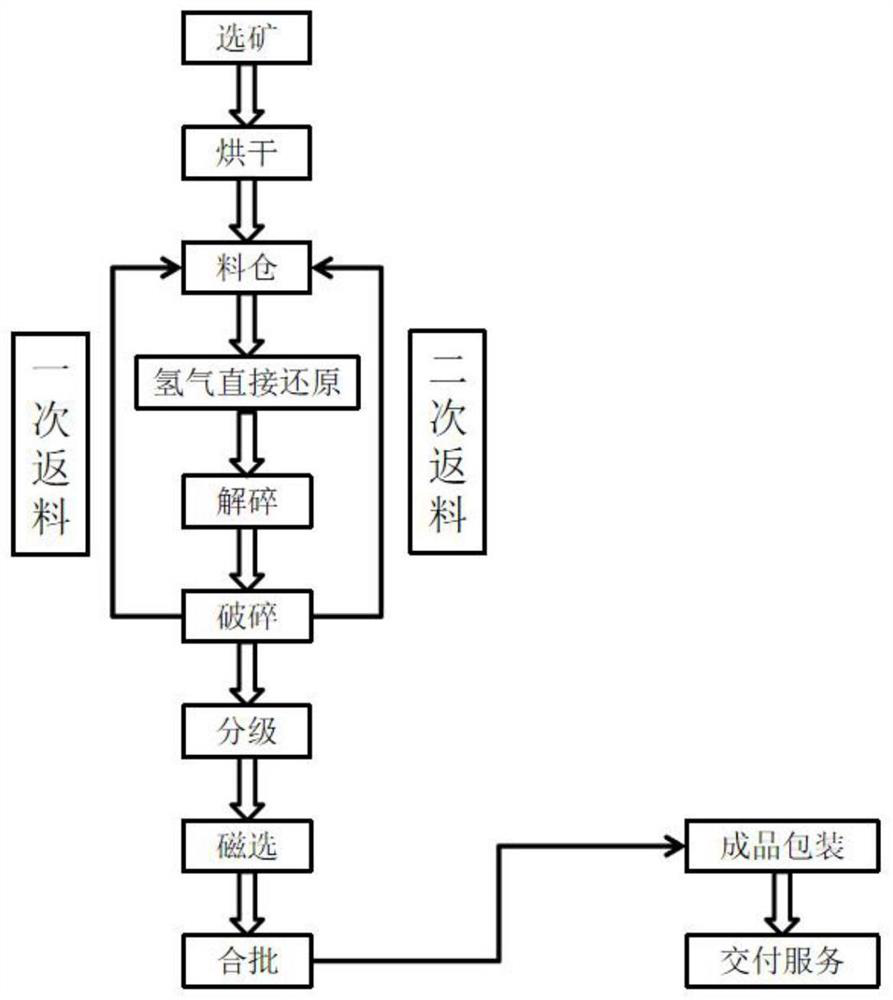

[0056] according to figure 1 The technological process shown, with 5 tons of iron concentrate powder, iron concentrate powder: TFe 72.1% (mainly Fe 2 o 3 ), Mn 0.088%, Si 0.053%, P 0.0039%, C 0.012%, S 0.040%; hydrochloric acid insoluble matter 0.30%; the remaining impurities are dried, and a reduction process is carried out in a steel belt reduction furnace. , the hydrogen flow rate is 39m 3 / h, the temperature is 820°C, the time is 4.5h, the belt speed is 110mm / s, the material thickness is 20mm, and after a stage of reduction, a stage of powder cake is obtained;

[0057] After one section of powder cake is broken and crushed, one section of reduced iron powder (element composition is (TFe84.12%, H 损 13.9%, Mn 0.087%, Si 0.052%, P 0.0039%, C 0.008%, S 0.035%, hydrochloric acid insoluble matter 0.20%; impurity balance);

[0058] The first-stage reduced iron powder is subjected to the second-stage reduction in the steel belt reduction furnace. During the second-stage reduct...

Embodiment 2

[0063] according to figure 1 The technological process shown, with 5 tons of iron concentrate powder (element composition is TFe 71.5%, Mn0.090%, Si0.055%, P 0.0040%, C 0.012%, S 0.030%; Hydrochloric acid insolubles 0.5%; amount) after drying, carry out a stage of reduction in the steel belt reduction furnace. During the stage of reduction, the hydrogen flow rate is 39m 3 / h, the temperature is 810°C, the time is 4.5h, the belt speed is 110mm / s, the material thickness is 20mm, after a stage of reduction, a stage of powder cake is obtained;

[0064] After a section of powder cake is disintegrated and broken, a section of reduced iron powder (element composition is (TFe82.12%, H 损 12.9%, Mn 0.087%, Si 0.054%, P 0.0035%, C 0.006%, S 0.035%; hydrochloric acid insoluble matter 0.20%; impurity balance);

[0065] The first-stage reduced iron powder is subjected to the second-stage reduction in the steel belt reduction furnace. During the second-stage reduction process, the hydrogen...

Embodiment 3

[0070] according to figure 1 The technological process shown, with 5 tons of iron concentrate powder (element composition is TFe 72.1%, Mn0.078%, Si0.050%, P 0.0039%, C 0.012%, S 0.038%; Hydrochloric acid insoluble matter 0.30%; amount) after drying, carry out a stage of reduction in the steel belt reduction furnace. During the stage of reduction, the flow rate of hydrogen is 39m 3 / h, the temperature is 830°C, the time is 4.5h, the belt speed is 110mm / s, the material thickness is 20mm, after a stage of reduction, a stage of powder cake is obtained;

[0071] After one section of powder cake is broken and crushed, one section of reduced iron powder (element composition is (TFe84.12%, H 损12.9%, Mn 0.080%, Si 0.050%, P 0.0039%, C 0.008%, S 0.035%; hydrochloric acid insoluble matter 0.20%; impurity balance);

[0072] The first-stage reduced iron powder is subjected to the second-stage reduction in the steel belt reduction furnace. During the second-stage reduction process, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com