Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Lost fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

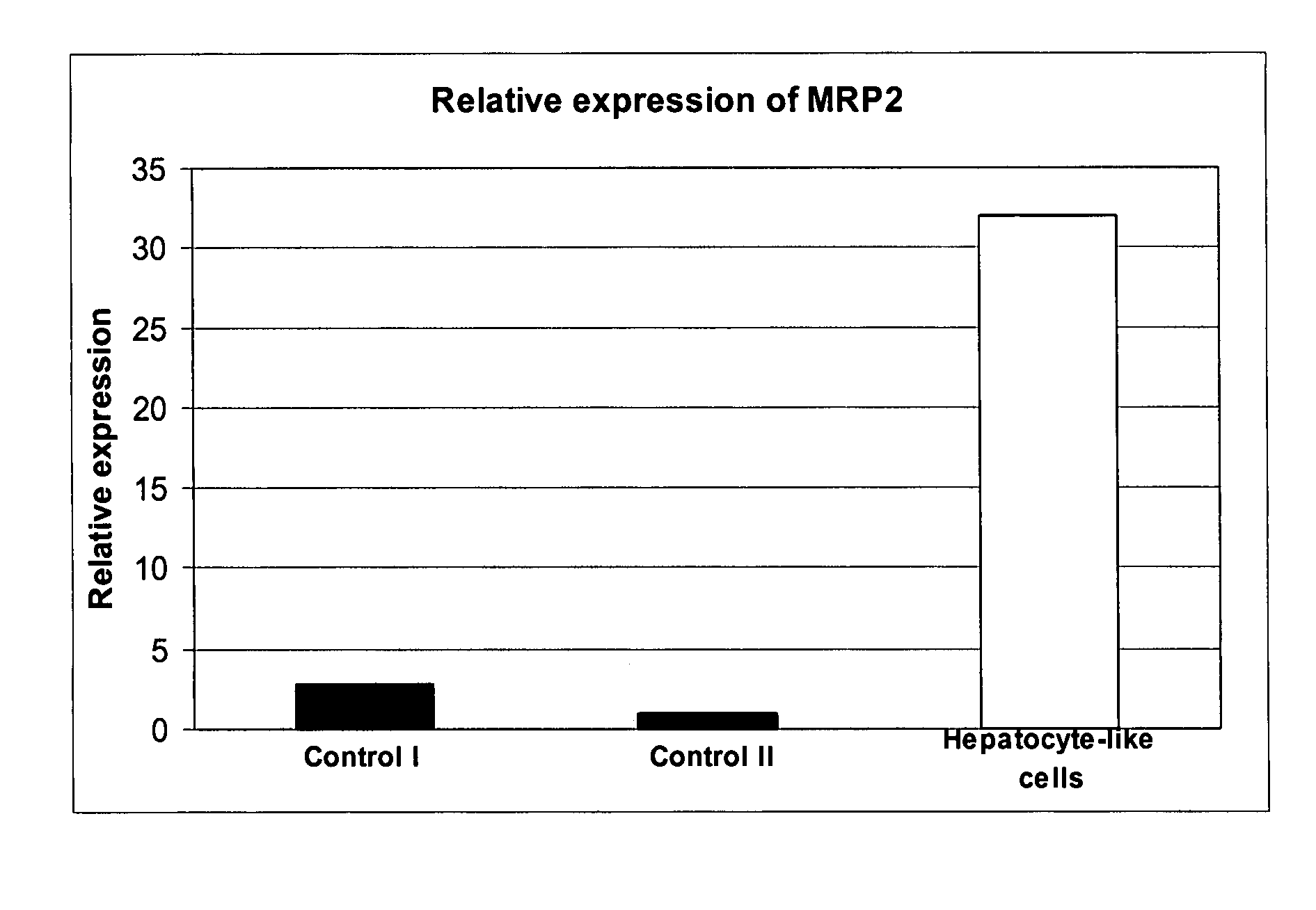

Novel hepatocyte-like cells and hepatoblast-like cells derived from hBS cells

InactiveUS20080019950A1Improve predictabilityReduce needBiocideHepatocytesIn vitro studyMother cells

The present invention relates to a novel hepatocyte-like cell population derived from hBS cells and to the potential use of such heopatocyte-like cells in e.g. medical treatment, drug screening and toxicity testing. Furthermore, the invention relates to hepatoblast-like cells that may have suitable characteristics so that they can be used for the same applications as the hepatocyte-like cells and that furthermore may be used in in vitro studies of hepatogenesis such as early hepatogenesis or hepato-regenerative disorders. Both the hepatocyte-like and the hepatoblast-like cells according to the invention express drug transporter and / or drug metabolising characteristics either at the gene or protein expression level.

Owner:CELLARTIS AB (SE)

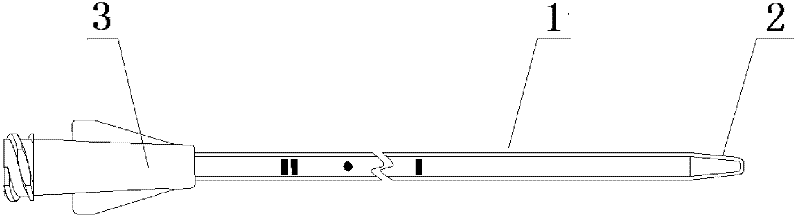

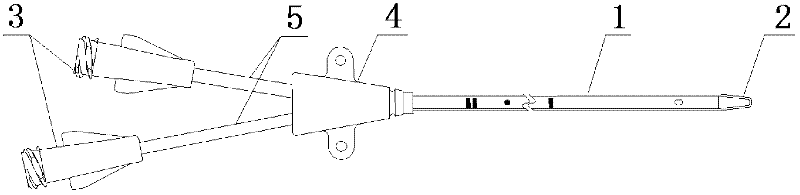

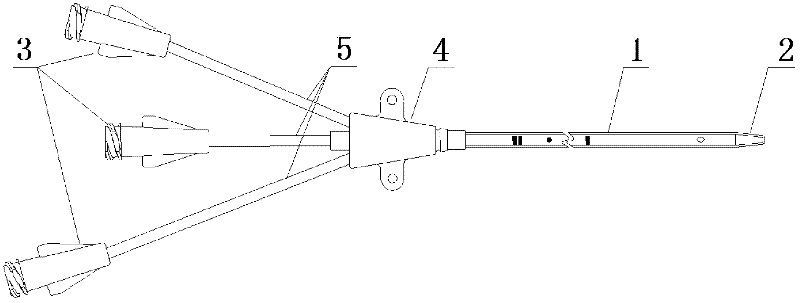

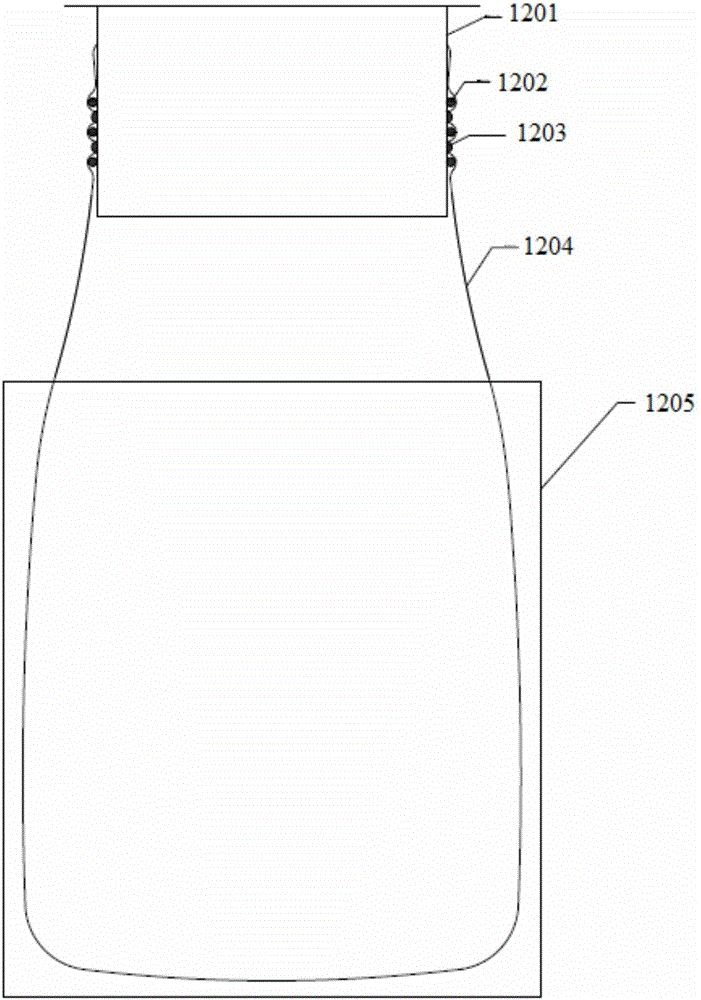

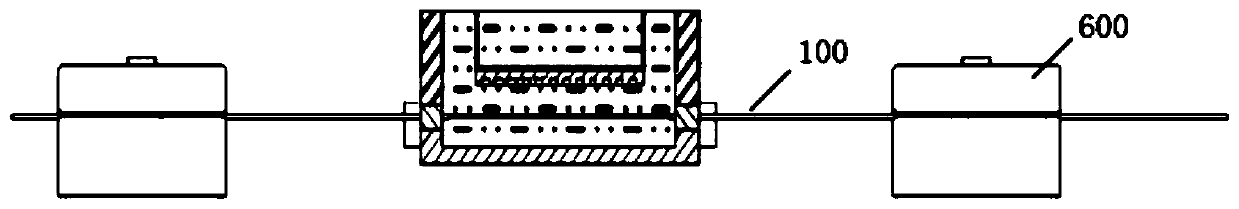

Anti-infection venous catheter and preparation method thereof

ActiveCN102500033ALost fastImprove efficacyAntibacterial agentsTetracycline active ingredientsVeinIntravenous catheter

The invention relates to an anti-infection venous catheter and a preparation method thereof. The venous catheter comprises a conduit main body tube, a tip end and a tube seat, and preferably also comprises a connecting seat and a plurality of epitaxial tubes, wherein the parts retained in a human body are the conduit main body tube and the tip end; and an anti-infection medicament rifampicin, an anti-infection medicament minocycline or combination of the two are uniformly loaded on the conduit main body tube. The preparation method of the venous catheter comprises the following steps of: dissolving the anti-infection medicament or the medicament combination to form soak solution; soaking the conduit into the soak solution to fully soak medicaments into the conduit; and drying to remove solvent to prepare the anti-infection venous catheter. During use, the medicaments are slowly released to fulfill the anti-infection aim of the conduit and avoid infection of the conduit during retention in the human body in surgery.

Owner:BEIJING DEMAX MEDICAL TECH

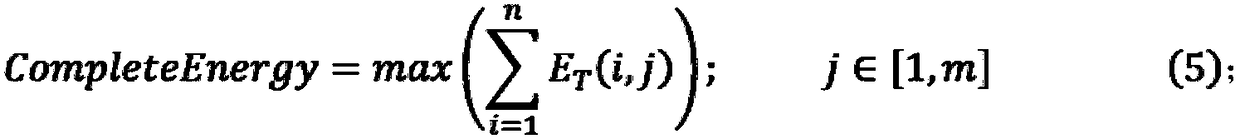

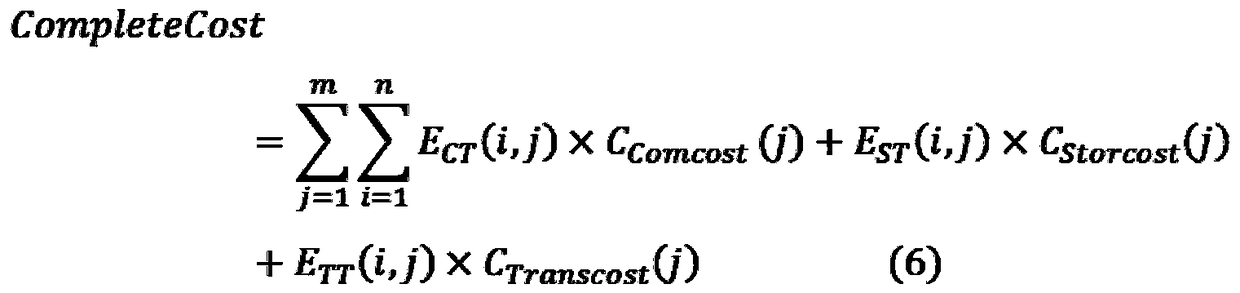

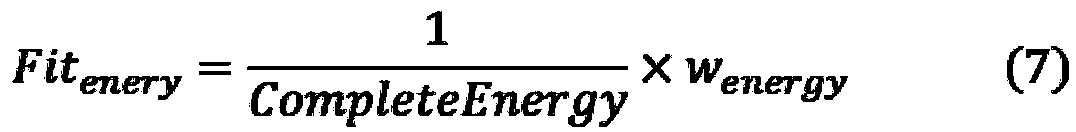

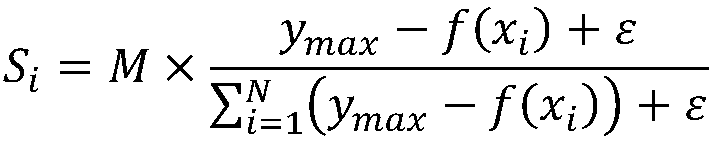

An energy consumption optimization management method for cloud platform based on fusion genetic algorithm and ant colony algorithm

InactiveCN109213585AImprove performanceReduce energy consumptionProgram initiation/switchingArtificial lifeGenetic algorithmCloud resources

The invention discloses a cloud platform energy consumption optimization management method based on a fusion genetic algorithm and an ant colony algorithm. The invention adopts a two-level dispatchingmode. The first-level dispatching dispatches a task to a virtual machine for execution according to the preference selection of a user on performance and cost. According to the task attributes and resource load, the second-level scheduling searches for the appropriate cloud resources to allocate to the virtual machine. The invention divides the demand of the user for the service quality into an energy consumption demand and a cost demand. The energy consumption demand reduces the energy consumption by reducing the calculation energy consumption, transmission energy consumption and storage energy consumption of the physical resources, and the cost demand reduces the calculation cost through the comprehensive energy consumption demand and the scheduling cost.

Owner:GUANGDONG UNIV OF TECH

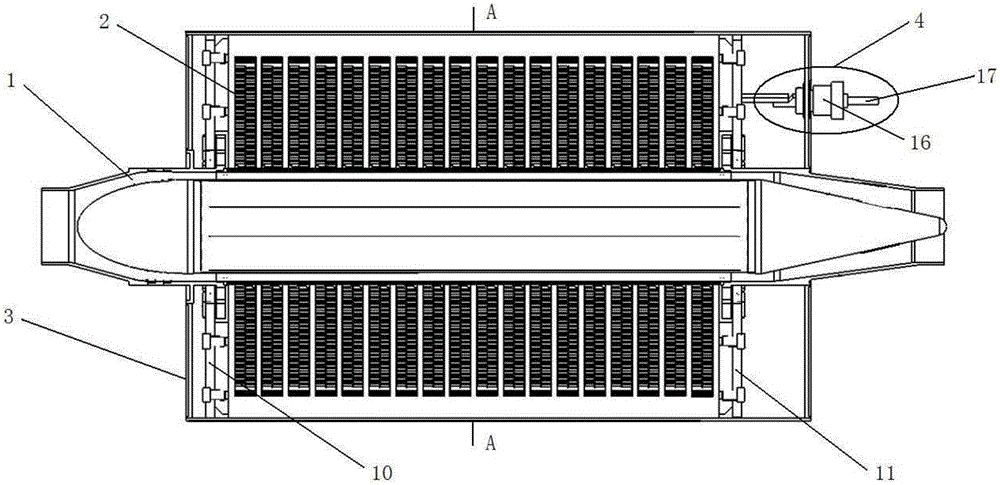

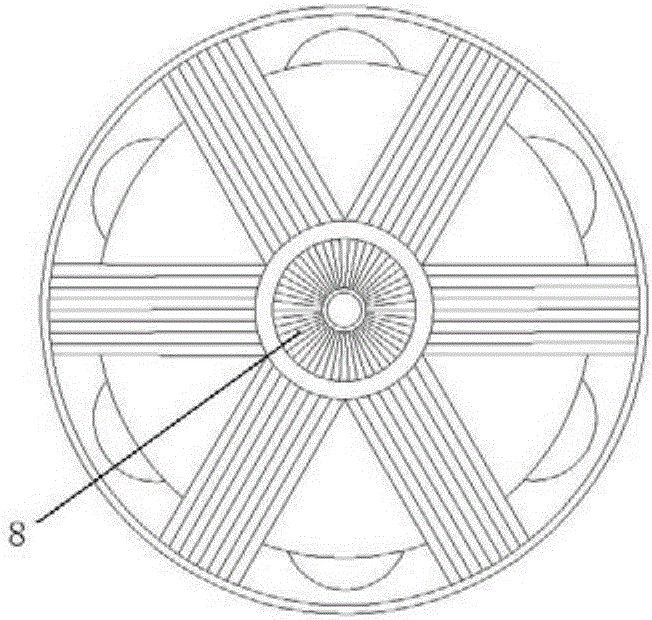

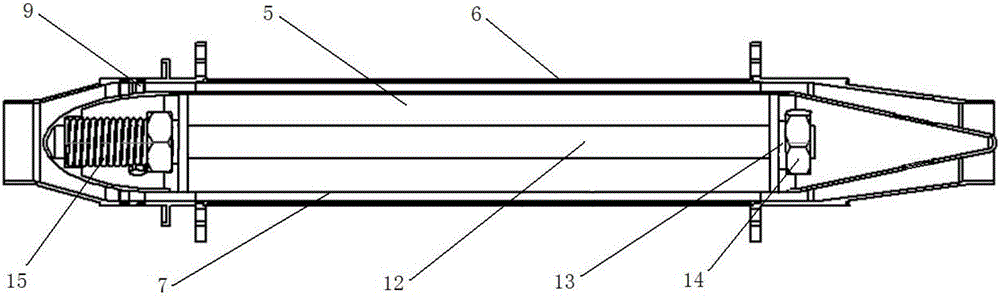

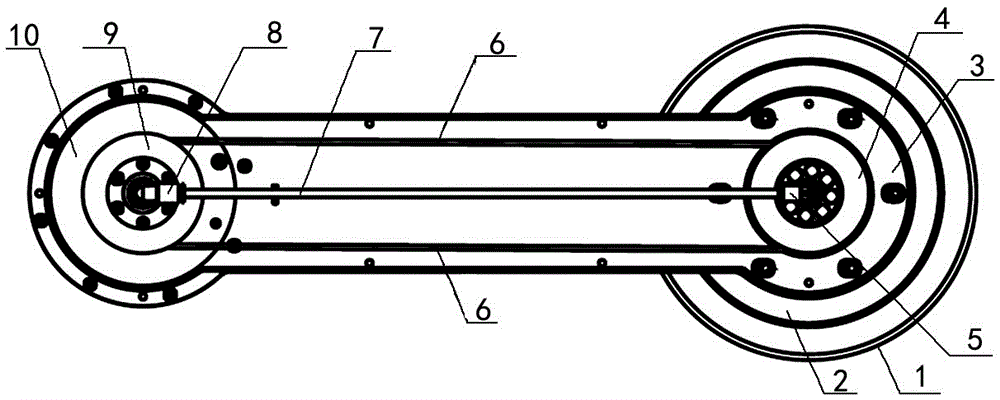

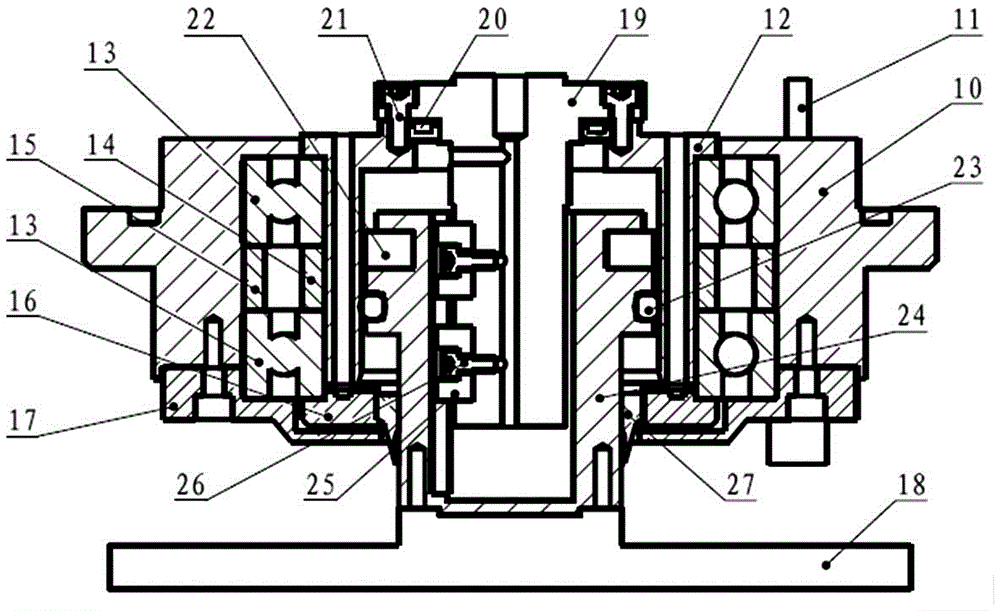

Liquid-state metal electromagnetic pump for space nuclear environment

ActiveCN106451996AReduce weightReduce volumeDynamo-electric machinesElectric power transmissionNuclear power

The invention relates to a liquid-state metal electromagnetic pump. Aiming at solving the problem that an existing electromagnetic pump cannot meet application requirements of a space nuclear power supply system, the invention provides a liquid-state metal electromagnetic pump for a space nuclear environment. The electromagnetic pump is composed of a pump groove assembly, an electromagnetic excitation structure assembly, a gas sealing shell assembly and a power transmission assembly. According to the liquid-state metal electromagnetic pump, an iron core structure has relatively good magnetism conducting efficiency and the weight and volume of the electromagnetic pump are easy to reduce; an annular flow channel of liquid-state metal can effectively improve the working efficiency of the electromagnetic pump; the electromagnetic pump is compact and firm in structure and can bear vibration and impacts from a launching phase to an orbit injection phase of a spacecraft; the gas sealing shell assembly and inert gas can provide effective protection for an electromagnetic excitation structure so that the service life is extremely prolonged and the reliability is extremely improved; and the electromagnetic pump adopts a relatively reasonable design structure so that the control of temperature distribution is facilitated and the electromagnetic pump can stably work for a long period in a vacuum environment.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

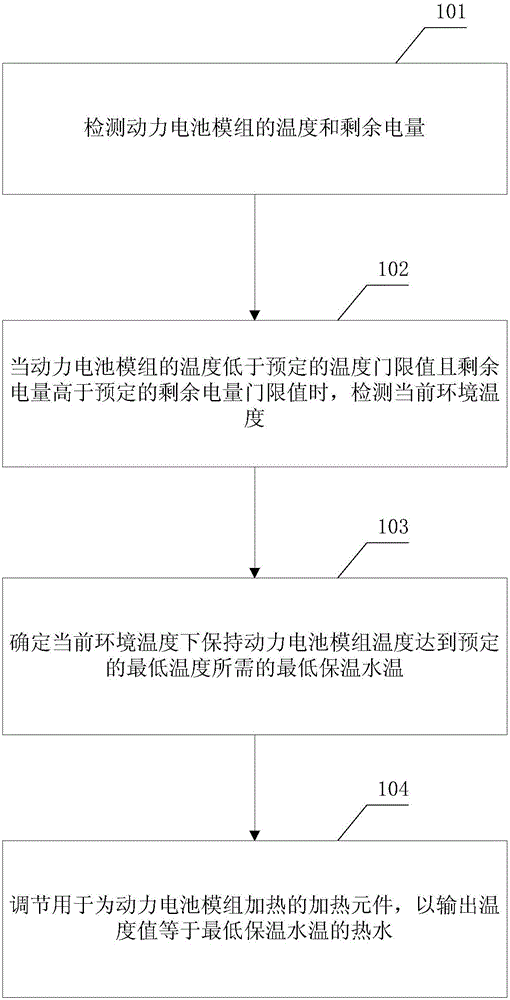

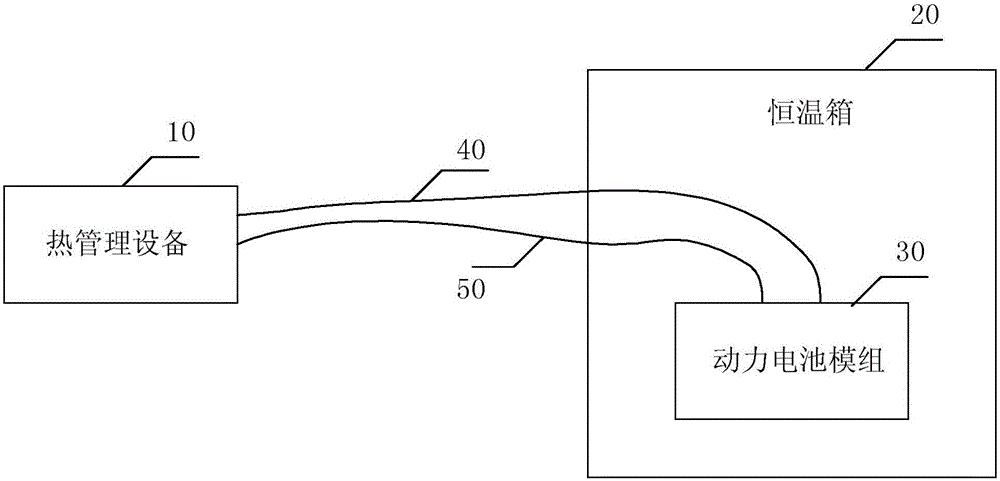

Thermal insulation method and thermal insulation device for electric vehicle power battery module

The embodiment of the invention discloses a thermal insulation method and a thermal insulation device for an electric vehicle power battery module. The thermal insulation method comprises the steps of detecting the temperature and remaining capacity of the power battery module; when the temperature of the power battery module is lower than a predetermined temperature threshold value and the remaining capacity is higher than a predetermined remaining capacity threshold value, detecting the current environmental temperate; determining a minimum thermal insulation water temperature required to maintain the temperature of the power battery module at the current environment to achieve a predetermined minimum temperature; and adjusting a heating element used for heating the power battery module, so as to output hot water with a temperature value equal to the minimum thermal insulation water temperature. The embodiment of the invention can reduce energy consumption, and can also be used in a thermal insulation process at the end of charging and a parking thermal insulation process under a discharged state.

Owner:CH AUTO TECH CORP CO LTD

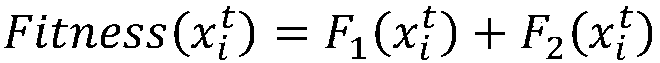

A cloud platform energy consumption optimization management method based on a fireworks algorithm

PendingCN109614216AImprove performanceReduce energy consumptionResource allocationCharacter and pattern recognitionFireworksFireworks algorithm

The invention discloses a cloud platform energy consumption optimization management method based on a fireworks algorithm, and on the basis of the fireworks algorithm, load balance, performance and energy consumption of each device in a cloud computing platform are combined, so that the overall energy consumption of the cloud computing platform is reduced, and meanwhile, the computing capability of the cloud computing platform is ensured.

Owner:GUANGDONG UNIV OF TECH

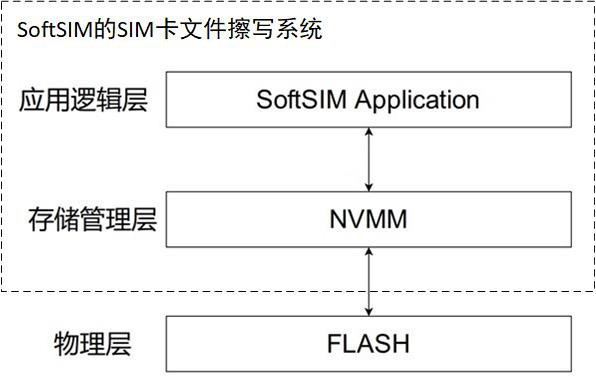

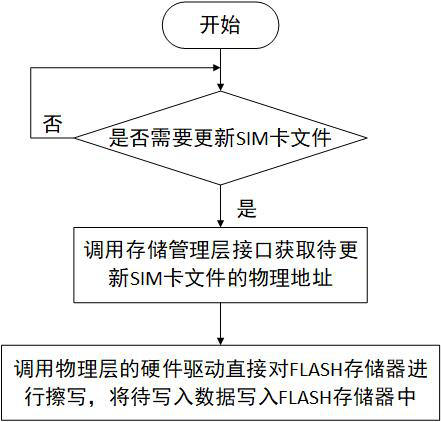

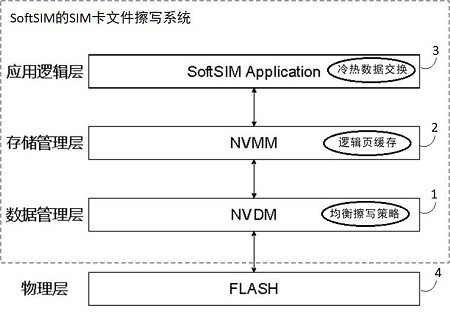

SIM card file erasing and writing system and method applied to SoftSIM and readable storage medium

ActiveCN112231244AErase levelingBalanced Erase and Write TimesMemory systemsNetwork data managementEngineeringStorage management

The invention discloses an SIM card file erasing and writing system and method applied to SoftSIM and a computer readable storage medium. The system comprises a data management layer, a storage management layer and an application logic layer; the application logic layer exchanges the storage positions of the cold data and the hot data when the communication module chip is powered on, the situationthat in the long-term erasing and writing process, the erasing and writing frequency of the storage area of the hot data is far larger than that of the storage area of the cold data, and consequentlyloss is too fast is avoided, erasing and writing balance of all the storage areas is achieved, and meanwhile, when the SIM card file needs to be updated, the data to be written is cached into the logic page of the memory space; the storage management layer writes the to-be-written data in the logic page into the logic address space formed by the data management layer when the page changing condition is met, and then the data management layer writes the to-be-written data into the FLASH memory of the communication module chip, so that the erasing and writing frequency of the FLASH memory is reduced. By achieving erasing and writing balance and reducing erasing and writing times, the service life of the FLASH memory is effectively prolonged.

Owner:SHENZHEN JETLINK TECH CO LTD

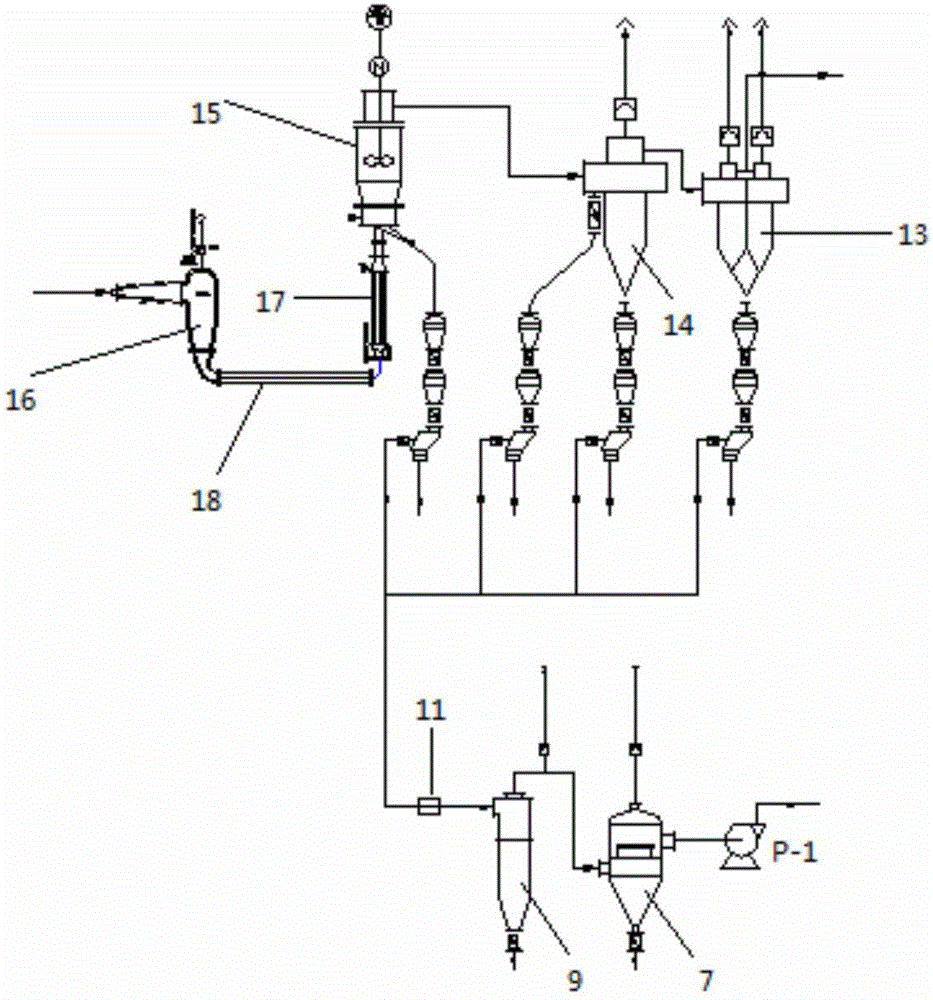

Aluminum alloy powder production system provided with inert gas protective dust removing device

An aluminum alloy powder production system provided with an inert gas protective dust removing device comprises an atomizing device, an atomizing chamber, a sleeve heat exchanger, a tubular heat exchanger, a centrifugal classifier, a cyclone classifier and a double-connection cyclone classifier which are sequentially connected, wherein a gas outlet pipeline of the double-connection cyclone classifier is divided into two branches; one branch is connected with an after-treatment system, and another branch is used as a dust removing system balancing pipe; a filter and a fire barrier are arranged on the dust removing system balancing pipe; the other end of the dust removing system balancing pipe is sequentially connected with a dust removing centrifugal classifier, a dust removing cyclone classifier and an efficient filter tank; the efficient filter tank communicates with a dust removing fan in a gas balancing tank. With the adoption of the production system, the potential risk of combustion and explosion can be effectively removed; in addition, dust product of which the particle size is uniformly distributed can be efficiently collected, so that the additional value of the product can be increased; meanwhile, the dust is not discharged to the outside at last, so that the problems of dust waste and environmental pollution can be further solved.

Owner:HUNAN JINHAO ALUMINUM IND

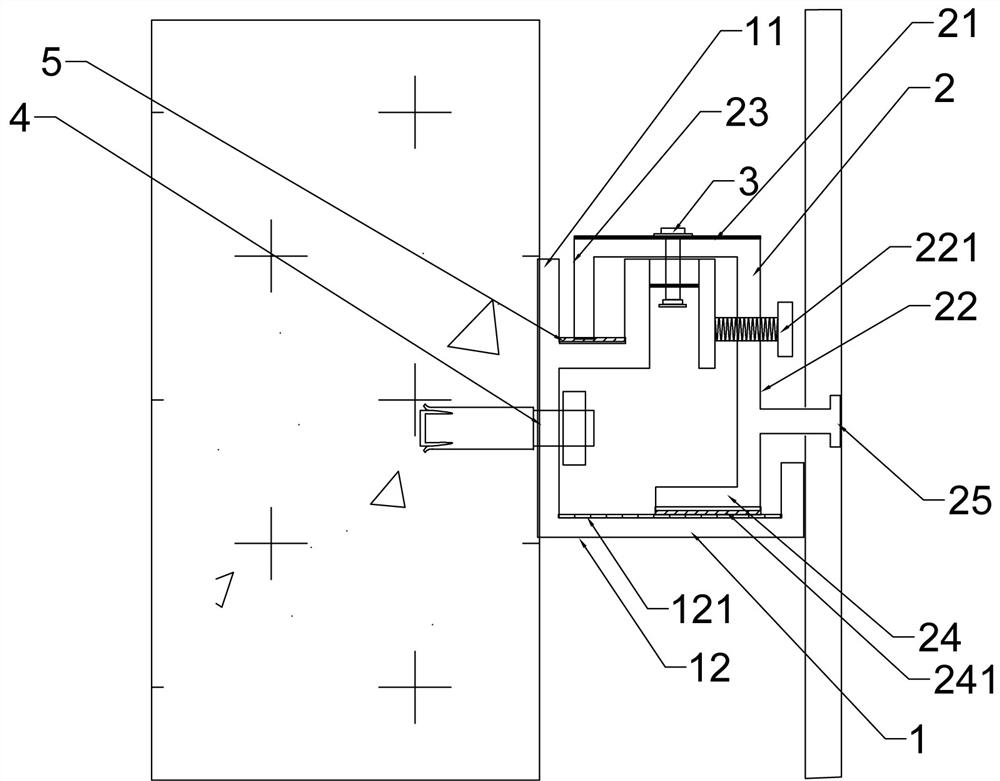

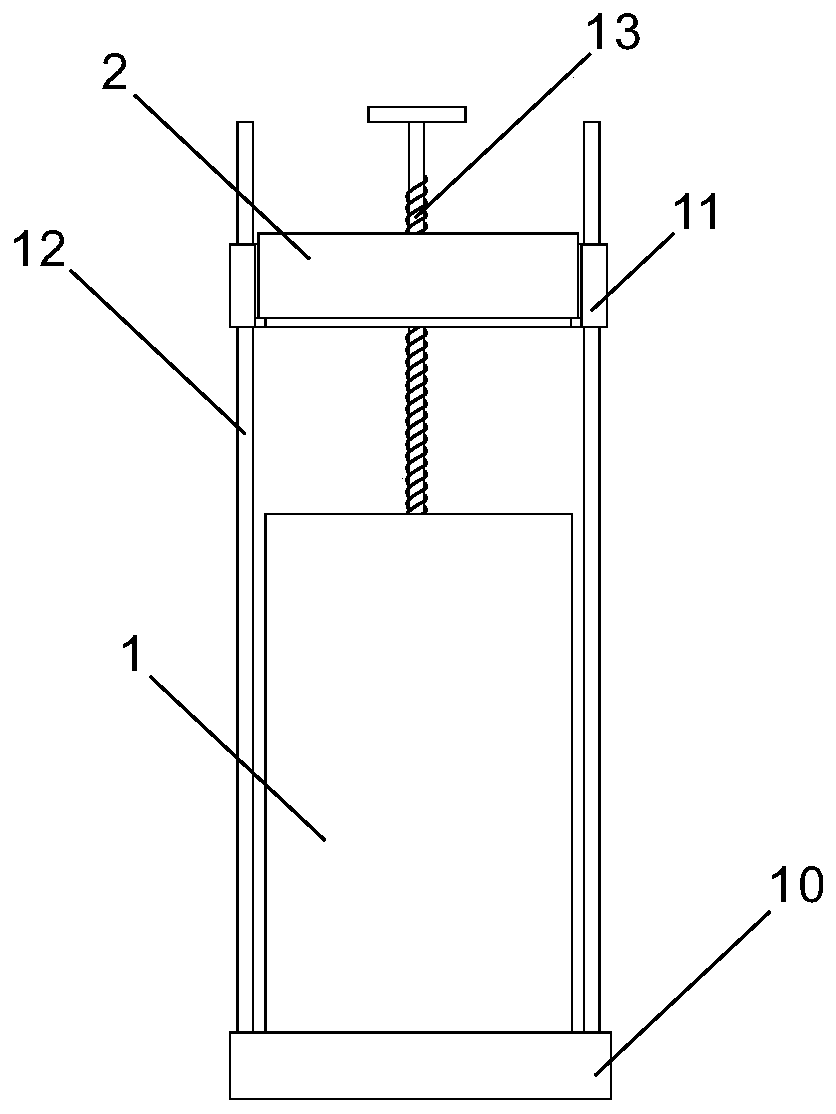

Wallboard mounting structure capable of achieving free leveling and mounting method thereof

The invention discloses a wallboard mounting structure capable of achieving free leveling and a mounting method thereof. The wallboard mounting structure comprises a first leveling piece and a secondleveling piece; the second leveling piece comprises a top plate, a first side plate, a second side plate and a bottom plate; the first side plate is provided with an internal threaded hole allowing afirst screw to penetrate through and a connecting piece used for clamping a wallboard; the first leveling piece comprises a base used for being attached to a wall surface body, a supporting base usedfor bearing the bottom plate, and a positioning part used for bearing the top plate and the second side plate; the positioning part comprises a first bearing part used for bearing the second side plate, a first stopping part used for stopping the second side plate, a second bearing part used for bearing the top plate and a second stopping part used for stopping the first screw; the top plate is provided with a first strip-shaped hole; the second bearing part is provided with a second strip-shaped hole; the first strip-shaped hole and the second strip-shaped hole partially overlap each other; the first strip-shaped hole and the second strip-shaped hole are connected in a penetrating mode and fixed through a fastener; and the wall surface body and the wallboard are connected and fastened.

Owner:ZHEJIANG YASHA DECORATION

Method for making lignocellulosic paper and paper product

ActiveUS9663899B2Improve dry strength propertyImprove accessibilityPulp properties modificationFats/resins/pitch/waxes removal in pulpCellulosePapermaking

Enzyme compositions comprising laccase, lipase, cationic polymer, and optionally laccase activator, for papermaking application are disclosed. It also relates to the use of the enzyme composition to improve dry strength property of a paper product made from lignocellulosic-containing materials before or after mechanical refining in a papermaking process.

Owner:SOLENIS TECH CAYMAN

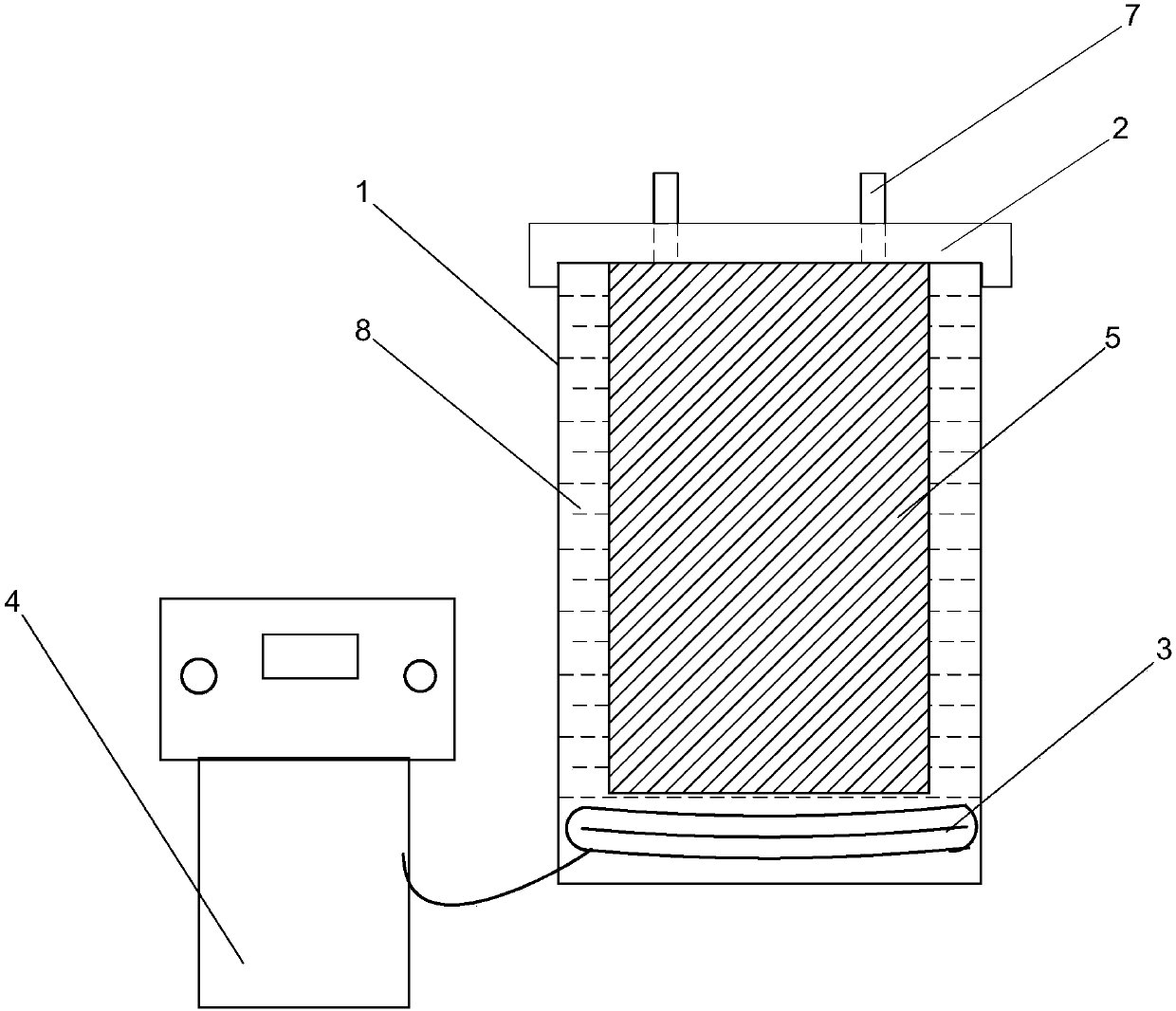

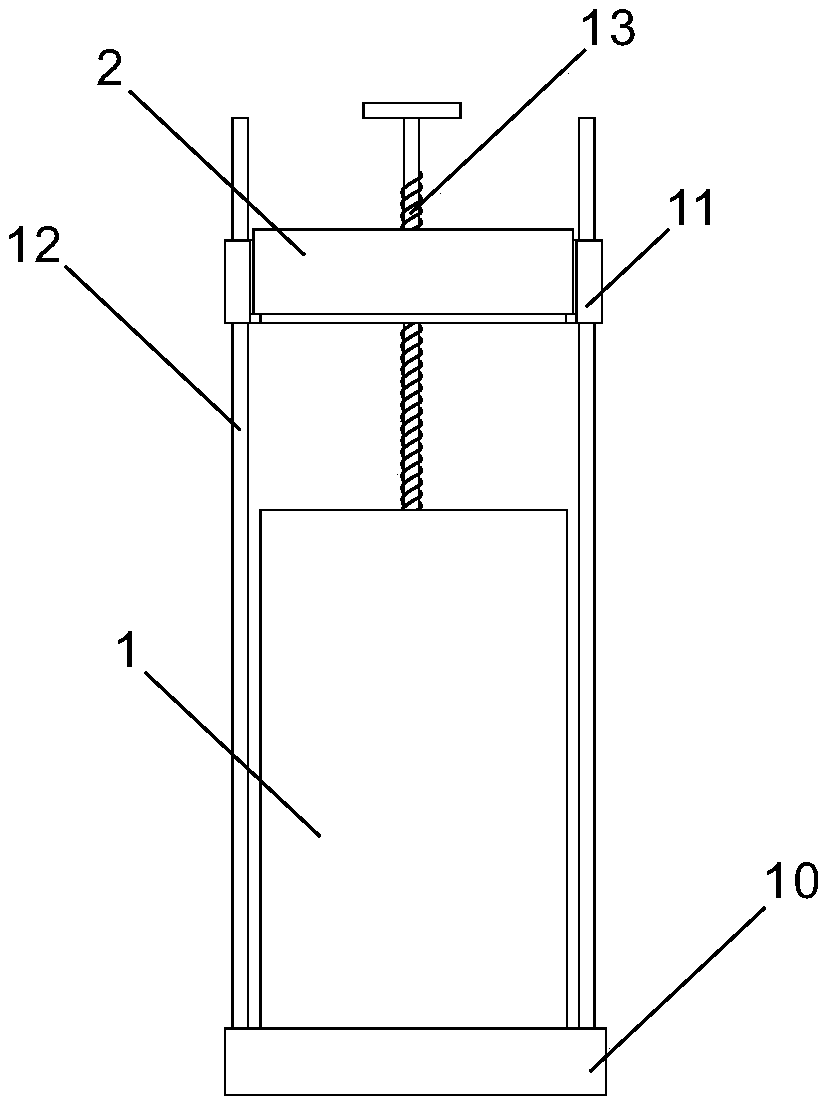

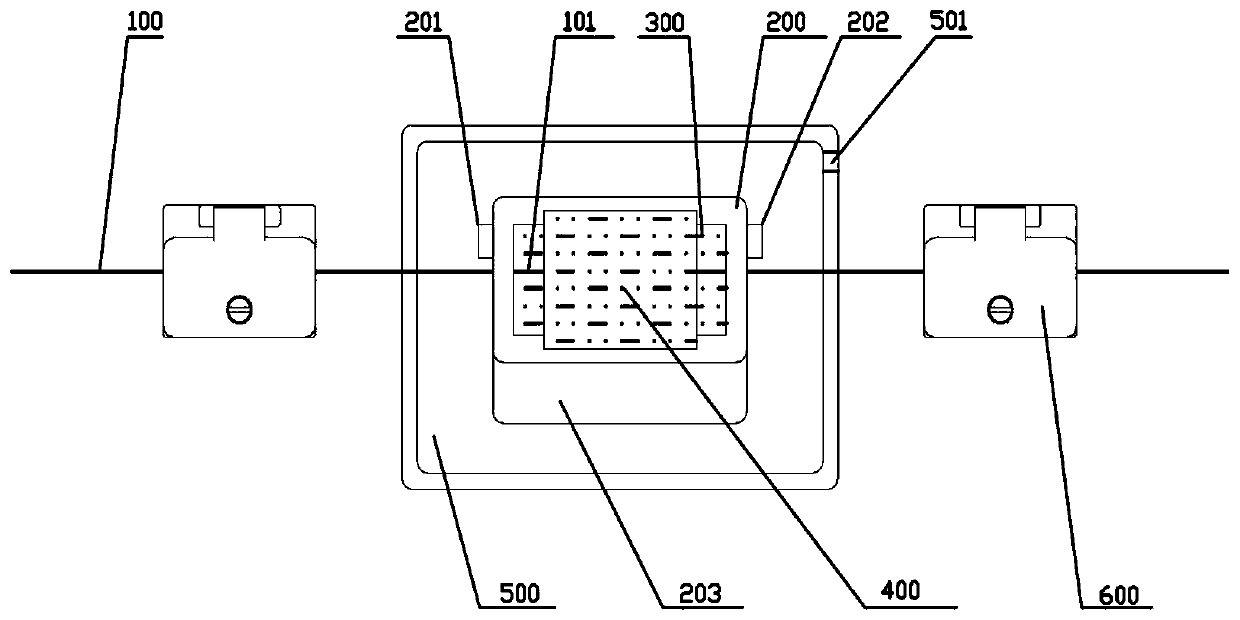

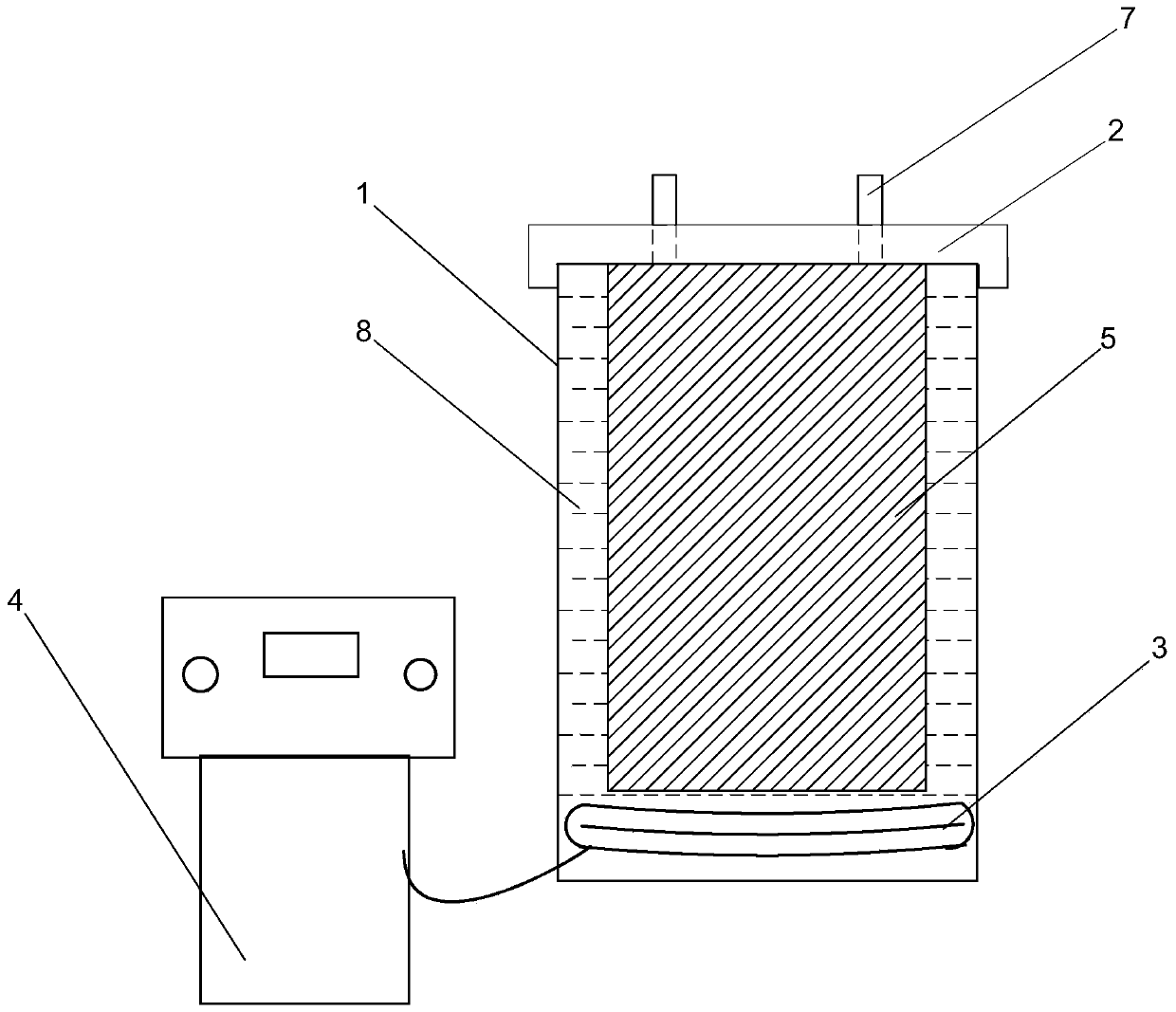

Plate grid corrosion test method at high temperature and apparatus therefor

ActiveCN107748132ASimplify the Corrosion Testing ProcessProlong the corrosion timeWeather/light/corrosion resistanceTemperature controlTest efficiency

The invention discloses a plate grid corrosion test method at high temperature and an apparatus therefor. In the invention, a more severe corrosion environment of a simulated battery under a working condition is provided, and a plate grid material is subjected to corrosion due to an electrolyte for longer time and at higher intensity, so that the plate grid material can be consumed quicker and theanti-corrosion performance of the plate grid material can be represented quickly, thereby greatly increasing test efficiency on corrosion of the plate grid without consumption of real battery products during the test. The test method only employs a less amount of plate grid material, so that test cost is greatly reduced; meanwhile, by means of a special plate grid corrosion test apparatus at hightemperature for carrying out the plate grid corrosion test at high temperature, temperature control of a colloid electrolyte and accurate sealing of a reaction tank cover are achieved, thereby bringing convenience to the test.

Owner:CHAOWEI POWER CO LTD

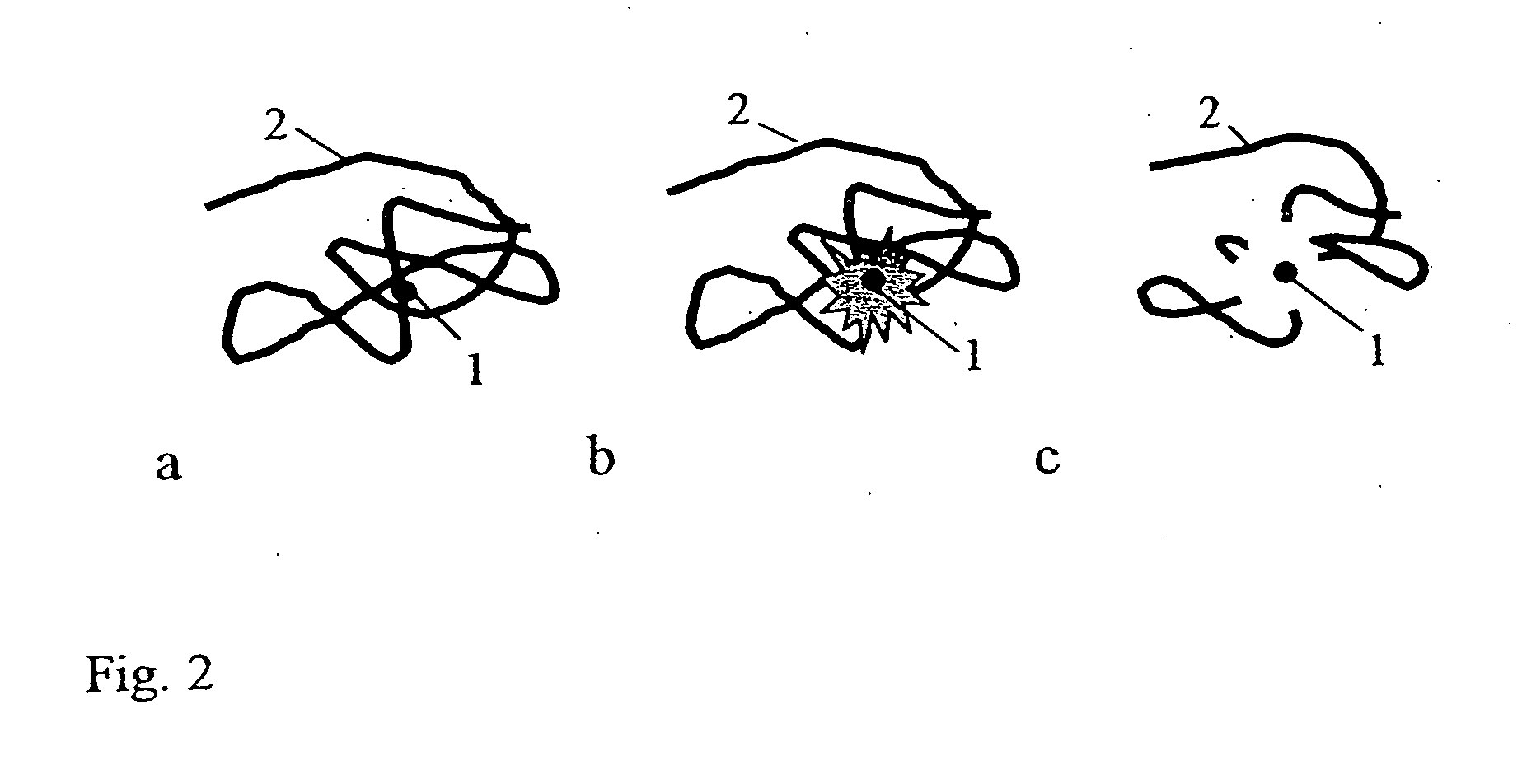

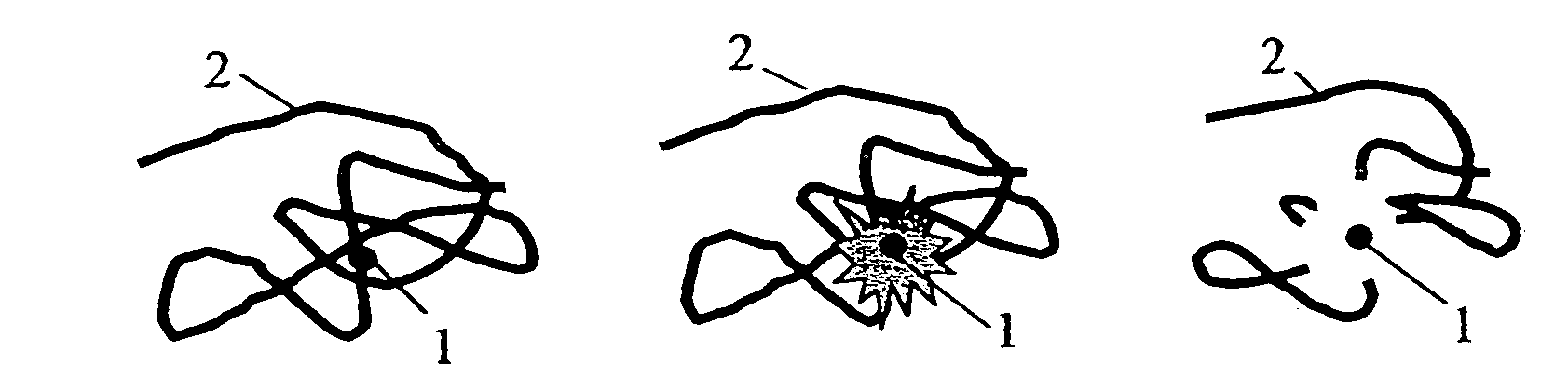

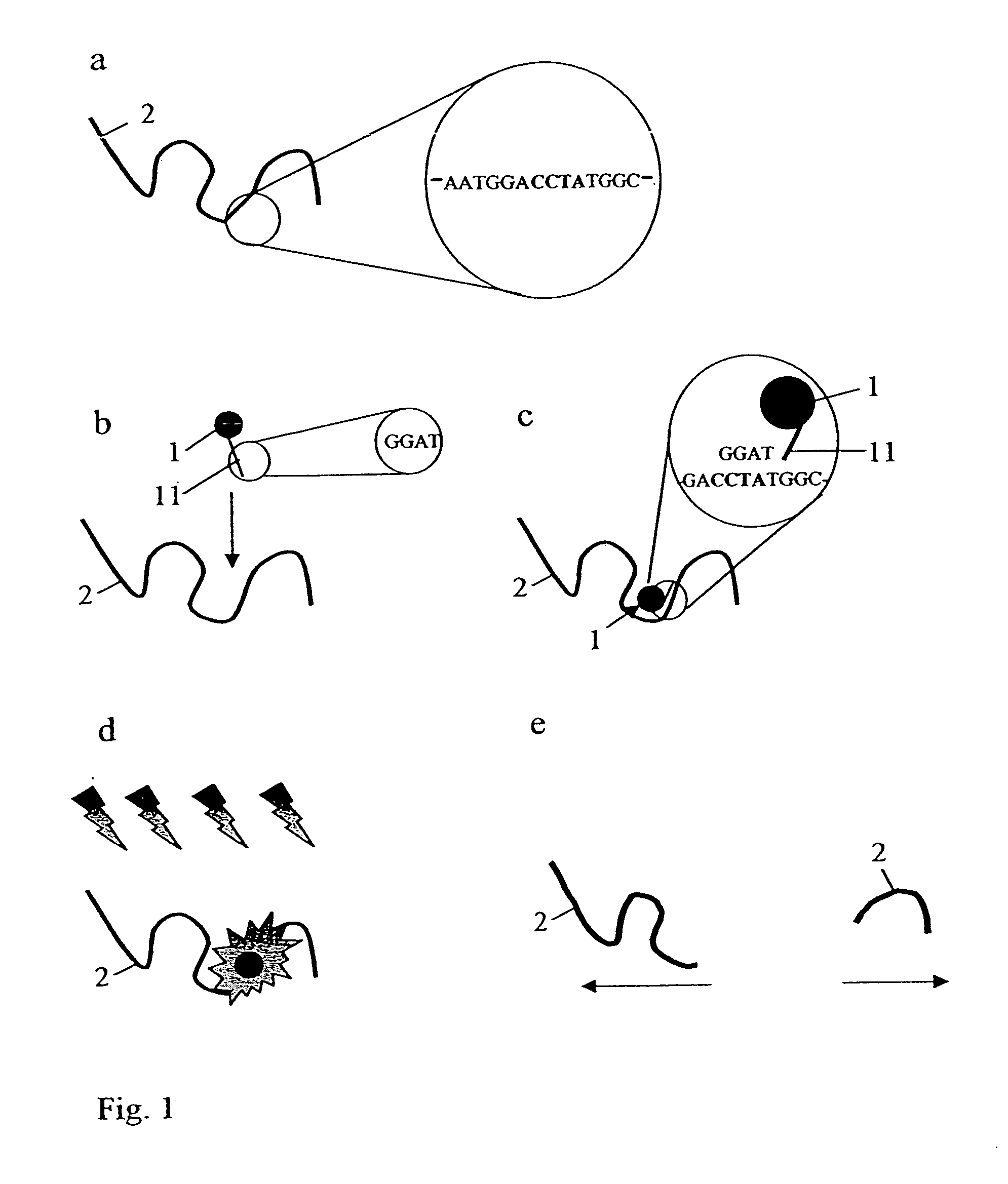

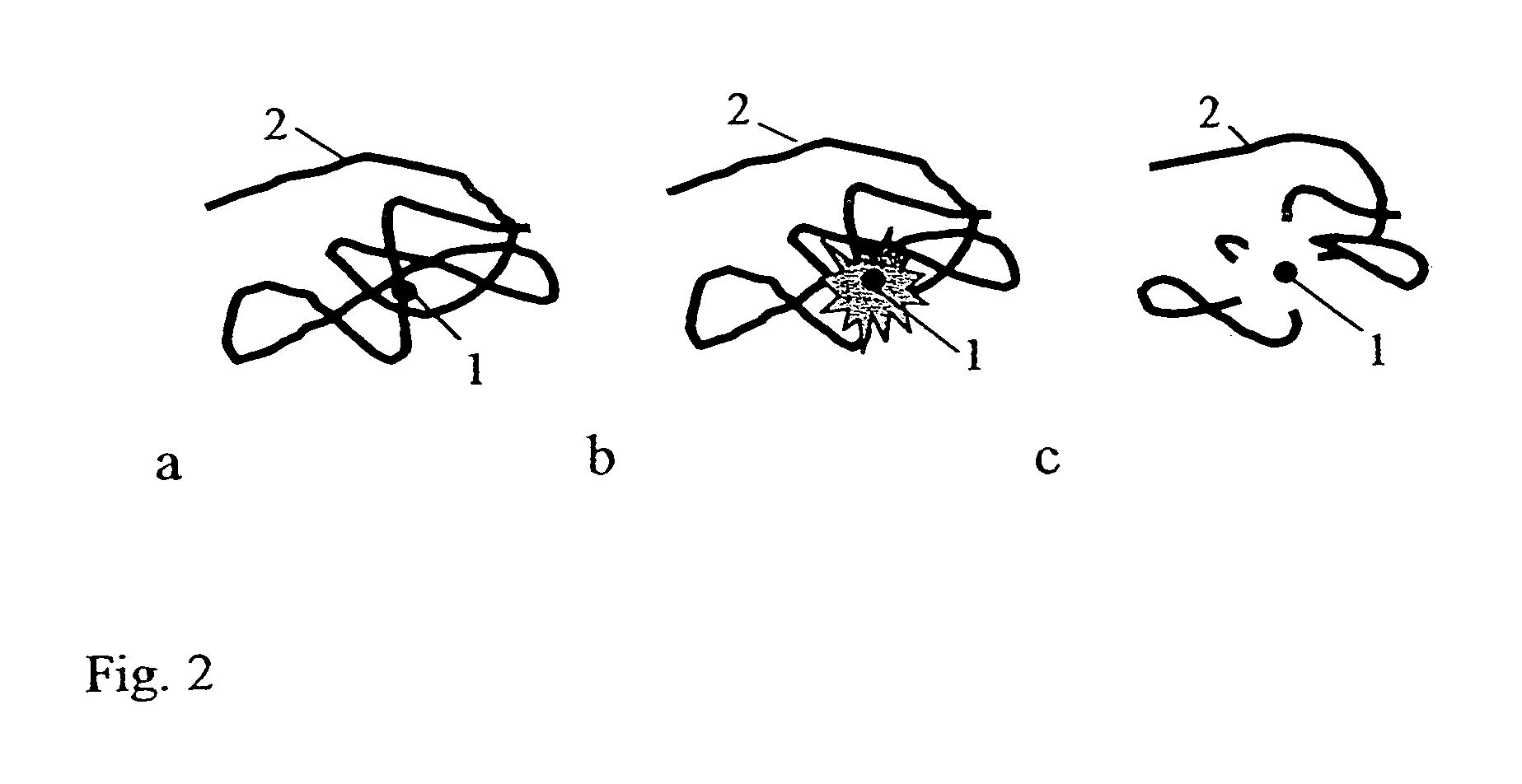

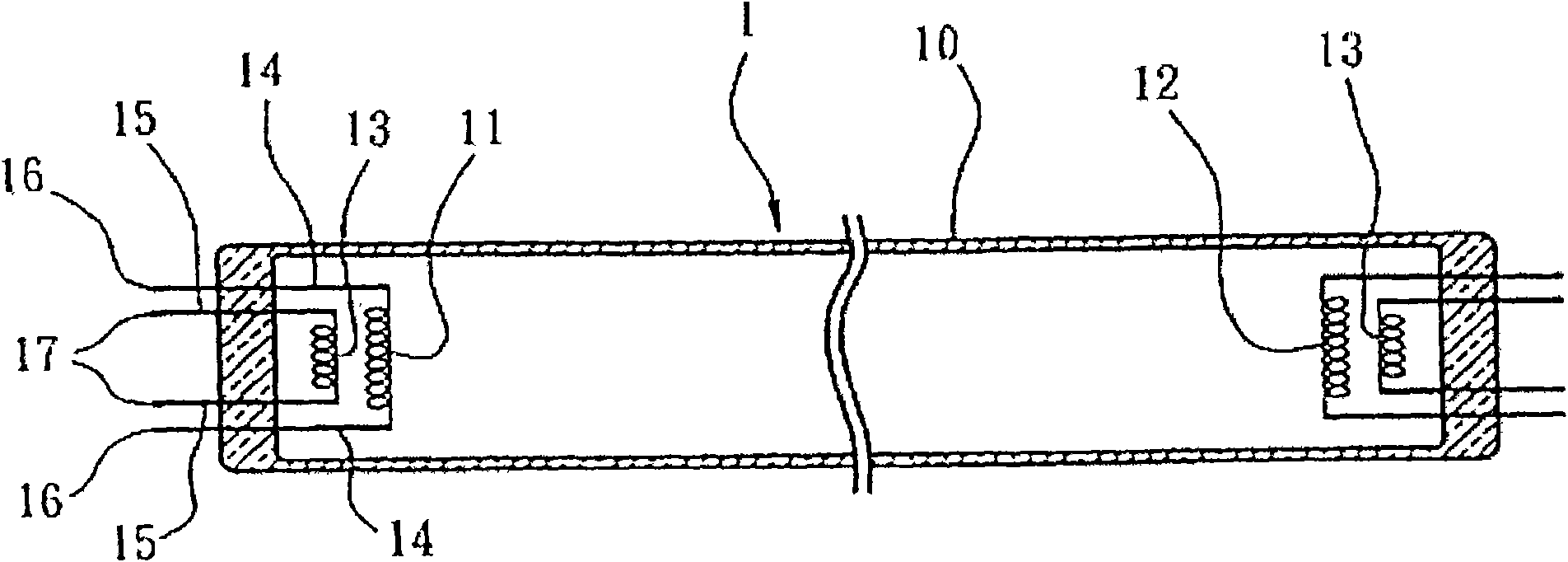

Method for the simultaneous dissection in specific positions of filiform organic molecular chains, in particular dna

InactiveUS20050026146A1Effective absorptionEnergy efficiencyNanotechMicrobiological testing/measurementNanoparticleHigh energy

The invention relates to a method for the simultaneous dissection in specific positions of filiform organic molecular chains, in particular DNA. The aim of the invention is to provided a method, by which a highly specific dissection can take place on certain sequences that can be freely selected and simultaneously on numerous filiform molecules. To achieve this, nanoparticles (1) are provided with a molecular chain (11) of any predeterminable sequence, which is selected to be complementary to a sequence of a molecule (2) that is to be dissected, said molecular chain(s) (11) is / are hybridised in the usual manner with the molecule, or specifically linked to said molecule in another manner and the nanoparticles (1) are subsequently subjected to a high-energy radiation of at least one wavelength, which can be absorbed by said nanoparticles (1).

Owner:KOENIG KARSTEN

Method for Making Lignocellulosic Paper and Paper Product

ActiveUS20170058459A1Well strength resultHigh weight ratioPulp properties modificationFats/resins/pitch/waxes removal in pulpPapermakingChemistry

Enzyme compositions comprising laccase, lipase, cationic polymer, and optionally laccase activator, for papermaking application are disclosed. It also relates to the use of the enzyme composition to improve dry strength property of a paper product made from lignocellulosic-containing materials before or after mechanical refining in a papermaking process.

Owner:SOLENIS TECH CAYMAN

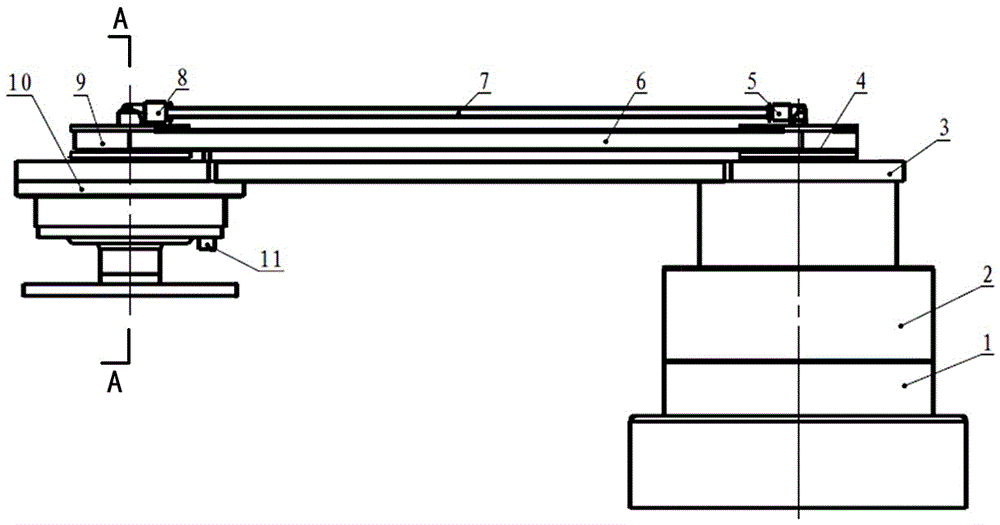

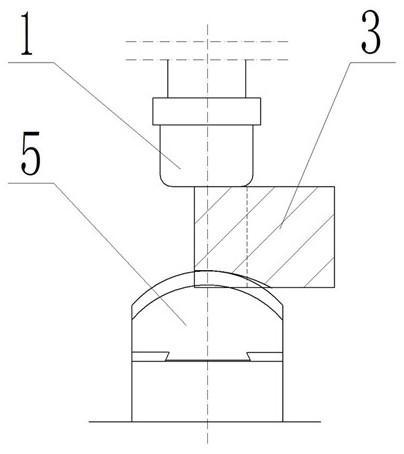

Pressure applying mechanism of polishing pad activator for CMP equipment and operating method thereof

ActiveCN106670970AIncrease lossLost fastLapping machinesAbrasive surface conditioning devicesBall bearingEngineering

The invention relates to a pressure applying mechanism of a polishing pad activator for CMP equipment. The mechanism comprises a bearing assembly, a power arm assembly, a transmission assembly and a gas path assembly; a bearing isolating sleeve is mounted between two ball bearing end surfaces in the bearing assembly in a sleeving manner; a sealed loss-preventing sleeve is arranged between the inner end cover of a bearing at the lower end surface of an air cylinder and a position shaft; a seal ring is arranged between a flange disc of a rotary shaft and a combining end surface of the upper end surface of the air cylinder for sealing; a guiding hub hole matched with a guiding key of the rotary shaft is formed in an inner cavity of the piston shaft, an O-shaped seal ring and an opening magnetic ring are embedded onto the external end surface, a grinding wheel disc which is horizontally arranged is fixedly connected to the lower end surface, and a pressure sensor is fixedly connected to a bearing pedestal. According to the mechanism provided by the invention, the rotary shaft, the air cylinder and the piston shaft are matched with the seal ring and the O-shaped seal ring to form a sealed cavity which replaces a conventional air bag cavity, so that the resources are saved, the cost is lowered, the loss is small, the service life is long, the reliability is good, the precision is high, pressure can be controllable, and the yield of wafers is improved.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

Method for the simultaneous dissection in specific positions of filiform organic molecular chains, in particular DNA

InactiveUS7263445B2Effective absorptionEnergy efficiencyNanostructure manufactureMicrobiological testing/measurementHigh energyNanoparticle

The invention relates to a method for the simultaneous dissection in specific positions of filiform organic molecular chains, in particular DNA. The aim of the invention is to provided a method, by which a highly specific dissection can take place on certain sequences that can be freely selected and simultaneously on numerous filiform molecules. To achieve this, nanoparticles (1) are provided with a molecular chain (11) of any predeterminable sequence, which is selected to be complementary to a sequence of a molecule (2) that is to be dissected, said molecular chain(s) (11) is / are hybridised in the usual manner with the molecule, or specifically linked to said molecule in another manner and the nanoparticles (1) are subsequently subjected to a high-energy radiation of at least one wavelength, which can be absorbed by said nanoparticles (1).

Owner:KOENIG KARSTEN

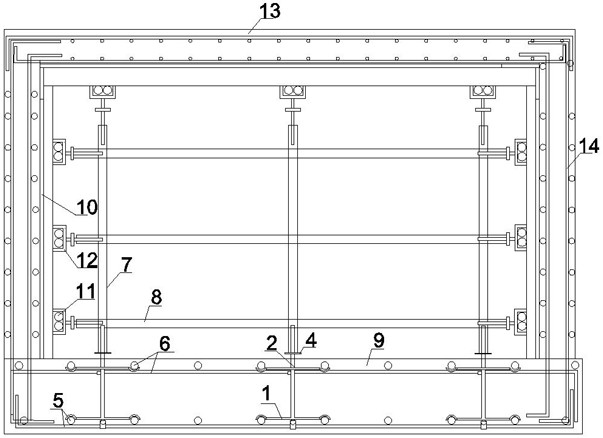

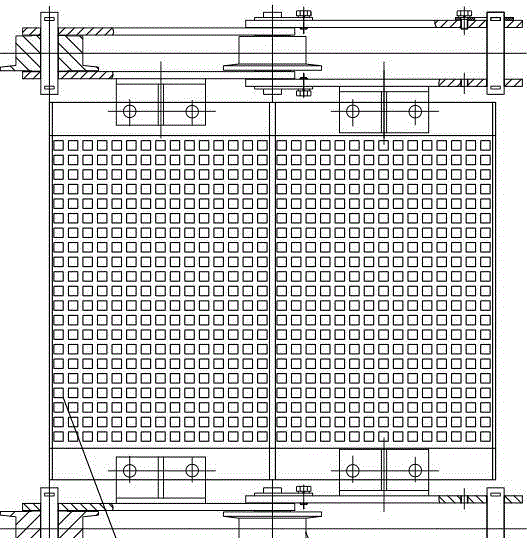

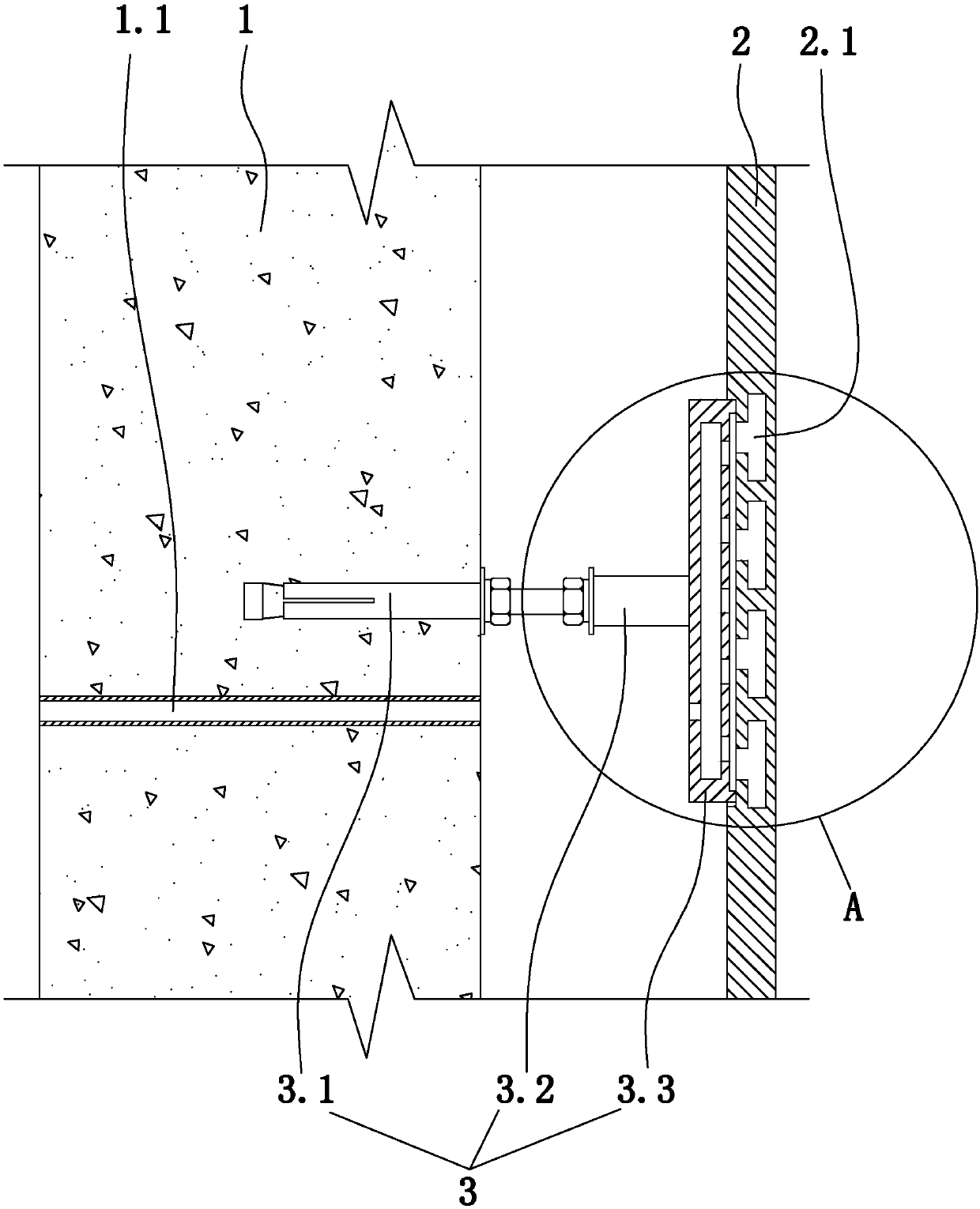

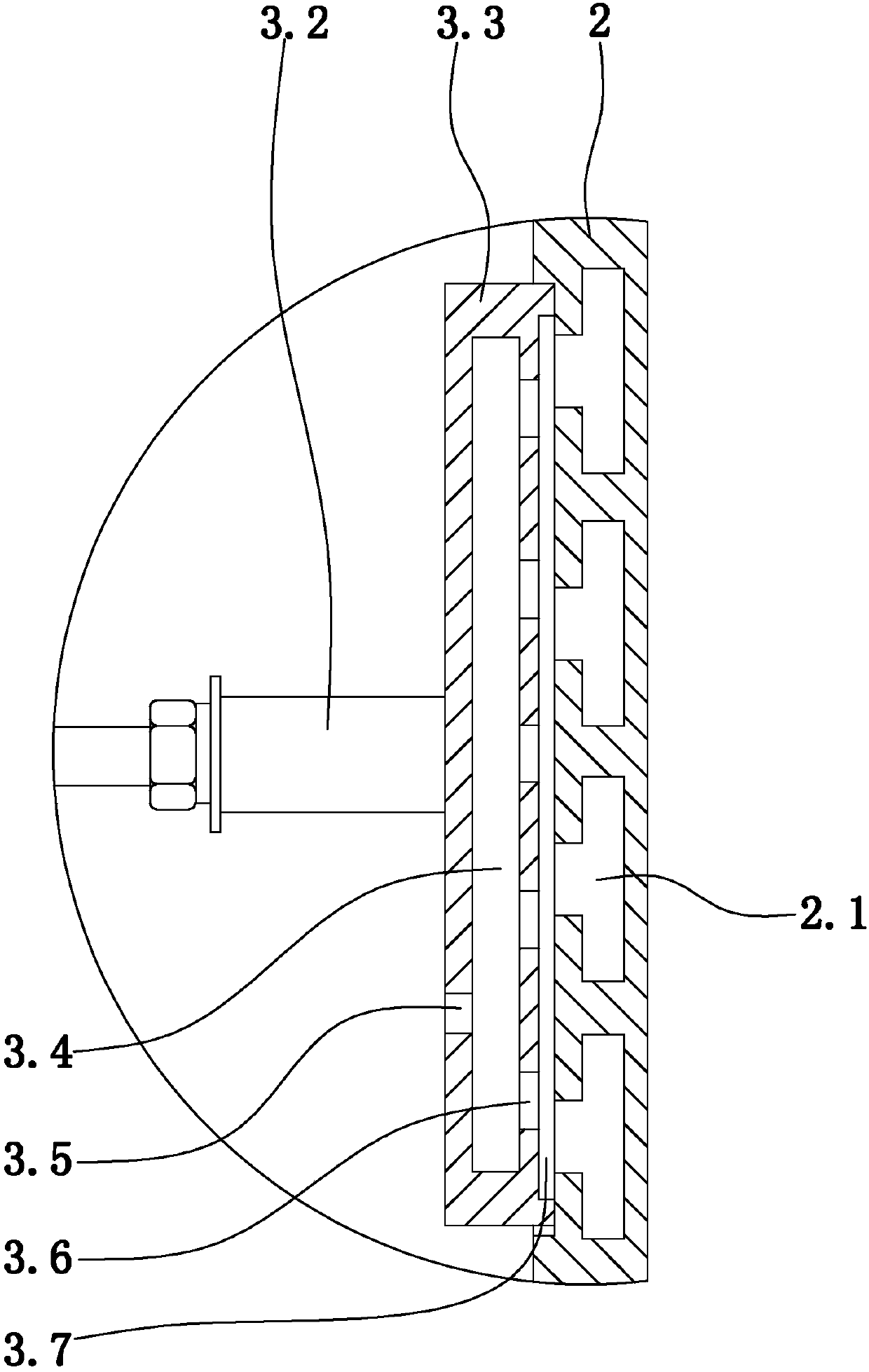

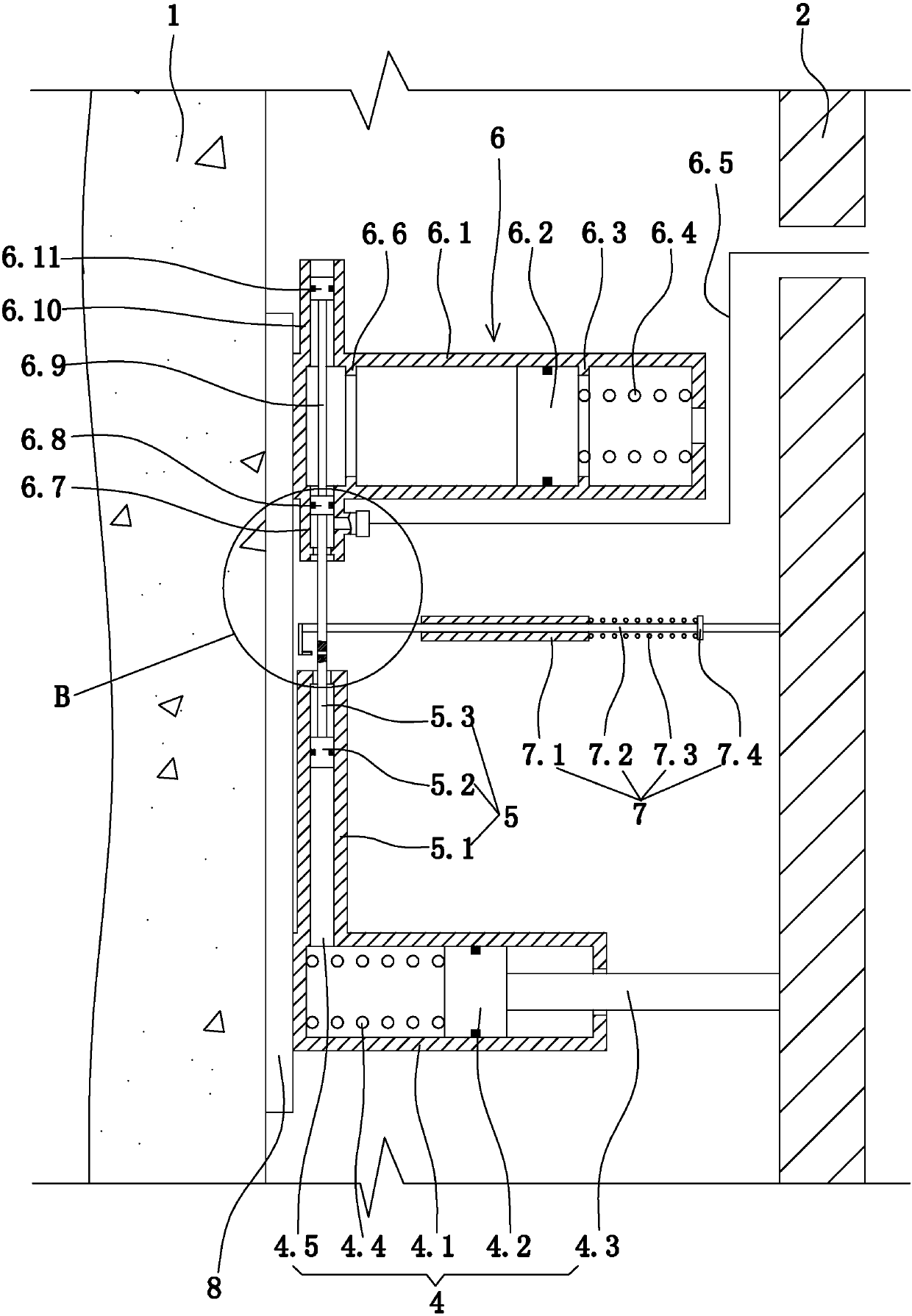

Construction method for synchronous formwork supporting and concrete pouring of bottom plate and top plate of cast-in-place pipe gallery

InactiveCN112982485AEasy to makeEasy to installArtificial islandsProtective foundationSupporting systemArchitectural engineering

The invention discloses a construction method for synchronous formwork supporting and concrete pouring of a bottom plate and a top plate of a cast-in-place pipe gallery, and relates to the technical field of concrete pouring. According to the method, the supporting strength of the concrete bottom plate is improved through a vertical supporting device, a formwork supporting system is erected on the bottom plate, the top plate and the side walls, meanwhile, concrete pouring and curing are carried out on the bottom plate, the top plate and the side walls, the formwork supporting system is disassembled after curing is completed, a vertical rod and a horizontal supporting rod on the upper surface of the bottom plate concrete are partially cut off, and simultaneous pouring operation is completed. According to the method, the vertical supporting device is easy to manufacture and convenient to install; the number of procedures is small, and the efficiency is high; the construction period of the supporting system is short, and the installation speed is high; the loss is small, and the construction cost is low; the supporting system does not need to be welded with bottom plate steel bars, and the application range is wide; the stress balance of the side walls is good, and the stability of the supporting frame is good; the supporting effect is good, and potential safety hazards are avoided; and the bottom plate, the top plate and the side walls are synchronously implemented, no construction joint exists, the integrity is good, the anti-seepage effect is good, and the construction period is greatly shortened.

Owner:CHINA 22MCC GROUP CORP

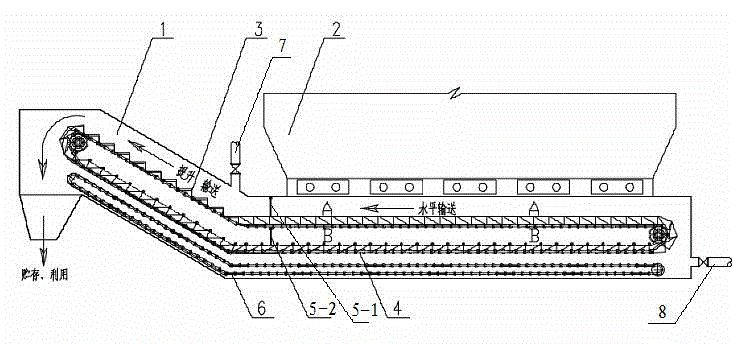

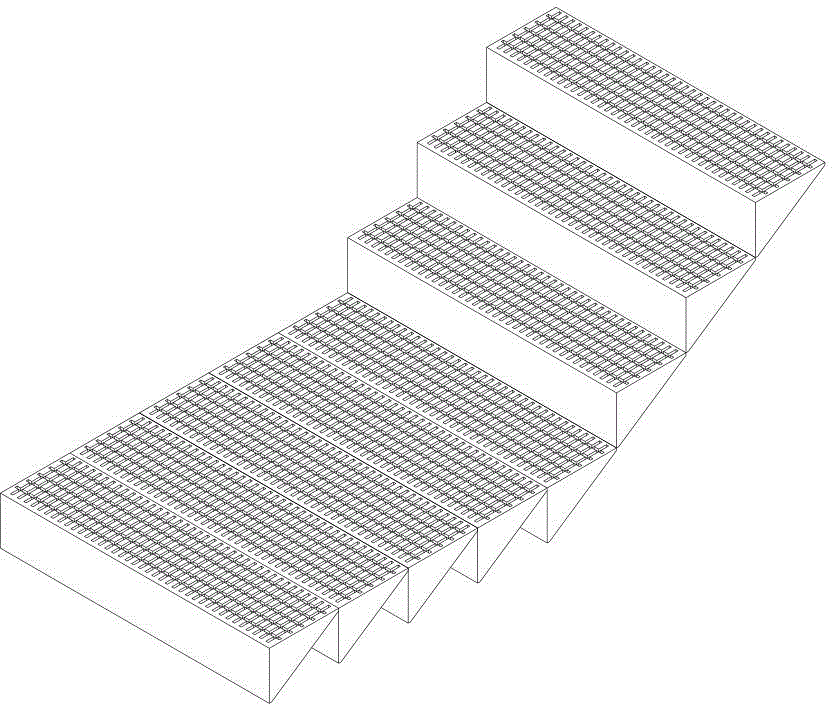

Plate link chain stepped dry slag remover

InactiveCN104421952ASolution to short lifeLost fastLighting and heating apparatusEnvironmental resistanceBoiler slag

The invention belongs to the technical field of dry deslagging systems of coal-fired boilers, and relates to a plate link chain stepped dry slag remover. The plate link chain stepped dry slag remover comprises a box of which one end is provided with a slag outlet, wherein the box is provided with a horizontal portion and an oblique portion; the other end of the oblique portion is connected with the slag outlet; the upper end face of the horizontal portion is provided with a slag inlet which is hermetically connected with the slag outlet in the lower portion of a boiler slag storage bucket; a high-temperature-resistant stepped conveying plate block for conveying slag falling off from the slag outlet to the slag outlet for dropping is arranged in the box; the high-temperature-resistant stepped conveying plate block comprises a horizontal conveying segment and a stepped ascending conveying segment; a partition baffle plate which partitions the inside of the box into a high-temperature cooling segment and a low-temperature cooling segment is arranged in the box. By adopting the plate link chain stepped dry slag remover, the defects of falling of slag, friction of a conveying device and slag, quick equipment wear, high maintenance cost and the like during conveying of large-sized slag in the slag remover are overcome, and long service life, high efficiency, large angle, stability, safety and environmental friendliness in running of the slag remover are realized.

Owner:QINGDAO ZHONGCE ENVIRONMENTAL PROTECTION EQUIP

Integral type blasting operation safety protective cover and manufacturing method thereof

The invention relates to an integral type blasting operation safety protective cover. The integral type blasting operation safety protective cover comprises a periphery structure, a cover plate, a hole opening cover plate, protective bars and hoisting rings of the safety protective cover; the periphery structure is composed of two longitudinal steel plates and two transverse steel plates; upper strengthening ribs and lower strengthening ribs are arranged on the periphery of the outer side of the periphery structure; a plurality of internal tie bars and internal strengthening ribs which are transversely and longitudinally crossed are arranged inside the periphery structure; the cover plate is arranged above the periphery structure and is connected with the longitudinal steel plates to enable the longitudinal steel plates and the periphery structure to form a whole; a cover plate exhaust hole is formed in the middle portion of the cover plate; the protective bars are arranged on the cover plate; the hole opening cover plate is placed between the cover plate and the protective bars and covers the cover plate exhaust hole; and the hoisting rings are arranged on the longitudinal steel plates. According to the integral type blasting operation safety protective cover, on the premise that the blasting speed of blasting operation on hard rock is guaranteed, safety of the blasting operation can be guaranteed, meanwhile, noise generated by the blasting operation is weakened, and the very good economical benefits and social benefits are achieved.

Owner:广西建工第五建筑工程集团有限公司

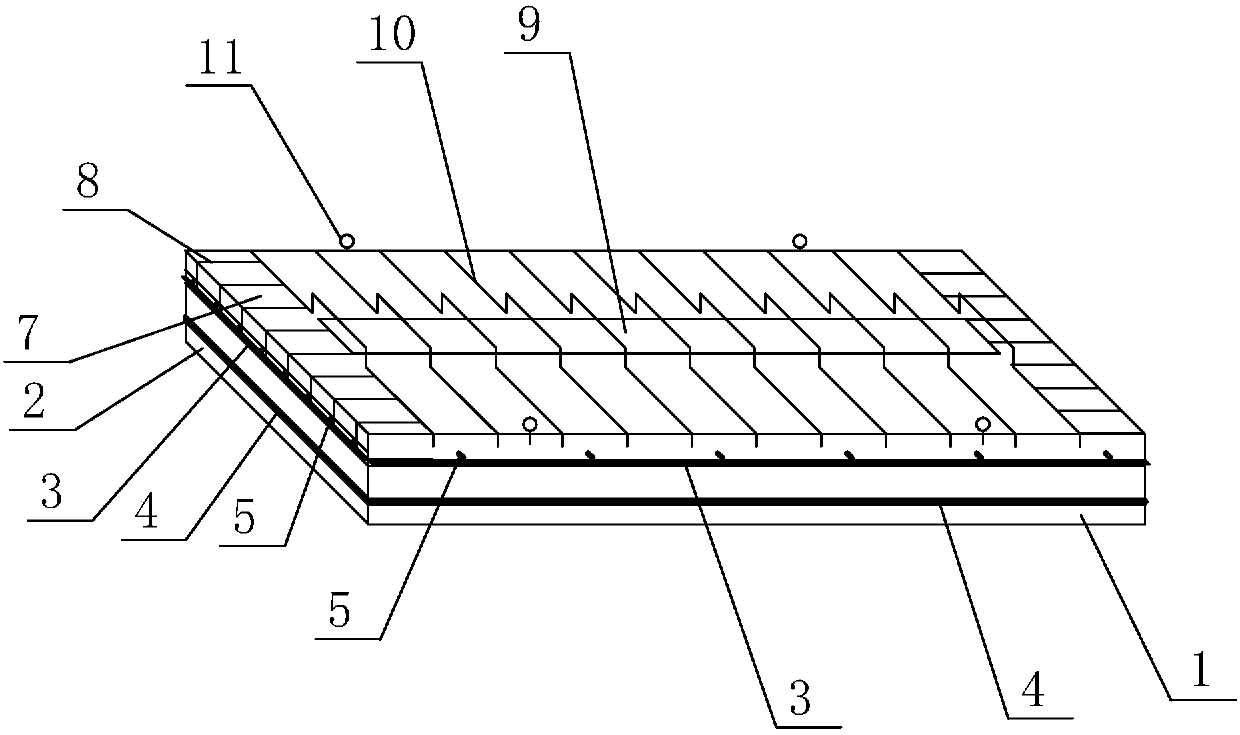

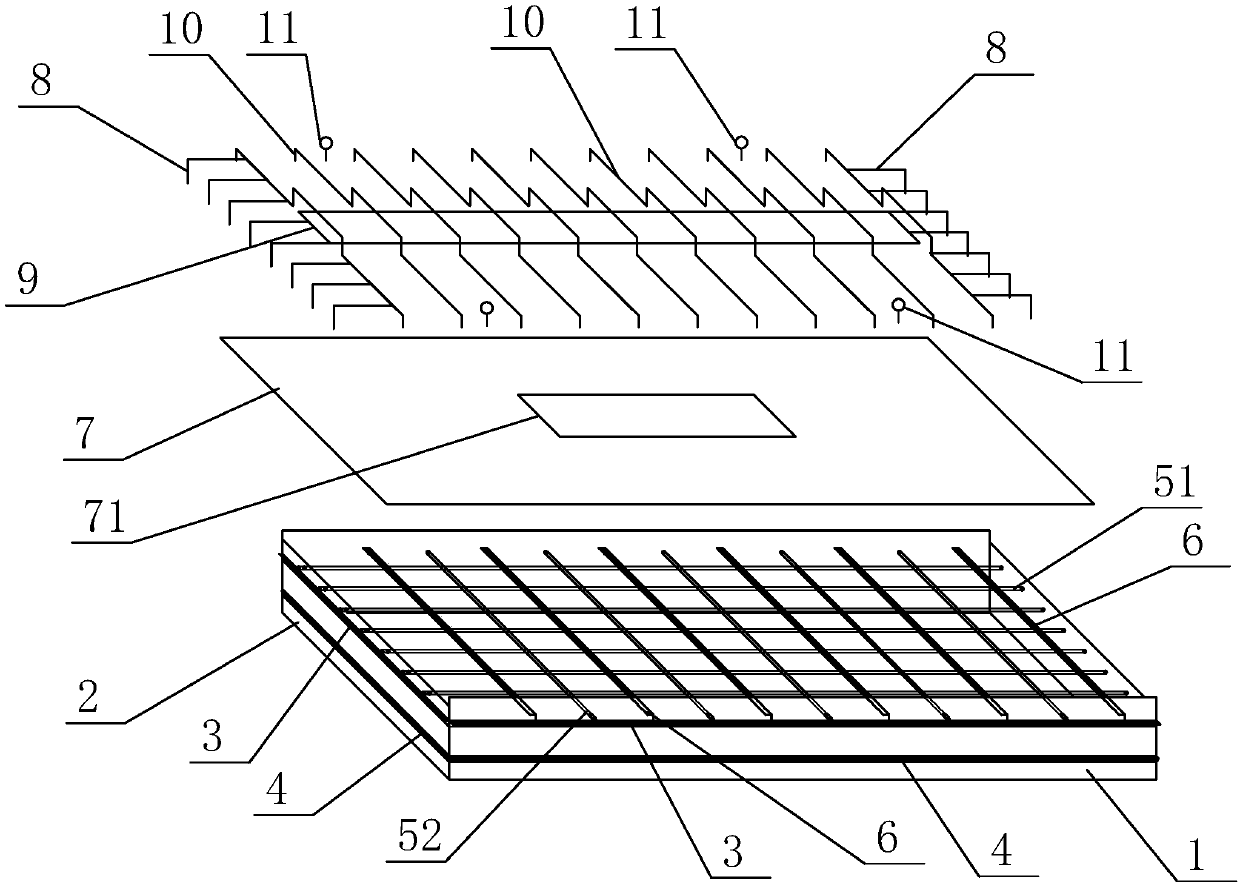

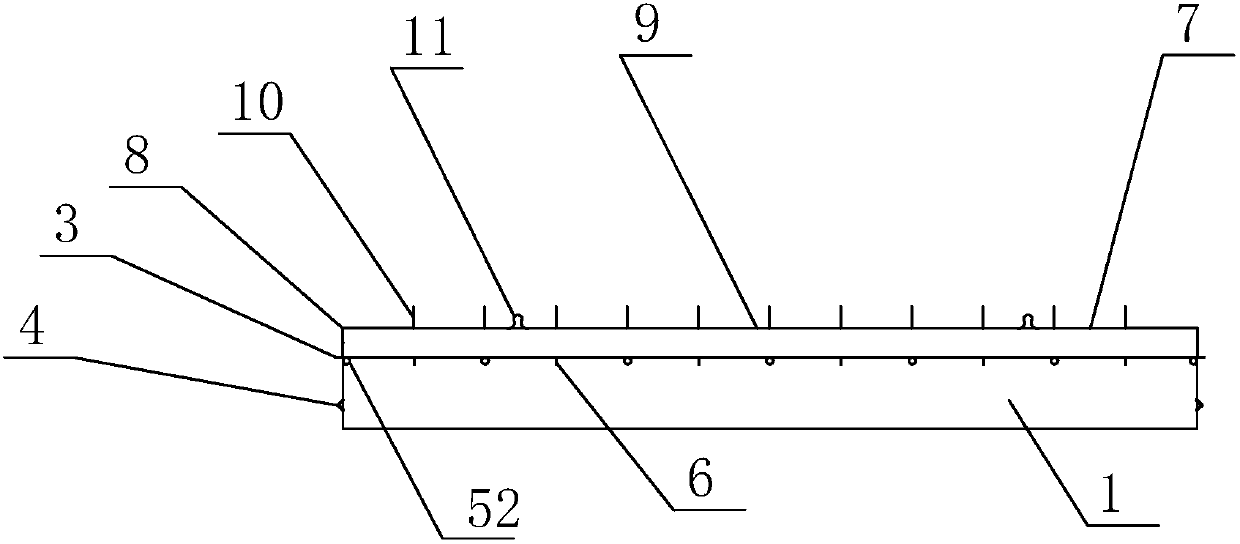

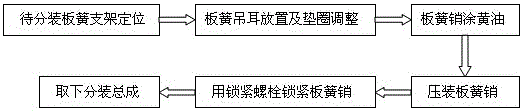

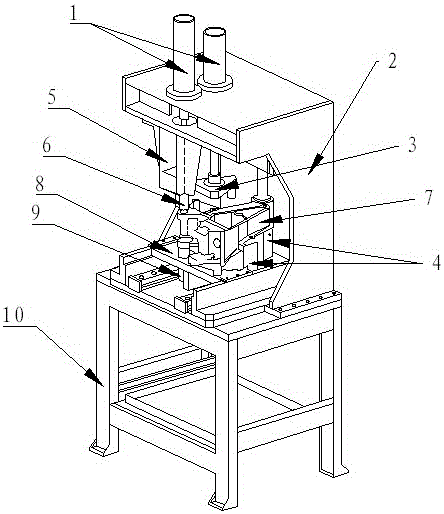

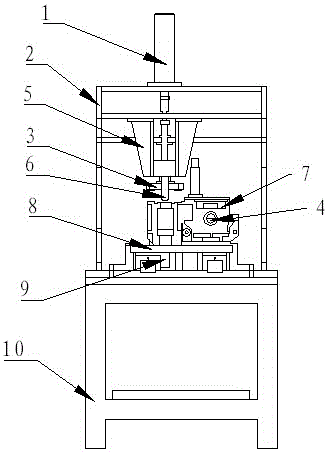

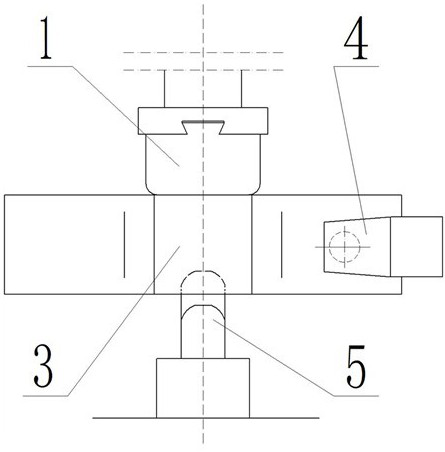

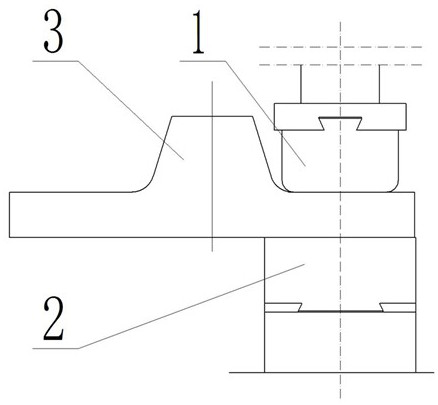

A press-fitting process for heavy-duty automobile leaf spring pins

The invention discloses a press-mounting technology and equipment for a heavy duty automobile plate spring pin. The press-mounting technology comprises the steps that (1) a plate spring bracket to be sub-mounted is positioned; (2) plate spring lugs are placed, and gaskets are adjusted; (3) the plate spring pin is coated with consistent grease; (4) the plate spring pin is mounted in a pressed mode; (5) the plate spring pin is locked through a locking bolt; (6) a sub-mounting assembly is taken down. The press-mounting equipment comprises a sub-mounting table, hydraulic cylinders, a dust cover, a plate spring pin guide and a press-mounting device. According to the press-mounting technology and equipment, the plate spring pin can be mounted quickly and accurately, mounting efficiency is enhanced, workpiece quality after mounting is also improved, and the cost is further reduced.

Owner:SINO TRUK JINAN POWER

Crank throw forming and forging process

PendingCN114309429AGood forging formabilitySmall machining allowanceForging/hammering/pressing machinesEngine componentsPhysicsCrank

The invention relates to a crank throw forming forging process which comprises a forging machine, a manipulator, an anvil replacing die, a reverse buckling bending die, a core die, an upper anvil, a lower anvil, a workbench and a forged piece. Firstly, a prefabricated forge piece with a boss arranged in the middle is pressed to be thin and drawn out, then a male die, a trapezoidal die and a female die are arranged below the boss, a concave anvil replacing die and an arc anvil replacing die are arranged above the boss, multi-angle left-right moving and overturning forging is conducted on the boss, forging of a curved neck cylindrical blank is completed, then reverse forging bending is conducted through a reverse buckling bending die, and the curved neck cylindrical blank is formed. And two wings of the prefabricated forge piece are bent and folded together, then a series of core molds with different thickness differences at the two ends are used for pressing, meanwhile, the boss head is forged into the quadrangular crank throw head, and finally the crank throw forge piece is finished to the set size. The forging die has the advantages of being good in forming degree, small in machining allowance, short in forging time, small in material loss and low in production cost.

Owner:ZHONGJUXIN OCEAN ENG EQUIP CO LTD +1

A kind of external wall dry-hanging structure and its dry-hanging method

The invention discloses an outer-wall dry-hanging structure and a dry-hanging method thereof. The problem that an existing wall brick dry-hanging structure is complex in structure, large in construction difficulty and material loss and long in construction period can be effectively solved. The outer-wall dry-hanging structure comprises a building outer wall, wall bricks and a dry-hanging mechanism. The dry-hanging mechanism comprises expansion bolts connected with the building outer wall and a vertical installation plate connected with the expansion bolts. A plate surface groove is formed in the plate surface of the vertical installation plate. A binder filling inner cavity is formed in the vertical installation plate. A plurality of connecting holes communicating with the binder filling inner cavity are formed in the bottom surface of the plate surface groove. The dry-hanging method of the outer-wall dry-hanging structure sequentially comprises the following steps that a, the expansion bolts are embedded into the building outer wall; b, the binder filling inner cavity, binder filling via holes and the plate surface groove are filled with binders, and an installation plate limit groove is filled with a binder; and c, the wall bricks are installed on the vertical installation plate.

Owner:ZHEJIANG XINGTAI CONSTR

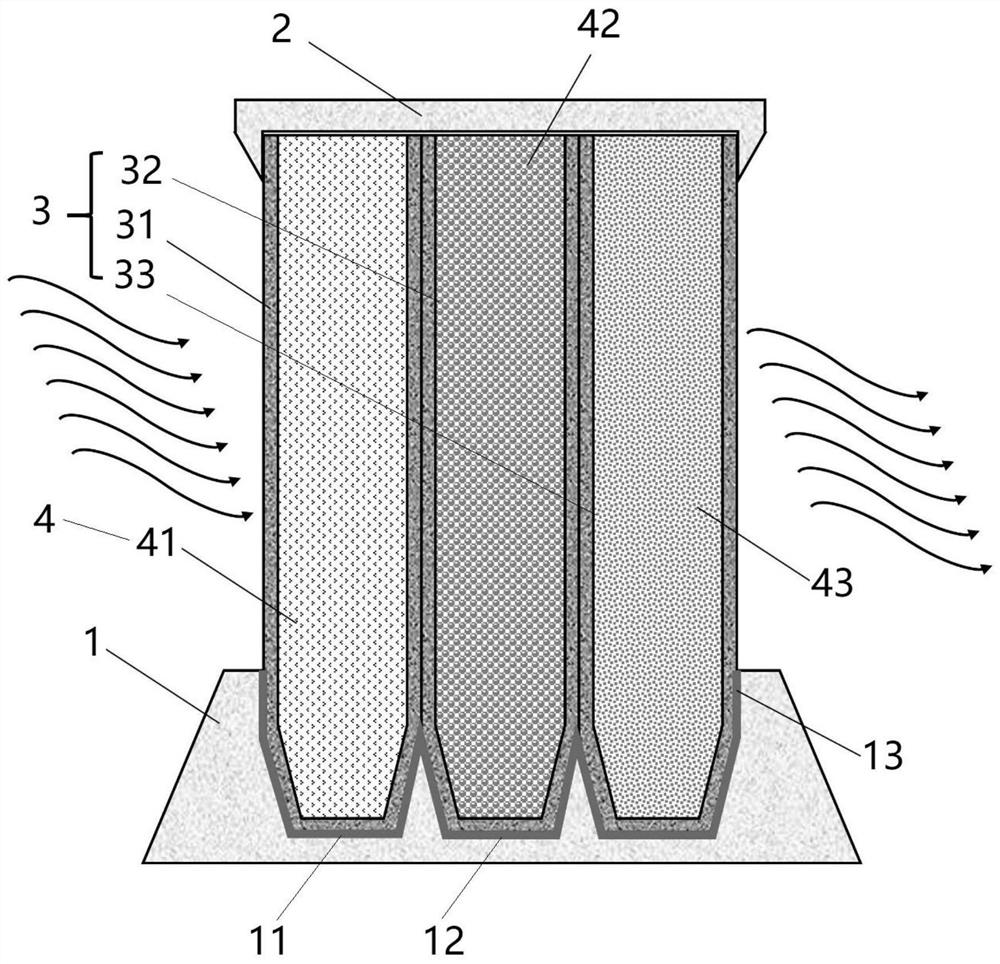

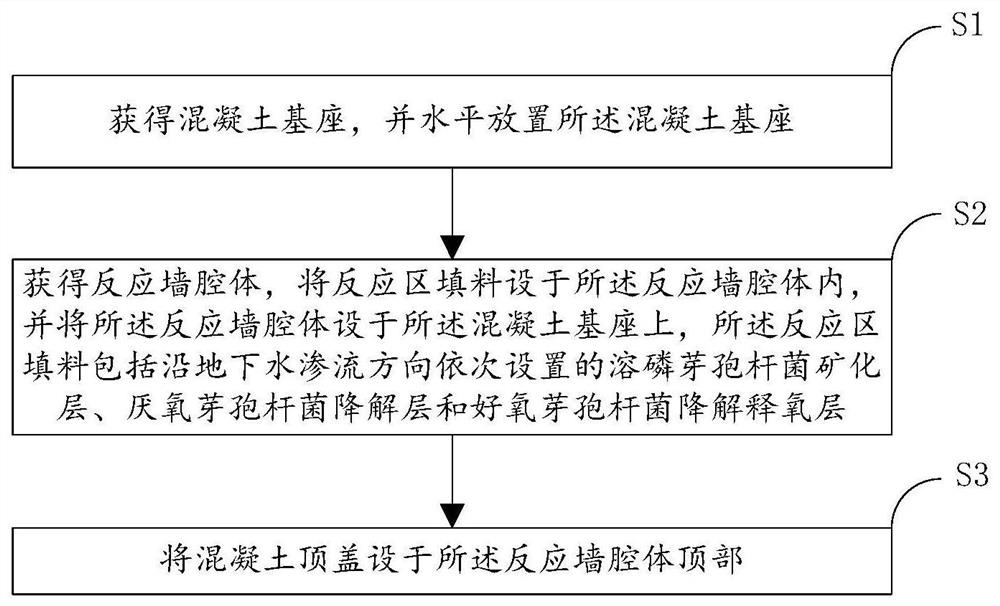

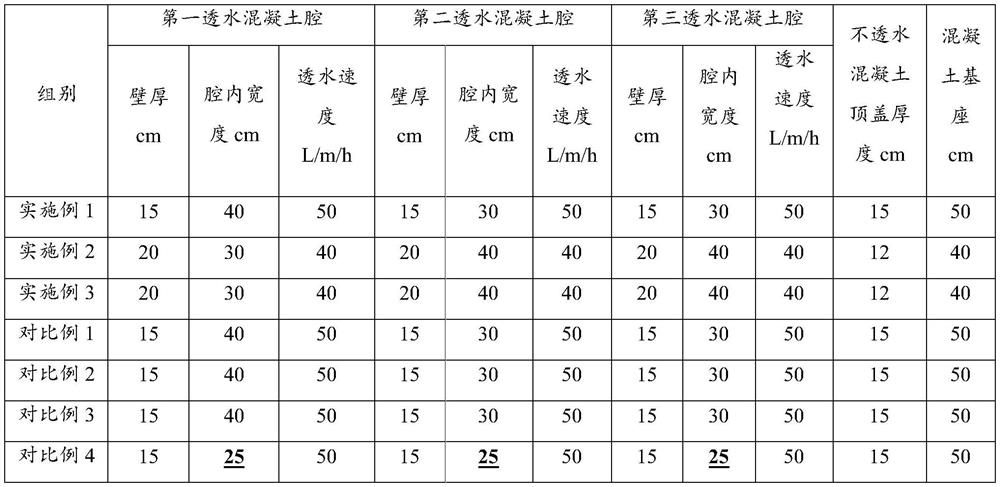

Biological permeable reactive barrier for combined pollution site and preparation method thereof

ActiveCN111924982AEfficient removalAchieve removalWater contaminantsContaminated soil reclamationPhosphateAerobic bacillus

The invention discloses a combined pollution site biological permeable reactive barrier which comprises a concrete base, a concrete top cover, a reactive barrier cavity and a reaction area filler, andthe reaction area filler comprises a phosphate-solubilizing bacillus mineralization layer, an anaerobic bacillus degradation layer and an aerobic bacillus degradation and oxygen release layer which are sequentially arranged in the seepage direction of underground water; the phosphate-solubilizing bacillus mineralization layer comprises phosphate-solubilizing bacillus, first quartz sand and phosphate ore powder; the anaerobic bacillus degradation layer comprises anaerobic bacillus, second quartz sand and first activated carbon; the aerobic bacillus degradation and oxygen release layer comprises aerobic bacillus, peroxide, third quartz sand and second activated carbon; heavy metal-organic matter combined pollution remediation can be achieved, and the purification capacity is high; the service strength can be elastically adjusted according to pollution degree changes, and the reactive barrier service life is prolonged; the combined pollution site biological permeable reactive barrier canbe used for preventing and treating high-risk sudden pollution sites.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

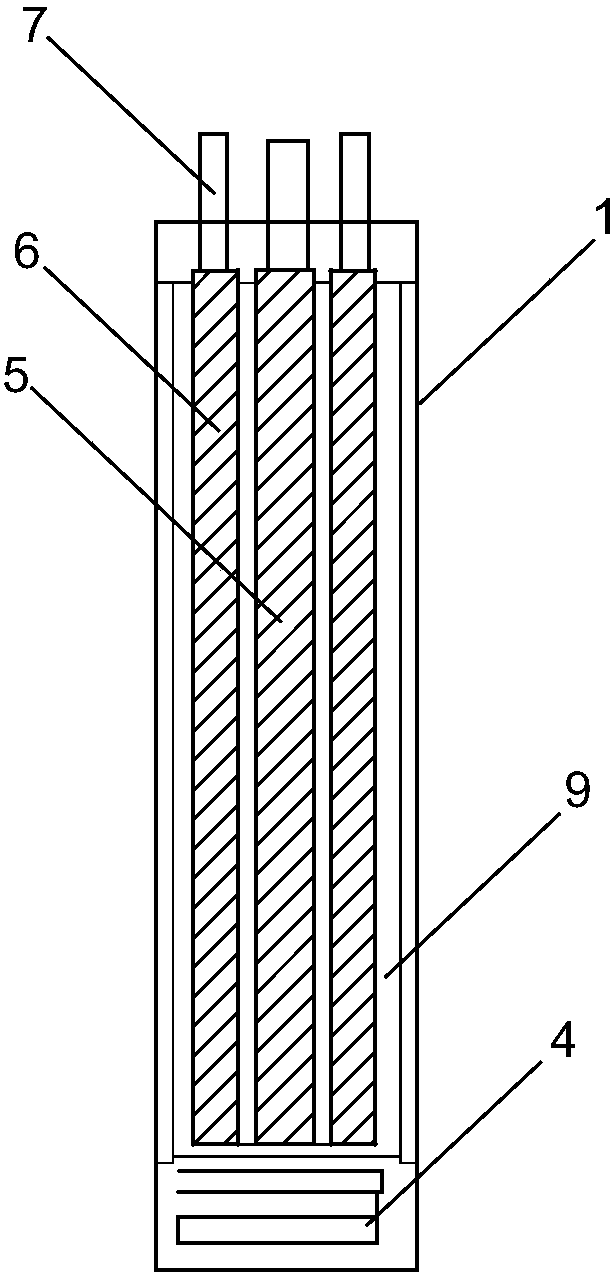

Fiber bragg grating manufacturing device and method

PendingCN111221070ATo achieve the purpose of makingReduce procurement and maintenance costsCladded optical fibreOptical waveguide light guideRefractive index modulationCore (optical fiber)

The invention relates to the technical field of fiber bragg grating manufacturing, and discloses a fiber bragg grating manufacturing device and method. The Fiber bragg grating manufacturing device comprises a light path immersion tool, the light path immersion tool comprises a hollow body, the body is filled with liquid with a preset refractive index, the body is provided with two channels which are symmetrically arranged and used for allowing photosensitive fibers to penetrate through, and the body is internally provided with a coating stripping window coaxial with the channels; a phase maskplate is arranged in the body, so that the photosensitive optical fiber is made into a fiber bragg grating. The invention provides the Fiber bragg grating manufacturing device and method. A phase maskplate and a photosensitive optical fiber are completely immersed into a prepared liquid; non-ultraviolet coherent light beams are converted into deep-ultraviolet coherent light beams, meanwhile, bright and dark stripes are generated under the action of the phase mask plate, corresponding periodic refractive index modulation is formed on a fiber core of the photosensitive optical fiber, and finally the purpose of manufacturing the fiber bragg grating is achieved.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

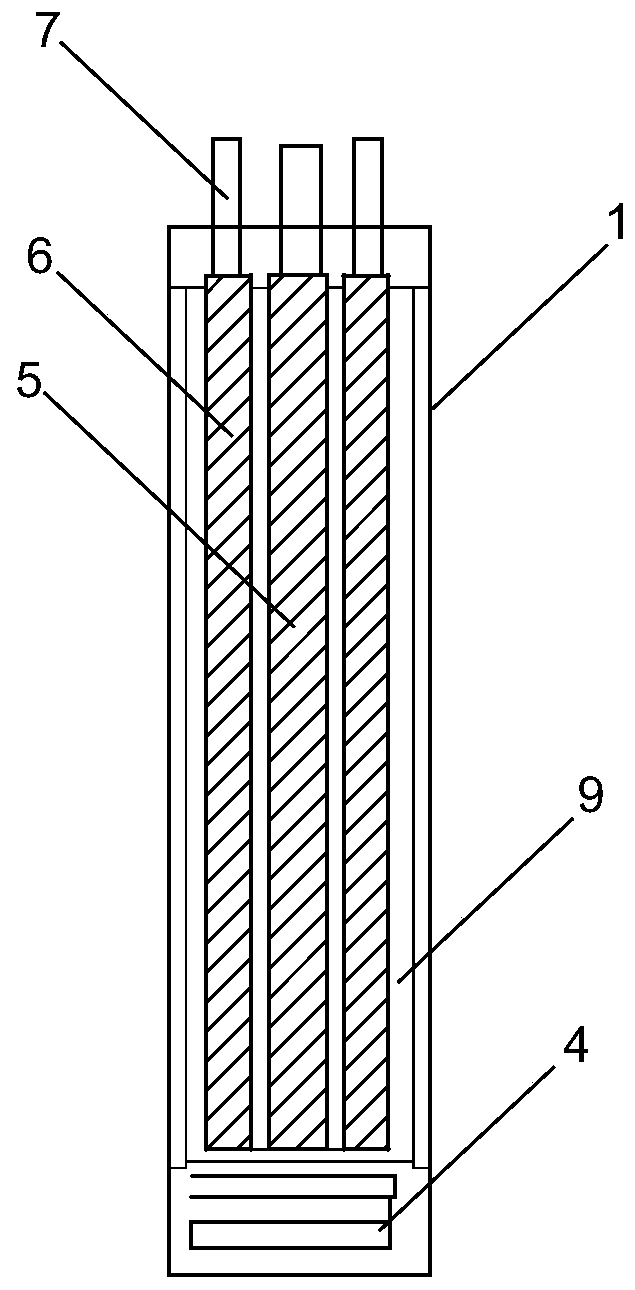

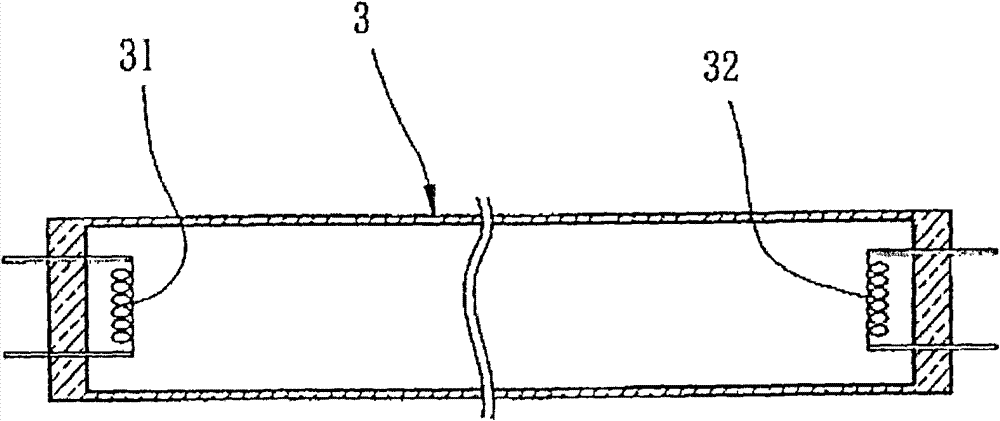

Indirect preheating starting discharge lamp and device thereof

InactiveCN101930898ASimple designLow costElectric lighting sourcesGas discharge lamp detailsGas-discharge lampFilling materials

An indirect preheating start discharge lamp and a device thereof, wherein the discharge lamp comprises a lamp tube with electrodes respectively arranged at the two ends therein and filling material sealed therein; one side of the electrode of at least one end inside the lamp tube is provided with an electric heating component, wherein the electrode and the lead of the electric heating component are respectively led out of the end part of the lamp tube to form a circuit joint, and is also provided with a lighting device with the discharge lamp. At the initial lighting stage of the discharge lamp, the electric heating component in the lamp tube emits electrons to heat adjacent electrode and fills initial electrons in the lamp tube, thereby reducing the trigger starting voltage of the lamp, protecting the electrode, and prolonging service life of the lamp.

Owner:卢静香

A high-temperature environment grid corrosion testing method and device thereof

ActiveCN107748132BSimplify the Corrosion Testing ProcessProlong the corrosion timeWeather/light/corrosion resistanceElectrolytic agentCorrosion testing

The invention discloses a plate grid corrosion test method at high temperature and an apparatus therefor. In the invention, a more severe corrosion environment of a simulated battery under a working condition is provided, and a plate grid material is subjected to corrosion due to an electrolyte for longer time and at higher intensity, so that the plate grid material can be consumed quicker and theanti-corrosion performance of the plate grid material can be represented quickly, thereby greatly increasing test efficiency on corrosion of the plate grid without consumption of real battery products during the test. The test method only employs a less amount of plate grid material, so that test cost is greatly reduced; meanwhile, by means of a special plate grid corrosion test apparatus at hightemperature for carrying out the plate grid corrosion test at high temperature, temperature control of a colloid electrolyte and accurate sealing of a reaction tank cover are achieved, thereby bringing convenience to the test.

Owner:CHAOWEI POWER CO LTD

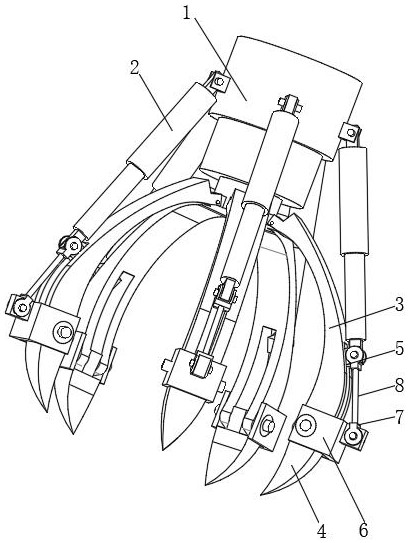

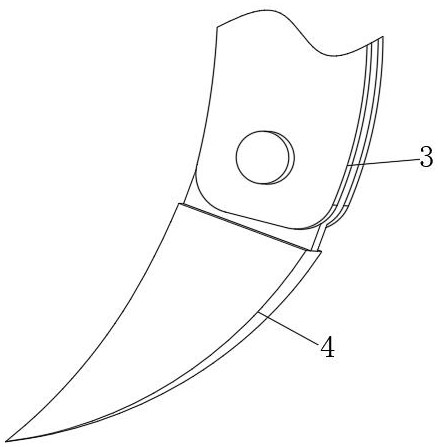

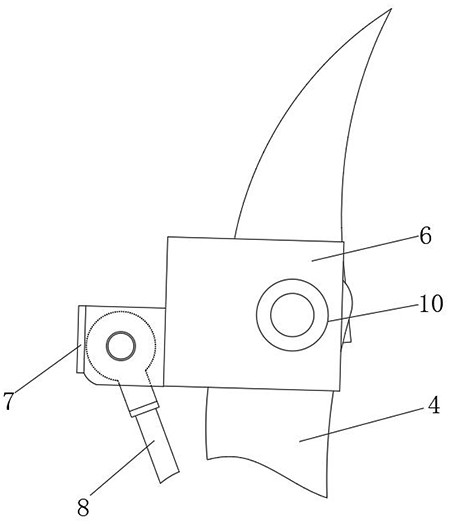

Lotus claw for grabbing waste steel

The invention relates to the technical field of mechanical arm equipment, and discloses a lotus claw for grabbing waste steel, the lotus claw comprises a connecting table fixedly connected with a mechanical arm, a hydraulic rod communicated with a hydraulic device and a grabbing flap hinged to the connecting table, the grabbing flap is composed of an upper flap and a tip end, and the upper flap is hinged to the tip end. According to the lotus claw for grabbing the waste steel, through two-section operation, the driving angle of the hydraulic rod is always at the optimal angle, meanwhile, lever amplification of acting force is achieved, under the same hydraulic oil pressure, the grabbing force is larger, harder objects can be crushed, heavier goods can be grabbed, meanwhile, the overall stress is reduced, and the grabbing efficiency is improved. The load of each part is smaller, the service life is longer, secondly, when the upper petal is driven to rotate, the driving point is close to the root of rotation, the higher running speed is achieved, after an object is grabbed, the driving point is close to the bottom, the larger driving force is achieved, and the running speed and the acting force are kept in the optimal state.

Owner:XUZHOU BUT CONSTR MASCH LTD

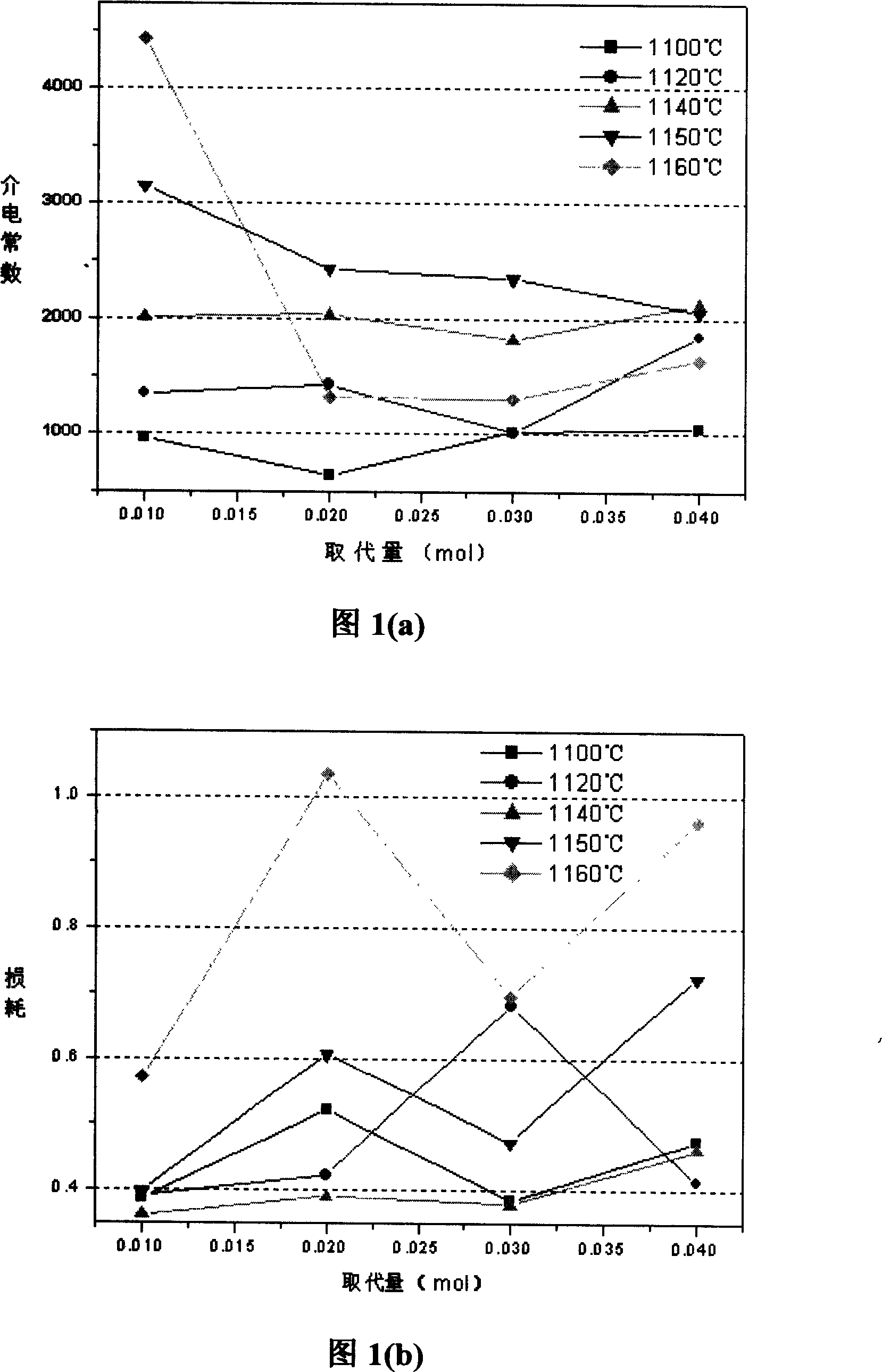

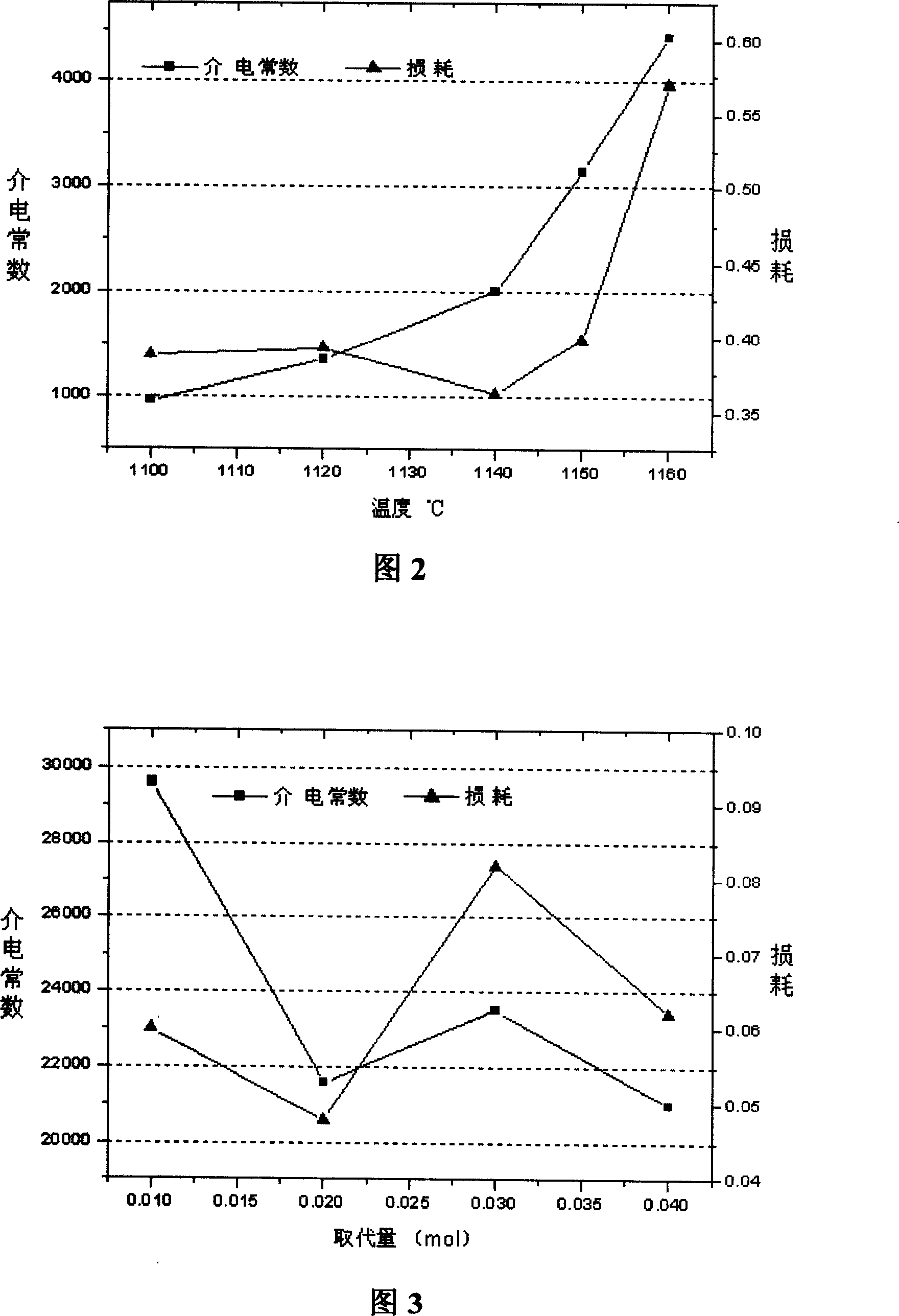

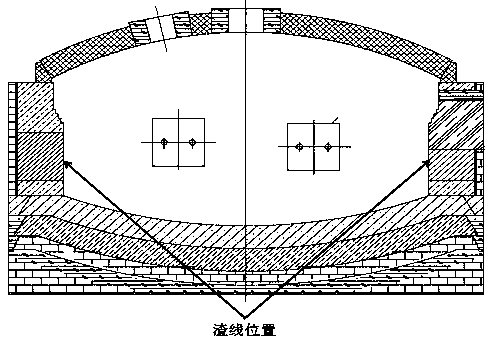

Doped copper titanium oxide capacitor ceramic dielectric and producing method thereof

InactiveCN1975943BReduced responseExtended service lifeFixed capacitor dielectricCeramicsDielectricCapacitance

A method for preparing a capacity material of doped CaCu3Ti4 O12 includes replacing Ca2+ ion at A position in CaCu3Ti4O12 material by adding Sr2+ ,Na2+ or K+ doping ion and replacing Ti4+ ion at B position in CaCu3Ti4O12 material by adding Zr4+ doping ion, sintering prepared material at temperature of 1140deg.c to obtain capacity material with high dielectric constant, using Automatic LCR meter 4225 ester to confirm dielectric performance and sintered character of doped capacity ceramic material.

Owner:TIANJIN UNIV

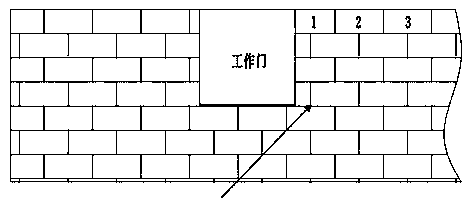

Method for patching side wall of dilution electric furnace

ActiveCN110567274ALost fastShorten maintenance cycleLinings repairFurnace temperatureTemperature control

The invention relates to a method for patching a side wall of a dilution electric furnace and belongs to the technical field of metallurgy. According to the method for patching the side wall of the dilution electric furnace, in-furnace temperature control is improved before blowing out of the furnace is conducted; in-furnace freezing is lowered to below the slag line position; after blowing out ofthe furnace is conducted, in-furnace cooling is conducted, and a manner of disassembling while masoning is adopted by patching in the slag line position till patching and replacing of furnace bricksin the slag line position is finished. By means of the method for patching the side wall of the dilution electric furnace, the dilution electric furnace can be mended rapidly; the furnace top structure is not influenced; the repair period is effectively shortened; and the production cost is lowered.

Owner:CHUXIONG DIANZHONG NONFERROUS METALS CO LTD

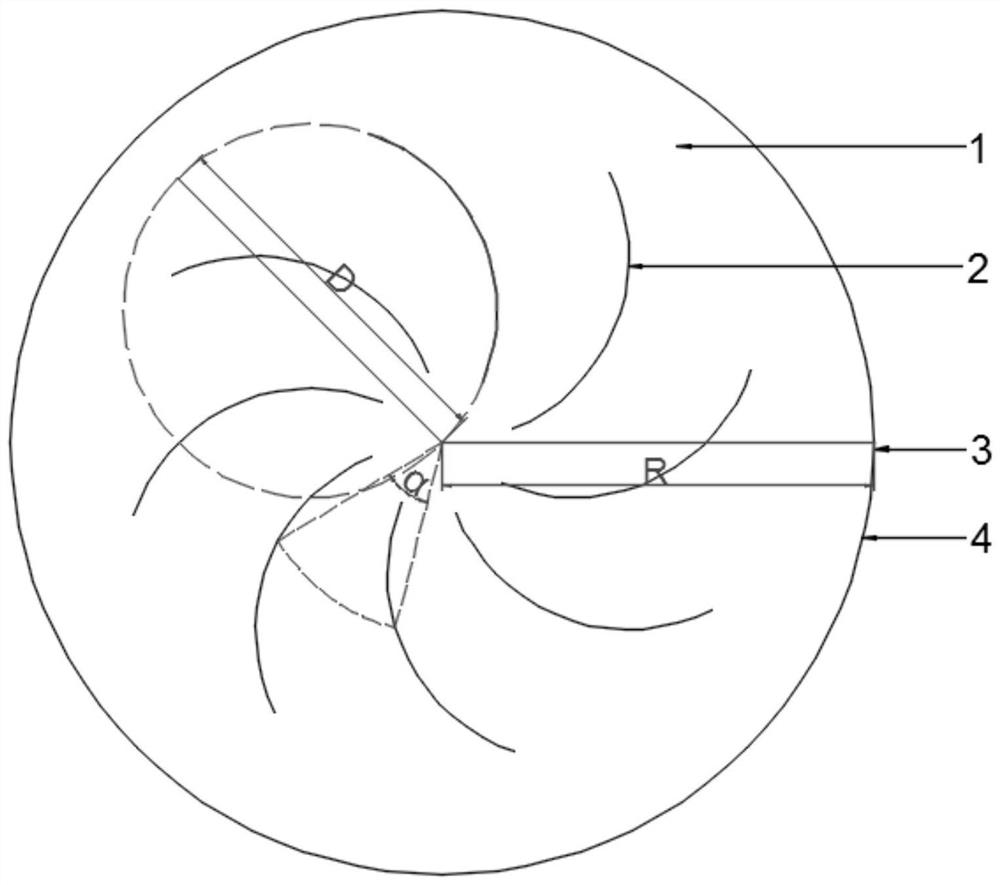

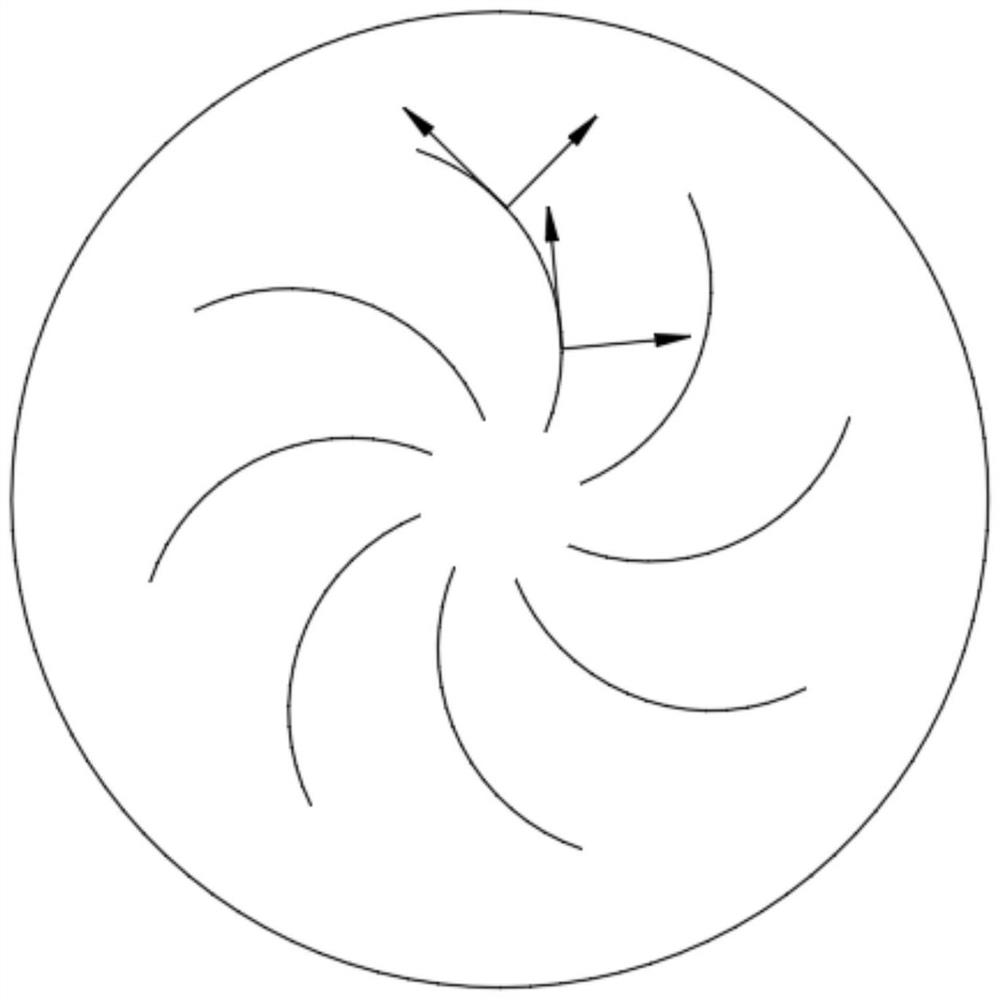

Fluid stirring and purifying element with arc air channel

PendingCN114309565AEfficient captureValid packageMelt-holding vesselsSustainable biological treatmentBrickEngineering

The fluid stirring and purifying element comprises a brick core body, the brick core body is internally provided with an arc air blowing channel, and the arc air blowing channel is arranged in the length direction of the brick core body. On any cross section of the brick core body, the arc blowing air channel extends from the position close to the axis of the brick core body to the position close to the outer vertical face of the brick core body, and the arc blowing air channel is in an arc shape. In the service process, the working face is easy to purge and clean, the blow-through rate is high, the air permeability is adjustable, meanwhile, the thermal shock stability is good, and the overall cross section of the working face can be prevented; and the problems of long oxygen burning cleaning time, high labor intensity of on-site hot repair operation, high stress generated in the service process of the air brick, poor molten steel stirring and purifying effects and the like of the existing fully-through slit air brick are solved.

Owner:PUYANG REFRACTORIES GRP CO LTD

Indirect preheating starting discharge lamp and device thereof

InactiveCN101930898BReduce the starting voltageExtended service lifeElectric lighting sourcesGas discharge lamp detailsGas-discharge lampFilling materials

An indirect preheating start discharge lamp and a device thereof, wherein the discharge lamp comprises a lamp tube with electrodes respectively arranged at the two ends therein and filling material sealed therein; one side of the electrode of at least one end inside the lamp tube is provided with an electric heating component, wherein the electrode and the lead of the electric heating component are respectively led out of the end part of the lamp tube to form a circuit joint, and is also provided with a lighting device with the discharge lamp. At the initial lighting stage of the discharge lamp, the electric heating component in the lamp tube emits electrons to heat adjacent electrode and fills initial electrons in the lamp tube, thereby reducing the trigger starting voltage of the lamp, protecting the electrode, and prolonging service life of the lamp.

Owner:卢静香

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com