A press-fitting process for heavy-duty automobile leaf spring pins

A heavy-duty vehicle and pin press-fitting technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity in leaf spring pin assembly, difficult assembly quality assurance, and high assembly cost, so as to save assembly time, Cost-saving and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

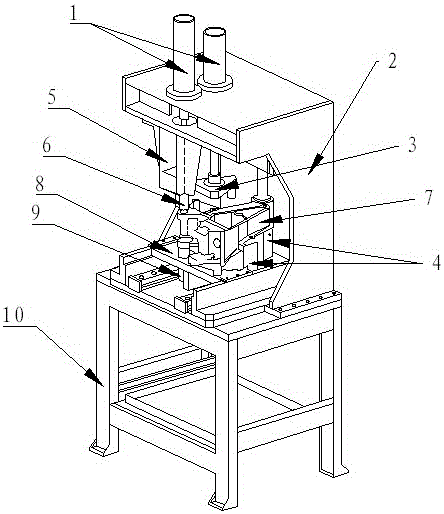

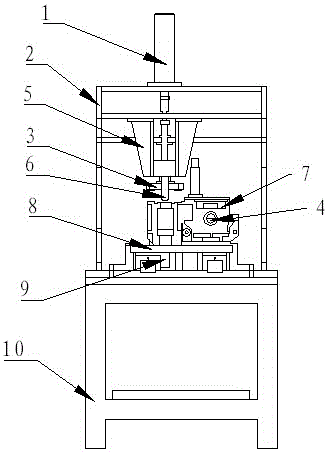

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

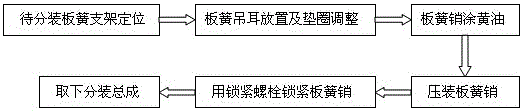

[0030] As shown in the figure: a heavy-duty automobile leaf spring pin press-fitting process, including the following steps:

[0031] (1) Positioning of the leaf spring bracket to be subassembled: take the leaf spring bracket 7 and place it on the subpackage table 10, and use two support blocks 4 and a positioning clamping device 3 on the subpackage table 10 for positioning to ensure that the Precise positioning of product parts;

[0032] (2) Placement of leaf spring lifting lug and adjustment of gasket: place the leaf spring lifting lug in the corresponding installation groove of the leaf spring bracket 7, install a washer on both sides of the lifting lug to eliminate the gap, and use the leaf spring overshoot to adjust the leaf spring pin Through the hole, make the washer, lug hole and bracket hole coaxial;

[0033] (3) Apply butter to the leaf spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com