Indirect preheating starting discharge lamp and device thereof

A technology for preheating and starting discharge lamps, which is applied to the parts of gas discharge lamps, lighting devices, electric light sources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

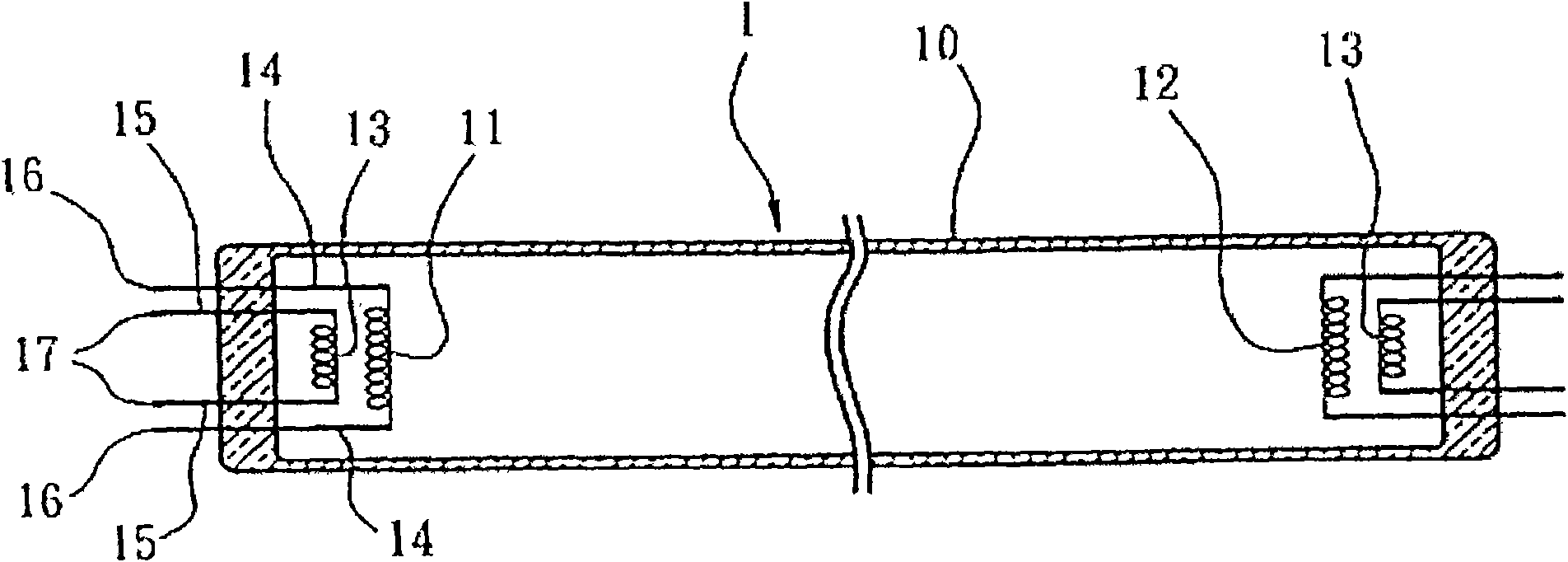

[0041] Such as figure 2 As shown, a discharge lamp 1 of the present invention includes: a lamp tube 10, electrodes 11, 12 are respectively provided at the inner ends of the lamp tube 10, and filled with fillers (not shown); and At least one side of the electrode 11 or 12 inside 10 is provided with an electric heating member 13. Wherein, the lamp tube 10 is a glass tube whose two ends are fusion-sealed, and the filler inside can be at least one light-emitting gas or mixed gas. The electrodes 11 and 12 and the wires 14 and 15 of the electrical component 13 respectively lead out the ends of the lamp tube 10 to form circuit contacts 16 and 17. In the discharge lamp 1 constructed in this way, the electrodes 11 and 12 at both ends are used for triggering and normal lighting when lighting, and the electric heating member 13 is used for preheating and emitting electrons in the initial stage of lighting, so as to use the emitted electrons to heat adjacent Electrodes 11, 12, and the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com