Construction method for synchronous formwork supporting and concrete pouring of bottom plate and top plate of cast-in-place pipe gallery

A technology of pouring concrete and construction methods, which is applied in the field of concrete pouring, and can solve the problems of large investment in steel bar brackets/steel plates, inconvenient lifting and installation of steel plates, and difficult control of steel plate plane leveling, etc., and achieves wide application range, small loss, The effect of no safety hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

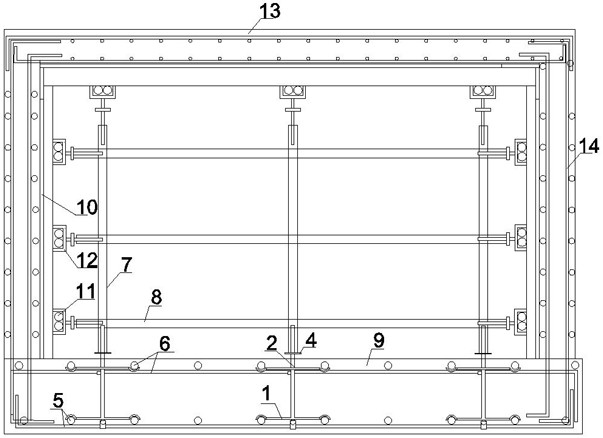

[0018] see figure 1 and figure 2 , the construction method of a kind of cast-in-place pipe rack bottom plate and top plate synchronous formwork pouring concrete provided by the present invention, carry out according to the following steps:

[0019] S1. Make the vertical support device: Weld the hooks facing downward at the four end points of the lower cross support rod 1, weld the vertical rod 2 on the midpoint of the lower cross support rod 1, and weld the upper cross in the middle of the vertical rod 2 The four ends of the support rod 3 and the upper cross support rod 3 are respectively welded with upwardly facing hooks; the upper part of the vertical rod 2 is fixedly welded with the horizontal support rod 4, and the height of the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com