Thermal insulation method and thermal insulation device for electric vehicle power battery module

A technology for power batteries and electric vehicles, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of high energy consumption of batteries, reduction of total charging efficiency, inability to perform heat preservation functions, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

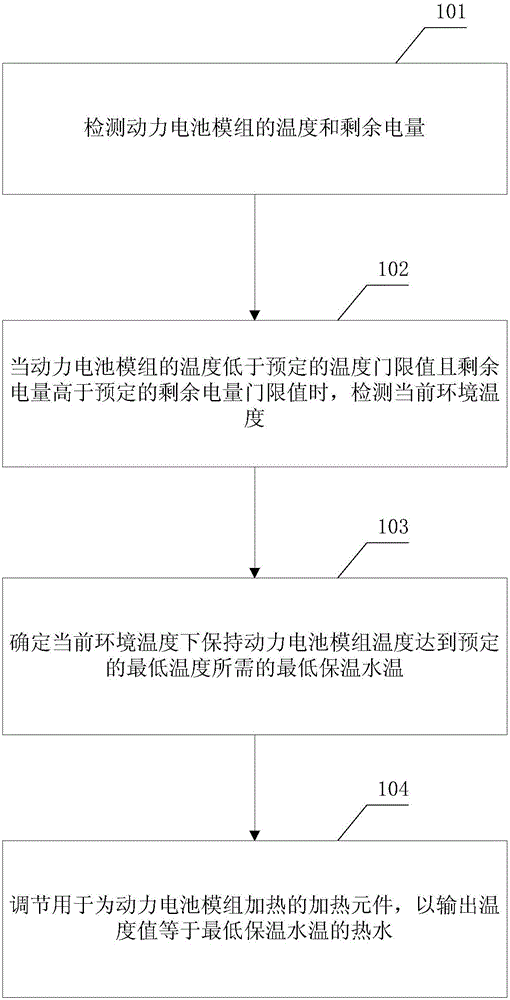

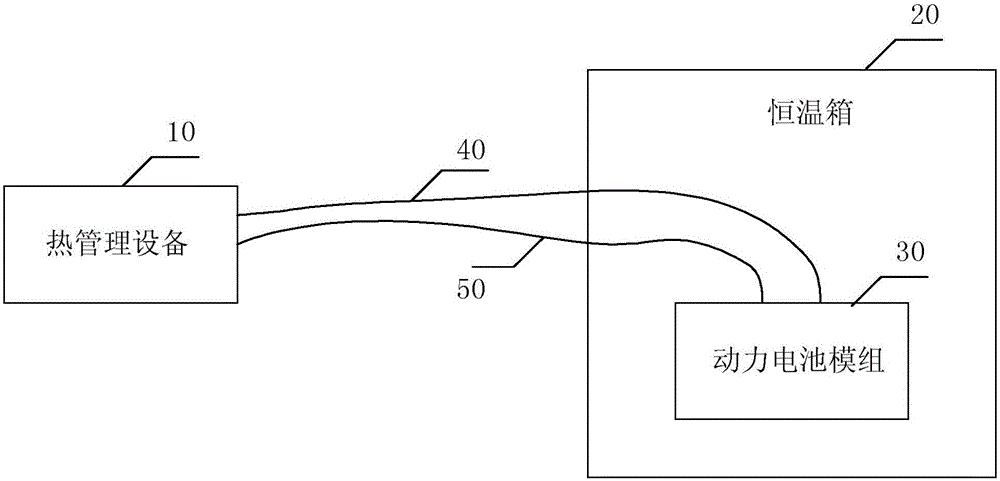

Method used

Image

Examples

example 1

[0055] When the temperature of the power battery module is 3 degrees Celsius and the remaining power of the power battery module is 45%, it is determined that the heat preservation process needs to be performed, and the current ambient temperature of the power battery module is detected.

example 2

[0057] When the temperature of the power battery module is 6 degrees Celsius and the remaining power of the power battery module is 35%, it is determined that the heat preservation process does not need to be performed, and the current ambient temperature of the power battery module is not detected.

example 3

[0059] When the temperature of the power battery module is 2 degrees Celsius and the remaining power of the power battery module is 35%, it is determined that the heat preservation process does not need to be performed, and the current ambient temperature of the power battery module is not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com