Plate link chain stepped dry slag remover

A step-type, slag remover technology, applied in the direction of lighting and heating equipment, can solve the problems of fast equipment loss, high maintenance costs, and easy slag rolling off, etc., to achieve the effect of fast equipment loss and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

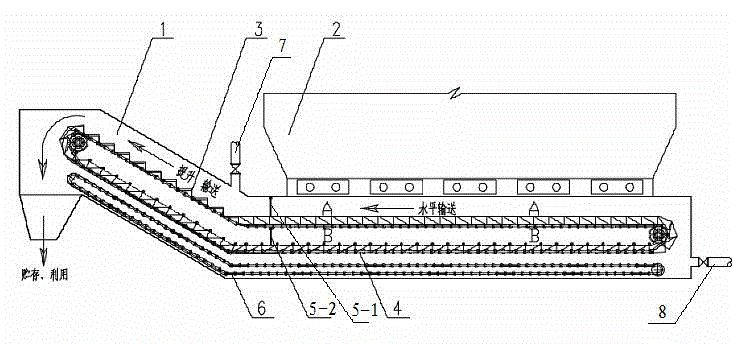

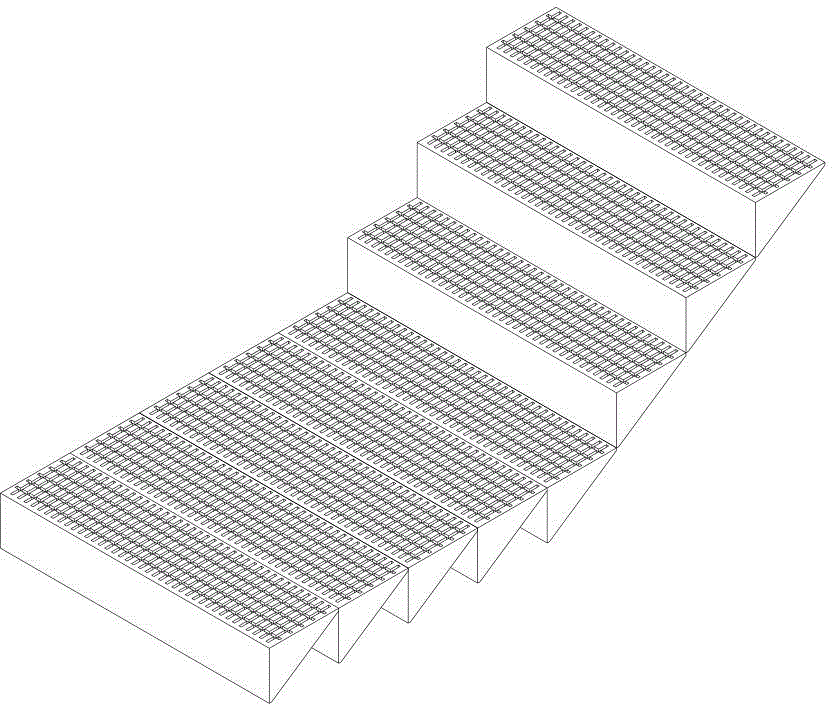

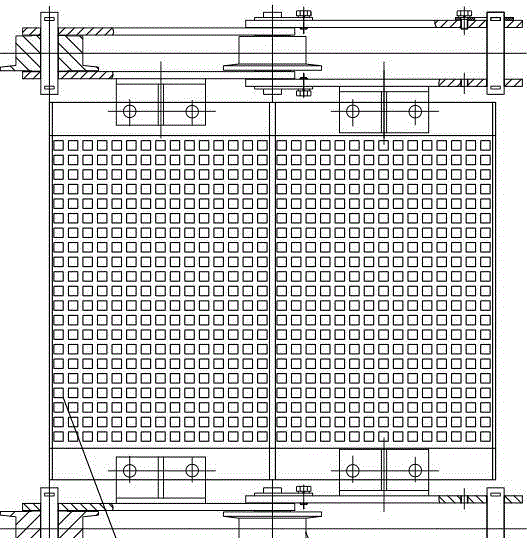

[0016] see Figure 1~4 , a plate chain stepped dry slag remover, comprising a box 1 with a slag outlet at one end, the box 1 has a horizontal portion and extends upwardly from one end of the horizontal portion pointing to the slag outlet An inclined part is formed, the other end of the inclined part is connected to the slag outlet; the upper end surface of the horizontal part has a slag inlet sealingly connected with the slag outlet at the bottom of the boiler slag storage hopper 2, and the box 1 is equipped with a high-temperature-resistant stepped conveying plate 3 that is used to transport the slag falling from the slag outlet to the slag outlet, and then falls into the slag warehouse for storage and utilization. It is pulled and operated by a plate chain mechanism, and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com