Wallboard mounting structure capable of achieving free leveling and mounting method thereof

A technology for installing structures and wall panels, applied in building construction, covering/lining, construction, etc., can solve the problems of high construction difficulty, large material loss, and long construction period, and achieve low construction difficulty, small material loss, and reliable installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

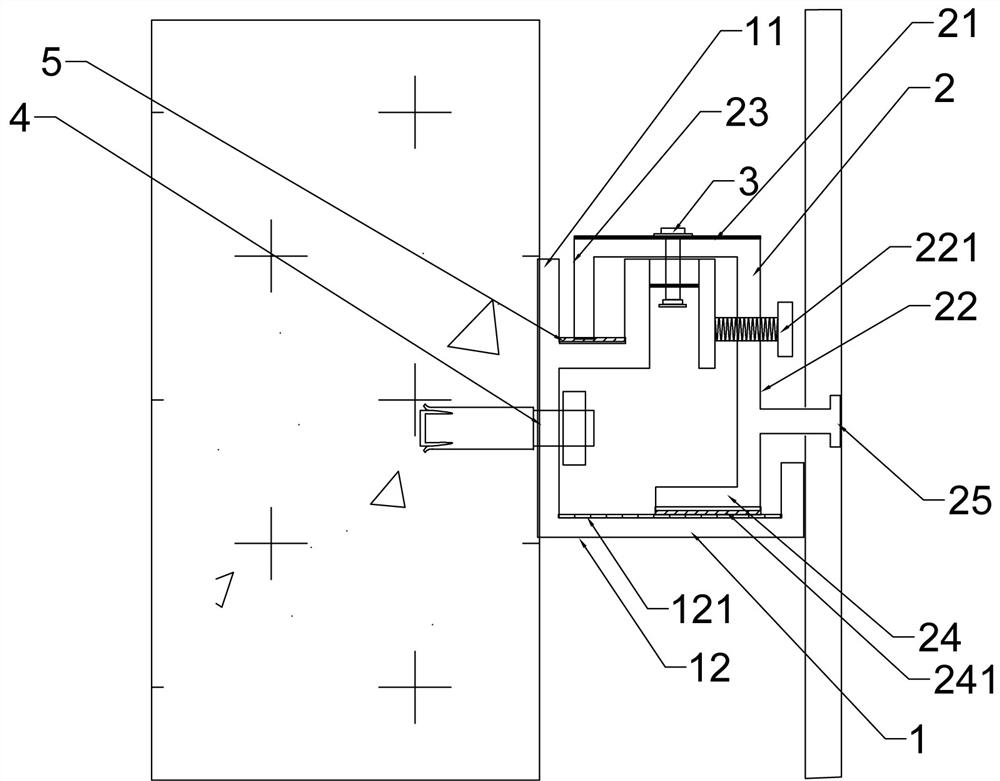

[0029] Such as figure 1 As shown, a free-leveling wall panel installation structure includes a first leveling piece 1 and a second leveling piece 2, such as image 3 The second leveling member 2 shown includes a top plate 21, a first side plate 22, a second side plate 23, and a bottom plate 24. The top plate 21 is parallel to the bottom plate 24, and the first side plate 22 is parallel to the second side plate. 23 parallel, the top plate 21 is perpendicular to the first side plate 22 and the second side plate 23, the length of the second side plate 23 is less than the length of the first side plate 22, the length of the bottom plate 24 is less than the length of the top plate 21, the first The side plate 22, the second side plate 23, the top plate 21, and the bottom plate 24 form a semi-enclosed rectangular space, and the first side plate 22 is provided with an internally threaded hole for the first screw 221 to penetrate, and is used to engage the connection of the wallboard....

Embodiment 2

[0036] A free leveling wall panel installation structure, including a first leveling piece 1, a second leveling piece 2, the second leveling piece 2 includes a top plate 21, a first side plate 22, a second side plate 23, Bottom plate 24, described top plate 21 is parallel to bottom plate 24, and described first side plate 22 is parallel to second side plate 23, and described top plate 21 is all perpendicular to described first side plate 22, second side plate 23, and second The length of side plate 23 is less than the length of first side plate 22, and the length of bottom plate 24 is less than the length of top plate 21, and first side plate 22, second side plate 23, top plate 21, bottom plate 24 form the rectangular space that half surrounds, and described first The side plate 22 is provided with an internally threaded hole for the first screw 221 to pass through, and a connecting piece 25 for engaging the wallboard. At a position lower than the center line of the first side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com