A kind of external wall dry-hanging structure and its dry-hanging method

A dry-hanging and exterior wall technology, which is applied to building structures, instruments, coverings/linings, etc., can solve problems such as difficult construction, large material loss, and complex structure, and achieve low construction difficulty, small material loss, and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

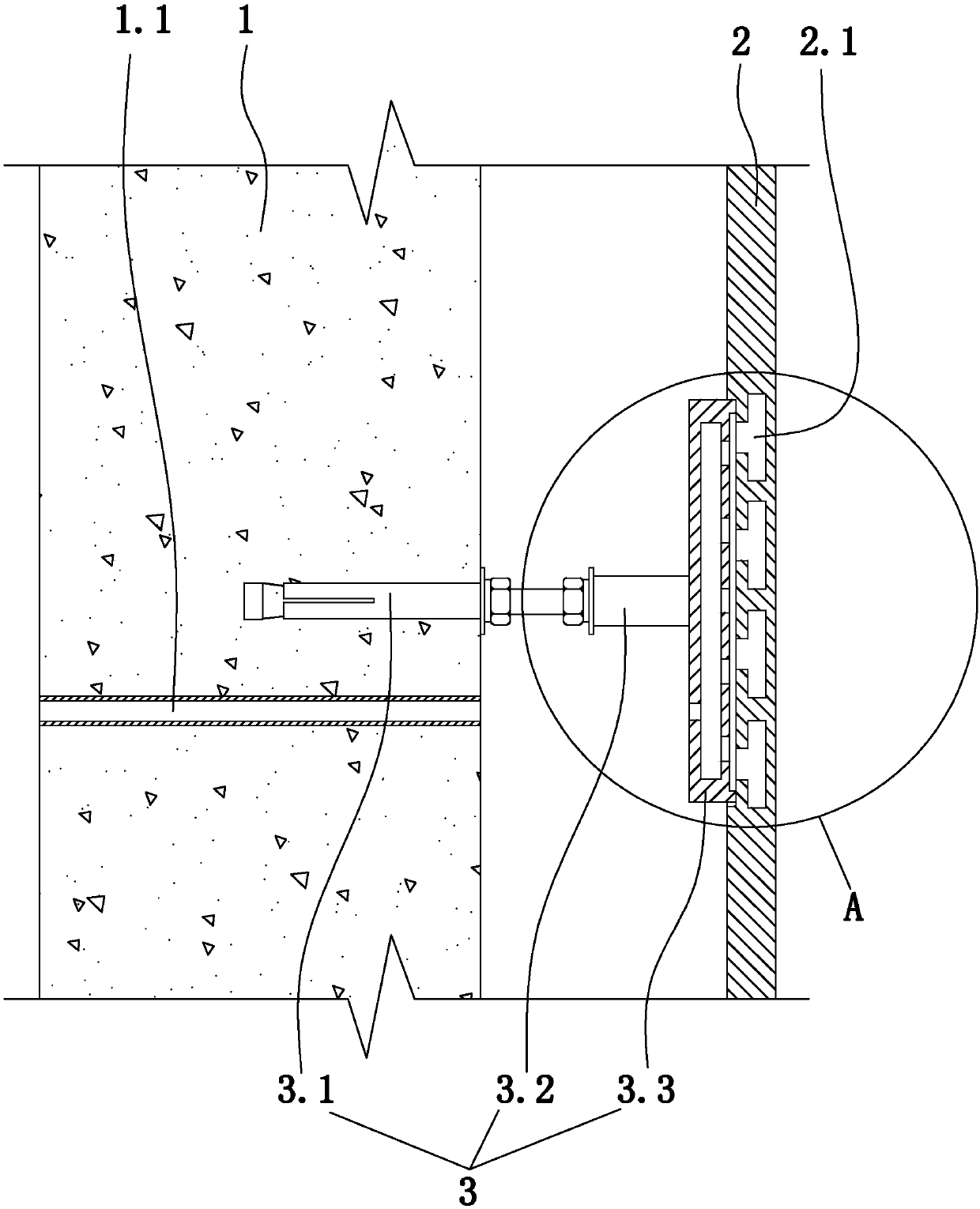

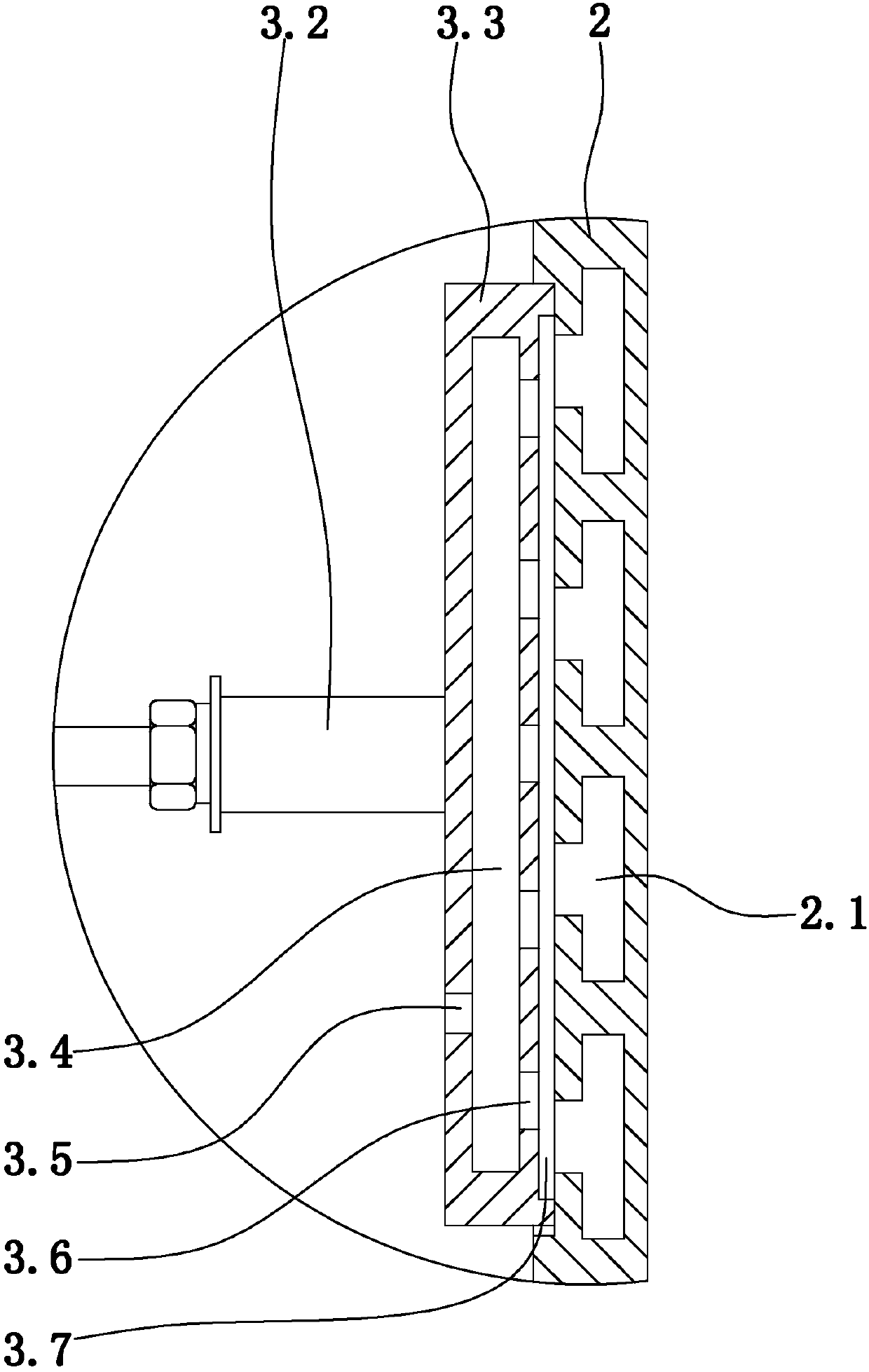

[0035] Embodiment 1: as figure 1 , figure 2 As shown, a dry-hanging structure for an exterior wall includes a building exterior wall 1, a pre-embedded pipeline 1.1 arranged in the exterior wall of the building and running through the interior and exterior sides of the exterior wall of the building, wall bricks 2, and an installation wall arranged on the exterior wall of the building Brick dry hanging mechanism 3. Pre-buried pipelines are set horizontally.

[0036] The dry-hanging mechanism comprises expansion bolts 3.1 embedded in the exterior wall of the building and a vertical mounting plate 3.3 connected with the expansion bolts. The middle part of the vertical mounting plate is provided with a connecting screw sleeve 3.2 that cooperates with the expansion bolt. The axis of the connecting threaded sleeve is perpendicular to the vertical mounting plate. The vertical mounting plate is connected with the expansion bolt through the connecting screw sleeve, and the connecti...

Embodiment 2

[0041] Embodiment 2: A dry-hanging method for an exterior wall dry-hanging structure. Refer to Embodiment 1 for the exterior wall dry-hanging structure of this embodiment.

[0042] A dry-hanging method for an exterior wall dry-hanging structure, comprising the following steps in sequence:

[0043] a. Bury the expansion bolts in the exterior wall of the building, and install the vertical installation plate on the expansion bolts through the connecting screw sleeve, so as to install the dry hanging mechanism on the exterior wall of the building, and make the extension line of the axis of the embedded pipe pass through Overfilled vias;

[0044] b. Fill adhesive in the adhesive-filled inner cavity, glue-filled vias and board grooves; fill adhesive in the limiting groove and filling groove of the mounting plate;

[0045] c. Install the wall tiles on the vertical mounting plate, a part of the vertical mounting plate extends into the limiting groove of the mounting plate, and the su...

Embodiment 3

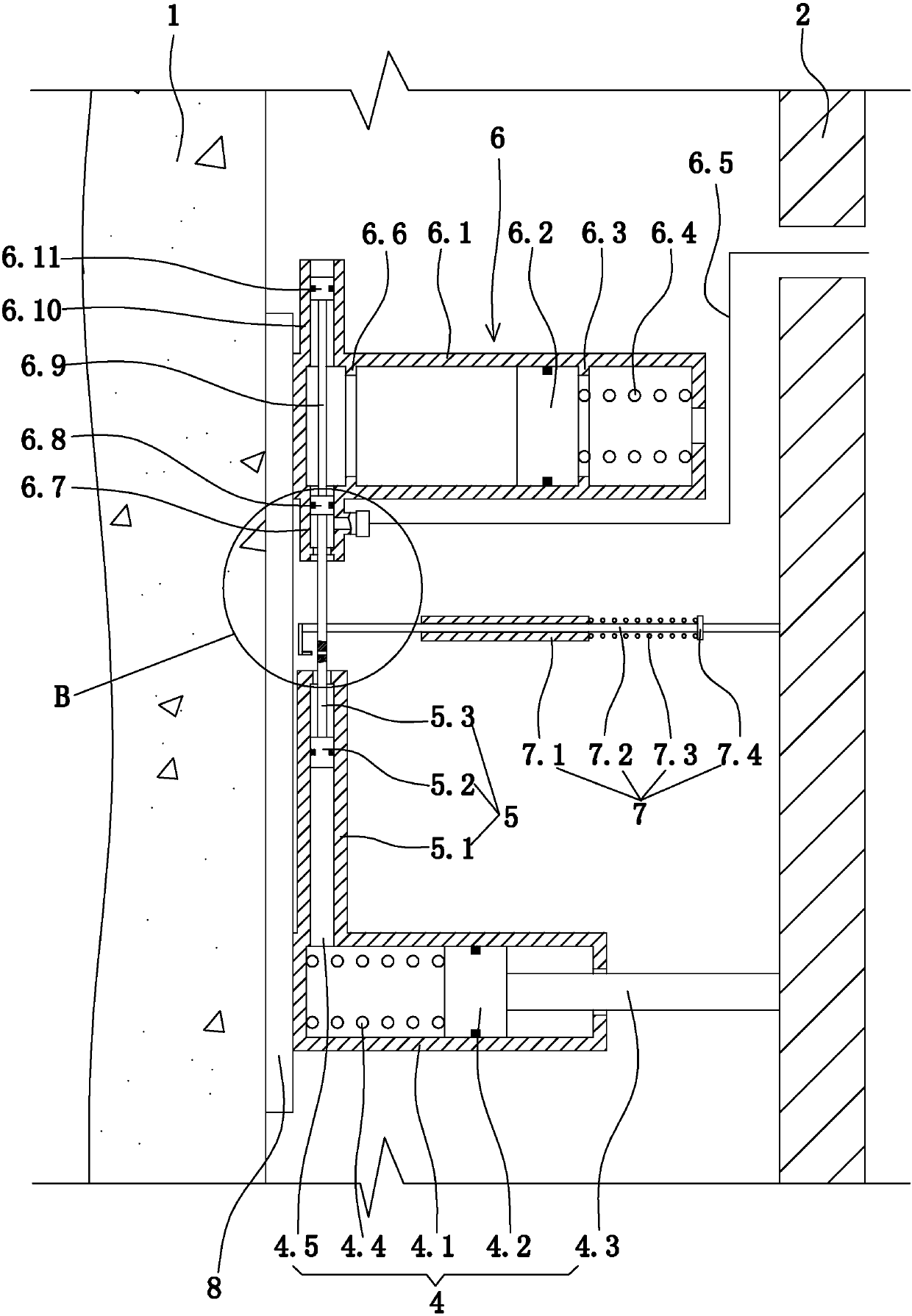

[0049] Embodiment 3: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0050] Such as image 3 , Figure 4 As shown, a dry-hanging structure for an exterior wall also includes a warning device for loosening of wall tiles. The warning device for loose wall tiles includes: a base plate 8, which is arranged on the surface of the building exterior wall; a trigger device 4, which is located between the building exterior wall and the wall brick; a conversion mechanism 5, which is located between the building exterior wall and the wall brick between; a self-triggering locking mechanism 7, the self-triggering locking mechanism is located between the building exterior wall and the wall brick; and a warning mechanism 6, the warning mechanism is located between the building exterior wall and the wall brick. The base plate is fixed on the surface of the exterior wall of the building through expansion bolts, and the base plate is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com