Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Long-lasting antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

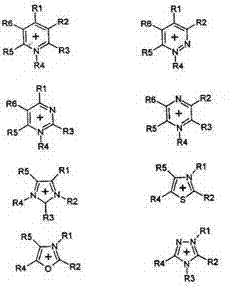

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

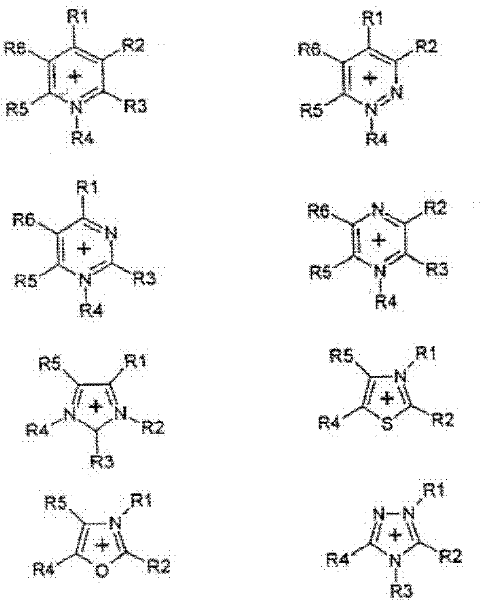

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

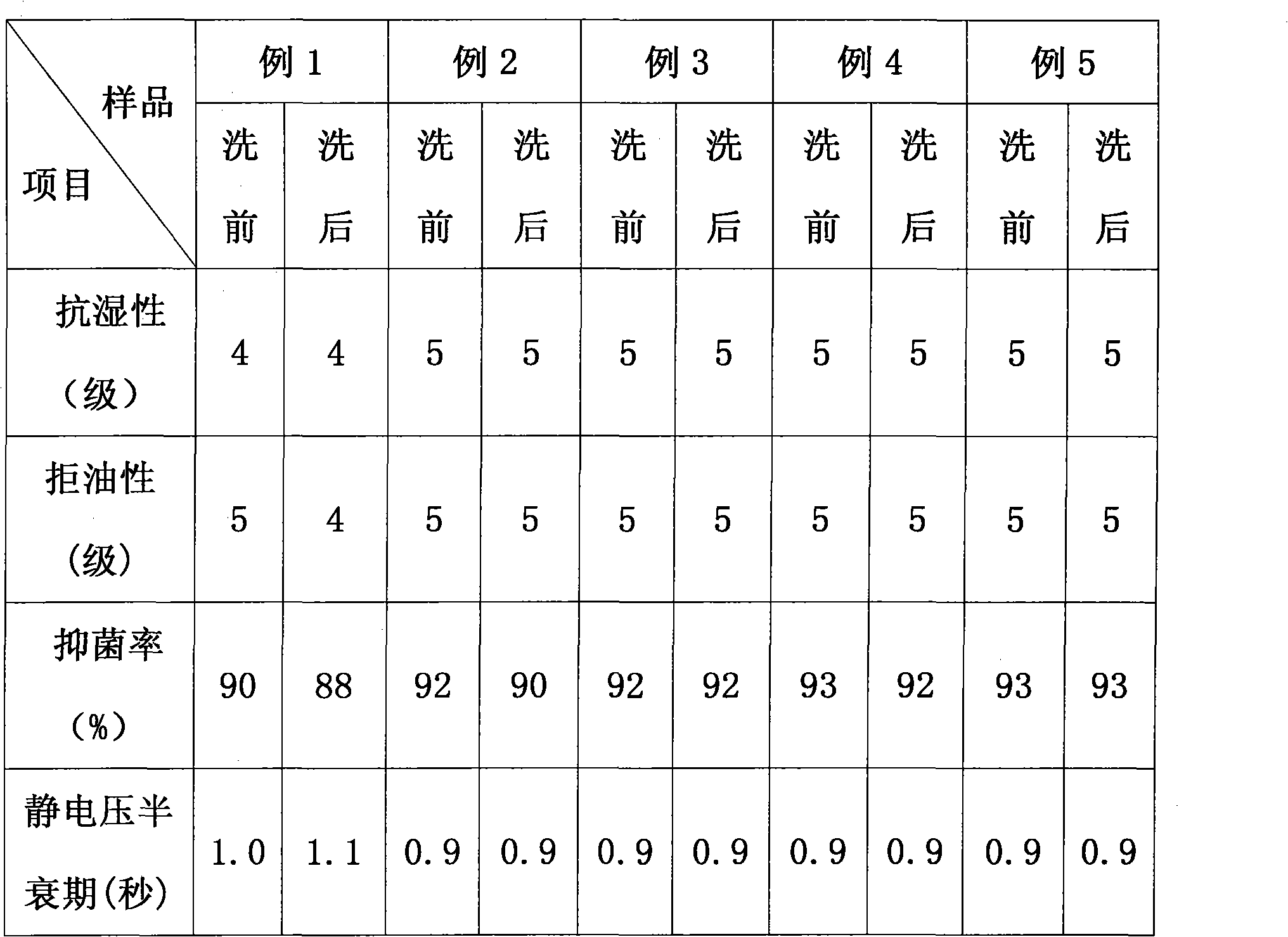

ActiveCN102108638AImprove washing resistanceGood film fastnessFibre treatmentGlycidyl methacrylateAdhesive

The invention provides a durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and a preparation method. The coating adhesive is prepared from methyl acrylate, n-butyl acrylate, glycidyl methacrylate, allyl methacrylate, 2,2,2-trifluoroethyl methacrylate, acryloyloxyethyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether XL90, hexadecyl trimethyl ammonium chloride, 2,2-azobis(2-methylpropionamidine)hydrochloride, deionized water and an associative polyurethane levelling and rheological agent WT-203 through the processes of emulsification, initiated polymerization and thickening.

Owner:DANDONG UNIK TEXTILE

Coloring agglomerate for polyethylene packing film and its prepn process

The coloring agglomerate consists of pigment, plastic assistants and carrier resin, and the plastic assistants include N, N'-ethylene amido bistearate, polyvinyl wax, zinc stearate and antistatic agent. The preparation process includes mixing the materials, high speed kneading in kneading pot with current controlled in 30-50 A, extruding the mixture in a double-screw extruder at 100-160 deg.c, cooling, stoving and pelletizing. The polyethylene tire-packing film with the coloring agglomerate has no color penetration, no adhesion, no falling off and antistatic performance, and may be used to complete the packing and storing of rubber tire at about 80 deg.c.

Owner:CHUNHUI PIGMENT MATERIAL XINTAI

Permanent anti-static PP (polypropylene) composite material and preparation method thereof

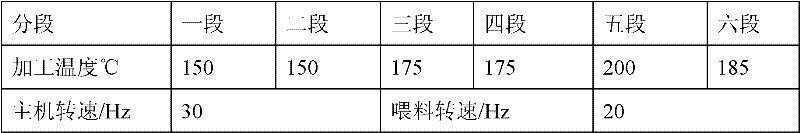

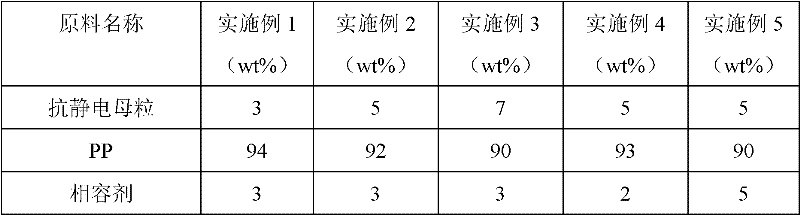

ActiveCN102399393ALong-lasting antistatic effectGood antistatic effectOther chemical processesSurface resistivityPolypropylene

The invention relates to a permanent anti-static PP (polypropylene) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of anti-static master batch, 80 to 95 percent of PP and 1 to 5 percent of compatilizer. The preparation method comprises the following steps of: weighing the raw materials according to weight proportion; placing the raw materials into a high mixing machine to mix the raw materials for 2 to 5 minutes; discharging; and then carrying out extrusion pelletizing by a double-screw extruder, wherein a processing temperature is in the range of 190 to 220 DEG C and screws have revolution of 35 to 40Hz. Compared with the prior art, the permanent anti-static PP composite material has the advantages of sustained anti-static effect, permanent anti-static effect, good anti-static effect, high comprehensive mechanical property, performance close to pure PP, light color, capability of being prepared into various colors, low cost, good heat resistance and the like. The surface resistivity of the permanent anti-static PP composite material can reach 106 to 108 ohm.m.

Owner:上海日之升科技有限公司

Antistatic environment-friendly glue

InactiveCN105086849AEasy to makeEasy to useNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyesterDehydroacetic acid

The invention discloses antistatic environment-friendly glue. The antistatic environment-friendly glue comprises, by weight, 60-160 parts of polyester, 30-40 parts of butanediol acrylate, 40-60 parts of trimethylolpropane, 10-30 parts of butanediol, 20-40 parts of metoxyphenol, 8-12 parts of acetone, 9-12 parts of acrylamide, 10-28 parts of styrene, 6-24 parts of ethyl alcohol, 2-6 parts of xylene, 20-30 parts of poly isobutyl ester, 10-30 parts of aluminum hydroxide, 24-48 parts of phosphotriester, 12-18 parts of antimonous oxide, 100-160 parts of methacrylic acid-2-hydroxy ethyl, 80-100 parts of methyl acrylate, 20-60 parts of methacrylic acid glycerol trilaurate, 12-16 parts of styrene, 20-40 parts of methacrylic acid, 8-16 parts of dehydroacetic acid and 20-40 parts of butanol. The antistatic environment-friendly glue is easy to manufacture, non-toxic production materials are selected, the glue is good in use effect and environmentally friendly, a tough coating can be formed, and lasting waterproofness and antistatic performance are achieved.

Owner:启东寅昶精密铸造有限公司

Waterproof paint

The invention discloses a waterproof paint. The waterproof paint comprises the following components in parts by weight: 75-125 parts of methyl acrylic acid-2-hydroxy ethyl acrylate, 20-40 parts of methyl acrylic acid, 100-150 parts of methyl methacrylate, 80-100 parts of dodecyl methacrylate, 200-300 parts of styrene, 150-200 parts of butyl methacrylate and 20-40 parts of styrene. The waterproof paint disclosed by the invention is simple to prepare, is prepared from nontoxic production raw materials, is good in using effect, is environment-friendly, is capable of forming a firm and tenacious coating, and has long-lasting waterproofness and antistatic property.

Owner:刘骏

Electroconductive color slurry and low-resistance polyurethane material thereof

The invention discloses electroconductive color slurry and a low-resistance polyurethane material thereof. The electroconductive color slurry is prepared from the following raw materials in parts by weight: 35-55 parts of carbon powder, 30-60 parts of ionic liquid and 0.2-1 part of dispersant. The low-resistance polyurethane material is prepared from the following raw materials in parts by weight: 100 parts of polyester polyol, 0.8-9 parts of electroconductive color slurry, 100-120 parts of isocyanate and 0.5-3 parts of catalyst. The electroconductive color slurry provided by the invention has low addition amount and good electrical conductivity; and the low-resistance polyurethane material provided by the invention is applicable to dust-free room and other clean places, and has good antistatic property, low humidity dependence and good physical and mechanical properties.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Permanent antistatic PA6 (Polyamide 6) composite material and preparation method thereof

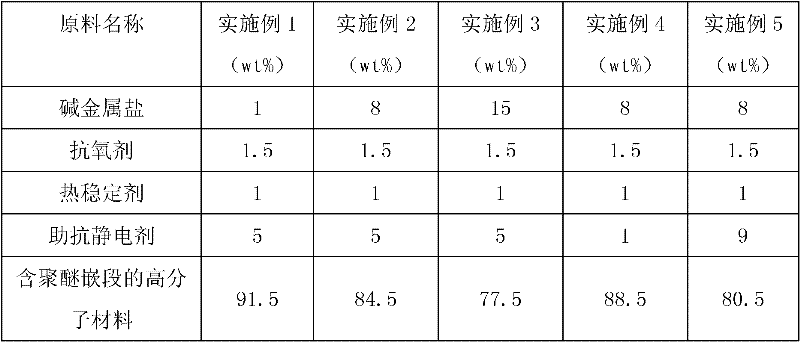

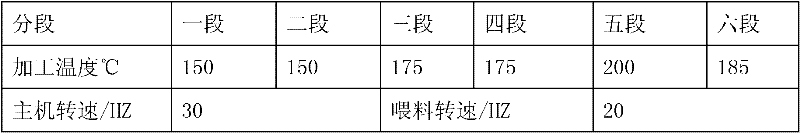

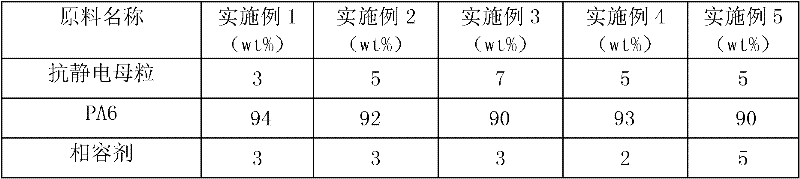

The invention relates to a permanent antistatic master batch and a preparation method thereof. The master batch comprises the following components in percentage by weight: 1-15 percent of alkali metal salt, 0.5-2 percent of antioxidant, 0.5-2 percent of heat stabilizer, 0-10 percent of assisting antistatic agent and 71-95 percent of polyether block-containing high polymer material. The preparation method comprises the following steps of: weighing raw materials according to the proportions, and putting into a high mixer for mixing for 2-5 minutes; discharging; and extruding and pelletizing with a double screw extruder to obtain the master batch, wherein the processing temperature is 150-200 DEG C, and the number of revolutions of a screw is 25-35 HZ. The invention further relates to a permanent antistatic composite material comprising the antistatic master batch and a preparation method thereof. The permanent antistatic master batch and the permanent antistatic composite material have the advantages of durable antistatic effect, permanent antistatic effect, various colors, low cost and high heat resistance.

Owner:SHANGHAI SUNNY

Electrostatic and electromagnetic compatible coating layer based on graphene

ActiveCN109796615AImprove stabilityGood weather resistancePolyurea/polyurethane coatingsElectrically-conductive paintsWeather resistanceSurface layer

The invention relates to an electrostatic and electromagnetic compatible coating layer based on graphene, and belongs to the technical field of surface coating. The electrostatic and electromagnetic compatible coating layer is arranged on the surface of plastic and comprises a bottom layer and a surface layer which are arranged on the surface of plastic, the bottom layer comprises the graphene, and the surface layer is provided with nano graphene pieces. The coating layer has the advantages of better stability and weather resistance, a durable electrostatic resistance and electromagnetic shielding effect can be achieved with lower graphene using amount, the cost is lower, and the coating layer can be extensively applied to plastic housings of electromechanical and electronic products.

Owner:袁瑞峰

Anti-fog paint

InactiveCN104559704AEasy to makeGood effectElectrically-conductive paintsPolyester coatingsMethyl methacrylateChemistry

The invention discloses an anti-fog paint. The anti-fog paint comprises the following components in parts by weight: 80-120 parts of an alkyd resin, 100-180 parts of dimethylaminoethyl methacrylate, 400-600 parts of isopropanol, 50-100 parts of benzyl bichloride, 60-160 parts of acrylamide, 40-80 parts of methyl methacrylate, 50-150 parts of chloroethylene ester and 20-60 parts of isobutanol. The anti-fog paint provided by the invention is simple to prepare, selects and adopts non-toxic production raw materials, is good in use effect and environment-friendly, can form a tough coating and has a lasting anti-fog property and an antistatic property.

Owner:姜云华

Antistatic reinforced Nylon 66 composite

The invention relates to an antistatic reinforced Nylon 66 composite, and belongs to the technical field of polymer materials. The antistatic reinforced Nylon 66 composite comprises the following raw materials: by weight, 90-110 parts of PA66, 0.5-0.8 part of an antioxidant, 0.5-2 part of ethoxylauramide, 0.1-0.5 part of lubricant TAF, 5-10 part of an aramid fiber and 0.2-0.5 part of a boric acid ester coupling agent. The antistatic reinforced Nylon 66 composite product not only maintains the advantage of prior art, but also has enhanced stability of nylon 66, and at the same time the antistatic reinforced Nylon 66 composite product has a lasting antistatic effect through the addition of the ethoxylauramide. In addition, the antistatic reinforced Nylon 66 composite is wide in application, and can be used in the production of automobiles, electronic devices and the like.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Medical non-woven fabric composite and preparation method and application thereof

InactiveCN106120152AGood broad-spectrum antibacterial propertiesLong-lasting antistatic propertiesElectroconductive/antistatic filament manufactureMelt spinning methodsChemistryAntistatic agent

The invention provides a preparation method of a medical non-woven fabric composite. The method specifically includes the following steps of firstly, weighing 30-50 parts by weight of adipic acid / polybutylene terephthalate, 20-30 parts by weight of polybutylene terephthalate and 30-40 parts by weight of polycarbonate to be sufficiently mixed to obtain a mixture A; secondly, blending the mixture in the first step with 1-4 parts by weight of antistatic agent and 0.5-2 parts by weight of antibacterial agent, and conducting extruding and granulating through a twin-screw extruder to obtain a blend; thirdly, conducting vacuum drying on the blend in the second step, conducting heating, fusing, extruding, stretching, cooling and self-adhering on the dried blend through a screw extruder to form a non-woven fabric; fourthly, spraying an anti-radiation layer on one side of the non-woven fabric obtained in the third step, and putting the fabric into a drying box to be dried and shaped. The prepared medical non-woven fabric composite has antibacterial performance, radiation prevention performance and antistatic performance and is mainly applied to preparing a medical mask.

Owner:朱小涛

Heat transfer printing antistatic paint special for plastics and preparation method

InactiveCN109535946AImprove antistatic performanceEffective conductive pathElectrically-conductive paintsPolyester coatingsOrganic solventNetwork structure

The invention discloses a heat transfer printing antistatic paint special for plastics and a preparation method. The method includes: a. preparing a graphene oxide dispersion liquid; b. preparing carboxylated graphene oxide; and c. adding carboxyl-terminated PET resin and carboxylated graphene oxide into an organic solvent, carrying out cross-linking reaction, and then reducing graphene oxide to obtain the antistatic paint special for plastics. During use, the paint is applied to uniform scrape coating and drying curing, the formed graphene-containing multi-network structure has an effective conductive path, can significantly improve the antistatic performance of a PET base layer, also no antistatic finish paint layer or brushing process is needed for modification, the antistatic effect ismore durable and long-acting, and the heat transfer printing quality can be effectively improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Process for preparing polyamide graphene composite material

InactiveCN109594143AImprove dispersion effectReduce dosageElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentSolventPolyamide

The invention belongs to the technical field of polyamide composite materials and relates to a process for preparing a polyamide graphene composite material. The method comprises the following steps:(1) carrying out pretreatment, namely carrying out surface treatment on graphene and functional aids by using a coupling agent respectively; (2) premixing, namely mixing the graphene treated in the step (1) with the functional aids, further adding carbodiimide, a surfactant and a solvent, and carrying out ultrasonic treatment for 30-60 minutes so as to obtain a modified mixed liquid; and 3) carrying out melt intercalation polymerization, namely mixing a polyamide monomer with the modified mixed liquid obtained in the step (2) to react for 8-10 hours, and carrying out extrusion pelletizing, thereby obtaining a graphene / polyamide composite material. By adopting the process, the functional aids are uniformly dispersed into a polyamide material, the addition amount of the functional aids is greatly reduced, and the material has excellent mechanical properties, antibacterial properties, negative oxygen ion release properties and far-infrared release properties, and has a beneficial effect on human skin health.

Owner:洪春

Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

ActiveCN102108638BImprove washing resistanceGood film fastnessFibre treatmentGlycidyl methacrylateAdhesive

The invention provides a durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and a preparation method. The coating adhesive is prepared from methyl acrylate, n-butyl acrylate, glycidyl methacrylate, allyl methacrylate, 2,2,2-trifluoroethyl methacrylate, acryloyloxyethyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether XL90, hexadecyl trimethyl ammonium chloride, 2,2-azobis(2-methylpropionamidine)hydrochloride, deionized water and an associative polyurethane levelling and rheological agent WT-203 through the processes of emulsification, initiated polymerization and thickening.

Owner:DANDONG UNIK TEXTILE

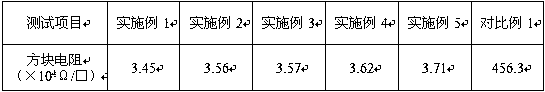

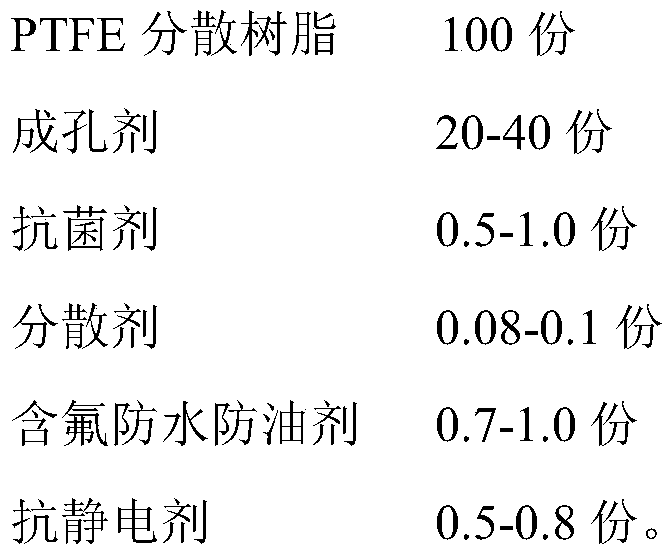

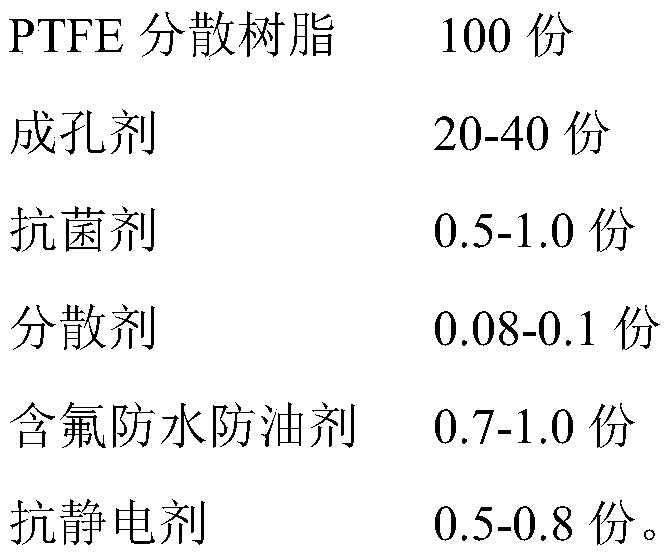

PTFE isolating membrane for medical protective clothing and preparation method of PTFE isolating membrane

ActiveCN111423676AExtended service lifeGood filter effectFlat articlesProtective garmentPolymer scienceMoisture permeability

The invention belongs to the technical field of medical protective clothing, and particularly relates to a PTFE isolating membrane for medical protective clothing and a preparation method of the PTFEisolating membrane. The PTFE isolating membrane is prepared from the following raw materials in parts by mass: 100 parts of PTFE dispersion resin, 20 to 40 parts of pore-forming agent, 0.5 to 1.0 partof antibacterial agent, 0.08 to 0.1 part of dispersing agent, 0.7 to 1.0 part of fluorine-containing waterproof and oilproof agent and 0.5 to 0.8 part of antistatic agent. The invention relates to aPTFE isolating membrane for medical protective clothing. The medical multifunctional protective clothing developed by adopting the polytetrafluoroethylene composite film as the isolating layer has durable physical and mechanical properties such as waterproofness, water repellency, antibiosis, static resistance, flame retardance and moisture permeability, and has good barrier property on blood andviruses (liquid weight or gas weight) under natural conditions and pressure conditions, and the barrier (filtering) efficiency is greater than 99%.

Owner:SHANDONG SENRONG PLASTIC IND TECH

Preparation method of polyester raschel blanket with natural long-acting antibacterial function

ActiveCN109440462ANatural and environmentally friendlyImprove antibacterial propertiesBiochemical fibre treatmentFibre typesPolyesterEscherichia coli

The invention discloses a preparation method of a polyester raschel blanket with a natural long-acting antibacterial function. A multifunctional solution is obtained from chitosan carried by silk fibroin and used for modifying a polyester raschel blanket. The modified blanket has Escherichia coli resistance of 50%-90% and antistatic decay time of 7-28 s. The problems of low air and water vapor permeability, poor handfeel and the like of the polyester raschel blanket modified with the traditional method are solved, the polyester raschel blanket is endowed with lasting natural antibacterial andantistatic functions and other functions, and additional value and market competitiveness of the polyester raschel blanket are increased.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Polypropylene antistatic composite material and preparation method thereof

InactiveCN102127262ADurable antistaticEasy to processOther chemical processesInorganic pigment treatmentPolypropylene compositesTetrachloride

The invention relates to a polypropylene antistatic composite material and a preparation method thereof, belonging to the technical field of polypropylene composite materials. The invention is characterized in that the polypropylene antistatic composite material contains conductive aluminum borate whiskers, and is AlB[w] / PP for short. The preparation method comprises the following steps: proportionally adding aluminum borate whiskers into distilled water, adding concentrated hydrochloric acid so that the acid concentration reaches 0.6-1.2 mol.L<-1>, proportionally adding tin tetrachloride and urea, heating the mixed liquor to 90-110 DEG C, reacting for 1-3 hours, filtering, washing to remove unreacted substances, drying the filter cake, and calcining to obtain conductive aluminum borate whiskers (AlB[w] for short); and proportionally mixing the AlB[w] and polypropylene, mixing, crushing, putting the mixture in a die, putting the die in a muffle furnace at 180-200 DEG C, keeping the temperature for 30-60 minutes, carrying out die forming in a flat vulcanizing machine, and depressurizing and stripping when the temperature of the die drops to below 60 DEG C, thereby obtaining the AlB[w] / PP.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultrahigh molecular weight polyethylene pipe with long-acting anti-static property and flame retardant property and preparation method thereof

ActiveCN104592617AImprove processing fluidityLong-lasting flame retardant and antistatic propertiesCarbon blackOrganosolv

The invention provides a method for improving anti-static property and flame retardant property of an ultrahigh molecular weight polyethylene pipe and the ultrahigh molecular weight polyethylene pipe with long-acting anti-static property and flame retardant property obtained through the method. According to the method, methyl vinyl siloxane grafted low-density polyethylene is used as a flame retardant and polyelectrolyte grafted low-density polyethylene is used as an anti-static agent in the machining process of the ultrahigh molecular weight polyethylene pipe, and molybdenum disulfide, a lubricant, superfine carbon black and a coupling agent are combined to enhance the processing fluidity, anti-static property, flame retardant property and compatibility with inorganic additives of the ultrahigh molecular weight polyethylene. The pipe wall thickness of the prepared anti-static flame retardant pipe can be up to 40 mm, the oxygen index is higher than 27, the surface resistance of the pipe is 105-1010 ohm, the anti-static property and the flame retardant property hardly decline after the processes of long-time friction, water washing and organic solvent washing, and the application prospect is good.

Owner:FOSHAN RISUN HANKE PLASTIC TECH

Coating for improving wear resistance of PVC (polyvinyl chloride) whole-core flame-retardant conveyor belt and preparation method of coating

ActiveCN113185902AImprove adhesionGood adhesionFireproof paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention provides a coating for improving wear resistance of a PVC (polyvinyl chloride) whole-core flame-retardant conveyor belt and a preparation method of the coating. The coating comprises an active interface treating agent coating and a modified polyurethane coating which are arranged on the surface of the PVC whole-core flame-retardant conveyor belt. The active interface treating agent contains methyl ethyl ketone, isopropanol, propylene glycol diacetate, dimethyl nylon acid and polyester glycol L3025. The modified polyurethane coating comprises a component A and a component B, polyester diol L3025 is used for preparing a prepolymer component A, and a reactive flame retardant and an antistatic agent are adopted in the component B. After the PVC whole-core flame-retardant conveying belt is treated by an active interface agent, the modified polyurethane coating is coated by using high-pressure spraying equipment to form a wear-resistant coating. The wear-resistant coating provided by the invention has good tensile strength and elongation at break. The coated PVC whole-core flame-retardant conveyor belt composite coating has excellent bonding strength, flame retardance and antistatic property, particularly has excellent wear resistance and is long in service life.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

Non-woven fabric material and preparation method thereof

InactiveCN106003933AImprove performanceIncrease elasticityElectroconductive/antistatic filament manufactureFlame-proof filament manufactureNonwoven fabricAntibacterial property

The invention provides non-woven fabric. The non-woven fabric is prepared from the following components: 60-80 parts of polylactic acid, 20-30 parts of polyurethane, 10-20 parts of polyimide, 30-45 parts of chitosan, 5-10 parts of a flow modifier, 1-3 parts of alkyl sodium solfonate serving as an anti-static agent, 2-4 parts of epsilon-polylysine serving as an antibacterial agent and 3-6 parts of decabromodiphenyl serving as a flame retardant. The non-woven fabric is prepared with an electrostatic spinning method; four easy-to-degrade raw materials including polylactic acid, polyurethane, polyimide and chitosan are used for preparing a spinning solution, and the prepared non-woven fabric is bio-degradable and very environment-friendly; additionally, the non-woven fabric integrates functions of an antibacterial property, radiation protection, water repellency, static resistance and the like, can basically meet various medical demands and has a wide application range.

Owner:毛文明

Antibacterial and antistatic edge band and preparation method thereof

The invention relates to the field of composite materials, and particularly discloses an antibacterial and antistatic edge band and a preparation method thereof. The edge band is prepared from, by weight, 45-55 parts of PVC resin, 20-30 parts of stone powder, 3-8 parts of a lubricant, 5-15 parts of a stabilizer, 1-3 parts of dye, 8-12 parts of a plasticizer, 5-10 parts of an antibacterial agent and 5-10 parts of an antistatic agent. The antibacterial agent is a nano-liposome dispersion liquid coated with chitosan quaternary ammonium salt; the antistatic agent is prepared by wrapping nano silver powder with mesoporous nano silicon dioxide, sodium dodecyl sulfate and mica powder. The edge band has antibacterial and antistatic effects. The preparation method comprises the following steps of weighing the raw materials in proportion, mixing, granulating, carrying out extrusion molding, and drying the printed pattern to obtain the edge band finished product. The method has the advantages ofsimple operation and easy production.

Owner:青岛创宇塑胶制品有限公司

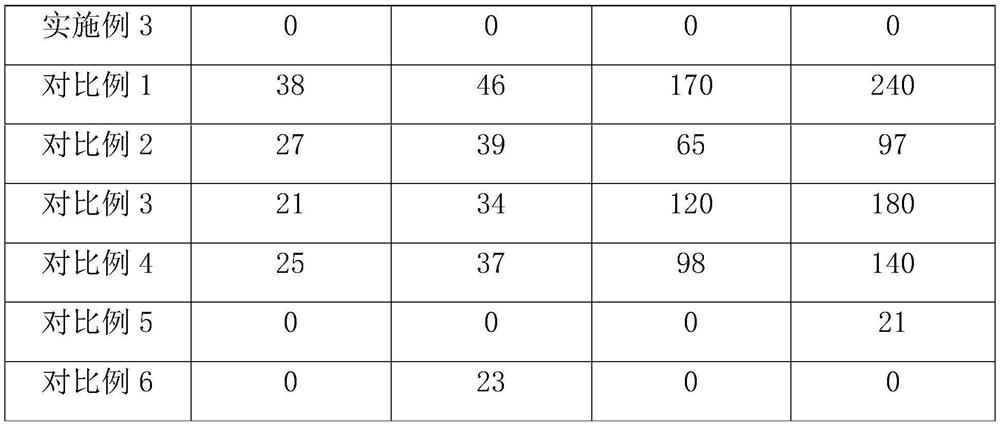

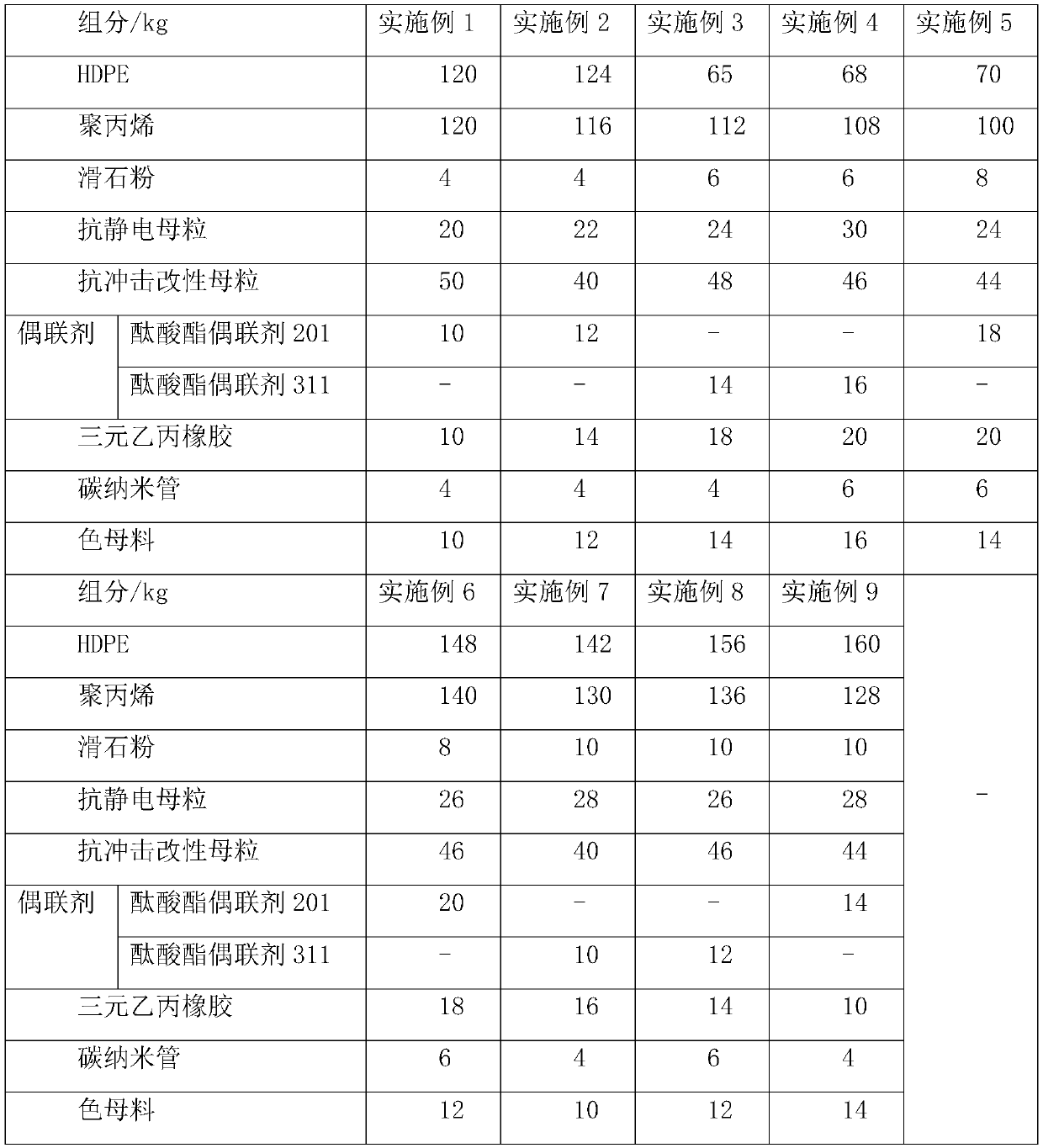

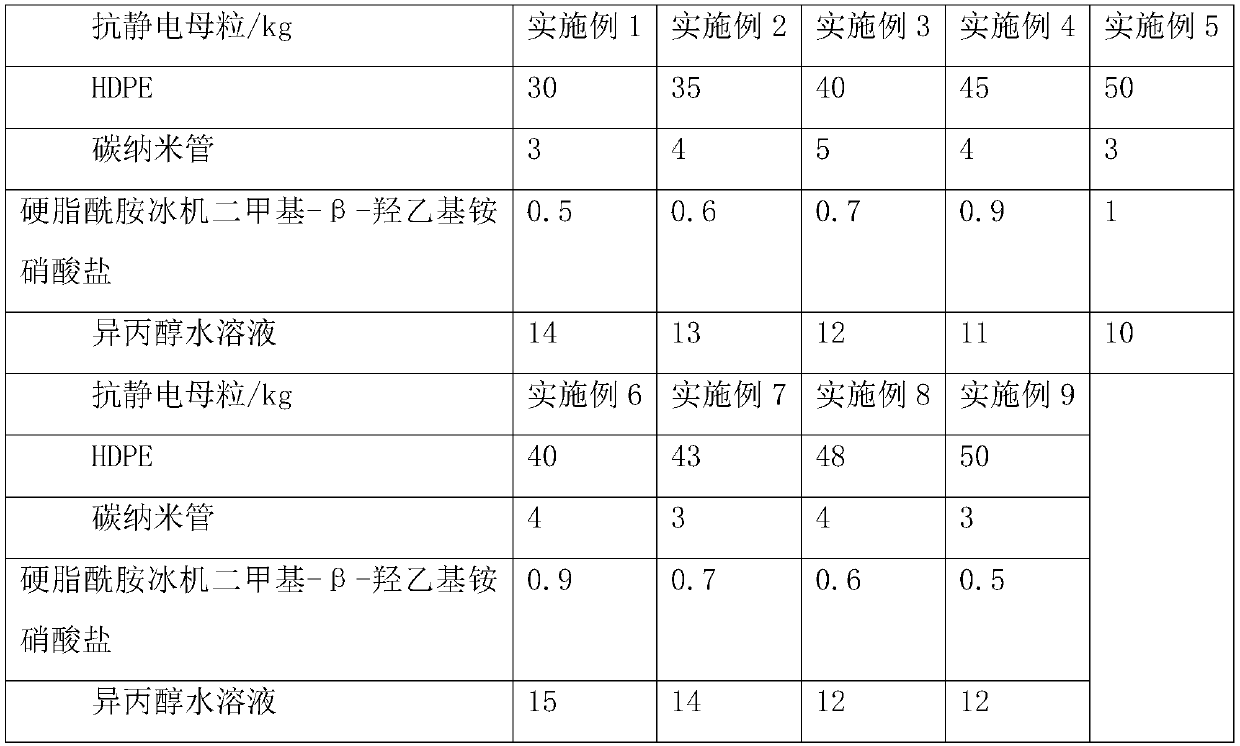

HDPE double-wall corrugated pipe and production process thereof

ActiveCN109880216AIncreased ring stiffnessImprove creep resistanceTubular articlesMasterbatchEthylene-propylene-diene-monomer

The invention relates to an HDPE double-wall corrugated pipe and a production process thereof. The double-wall corrugated pipe is prepared from the following components in parts by weight: HDPE, polypropylene, talcum powder, antistatic masterbatch, anti-impact modified masterbatch, coupling agents, ethylene-propylene-diene monomers, carbon nanotubes and color masterbatch. The production process comprises the following steps: step 1, weighing the raw materials according to parts by weight, then stirring and mixing uniformly to obtain a raw material mixture; step 2, melting the raw material mixture, then extruding through a twin-screw extruder, and then forming through a die to obtain a primary product; step 3, drawing the primary product, and then cutting the primary product according to aspecification to obtain an intermediate product; and step 4, flaring the intermediate product to obtain the double-wall corrugated pipe. According to the HDPE double-wall corrugated pipe and the production process thereof, polypropylene, the anti-impact modified masterbatch, ethylene-propylene-diene monomers and the carbon nanotubes are added into the HDPE double-wall corrugated pipe, so that thedefects of the HDPE double-wall corrugated pipe are overcome, and the ring stiffness and the creep resistance of the corrugated pipe are improved.

Owner:陕西飞天管业科技有限公司

Antistatic environment-friendly coating

InactiveCN105086540AEasy to makeGood effectElectrically-conductive paintsButyl methacrylateChemistry

The invention discloses antistatic environment-friendly coating. The antistatic environment-friendly coating comprises, by weight, 20-30 parts of poly isobutyl ester, 10-30 parts of aluminum hydroxide, 24-48 parts of phosphotriester, 12-18 parts of antimonous oxide, 100-160 parts of methacrylic acid-2-hydroxy ethyl, 80-100 parts of methyl methacrylate, 20-60 parts of methacrylic acid glycerol trilaurate, 12-16 parts of styrene, 150-200 parts of butyl methacrylate, 20-40 parts of methacrylic acid, 8-16 parts of dehydroacetic acid, 20-40 parts of butanol and 8-16 parts of acetone. The antistatic environment-friendly coating is easy to manufacture, non-toxic production materials are selected, the coating is good in use effect and environmentally friendly, a tough coating can be formed, and lasting waterproofness and antistatic performance are achieved.

Owner:启东寅昶精密铸造有限公司

Antistatic decorative board and preparation method thereof

ActiveCN103507374BImprove adhesionUV resistantLayered product treatmentSynthetic resin layered productsFiberAntistatic agent

The invention discloses an antistatic compact grade laminate. A core plate of the antistatic compact grade laminate is made by the following raw materials in percentage by weight: 40-50% of fiber, 35-45% of phenolic resin, 3-8% of antistatic agent, 5-10% of carbon black and 1-3% of coupling agent; and the antistatic agent is coated on the surfaces of decorative papers. During the preparation of the compact grade laminate, the antistatic agent is added in the core plate and the decorative papers on two surfaces of the core plate respectively, so that a stereoscopic antistatic effect jointly acted by interior and surfaces is formed and excellent properties such as antistatic property and high density are obtained; the antistatic compact grade laminate is widely suitable for special industries or occasions having antistatic requirements on building decorative materials; the surface and stereoscopic antistatic property is lasting and not easy to fade way; and the carbon black has electric conductivity. Moreover, according to the invention, the characteristic of being made by paper of the conventional compact grade laminates is changed and craft paper is replaced by fiber, so that the aim of reducing the cost is achieved.

Owner:CHANGZHOU WUJIN ZHONGTIAN COMPUTERROOM EQUIP CO LTD

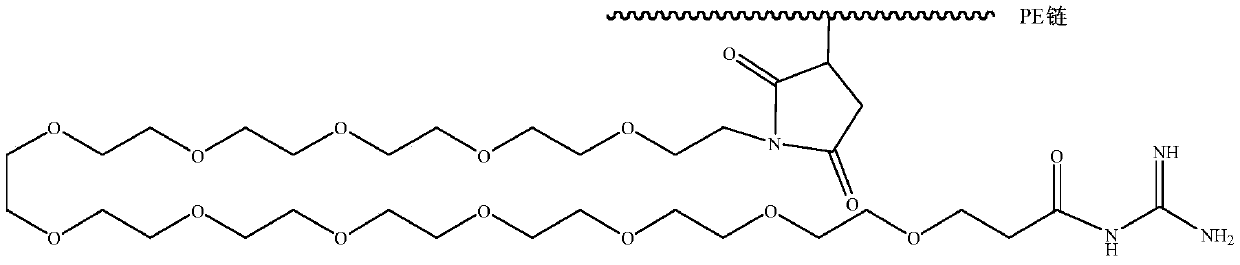

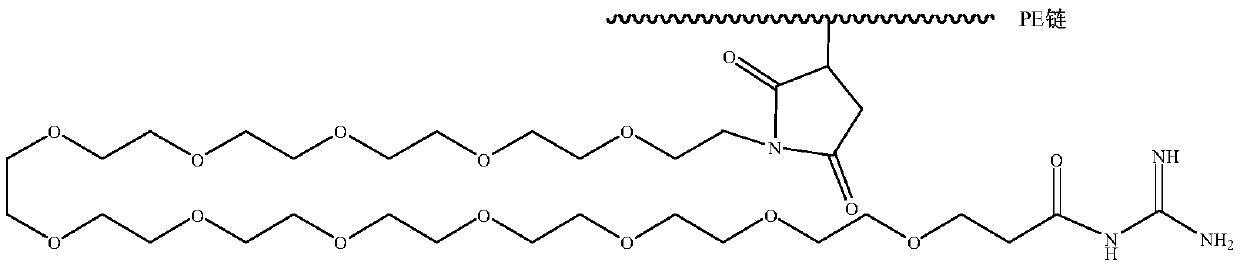

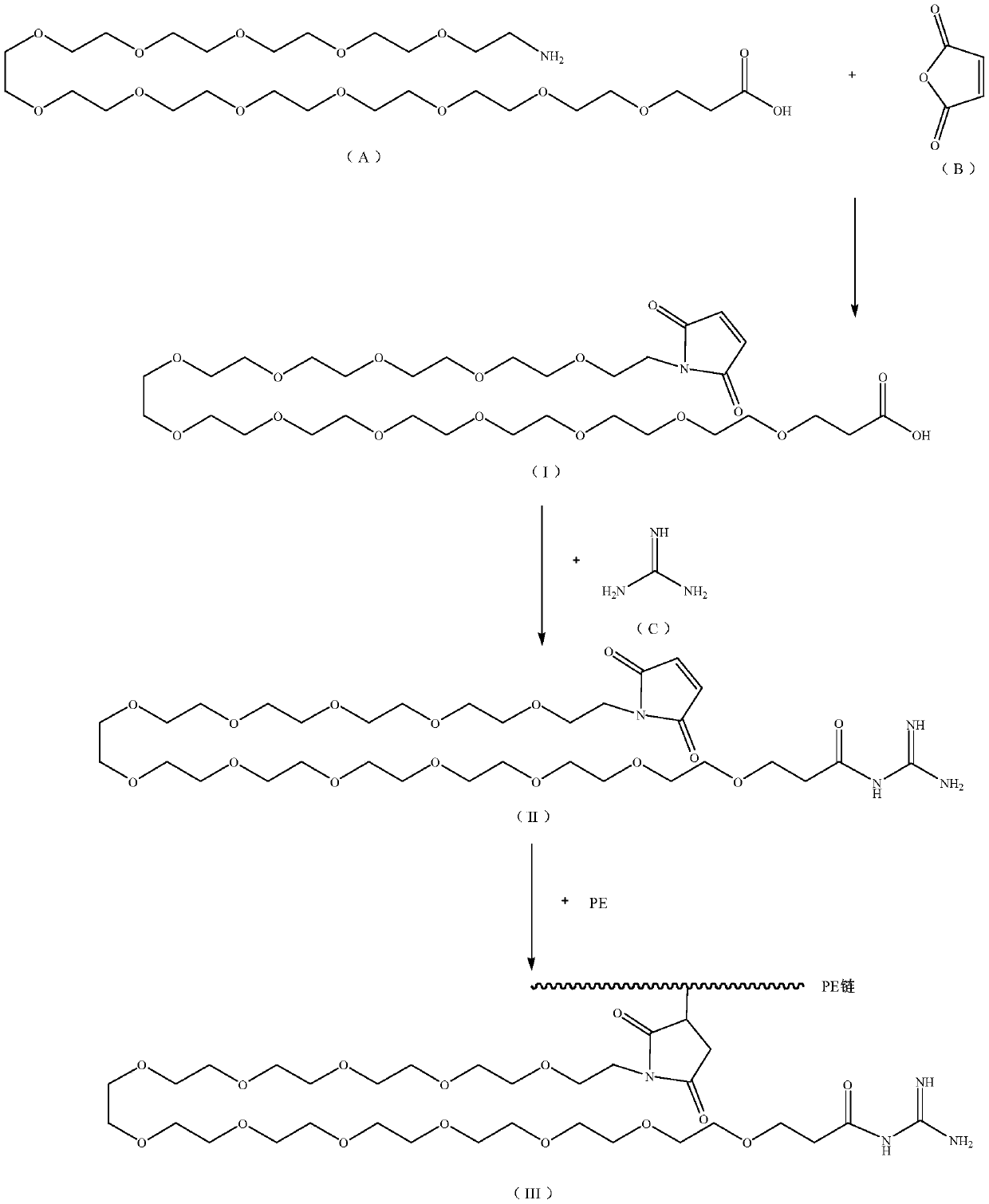

Novel antibacterial antistatic additive for PE and preparation method thereof

ActiveCN111171375AEasy to operateSuitable for industrial productionOrganic chemistryPolymer sciencePolythylene glycol

The invention belongs to the field of plastic processing aids. The invention relates to a novel antibacterial antistatic additive for PE and a preparation method of the novel antibacterial antistaticadditive. The method comprises the following steps: with amino-dodecapolyethylene glycol-carboxylic acid (A), maleic anhydride (B), guanidine (C) and polyethylene as raw materials, performing multi-step amidation reaction; and performing blending extrusive blow-molding treatment to obtain a target product, namely the novel antibacterial and antistatic additive. The antistatic agent has certain flame-retardant and plasticizing effects while effectively overcoming the defects of durability and no bacterium resistance of the existing antistatic agent, structurally provides antibacterial and antistatic groups, reduces the consumption of a plasticizer, reduces electrostatic accumulation, improves the flame retardancy, prolongs the service life, enriches the application field, and is particularly suitable for food packaging films.

Owner:泉州绿陆新材料科技有限公司

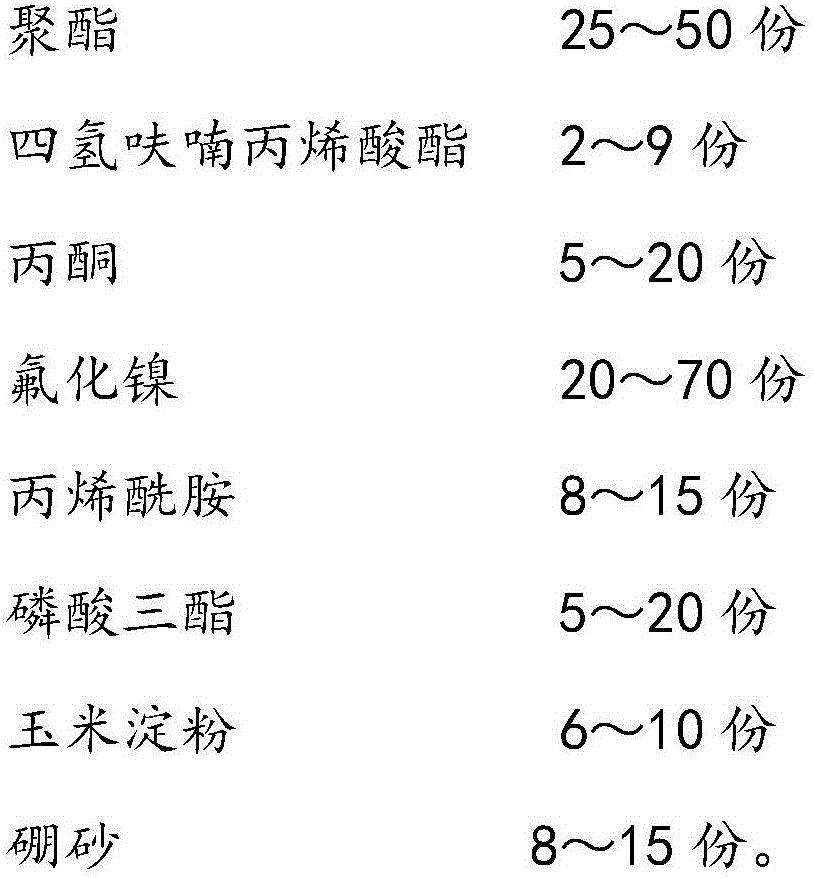

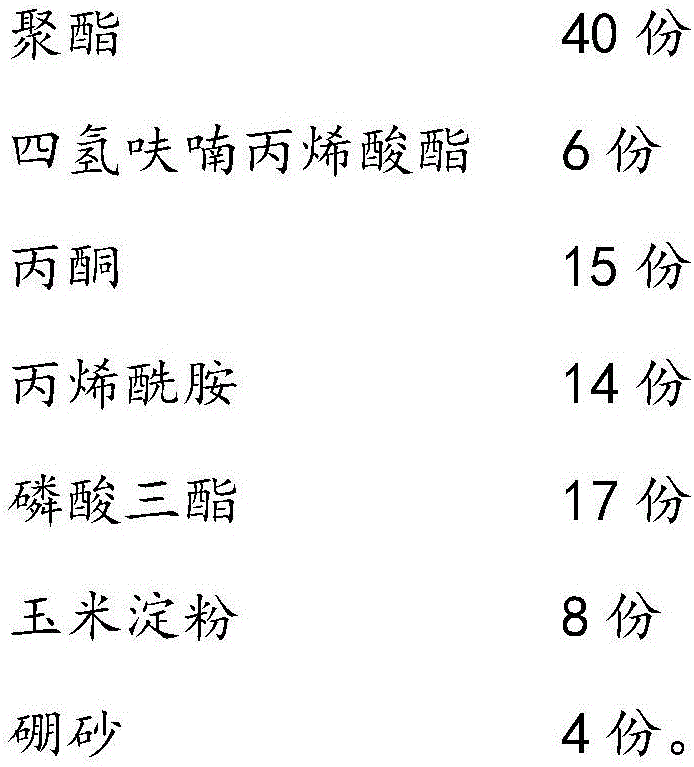

Antistatic environment-friendly glue

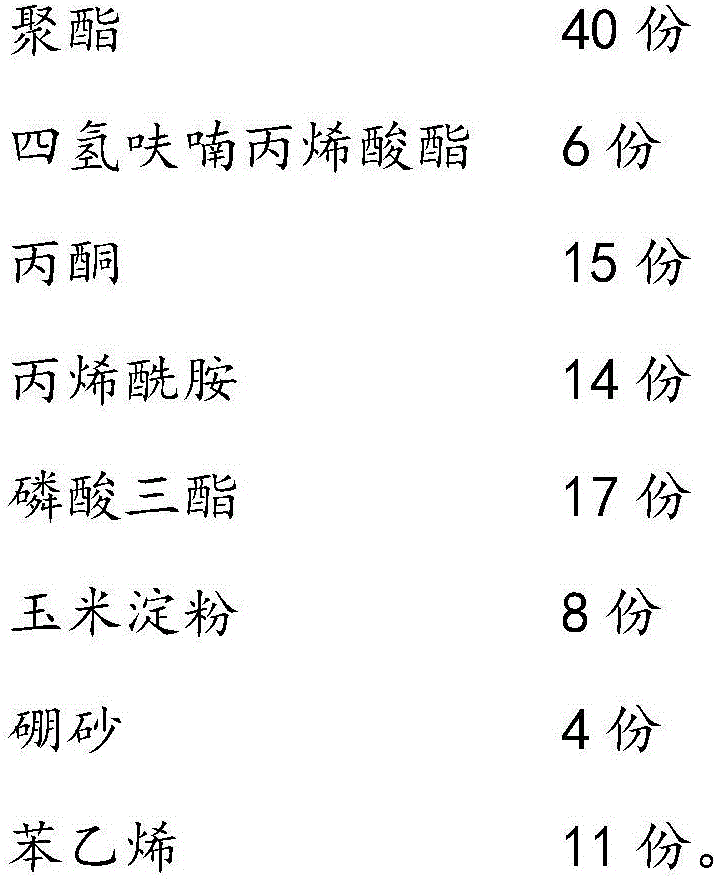

InactiveCN106366947AEasy to useEasy to makeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyesterTetrahydrofuran

The invention relates to antistatic environment-friendly glue. The antistatic environment-friendly glue is prepared from, by weight, 25-50 parts of polyester, 2-9 parts of tetrahydrofuran acrylate, 5-20 parts of acetone, 8-15 parts of acrylamide, 5-20 parts of phosphotriester, 6-10 parts of corn starch and 8-15 parts of borax. The antistatic environment-friendly glue is easy to make, the adoption production raw materials are free of toxicity, and the glue is good in use effect and environmentally friendly, can form a tough coating and has lasting waterproofness and an antistatic property.

Owner:梁乔保

Coloring agglomerate for polyethylene packing film and its prepn process

Owner:CHUNHUI PIGMENT MATERIAL XINTAI

Antistatic plush fabric

PendingCN110714345AImprove antistatic performanceFirmly attachedDyeing processPolymer scienceCotton fibre

The invention discloses an antistatic plush fabric. The antistatic plush fabric comprises cotton fibers or viscose fibers as raw materials. An antistatic agent, a penetrating wetting agent, a dispersing agent and a leveling agent are added into a dyeing solution, wherein dye in the dyeing solution is light-fast dye; the antistatic agent is a light stabilizer which is compatible and compounded withthe light-fast dye; the dye and the antistatic agent are uniformly attached and coated on the surface of the cotton fibers or viscose fibers for a long time through a dyeing process, thus, antistaticdyed plush fibers are obtained, and the antistatic dyed plush fibers are subjected to a weaving process to obtain the antistatic plush fabric; and the antistatic treatment method is simple, and durable antistatic and dyeing effects can be simultaneously achieved.

Owner:常熟市云宇织造有限公司

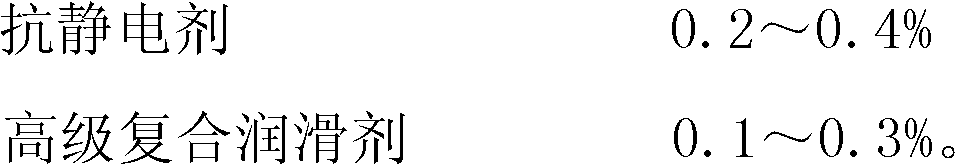

Color master batches used by polyvinylidene fluoride OK cable product and preparation method of color master batches

InactiveCN102432964AReduce surface resistanceHigh antistatic performancePolyvinylidene fluoridePOLYETHYLENE WAX

The invention provides color master batches for a polyvinylidene fluoride OK cable. The color master batches consist of a pigment, a plastic auxiliary agent and carrier resin, wherein the plastic auxiliary agent contains N-N' aethylenum di-octadecanamide, polyethylene wax, zinc stearate, an antistatic agent and a high-grade composite lubricant. The preparation method comprises the following steps of: mixing the materials according to the formula; kneading the materials in a kneading pot at a high speed; and putting the uniformly stirred mixture into a double-screw extruder of which the host temperature is controlled to be between 180 and 210 DEG C, and extruding the mixture; cooling, drying and cutting the mixture into particles to obtain the needed color master batches. The color master batches disclosed by the invention have the advantages of good dispersity and strong covering power, are easy to stir, are bleeding-free and static-free, and cannot cause environmental pollution.

Owner:江苏昊华光伏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com