PTFE isolating membrane for medical protective clothing and preparation method of PTFE isolating membrane

A technology of PTFE and isolation membrane, which is applied in the field of medical protective clothing, can solve the problems of poor air permeability, moisture permeability, poor protection uniformity, and unsatisfactory work, and achieve good flame retardancy, small frictional resistance, and good filtration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

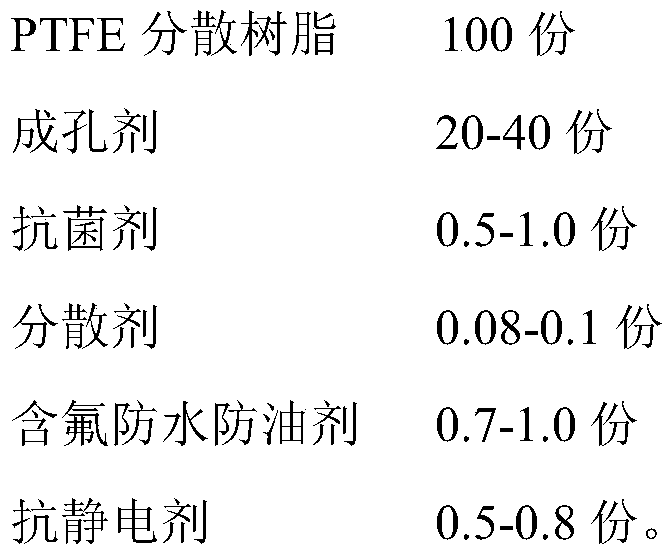

[0041] The medical protective clothing PTFE isolation membrane described in the present embodiment 1, in parts by mass, has the following composition of raw materials:

[0042]

[0043]

[0044] in:

[0045] Described PTFE dispersion resin is 106C, and manufacturer is Japan Daikin.

[0046] The technical indicators of 106C are: bulk density 563g / L, tensile strength 34.6MPa, moisture content 0.001%, average particle size 420μm.

[0047] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is iso-dodecane; the mass ratio of white oil to iso-dodecane is 4.0:0.9.

[0048] The antibacterial agent is anatase titanium dioxide.

[0049] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 3-trimeric epoxyhexafluoropropane amidopropyl betaine.

[0050] The fluorine-containing waterproof and oil-repellent agent is an organic fluorine resin, and the organic fluorine resin is a mixture of TG-528A and ...

Embodiment 2

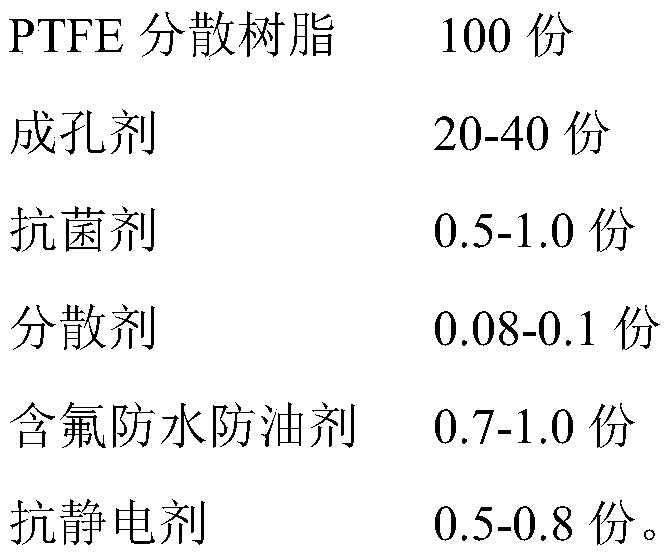

[0066] The medical protective clothing PTFE isolation film described in the present embodiment 2, in parts by mass, has the following composition of raw materials:

[0067]

[0068] in:

[0069] The PTFE dispersion resin is DF-206, and the manufacturer is Shandong Dongyue Polymer Material Co., Ltd.

[0070] The technical indicators of DF-206 are: the tensile strength is 34.4MPa, the bulk density is 500g / L, and the particle size is 475 microns.

[0071] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is isomerized hexadecane; the mass ratio of white oil to isomerized hexadecane is 3.5:0.8.

[0072] The antibacterial agent is anatase titanium dioxide.

[0073] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 8-3-9 fluorocarbon-hydrocarbon flexible bridge mixed-chain diquaternary ammonium.

[0074] The fluorine-containing waterproof and oil-repellent agent is an organic fluorine resin, ...

Embodiment 3

[0090] The medical protective clothing PTFE isolation film described in the present embodiment 3, in parts by mass, has the following composition of raw materials:

[0091]

[0092] in:

[0093] Described PTFE dispersion resin is 106C, and manufacturer is Japan Daikin.

[0094] The technical indicators of 106C are: bulk density 563g / L, tensile strength 34.6MPa, moisture content 0.001%, average particle size 420μm.

[0095] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is iso-dodecane; the mass ratio of white oil to iso-dodecane is 5:1.

[0096] The antibacterial agent is anatase titanium dioxide.

[0097] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 8-3-9 fluorocarbon-hydrocarbon flexible bridge mixed-chain diquaternary ammonium.

[0098] The fluorine-containing waterproof and oil-repellent agent is an organic fluorine resin, and the organic fluorine resin is a mixture of TG-52...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com