Electroconductive color slurry and low-resistance polyurethane material thereof

A polyurethane material and color paste technology, which is applied in the field of polyurethane materials, can solve the problems of insufficient improvement in the antistatic performance of polyurethane materials, such as the physical and mechanical properties of polyurethane materials, and achieve control of cell nucleation rate, low humidity dependence, and improved electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

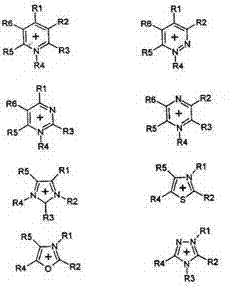

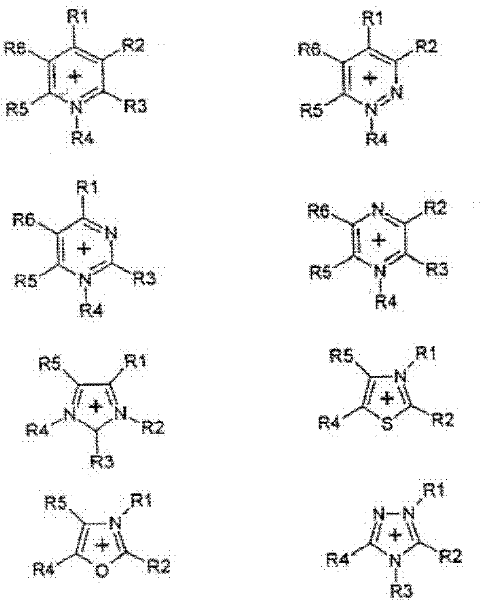

[0028] Embodiment 1, a kind of conductive color paste, including the following raw materials by weight: carbon powder (0.7 μm) 55, 1-ethyl-3-methylimidazolium chloride 43, DA dispersant (sodium polyacrylate) 0.5, Titanate coupling agent 0.2.

[0029] Preparation method: fully stir and mix carbon powder, ionic liquid (1-ethyl-3-methylimidazolium chloride), dispersant and titanate coupling agent, and then use a three-roll mill at a rate of one kilogram per 10 minutes. Grind at a speed for 3 times, or use a ball mill for 3 times at a speed of 1 kg per 15 minutes, so that the mixture forms a homogeneous phase, that is, a conductive color paste A is obtained.

Embodiment 2

[0030] Embodiment 2, a kind of conductive color paste, including the following raw materials by weight: carbon powder (0.7 μm) 50, 1-ethyl-3-methylpyridine bisfluoroalkylsulfonylamide salt 53, DA dispersant (sodium polyacrylate) 0.5, phosphate coupling agent 1.

[0031] Preparation method: fully stir and mix carbon powder, ionic liquid (1-ethyl-3-methylpyridine bisfluoroalkylsulfonylamide salt), dispersant and titanate coupling agent, and then use a three-roll mill Grind 4 times at a speed of 1 kg per 10 minutes, or use a ball mill for 3 times at a speed of 1 kg per 15 minutes, so that the mixture forms a homogeneous phase, that is, conductive paste B is obtained.

Embodiment 3

[0032] Embodiment 3, a kind of conductive color paste, including the following raw materials by weight: carbon powder (0.7 μm) 45, 1-ethyl-3-methylimidazole nitrate 52, DA dispersant (sodium polyacrylate) 0.5, Titanate coupling agent 0.5.

[0033]Preparation method: fully stir and mix carbon powder, ionic liquid (1-ethyl-3-methylimidazolium nitrate), dispersant and titanate coupling agent, and then use a three-roll mill at a rate of one kilogram per 10 minutes. Grind at a speed for 5 times, or use a ball mill for 4 times at a speed of 1 kg per 15 minutes, so that the mixture forms a homogeneous phase, that is, a conductive color paste C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com