Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Large hydrogen storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

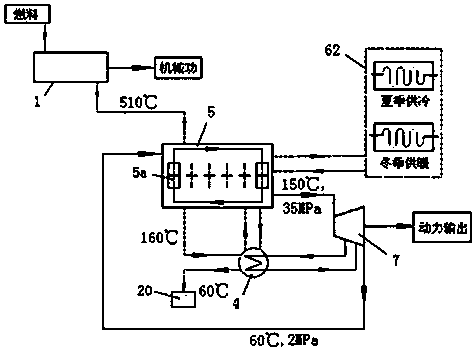

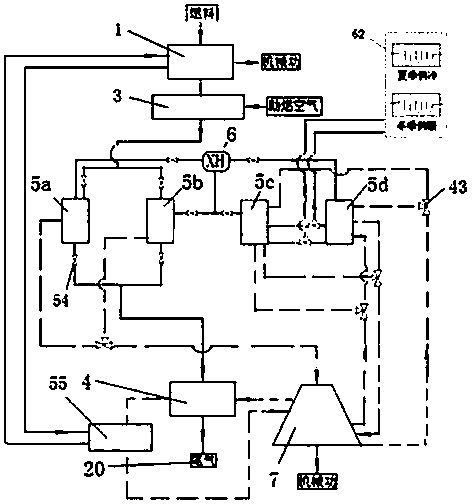

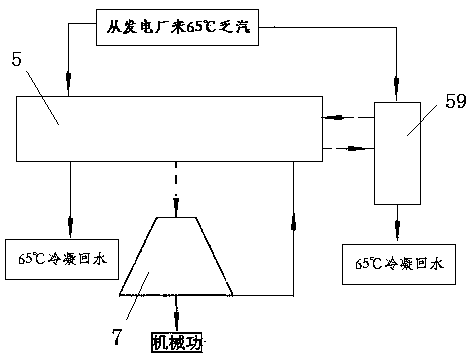

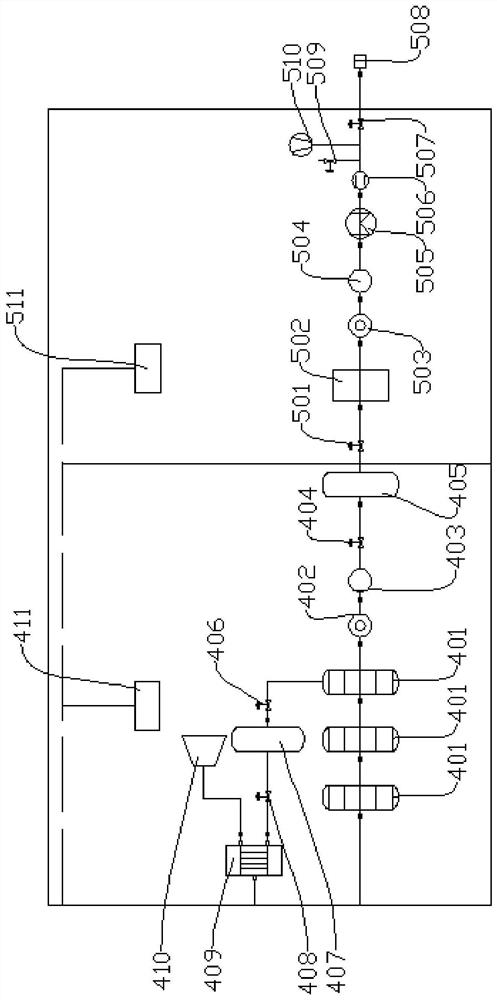

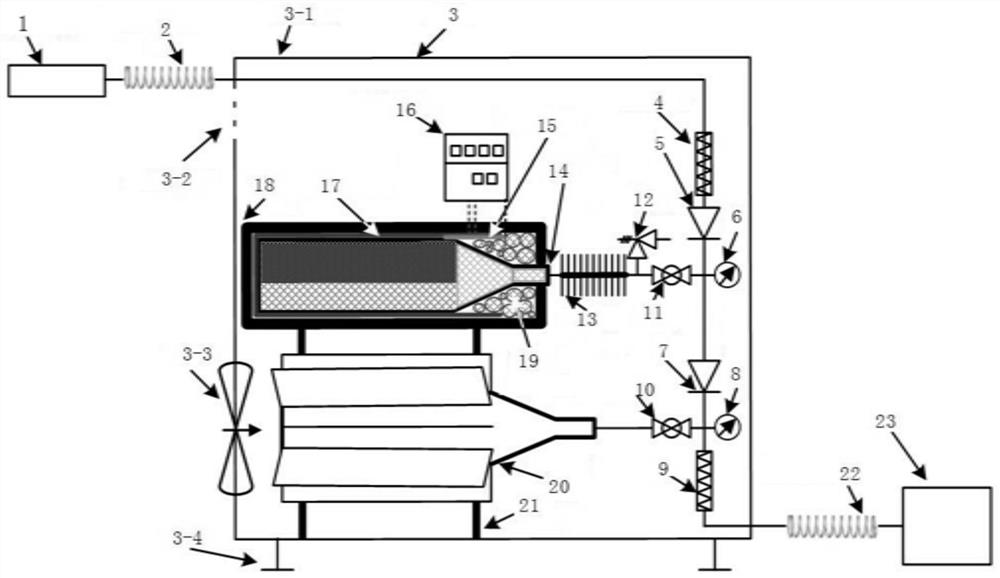

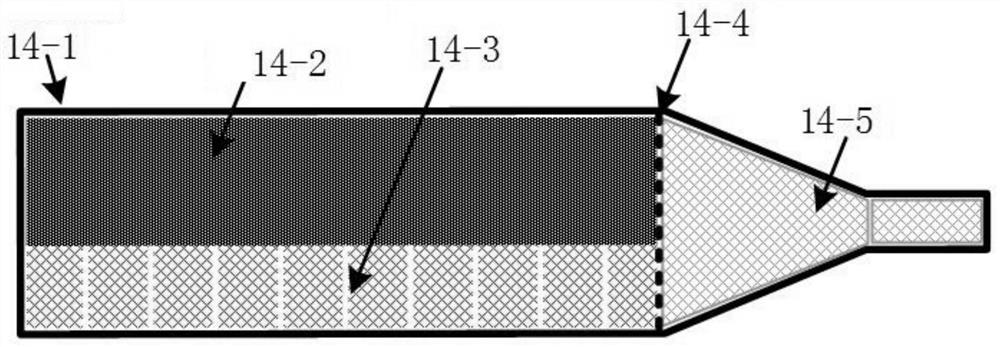

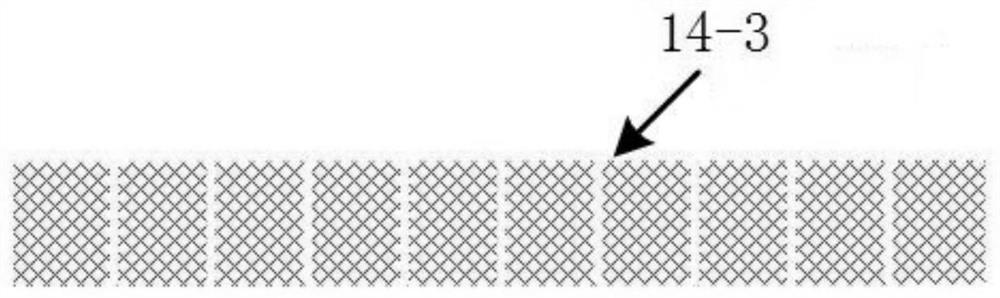

Heat engine-hydrogen reaction bed combined circulating system

ActiveCN107605559ADischarge cleaningImprove efficiencySteam engine plantsHigh pressure hydrogenExhaust gas

The invention relates to a heat engine-hydrogen reaction bed combined circulating system comprising a heat engine, a hydrogen compression unit, an intermediate reheater and an expansion machine. The hydrogen compression unit is provided with at least one set of hydrogen reaction beds, each set comprises the at least two hydrogen reaction beds, and the hydrogen reaction beds mutually communicate. The expansion machine adopts multiple stages, and a thermal medium outlet of the heat engine is connected to a tail gas discharging opening through the hydrogen reaction beds and the intermediate reheater. The hydrogen reaction beds of the hydrogen compression unit are connected to an inlet of the expansion machine, a first-stage outlet and / or a second-stage outlet of the expansion machine are / is connected with the intermediate reheater or the hydrogen compression unit, an outlet of the intermediate reheater or the hydrogen compression unit is connected with a next-stage inlet of the expansionmachine, and the outlets of the expansion machine are connected to the hydrogen reaction beds of the hydrogen compression unit. The heat engine and the hydrogen reaction beds of the hydrogen compression unit are combined, tail gas waste heat after the heat engine does work is fully utilized to heat metal hydride, high-pressure hydrogen is generated to promote the expansion machine to do work, andthus the thermal efficiency is advantageously improved.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

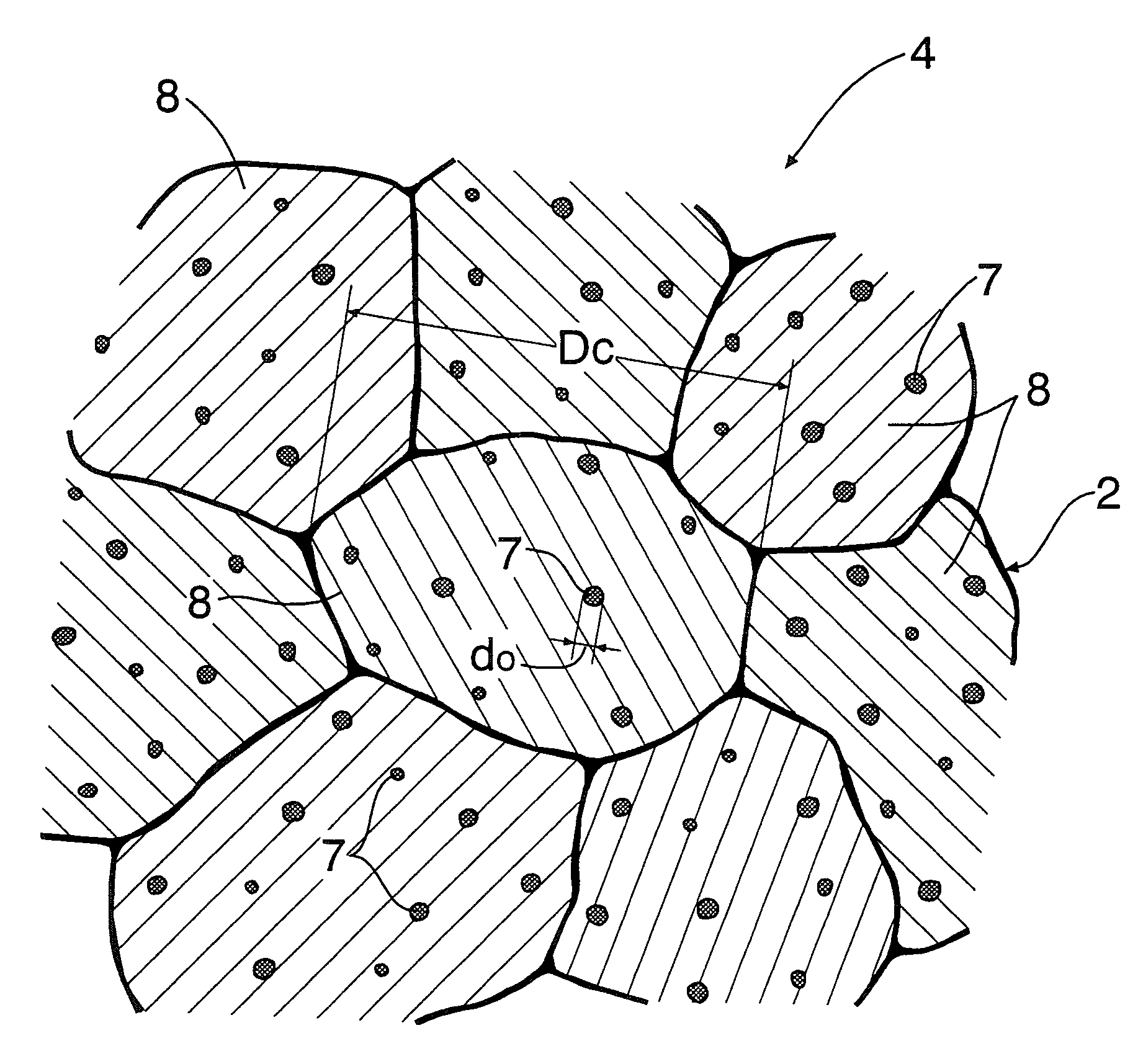

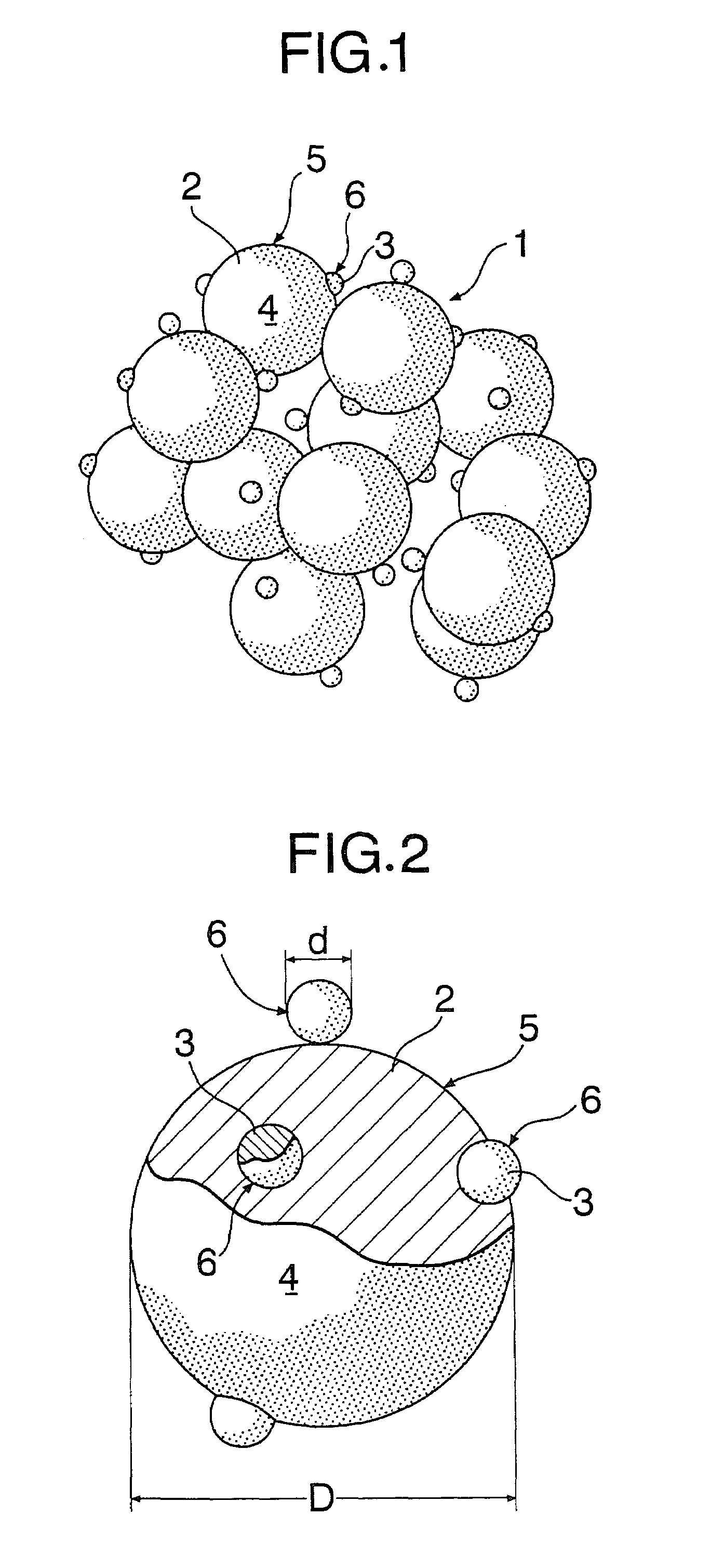

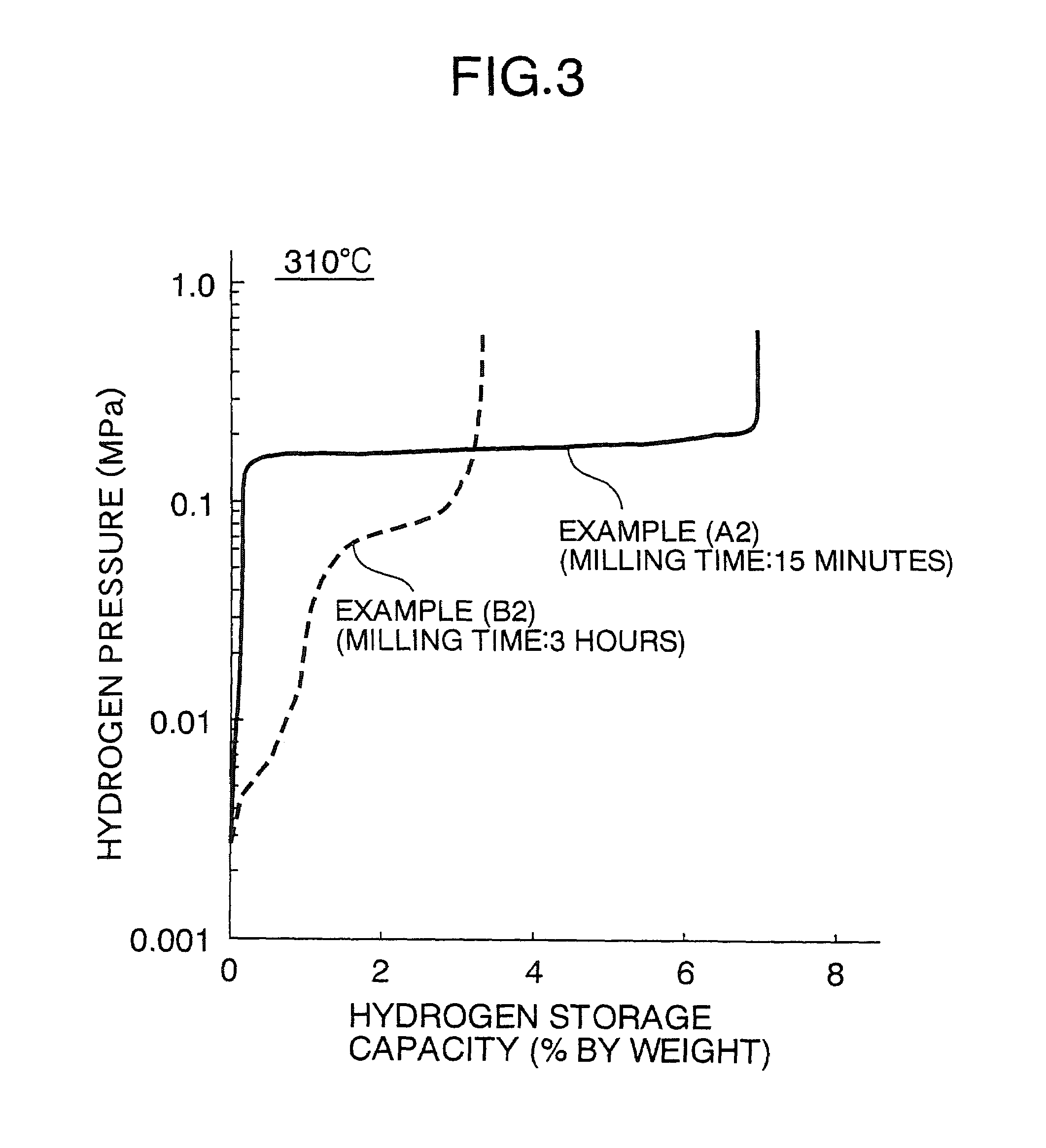

Hydrogen absorbing alloy powder and hydrogen storing tank for mounting in a vehicle

InactiveUS7060120B1Shorten milling timeLong milling timeHydrogenTransportation and packagingMetalHydrogen absorbing alloy

To produce a hydrogen absorbing alloy powder which is an aggregate of alloy particles each including a metal matrix and added-components, an aggregate of metal matrix particles and an aggregate of added-component particles are used, and mechanical alloying is carried out. In this case, the relationship between the particle size D of the metal matrix particles and the particle size d of the added-component particles is set at d≦D / 6. Thus, the milling time can be shortened remarkably.

Owner:HONDA MOTOR CO LTD

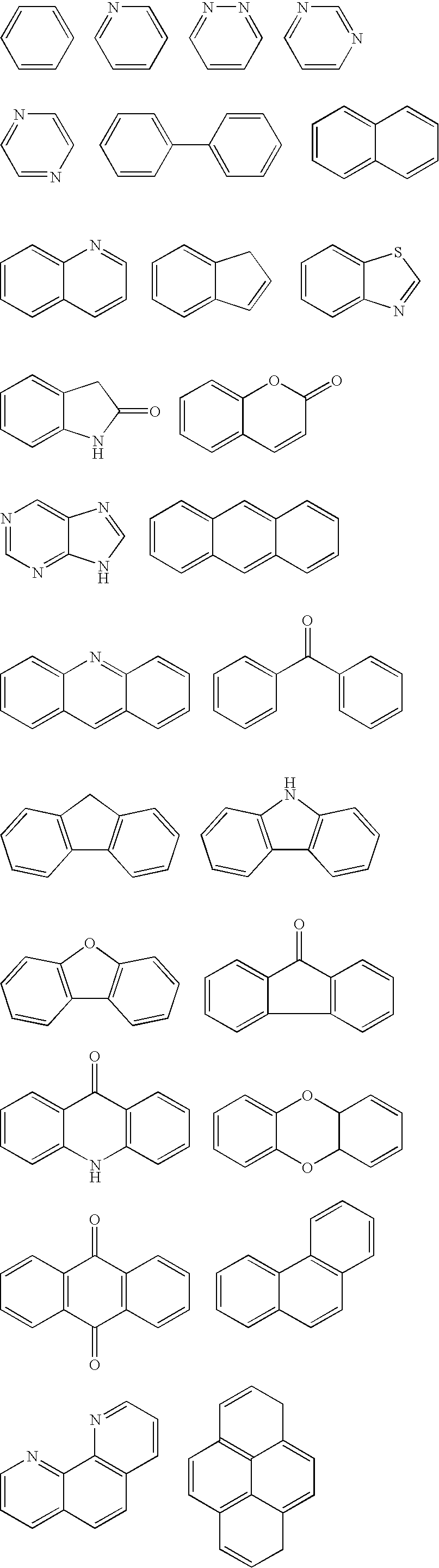

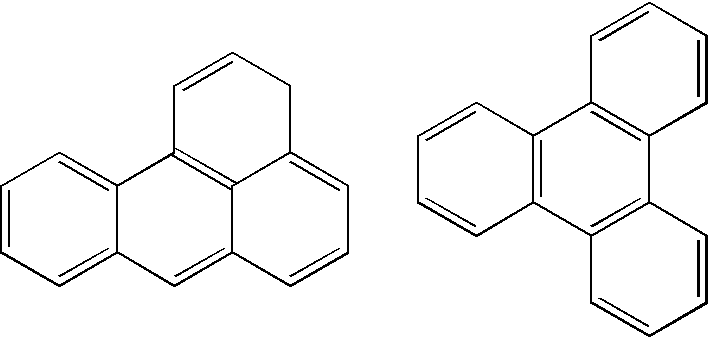

More advanced preparation method of organic-transition metal hydride complexes containing aryl group or alkyl group as hydrogen storage materials

InactiveUS20100036145A1Strong reducing powerHigh yieldGroup 1/11 organic compounds without C-metal linkagesGroup 5/15 element organic compoundsArylAlkaline earth metal

The present invention relates to a more advanced preparation method of organic-transition metal hydride as a hydrogen storage material, precisely a more advanced preparation method of organic-transition metal hydride containing aryl or alkyl group that facilitates safe and reverse storage of massive amount of hydrogen.The present invention relates to a preparation method of an organic-transition metal hydride comprising the steps of preparing a complex reducing agent composition by reacting alkali metal, alkali earth metal or a mixture thereof and (C10˜C20) aromatic compound in aprotic polar solvent; and preparing organic-transition metal hydride by reacting the prepared complex reducing agent composition and organic-transition metal halide.The method of the present invention has advantages of minimizing the numbers and the amounts of byproducts by using a complex reducing agent and producing organic-transition metal hydride safely without denaturation under more moderate reaction conditions.

Owner:HANWHA CHEMICAL CORPORATION

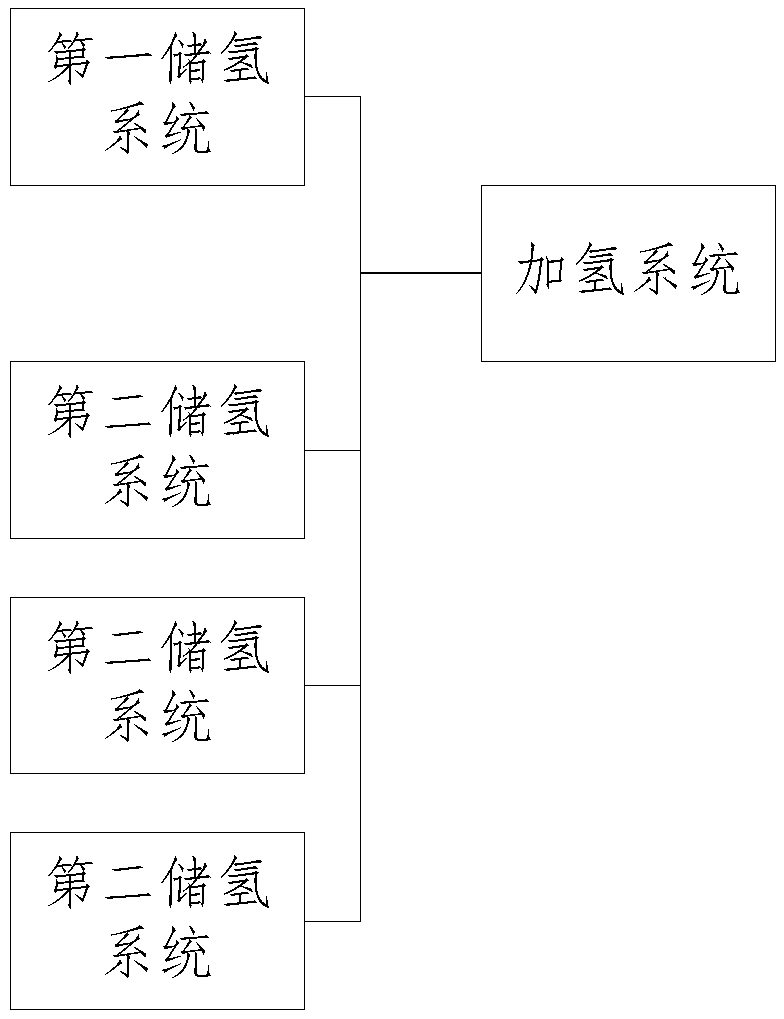

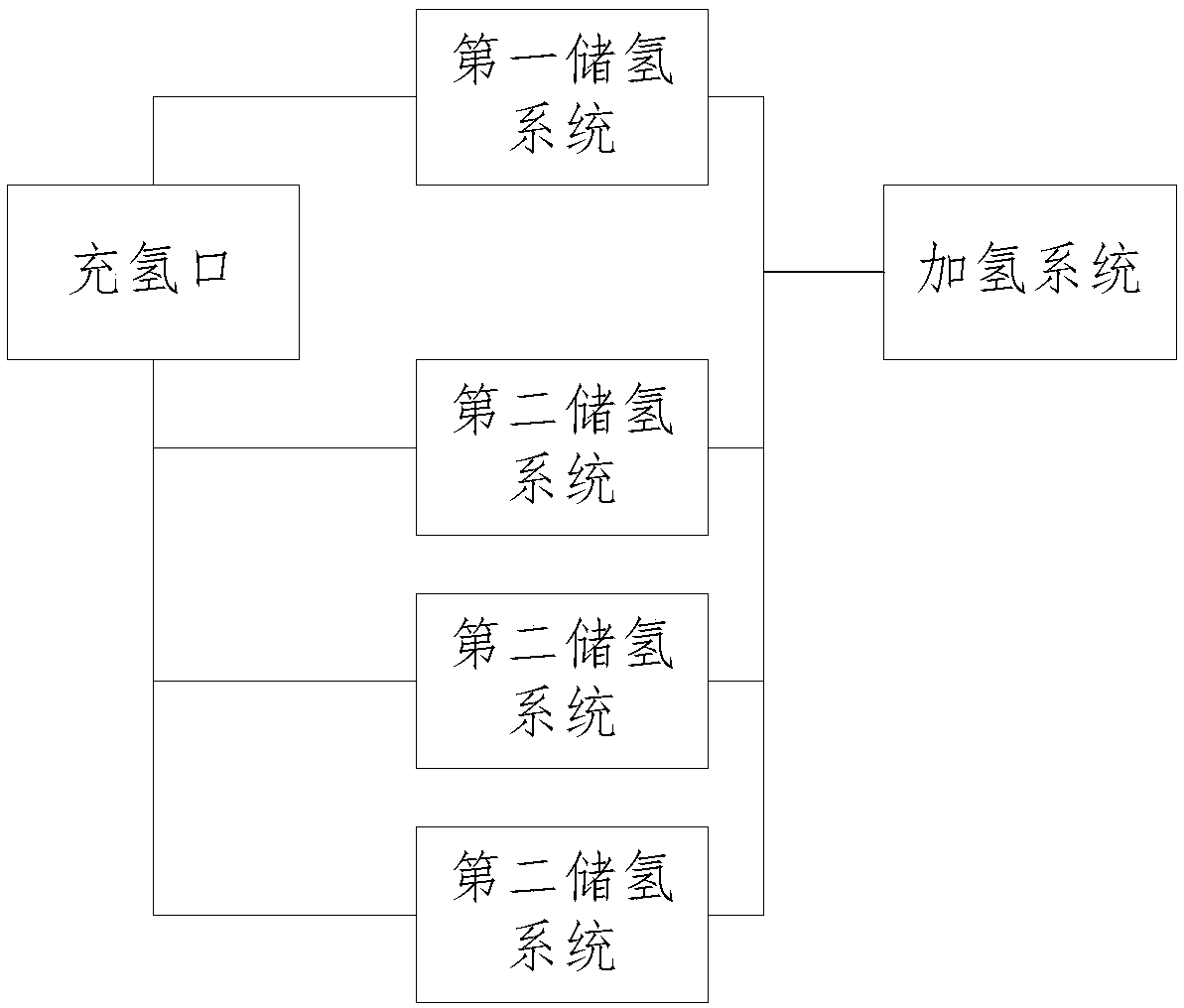

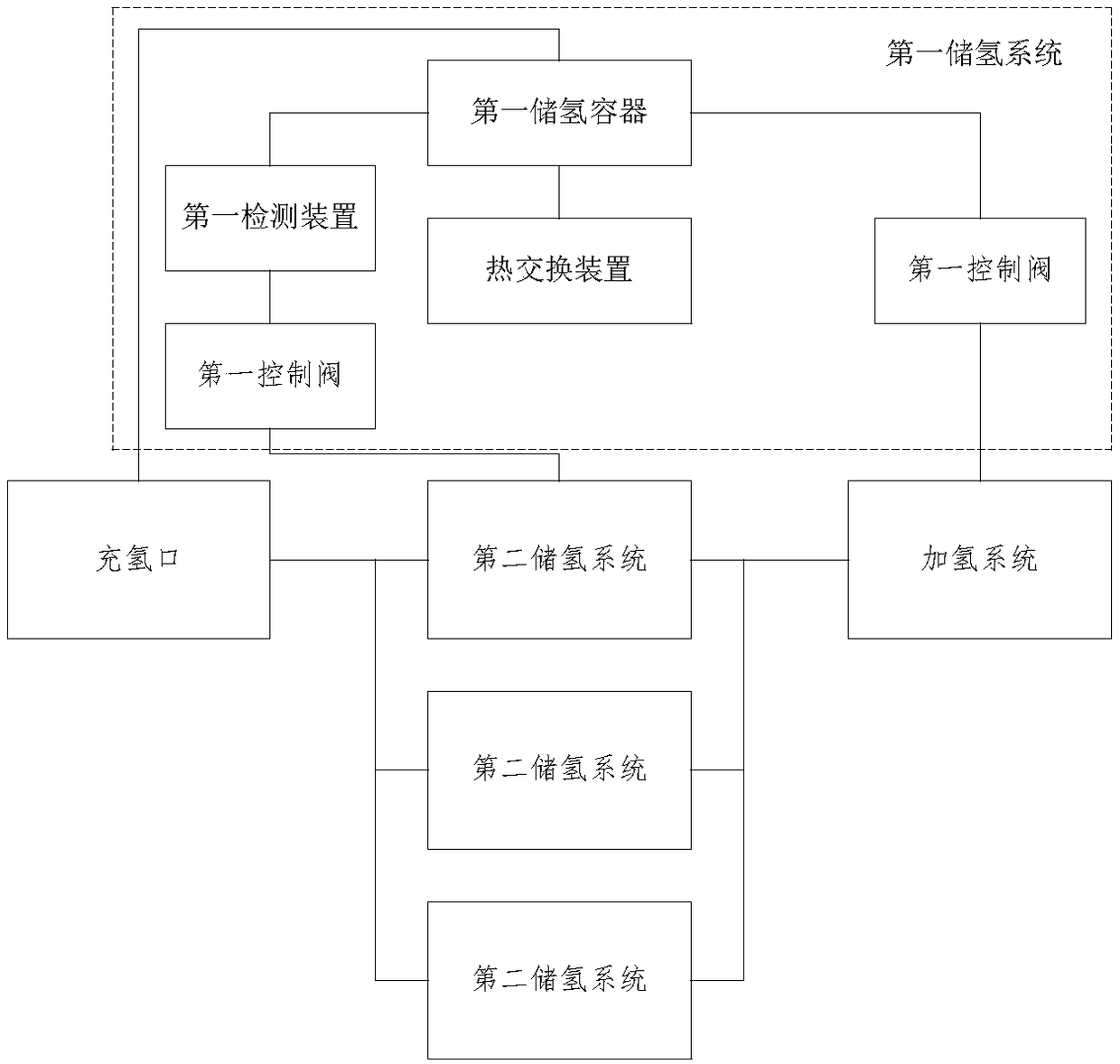

Hydrogenation station and hydrogenation control method

InactiveCN109210370AReduce construction costsShort cycleFluid handledRoad vehiclesHydrogen storage systemPurchasing

The invention provides a hydrogenation station. The hydrogenation station comprises a first hydrogen storage system, second hydrogen storage systems and a hydrogenation system. The first hydrogen storage system communicates with the second hydrogen storage systems. At least three second hydrogen storage systems are arranged. The three second hydrogen storage systems communicate with the hydrogenation system after being communication in parallel. The hydrogenation system is used for hydrogenation for hydrogen purchasing equipment and communicates with the first hydrogen storage system and the second hydrogen storage systems. The hydrogenation station, an oiling station and a gas station can be jointly built, the hydrogenation station can be loaded on a transportation tool, and a vehicle-mounted movable hydrogenation station is formed. The hydrogenation station is large in hydrogen storage volume and can serve as hydrogen transportation equipment. A better-optimized hydrogenation controlmethod can achieve self-pressurizing and is higher in hydrogen utilization rate and safety. The advantages that the hydrogenation station construction cost and the hydrogen transportation cost are reduced, and usage is convenient are achieved.

Owner:BEIJING JONTON HYDROGEN TECH

Method for compositing storage hydrogen from hydrogen cage-type compound

ActiveCN101804963AGentle conditionsImprove harsh high pressure conditionsOrganic compound preparationHydroxy compound preparationAlcoholProton

The invention discloses a method for compositing storage hydrogen from a hydrogen cage-type compound; organic matter serves as hydrogen storage material, and simultaneously two methods are adopted to composite the storage hydrogen; the hydrogen not only can exist on a cage-type main molecule body in the form of a proton, but also can be stored in a cage-type hole in the form of a hydrogen molecule. The hydrogen storage material of the invention stores hydrogen in two ways, and the alcohol and the phenol of the main skeleton molecule body which forms hydrate store the hydrogen in the form of protons; hydrogen bonds between the organic molecules interact to form an inclusion compound, and the hydrogen molecules serve as guest molecules and are wrapped in the cage-type hole; the gas storage density is high and can be improved by 100 to 300 percent compared with pure hydrate storage hydrogen; and the gas storage conditions are mild.

Owner:SOUTH CHINA UNIV OF TECH

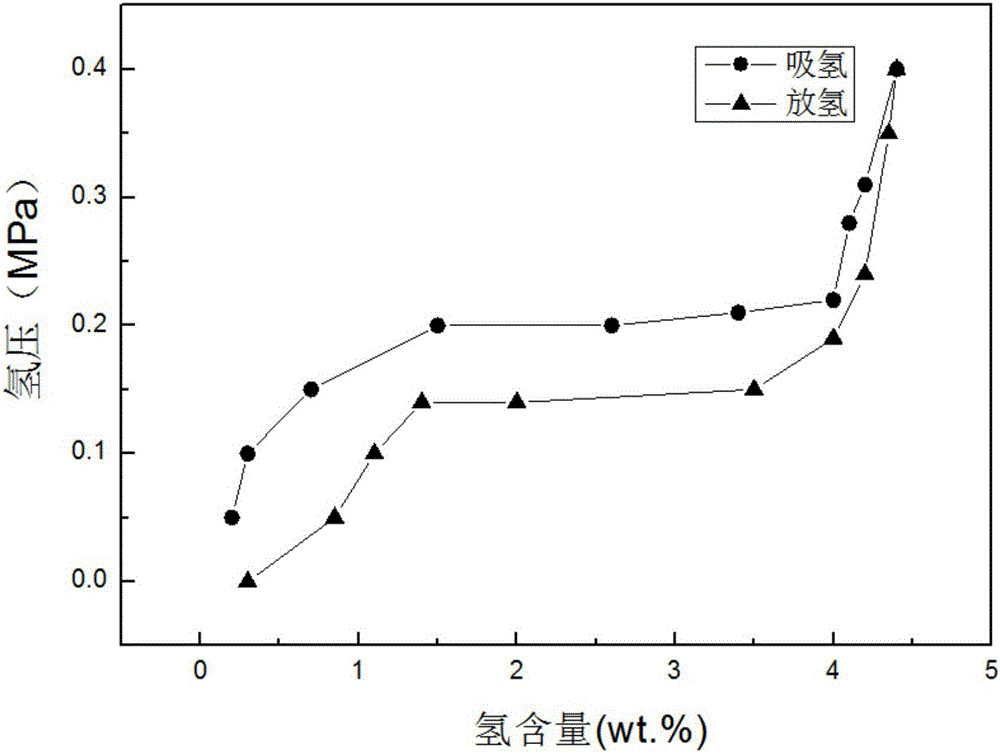

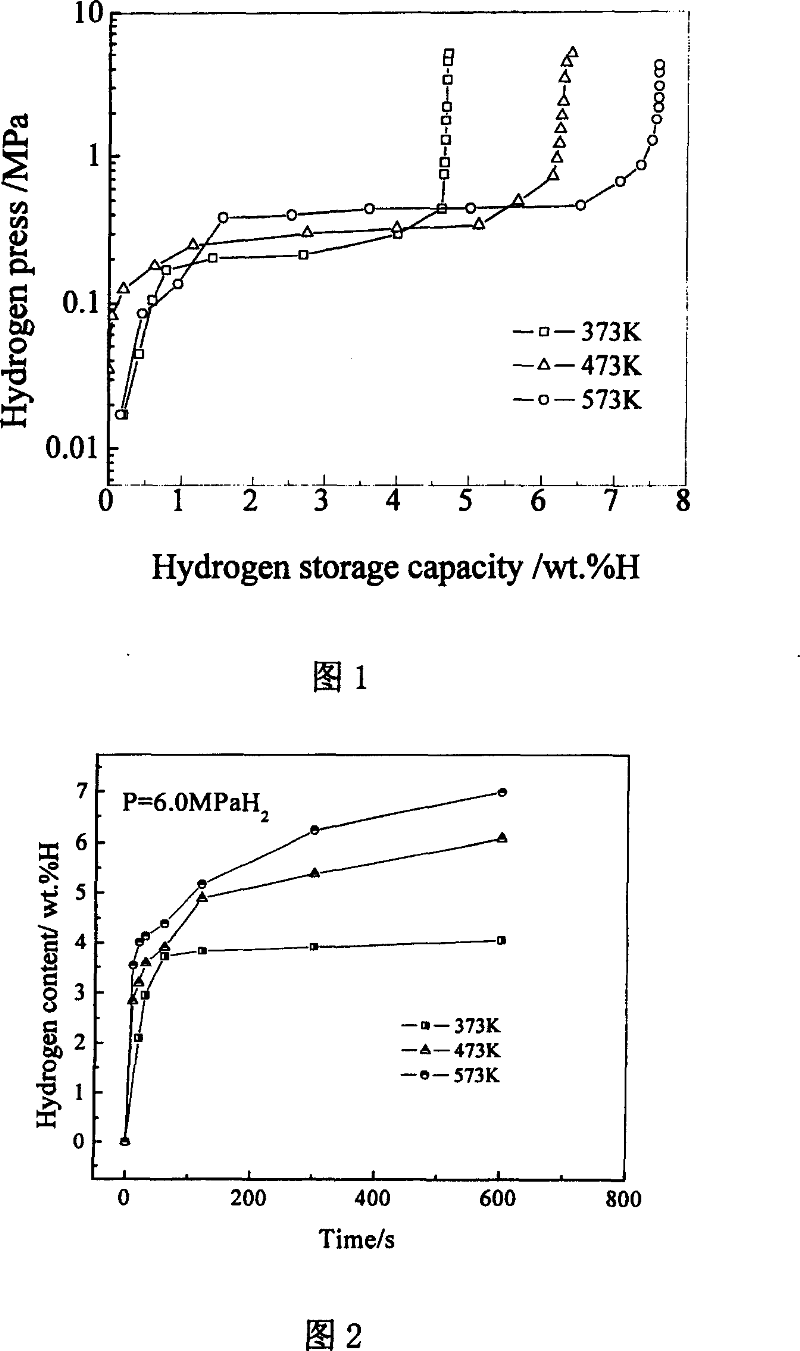

Magnesium-based complex phase hydrogen storage material and preparation thereof

InactiveCN101279717ALarge hydrogen storage capacityLow hydrogen release temperatureMultiple metal hydridesHydrogen fuelMagnesium

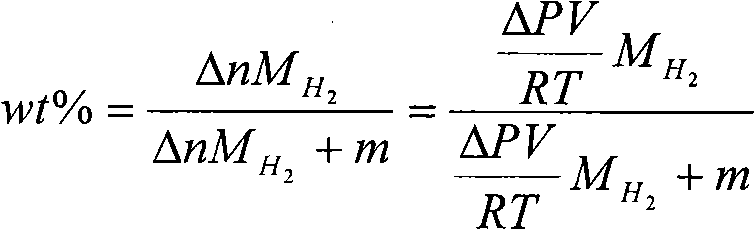

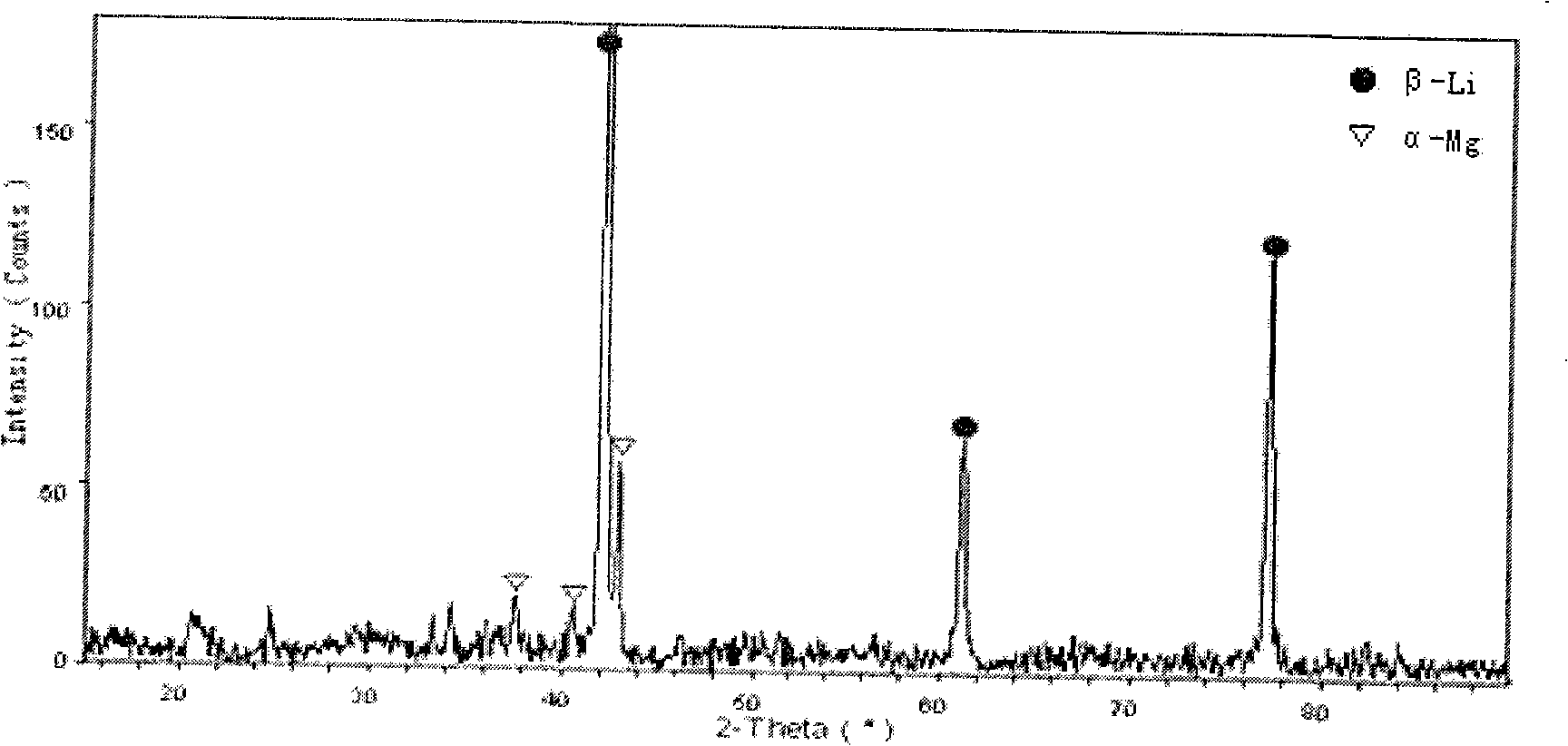

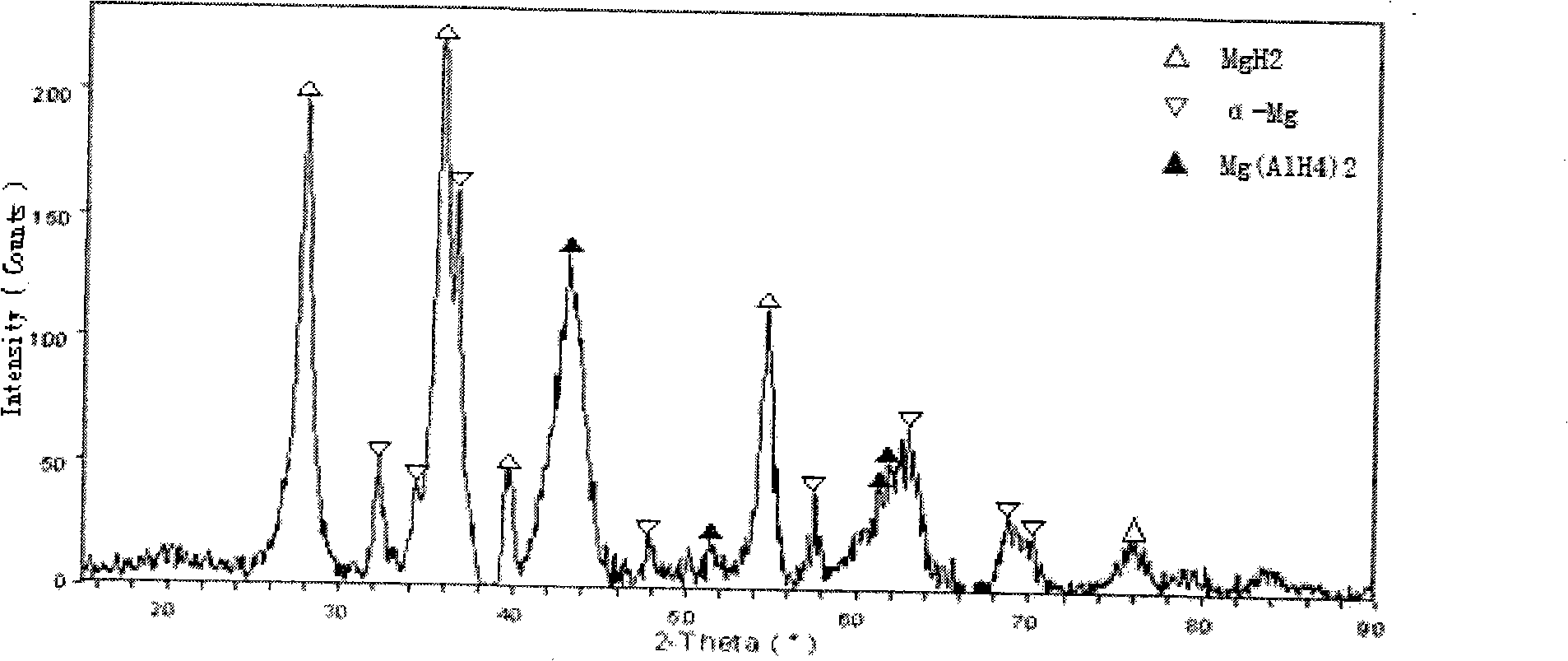

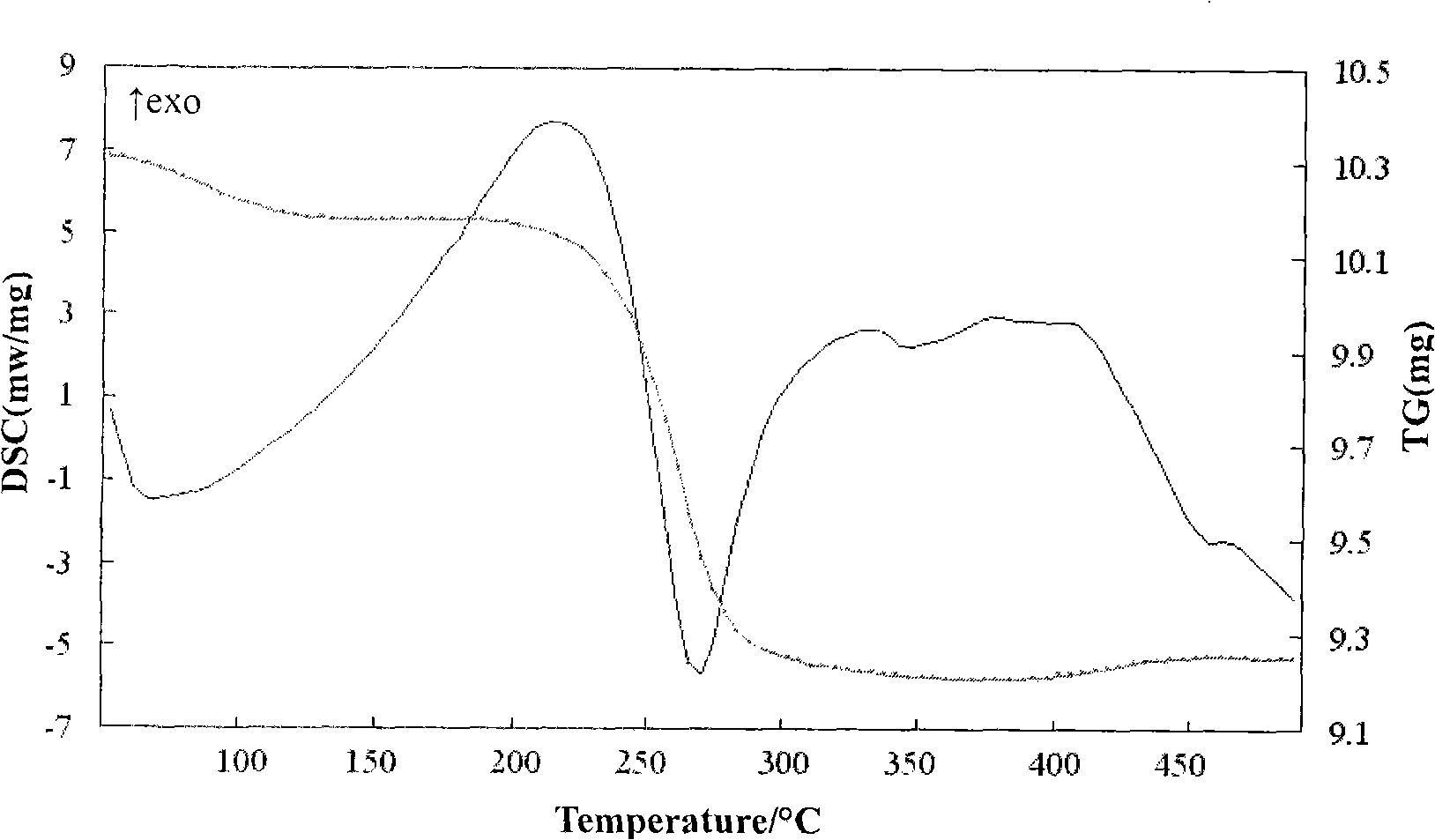

The invention provides high-volume mg-based multiphase hydrogen storage material and a preparation method thereof. A fusion casting and ball milling method is adopted, which comprises the specific steps: (1) under vacuum or argon protection, Mg-Li-Al alloy ingot is melted and cast in an induction furnace; (2) the ingot is milled into fines with a milling machine and is thinning ground in a ball milling machine for 2-20 hours; (3) reaction milling is carried out under hydrogen atmosphere; the hydrogen pressure is 0.1-1 MPa; hydrogen is filled in a ball milling tank to the initial value of the hydrogen pressure at short intervals during the ball milling process; and the way of compulsory cooling is adopted to control the working temperature in the ball milling tank less than 50-60 DEG C; then the mg-based multiphase hydrogen storage material is prepared after argon packaging. The preparation process of the method and modification of the material are accomplished simultaneously. The initial hydrogen desorption peak temperature of the prepared hydrogen storage material is only 62 DEG C and the hydrogen storage amount is as high as 10.6wt percent. The hydrogen storage material is black nano-powder and has large hydrogen storage amount, low temperature and rapid speed for hydrogen desorption. The material can be used for hydrogen fuel vehicles, rechargeable batteries and fuel cells, etc. The method has moderate preparation condition, simple device and convenient operation.

Owner:CHONGQING UNIV

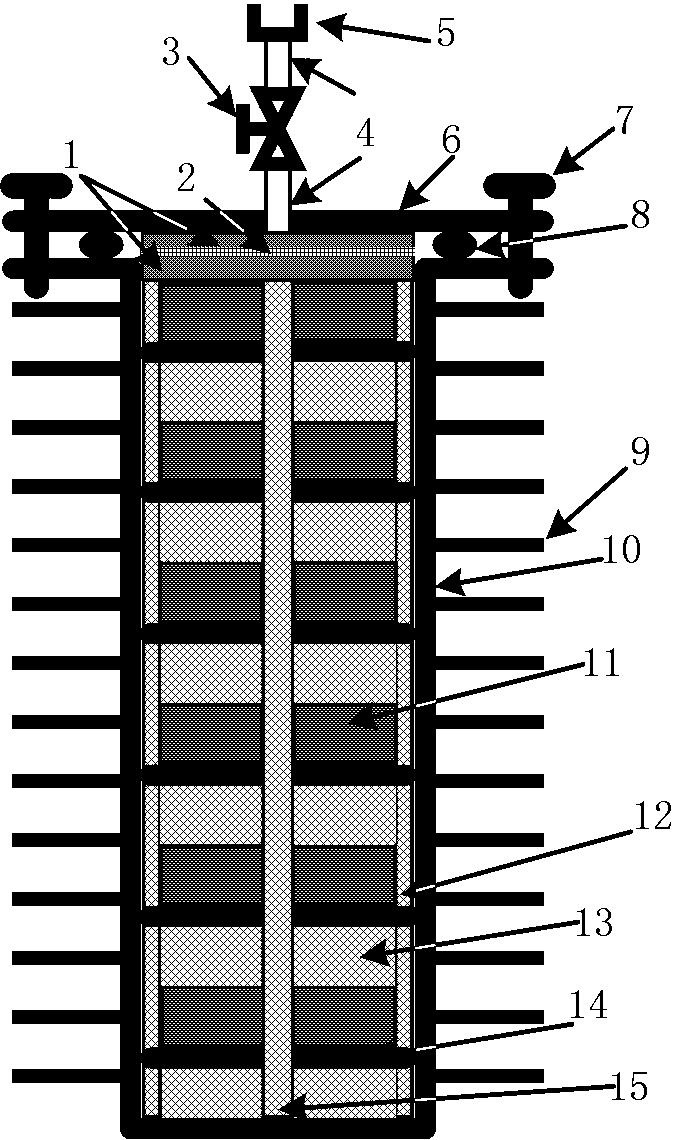

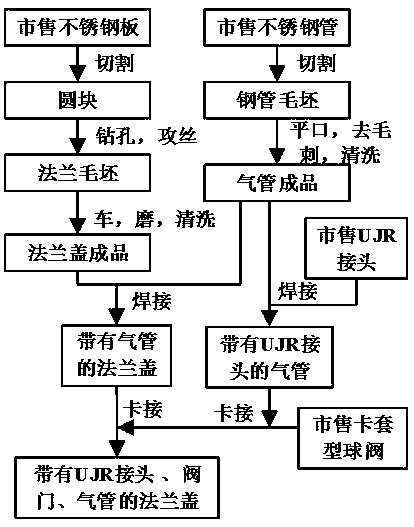

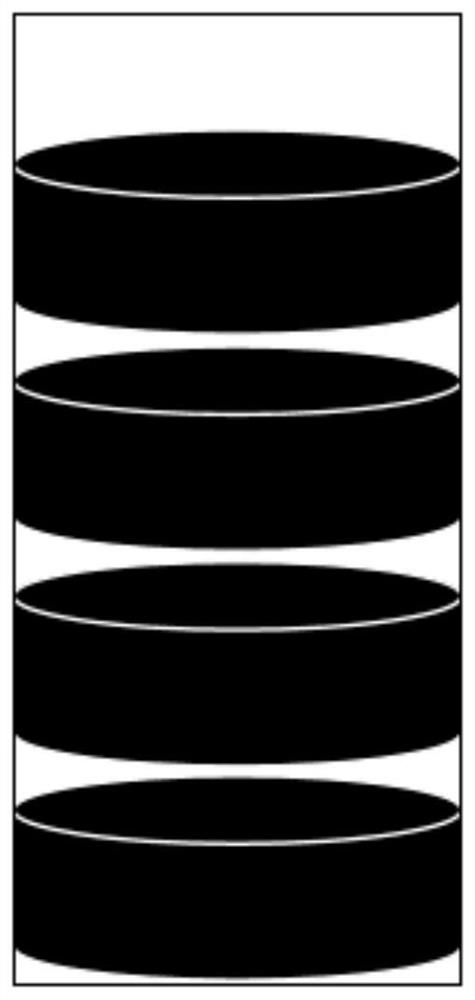

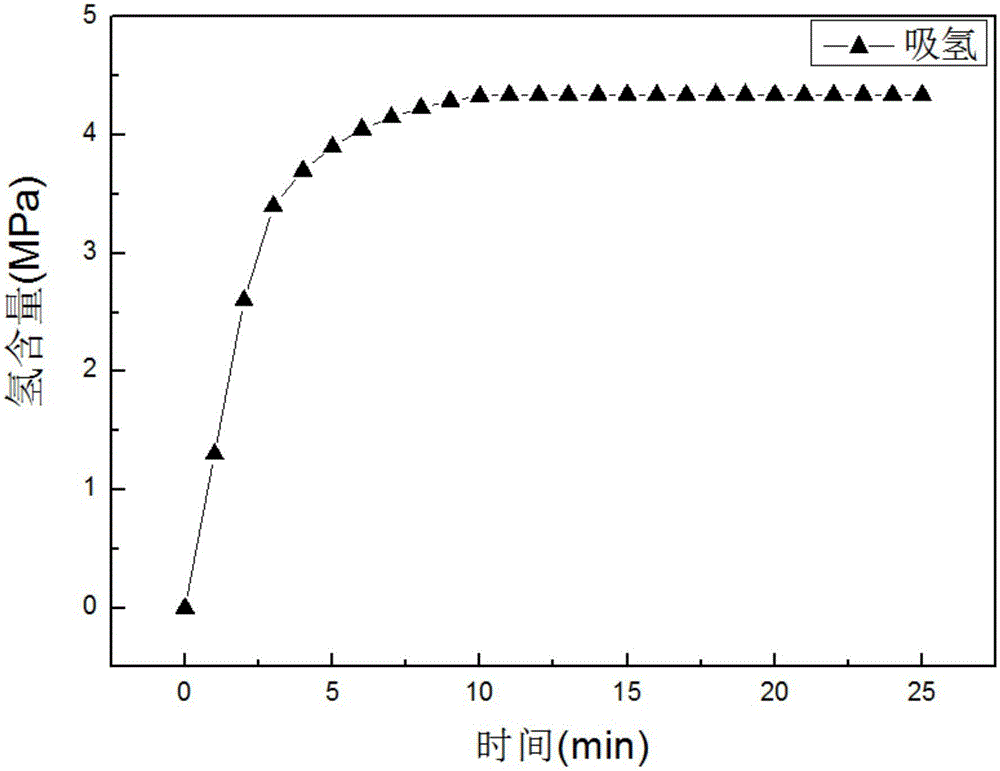

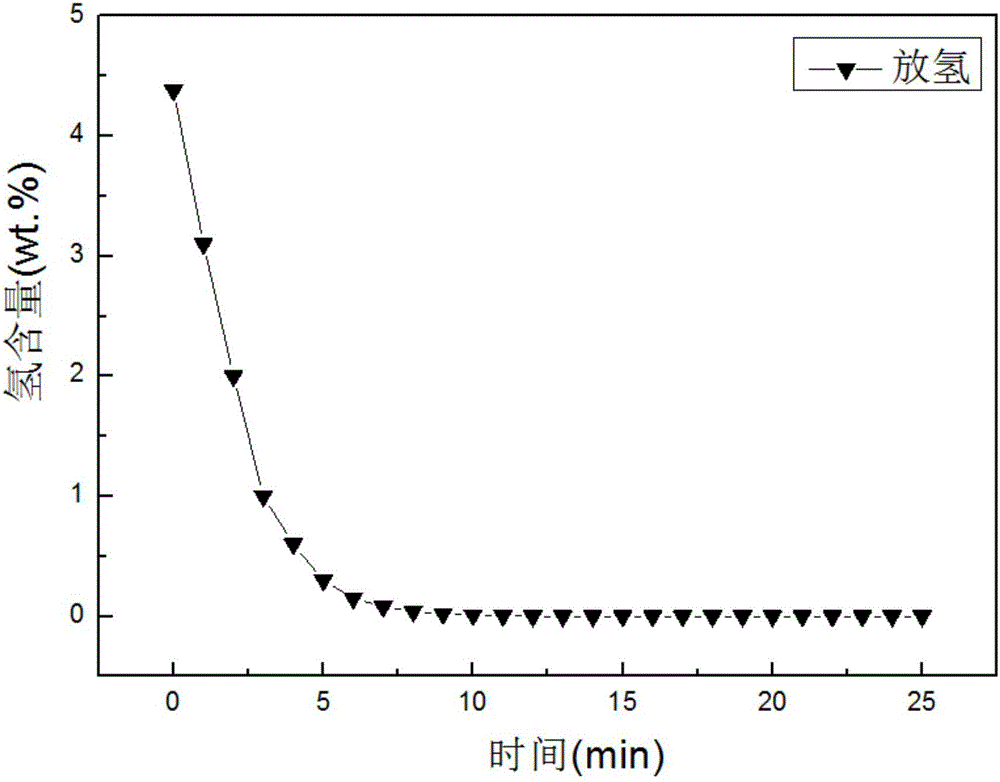

Manufacturing method of metal-hydride hydrogen storage tank

ActiveCN111195808ASimple structureImprove space utilizationVessel manufacturingVessel wallsCircular discMetallic hydrogen

The invention relates to a manufacturing method of a metal-hydride hydrogen storage tank. The method includes the steps of machining of a tank body, machining of a flange cover, machining of foam copper elements, preparation of hydrogen storage alloy powder and assembly line assembling and production of the hydrogen storage tank. The hydrogen storage tank comprises parts including a round foam copper cover, a mat type copper net, a clamping sleeve type ball valve, an air pipe, a UJR joint, the flange cover, bolts, an O-shaped sealing ring, cooling fins, the tank body, the hydrogen storage alloy powder, a foam copper drum, a foam copper disk, a copper-water heating pipe, a foam copper cylinder and the like. The manufacturing method is high in production efficiency, high in yield and low inmanufacturing cost, the metal-hydride hydrogen storage tank manufactured with the method is simple in structure, high in space utilization rate, large in hydrogen storage amount, good in sealing performance, excellent in heat and mass transfer performance, high in hydrogen absorption and release speed and good in long-time use safety, breakage of the tank body due to hydrogen absorption expansionof a hydrogen storage material can be avoided, no cooling media are required to be introduced, repeated recycling can be realized, and the use cost is low.

Owner:YANGZHOU UNIV

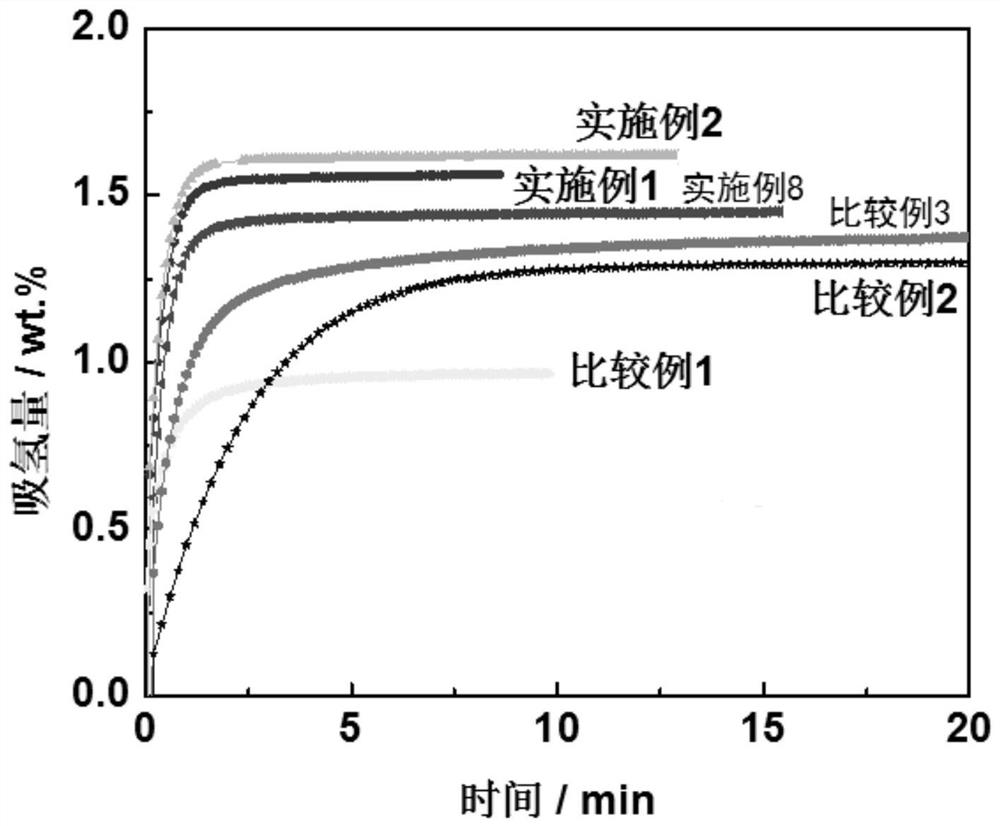

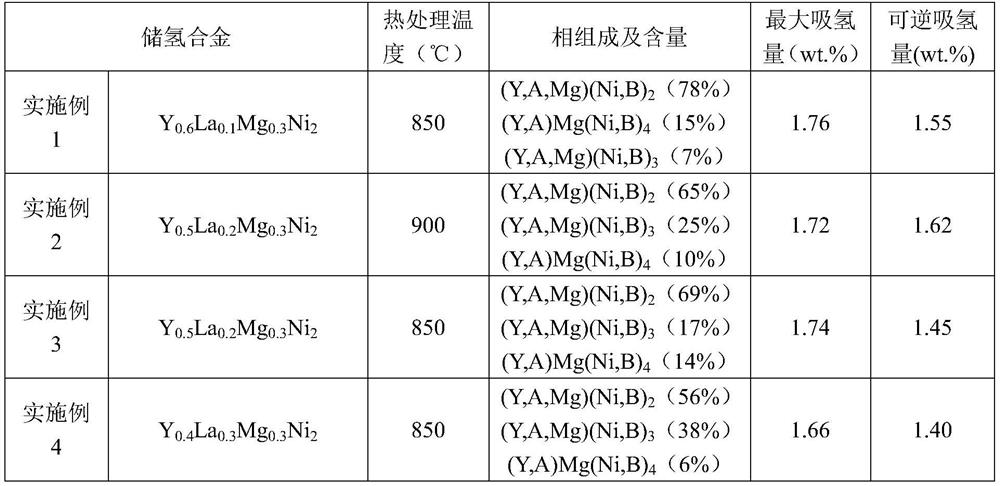

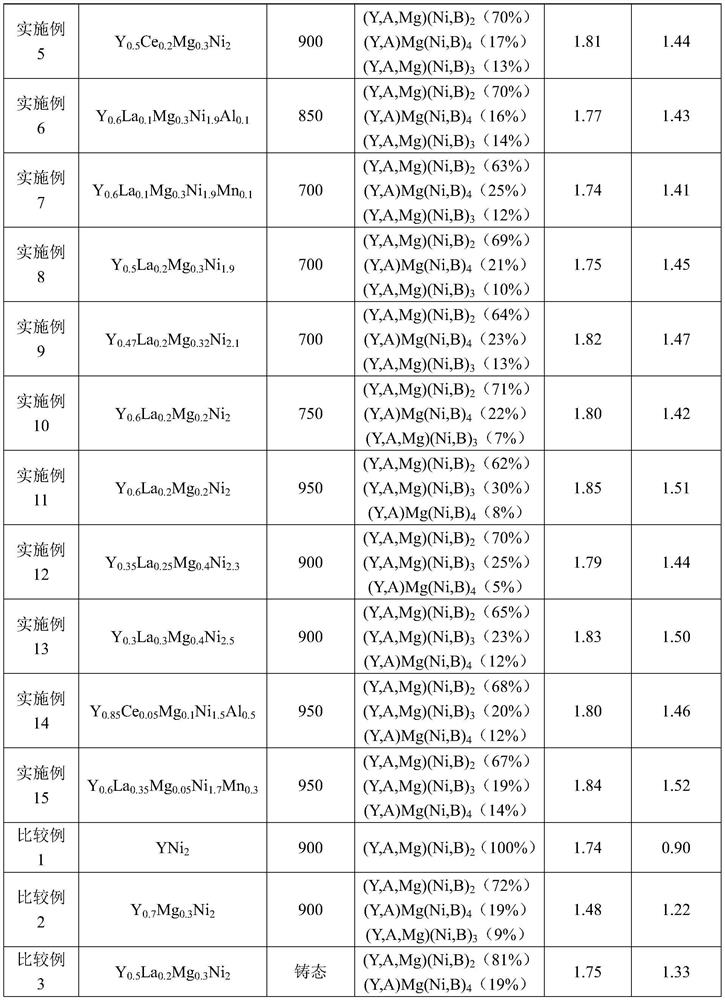

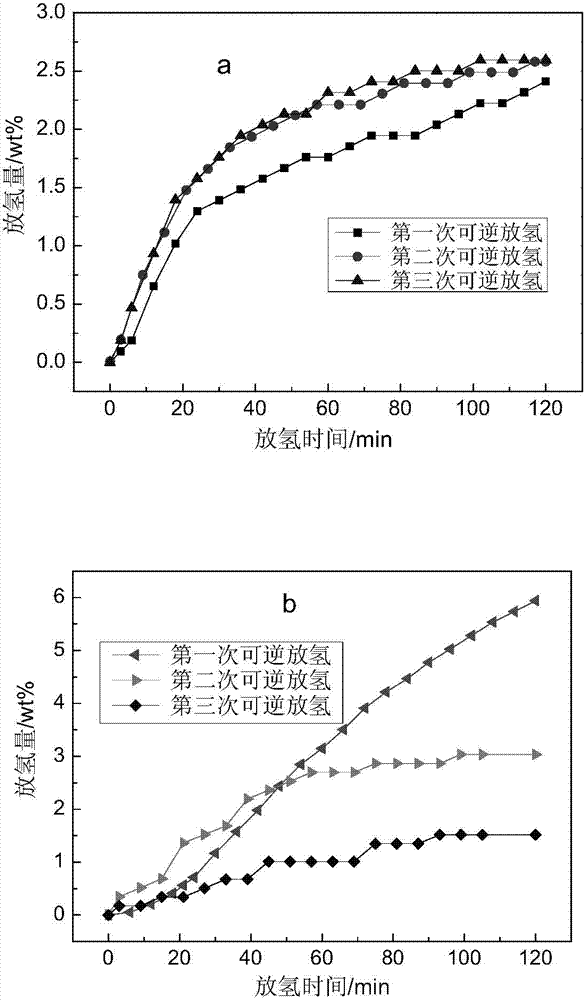

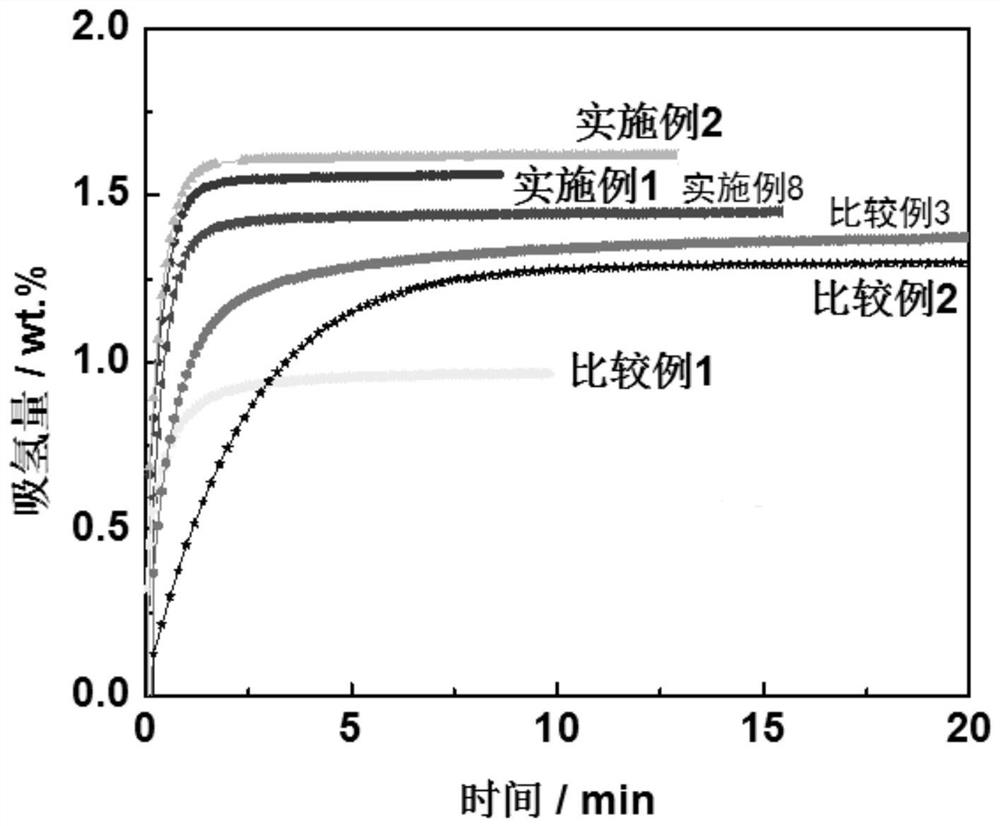

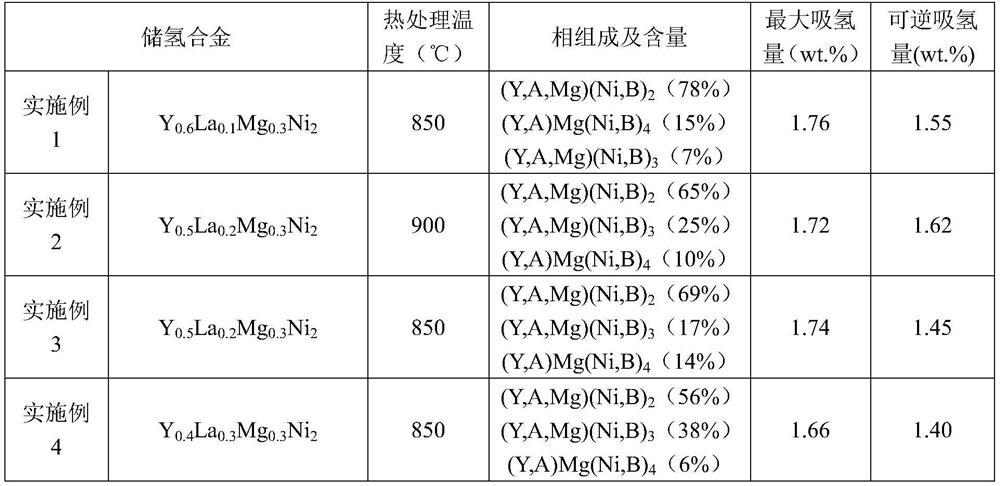

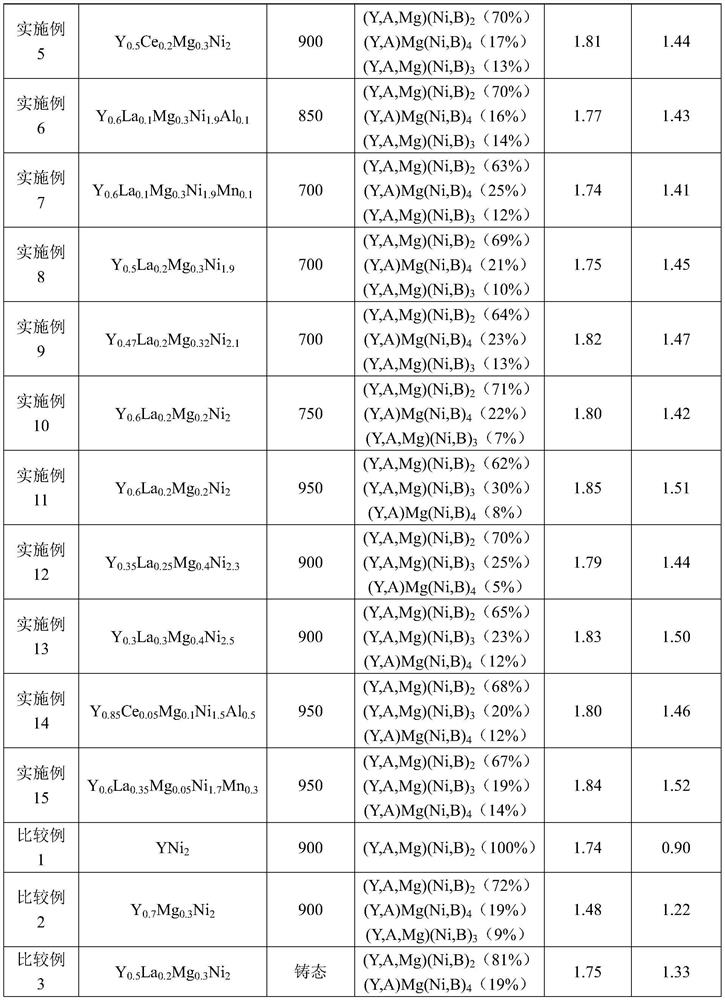

Rare earth hydrogen storage material and preparation method thereof

ActiveCN111647773AGood reversible hydrogen absorption and desorption characteristicsImprove structural stabilityHydrogenArgon atmospherePhysical chemistry

The invention discloses a rare earth hydrogen storage material and a preparation method thereof, and relates to AB2-type yttrium-magnesium-nickel base rare earth hydrogen storage materials. The rare earth hydrogen storage material thereof is a yttrium-magnesium-nickel base hydrogen storage material having a general formula of YaAbMgcNixBy, and the material has a mixed-phase structure that regardsthe AB2-type (Y,A,Mg)(Ni,B)2 phase as a main phase, and contains the A2B4-type (Y,A)Mg(Ni,B)4 phase and AB3-type (Y,A,Mg)(Ni,B)3 phase at the same time. The preparation method thereof adopts a methodof induction melting, and anneals the obtained alloy ingot in a vacuum or argon atmosphere. In the AB2-type yttrium-magnesium-nickel base rare earth hydrogen storage material provided by the invention, A side is replaced by the Mg part, which can obviously improve the structural stability of AB2 phase in alloys and reduce hydrogen-induced amorphization and hydrogen-induced disproportionation of alloys; at the same time, Al, Mn and the like with a larger atomic radius are used to replace Ni elements to increase the unit cell volume of alloys, thereby increasing the hydrogen storage capacity ofalloys; and the material has good characteristic of reversible hydrogen absorption and desorption, and the maximum hydrogen storage capacity is greater than 1.6wt.%.

Owner:GRIMAT ENG INST CO LTD

Catalytic hydrogenation method adopting naphthalene as hydrogen storage agent

InactiveCN106542955AEasy to storeEasy to achieve releaseHydrocarbon by hydrogenationNaphthaleneChemistry

The invention discloses a catalytic hydrogenation method adopting naphthalene as a hydrogen storage agent. The catalytic hydrogenation method adopting the naphthalene as the hydrogen storage agent is characterized by adopting the naphthalene as a carrier, adopting an amorphous Ni / Al alloy as a catalyst, and carrying out catalytic hydrogenation at the pressure ranged from 2.0 to 5.0MPa and the temperature ranged from 100 DEG C to 280 DEG C to generate decahydronaphthalene for storing hydrogen. Compared with the prior art, the catalytic hydrogenation method adopting the naphthalene as the hydrogen storage agent provided by the invention has the advantages of simple hydrogen storage equipment, large hydrogen storage capacity, simple method, low cost, highly reversible hydrogen storage reaction, convenience in storing and releasing hydrogen, safety in storage and transportation, and high reaction conversion rate, the conversion rate of the naphthalene can achieve 99.6 percent, and the yield of the decahydronaphthalene can achieve 99.2 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

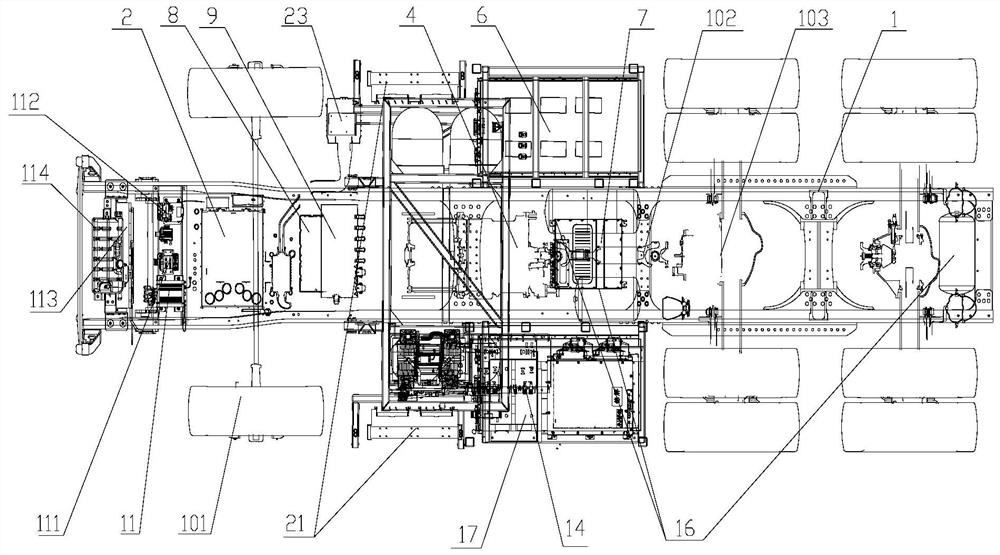

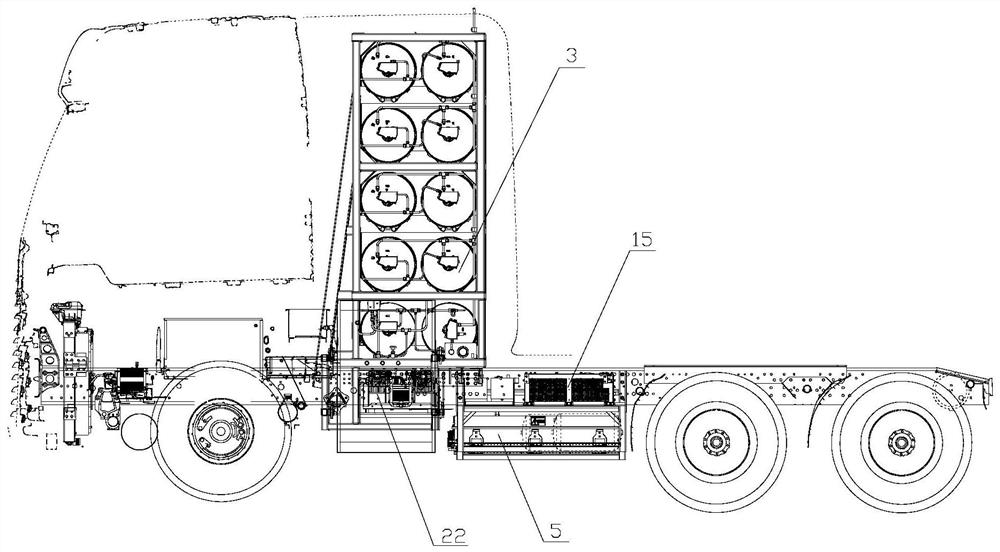

Traction truck chassis platform suitable for fuel cell and traction truck

PendingCN113104113ALarge hydrogen storage capacityImprove battery lifeUnderstructuresPropulsion by capacitorsTruckSupply & distribution

A traction truck chassis platform suitable for a fuel cell and a traction truck relate to the technical field of hydrogen energy automobiles and comprise a frame, an electric pile assembly, a hydrogen cylinder assembly, a motor assembly, a power cell, a super capacitor, a motor controller, a power supply distribution unit, a high-voltage distribution box and a driving assembly. The electric pile assembly, the power distribution unit and the high-voltage distribution box are all located on the front frame, the hydrogen bottle assembly, the motor assembly, the super capacitor and the motor controller are all located on the middle frame, and the power battery and the super capacitor are both located on the rear frame. The hydrogen bottle assembly is used for storing hydrogen and conveying the hydrogen to the electric pile assembly; the electric pile assembly is used for carrying out a fuel cell chemical reaction and transmitting generated electric energy to the super capacitor; and the super capacitor stores the electric energy generated by the electric pile assembly and provides the electric energy for the power battery. By designing a new chassis framework of the traction truck, arrangement and installation of different systems in the traction truck are achieved.

Owner:黄冈格罗夫氢能汽车有限公司

Porous hydrogen storage material and preparation method thereof

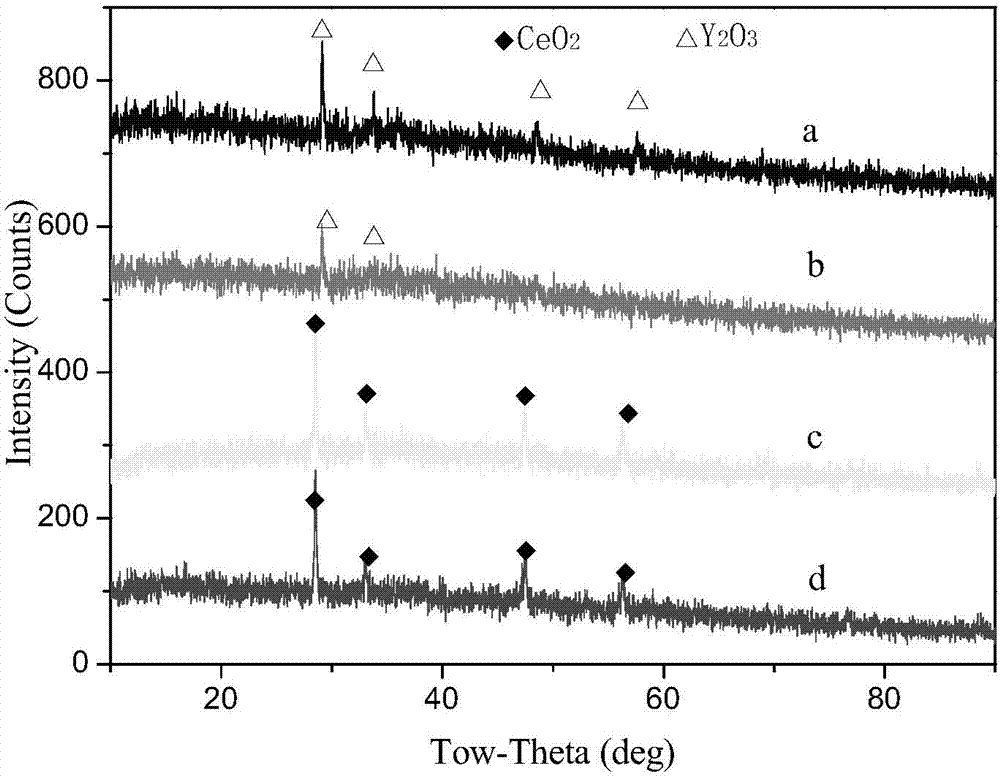

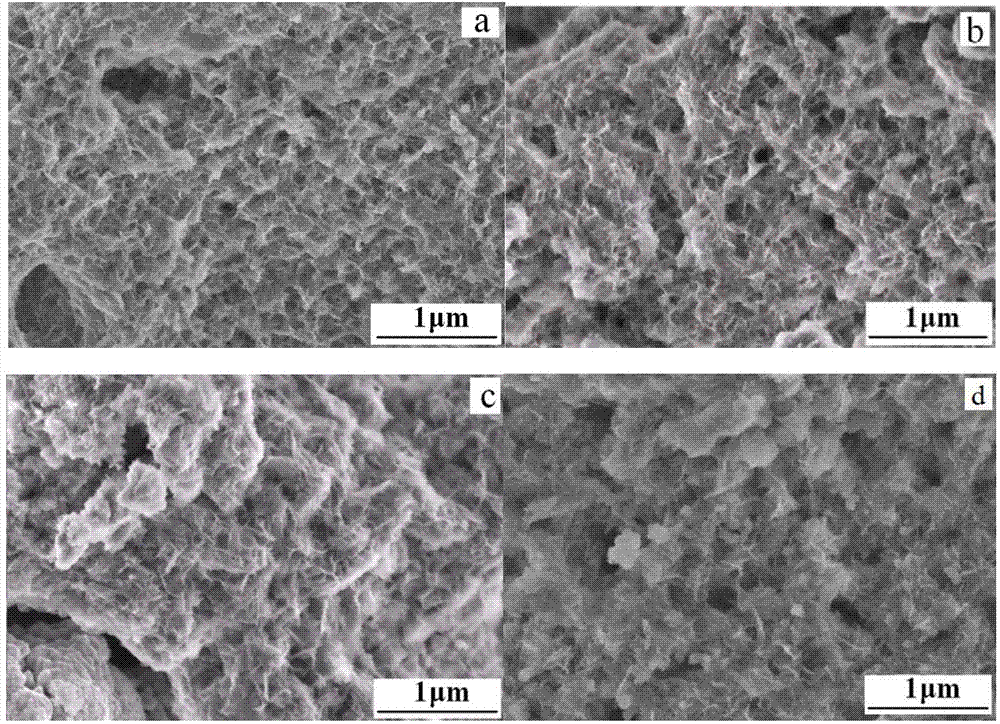

InactiveCN103922277ASimple processLarge hydrogen storage capacityHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsRare earthAmorphous phase

The invention provides a porous hydrogen storage material and a preparation method thereof. The porous hydrogen storage material comprises an amorphous phase and rare earth oxide, wherein the mass fraction of the rare earth oxide in the hydrogen storage material is 1-20 percent, and the amorphous phase is formed by hydrolyzing NaBH4 to release hydrogen and drying. The porous hydrogen storage material provided by the invention comprises the amorphous phase and the rare earth oxide, has a microstructure being a sheet porous structure, has the characteristics of large hydrogen storage amount, gentle conditions for absorbing and releasing hydrogen, high hydrogen absorbing speed and the like, and is suitable for efficient storage and safe transportation of hydrogen. The preparation method of the porous hydrogen storage material provided by the invention is simple in process and is easy to control; in addition, materials are from the products of hydrolysis of sodium borohydride, and the cost is low.

Owner:CHANGAN UNIV

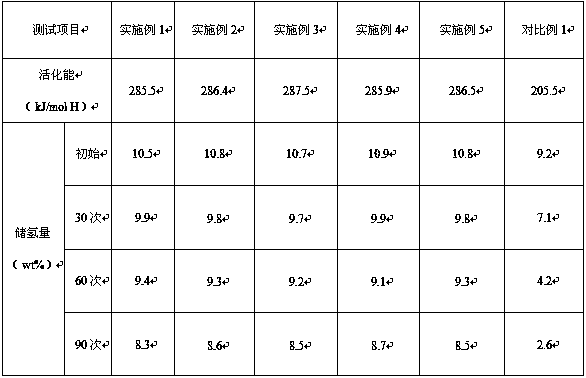

Magnesium, aluminum, boron and nickel-based hydrogen storage material and preparing method thereof

The invention discloses a magnesium, aluminum, boron and nickel-based hydrogen storage material. The chemical component of the magnesium, aluminum, boron and nickel-based hydrogen storage material is xAl-yB-zNi-(1-x-y-z)Mg, wherein the mass fraction, by weight, of x is larger than or equal to 1% and smaller than or equal to 5%, the mass fraction, by weight, of y is larger than or equal to 0.5% and smaller than or equal to 1%, and the mass fraction, by weight, of z is larger than or equal to 5% and smaller than or equal to 20%. A preparing method for the hydrogen storage material comprises the steps that magnesium powder, nickel powder, boron powder and aluminum powder are evenly mixed according to the composition and pressed into a cylinder with the diameter of 10 mm and the height of 8 mm; and then a cubic press is used for heat preservation and pressure maintaining for 30-60 min at 4-6 GPa and 1200-1800 DEG C; and liquid nitrogen is immediately used for cooling an alloy, and the magnesium, aluminum, boron and nickel-based hydrogen storage material is obtained. The preparing method is simple and short in production period, and the prepared hydrogen storage alloy has the good performance of being short in activation period, high in hydrogen absorbing and desorbing rate and the like.

Owner:YANSHAN UNIV

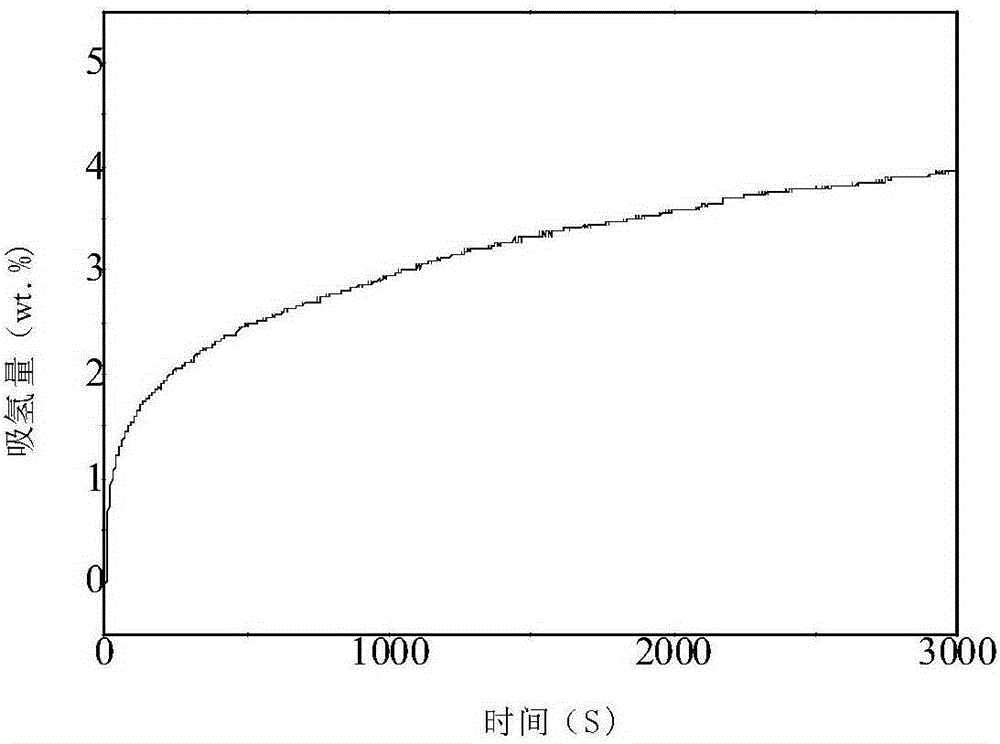

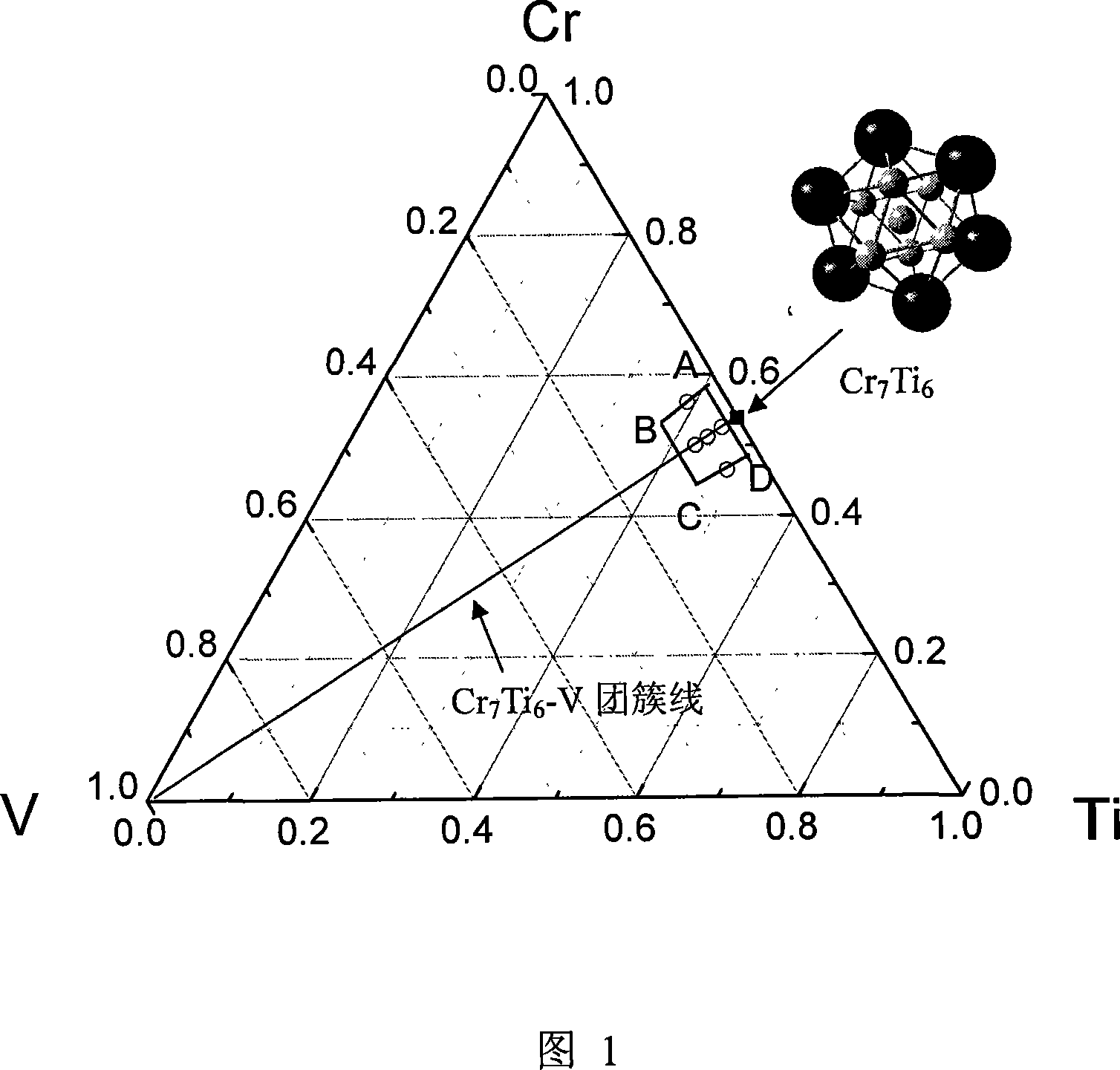

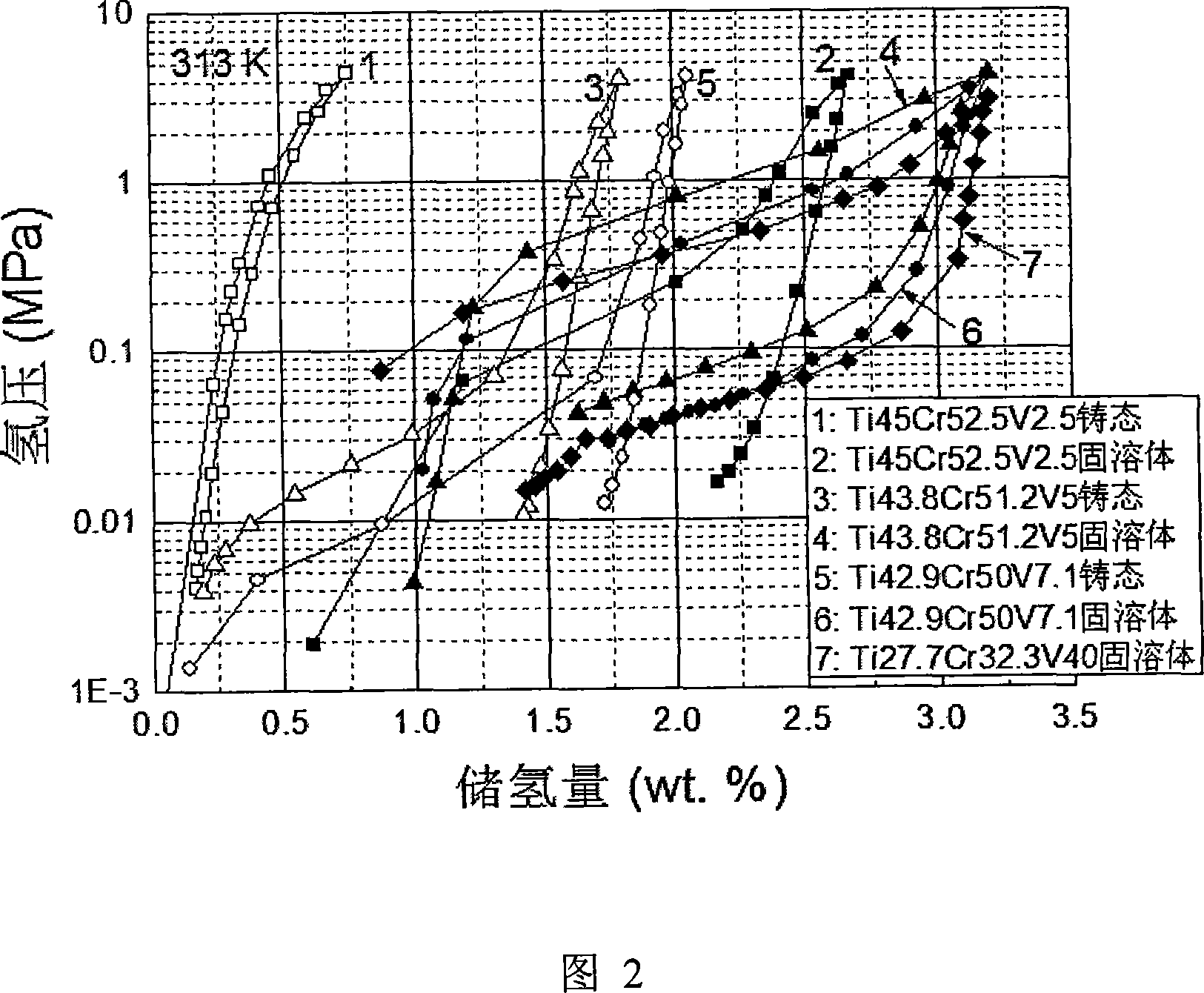

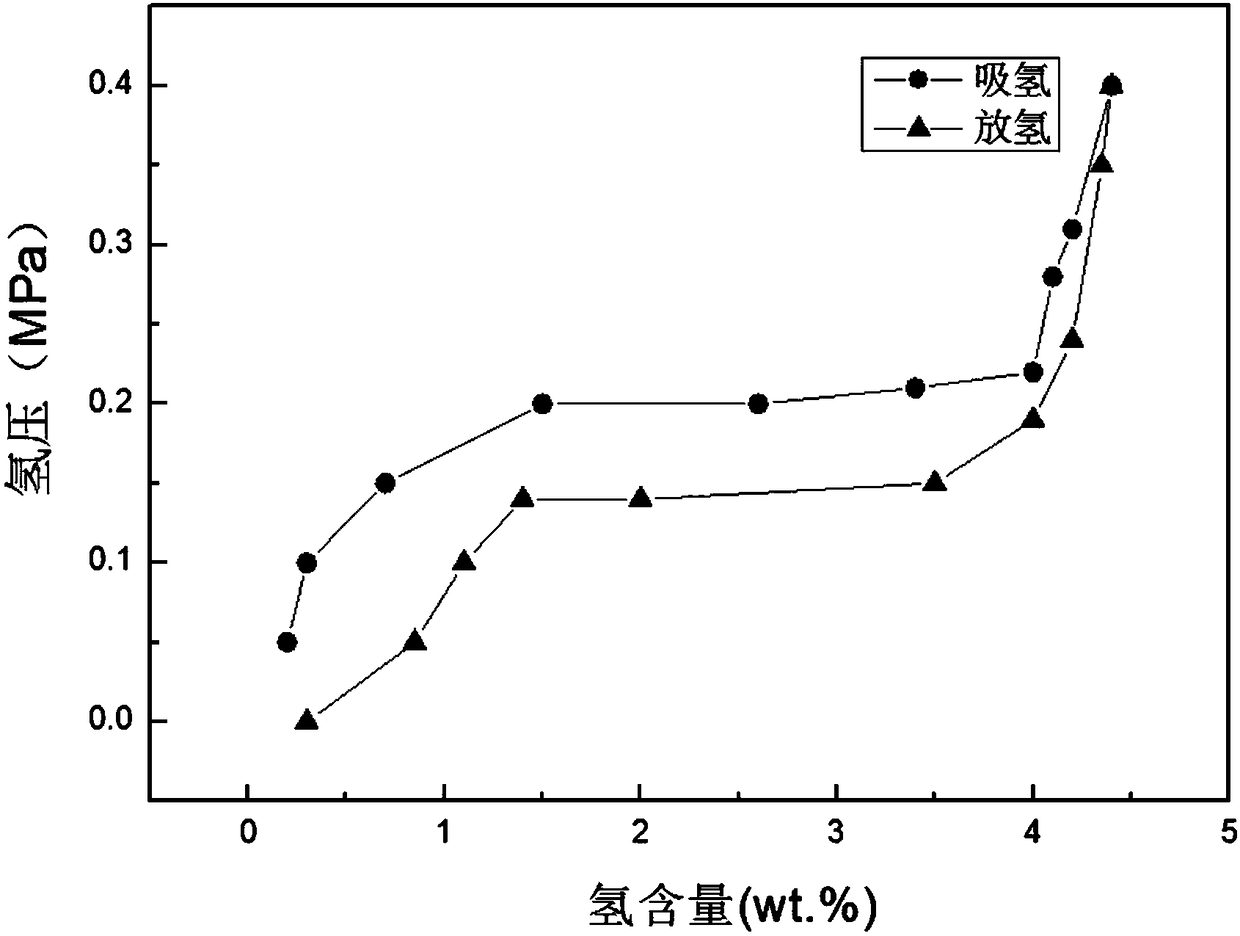

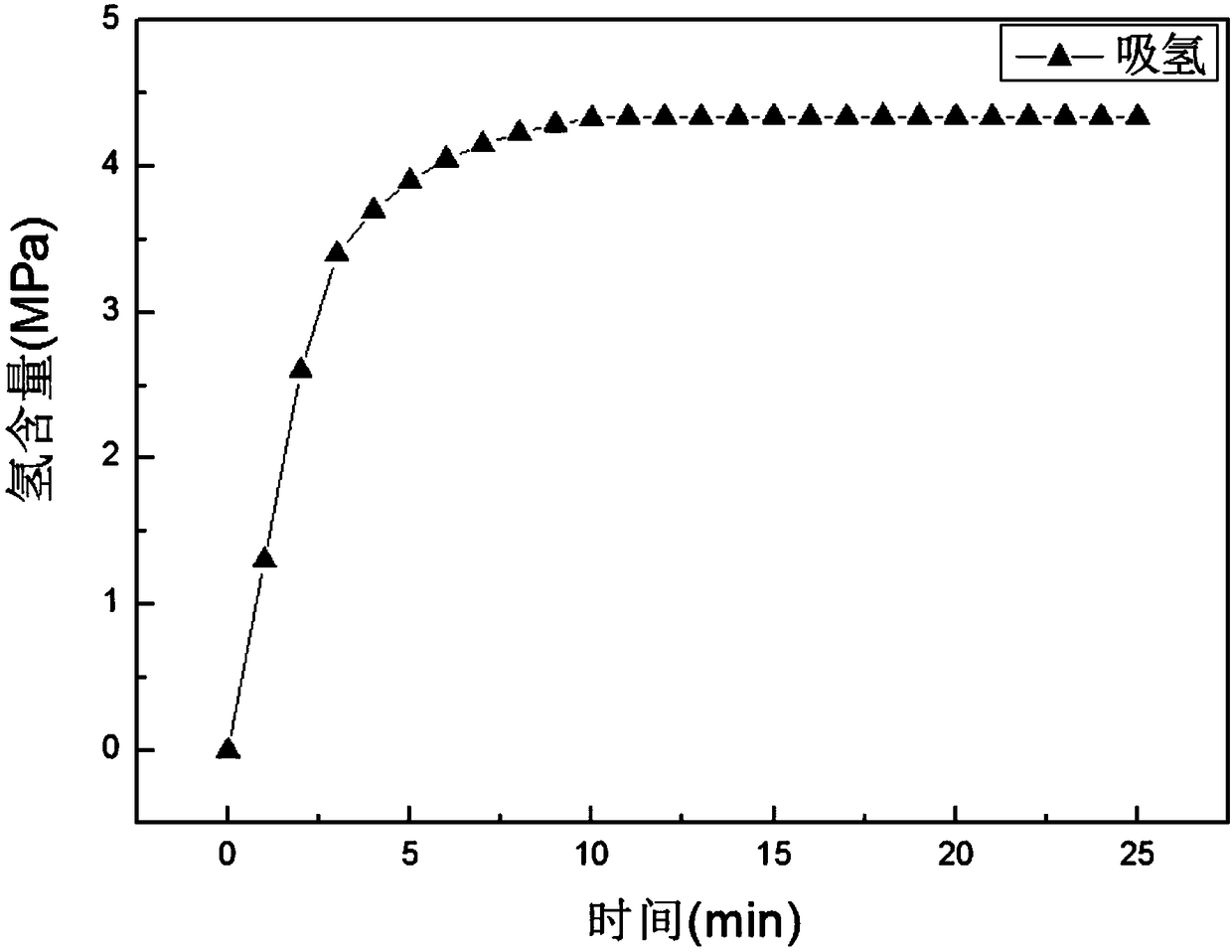

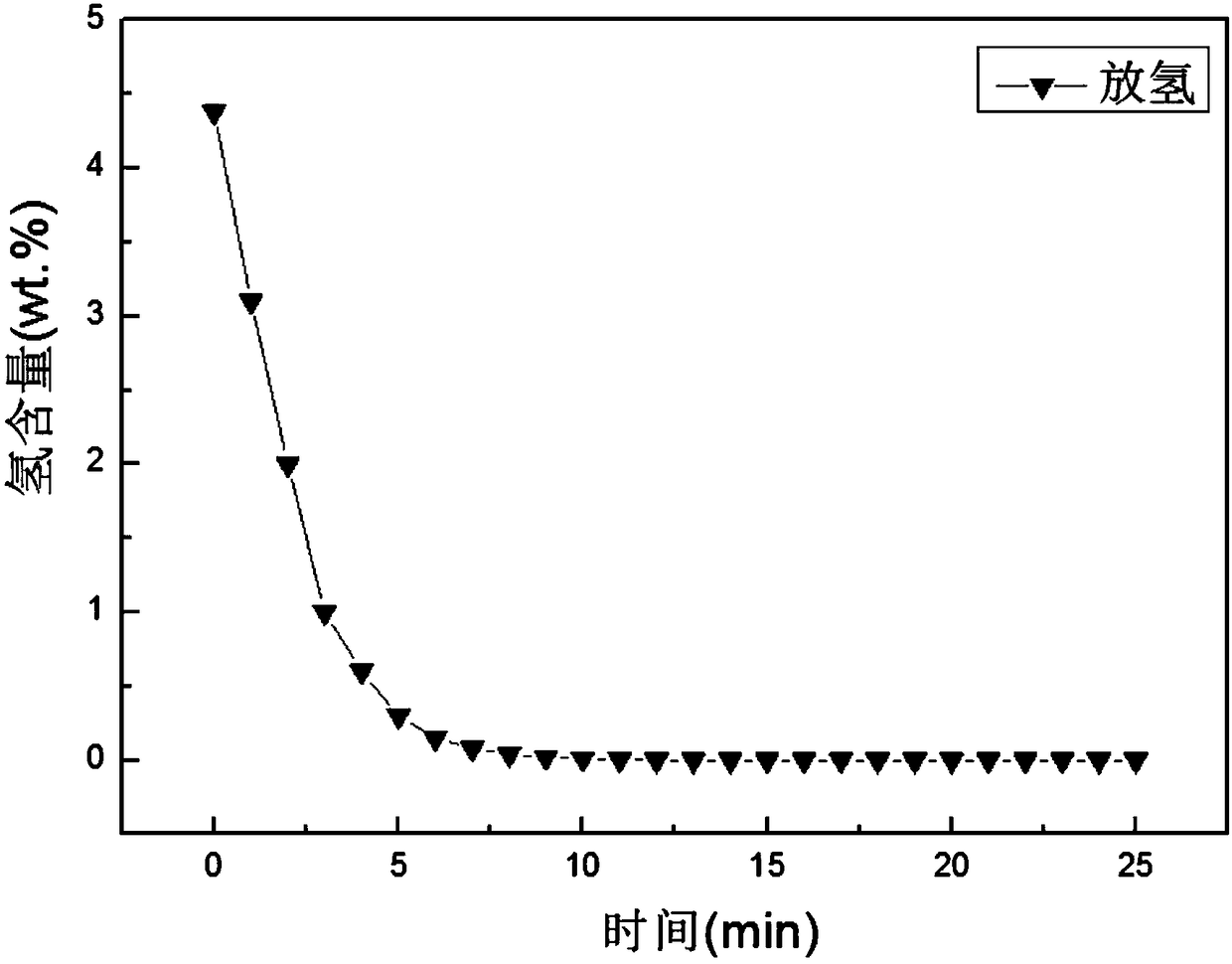

Ti-Cr-V solid solution alloy with high weight of hydrogen and low V content

The invention relates to a Ti-Cr-V solid solution alloy with high hydrogen storage capacity as well as low V content, which belongs to the new material field. The invention comprises a Ti element, a Cr element and a V element and is characterized in that the alloy is formed by the alloying of the a binary cluster Cr7Ti6 and the nearby composite by adding few V; the composite scope is (TiCry)(100 minus x) / (1 plus y)Vx, that is, V atom per centage scope x is equal to 2 minus 10at. per cent, and Cr / Ti atom per centage scope y is equal to 0.96 minus 1.44; the maximum hydrogen absorption capacity of the solid solution alloy Ti43.8Cr51.2V5 and Ti42.9Cr50V7.1 with maximum hydrogen uptake is 3.2wt. per cent (313K), which processes good hydriding and dehydriding kinetics performance; the solid solution alloy with low V content is processed by adopting the vacuum arc melting and the water-cooled copper mold method. The invention has the advantages that the invention defines the composite range of the low V content in accordance with the cluster, which overcomes the arbitrary composite selection. By adoption of the water-cooled copper mold method, the invention ensures the alloy is the V solid solution alloy structure with low V content, and simplies the process preparation; the invention is capable of replacing the solid solution alloy with V content, lowers the material cost and is capable of being used as fuel cell hydrogen source alloy.

Owner:DALIAN UNIV OF TECH

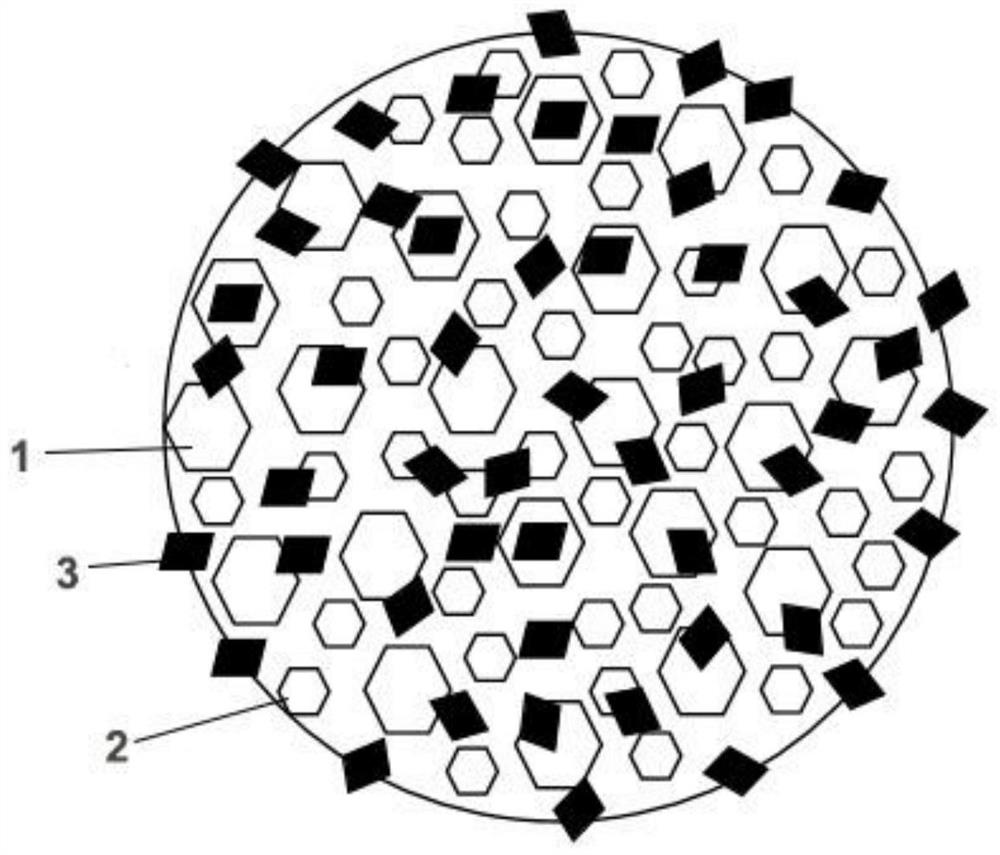

Method for preparing magnesium-based nanocomposite hydrogen storage material

InactiveCN111515405ATo achieve the purpose of hydrogen storageNot easy to explodeMaterial nanotechnologyReversible hydrogen uptakeCarbon nanotubeChemical adsorption

The invention relates to a method for preparing a magnesium-based nanocomposite hydrogen storage material, and belongs to the technical field of hydrogen storage materials. In the method, carbon nanotubes are grown in situ on the surface of a molecular sieve to serve as a substrate, rare earth lanthanum is used as a target, a layer of lanthanum hydride film is formed on the surface of the substrate by sputtering to serve as a filler of the hydrogen storage material, and with magnesium hydride as a raw material, the magnesium-based nanocomposite hydrogen storage material is prepared by mechanical ball milling. When hydrogen molecules make contact with the material, the hydrogen molecules are adsorbed on the alloy surface, H-H bonds of the hydrogen molecules dissociate into atomic hydrogen,hydrogen atoms diffuse inwards from the material surface to be immersed into metal atoms with the radius much larger than that of the hydrogen atoms and among crystal lattices in the gaps of metal toform a solid solution, hydrogen solidly dissolved in the metal continues to diffuse inwards, the diffusion must have activation energy of conversion from chemical adsorption to dissolution, after thesolid solution is saturated by hydrogen, excess hydrogen atoms react with the solid solution to produce metal hydride, and thus the purpose of hydrogen storage is achieved.

Owner:深圳市亚环环保科技有限公司

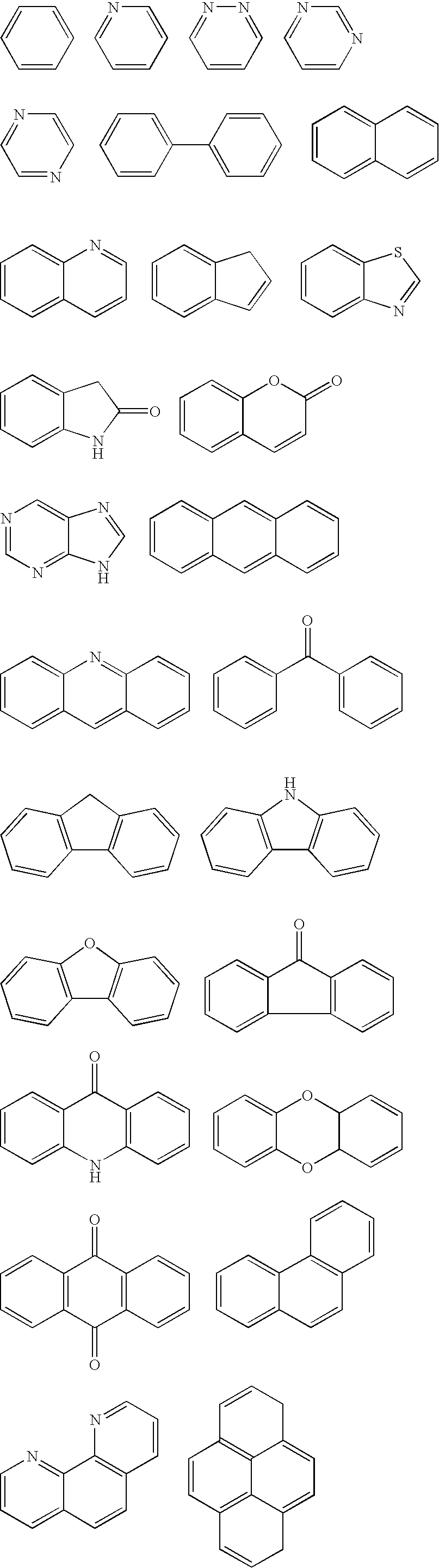

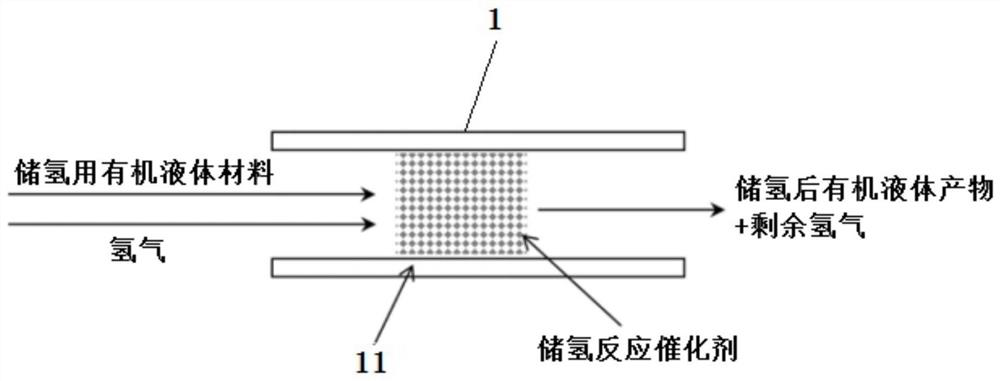

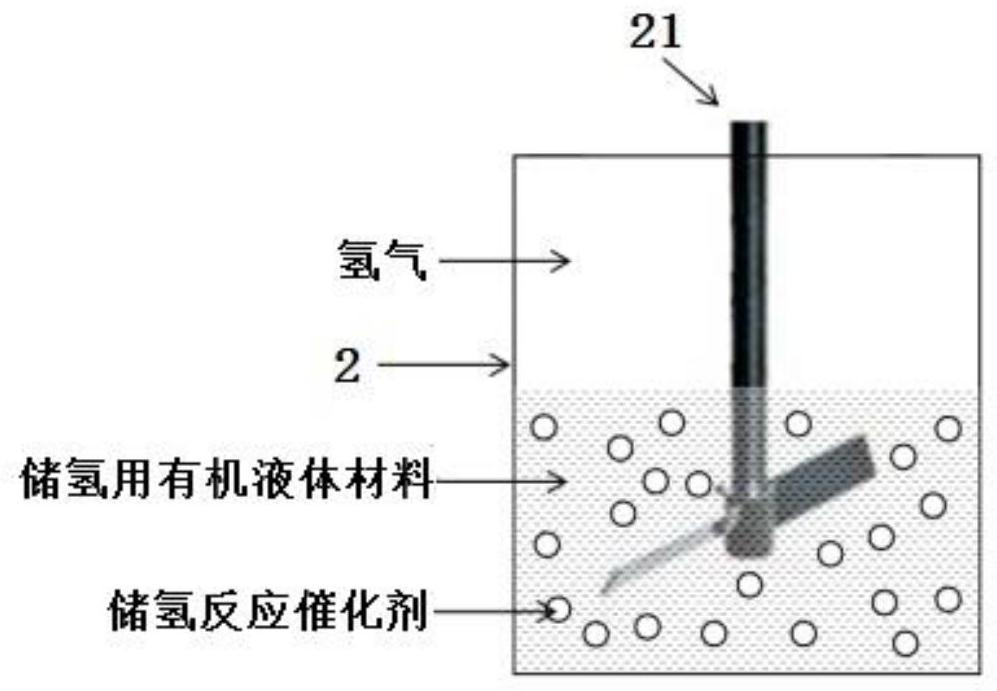

Organic liquid material for hydrogen storage, catalytic hydrogen storage system and hydrogen storage method

PendingCN114497630AIncreased theoretical hydrogen storage capacityImprove liquidityReactant parameters controlDibenzyltoluenePtru catalyst

The invention discloses an organic liquid material for hydrogen storage, a catalytic hydrogen storage system and a hydrogen storage method.The organic liquid material is composed of a hydrogen storage raw material A and a hydrogen storage raw material B. The hydrogen storage raw material A is one or two of benzyl toluene and dibenzyl toluene, the mass content of the dibenzyl toluene is not larger than 80%, and the mass content of the hydrogen storage raw material B is not larger than 80%. The hydrogen storage raw material B is one or more of naphthalene, 1-methylnaphthalene and 2-methylnaphthalene. The catalytic hydrogen storage system comprises an organic liquid material for hydrogen storage and a hydrogen storage reaction catalyst, and the hydrogen storage reaction catalyst is a supported metal catalyst and comprises a catalyst carrier and a catalyst active metal component. The invention solves the problem of lack of hydrogen storage technology based on organic liquid materials in the technical field at present, and has the advantages of low raw material cost, large scale, low-temperature liquid property, low catalyst cost in the hydrogen storage process, large hydrogen storage capacity, relatively mild hydrogen storage conditions and the like.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST

Cage-shaped structure composite hydrogen storage method

ActiveCN101798060AGentle conditionsImprove harsh high pressure conditionsHydrogenLight irradiationHydrogenation reaction

The invention discloses a cage-shaped structure composite hydrogen storage method. The invention uses organic matters which contain C-C double bonds and can form hydrogen bonds as hydrogen storage materials, double bonds of the hydrogen storage materials can be broken under the condition of light irradiation and existence of hydrogenation catalysts. Carbon atoms accept hydrogen protons at the broken parts of the double bonds for forming novel single bonds, i.e. the catalytic hydrogenation reaction is carried out. After the organic matter takes the catalytic hydrogenation reaction, cage-shaped compounds with polyhedral holes can be formed through hydrogen bonds, a plurality of cage-shaped holes are formed in the cage-shaped compounds, and hydrogen gas molecules can enter the holes, i.e. the hydrogen gas molecules are covered in the cage-shaped holes. The invention can use one kind of gas storage materials for simultaneously storing the gas in two modes, in addition, the hydrogen gas stored in the hydrogen cage type hydrates can be easily desorbed, and the invention has the advantages of high gas storage density, safety, convenient transportation and the like.

Owner:SOUTH CHINA UNIV OF TECH

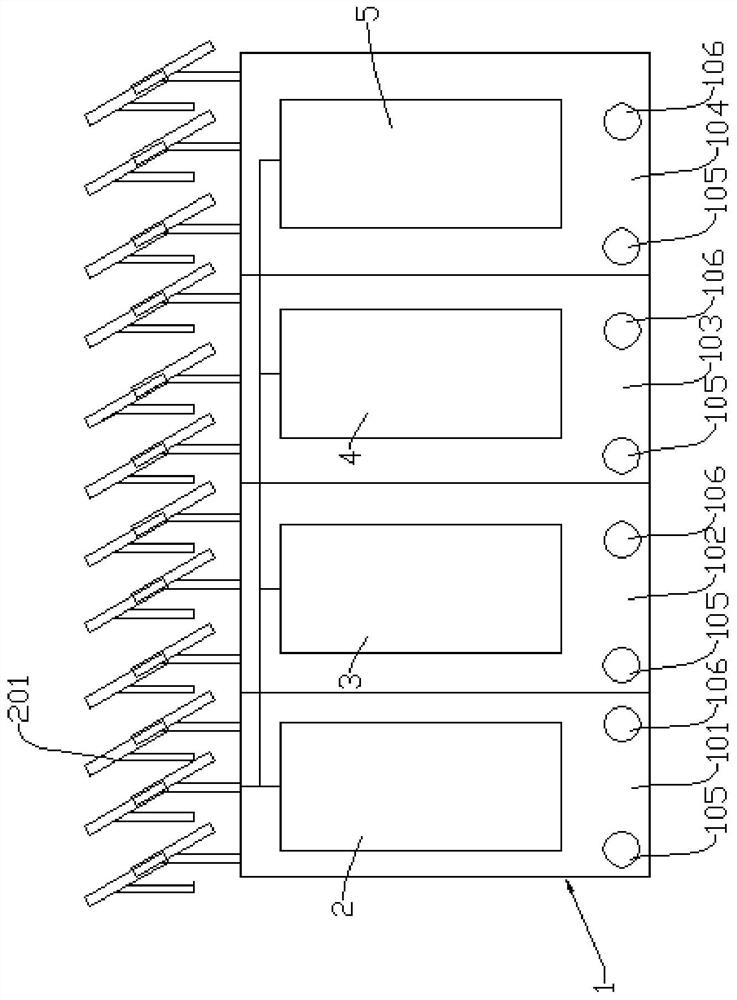

Mobile intensive marine instant hydrogen production and hydrogenation integrated system

PendingCN112811389AAchieving Mobility ReplenishmentImprove work efficiencyPropulsion based emission reductionHydrogen separation using solid contactThermodynamicsHydrogen fuel cell

The invention relates to the technical field of hydrogen fuel cell ships, in particular to a mobile intensive marine instant hydrogen production and hydrogenation integrated system. The system comprises a container, a first container compartment, a second container compartment, a third container compartment and a fourth container compartment are arranged in the container, a photovoltaic power generation unit is arranged on the container, an ethanol dehydrogenation hydrogen production unit is arranged in the second container compartment, and a hydrogen purification unit is arranged in the third container compartment. And a hydrogen filling unit is arranged in the fourth container compartment. The movable intensive marine instant hydrogen production and hydrogenation integrated system is mounted on the deck of the guarantee ship, and the hydrogen is produced and used at present, so that maneuverability supply of the hydrogen fuel cell ship can be realized, the situation that the hydrogen fuel cell ship needs to frequently go back and forth to a fixed port base for hydrogen supply is avoided, and the working efficiency of the hydrogen fuel cell ship is improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Ferrotitanium alloy hydrogen storage material used for fuel cell car and preparing method

InactiveCN108907227AHigh activityImprove stabilityTransportation and packagingMetal-working apparatusIron saltsFuel cells

The invention discloses a ferrotitanium alloy hydrogen storage material used for a fuel cell car and a preparing method. The ferrotitanium alloy hydrogen storage material is prepared through the following steps that a, a water solution containing iron salt and titanium salt, a reducing agent, a pore-forming agent and a flocculating agent are added into ethyl orthosilicate, after the stirring reaction, standing and aging are carried out, and a gelatinous material is made; b, the gelatinous material and doped metal powder are mixed for carrying out low-temperature heat treatment, and through subsequent forming, the ferrotitanium alloy hydrogen storage material is obtained. The method has following beneficial effects that silicon dioxide evenly wraps the ferrotitanium alloy surface, the activity and the stability of an alloy material can be obviously improved, the material is large in hydrogen storage amount, the service life is long, the whole preparing process is simple, the cost is low, and the ferrotitanium alloy hydrogen storage material used for the fuel cell car has the wide application prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

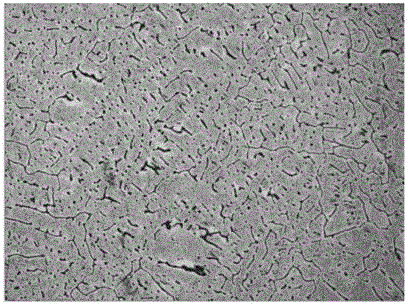

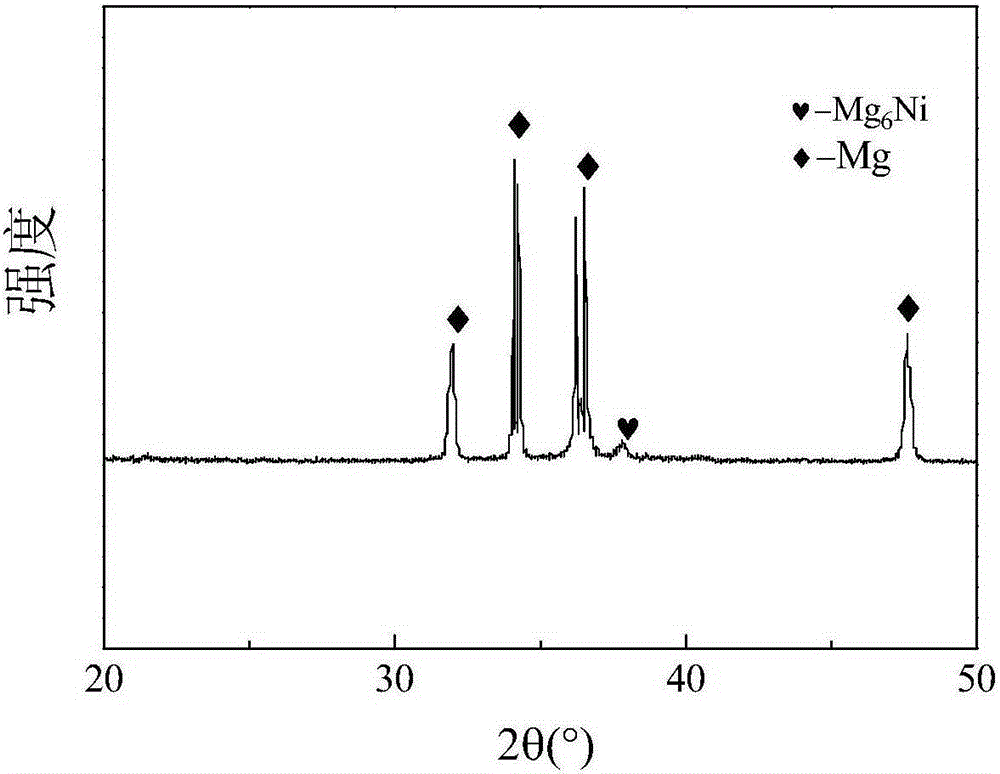

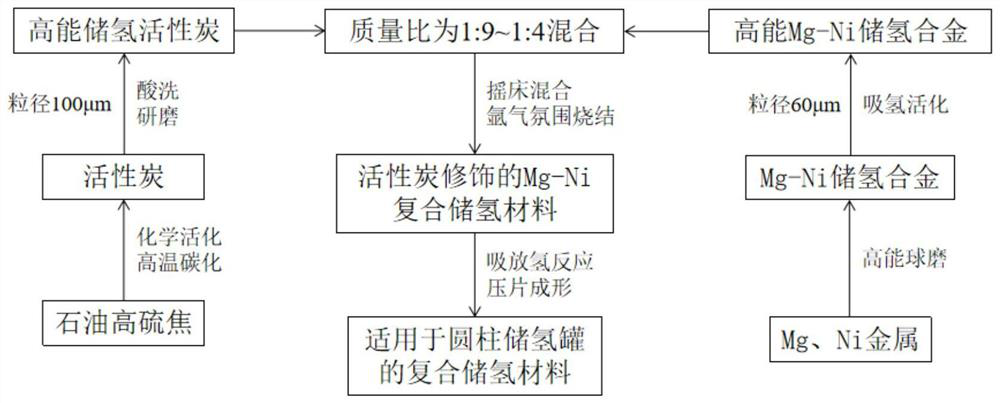

Magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and preparation method thereof

PendingCN112777564ATake advantage ofLarge hydrogen storage capacityHydrogenActivated carbonArgon atmosphere

The invention relates to a magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage alloy materials. The method comprises the following steps: 1, preparing petroleum coke activated carbon; 2, preparing Mg-Ni hydrogen storage alloy; and 3, loading the composite hydrogen storage material: 31) uniformly mixing the petroleum coke activated carbon prepared in the step 1 with the Mg-Ni hydrogen storage alloy prepared in the step 2, and then placing the mixture on a muffle furnace protected by an argon atmosphere for high-temperature sintering; 32) placing the sintered composite hydrogen storage material in a hydrogenation reactor for activating treatment; and (33) putting the activated composite hydrogen storage material into a tablet press, and extruding the composite hydrogen storage material into a cylindrical shape. The spherical cage effect can be generated by means of dense apertures and gaps of the petroleum coke activated carbon, discrete aggregation of the pulverized hydrogen storage alloy is efficiently limited, and the magnesium nickel-petroleum coke activated carbon composite hydrogen storage material has the advantages of being high in hydrogen storage capacity, high in hydrogen absorption and desorption rate, low in strain accumulation and the like.

Owner:SHANDONG UNIV

Catalytic hydrogenation method by taking toluene as hydrogen storing agent

The invention discloses a catalytic hydrogenation method by taking toluene as a hydrogen storing agent, which is characterized in that toluene and cyclohexane are taken as carriers, amorphous nickel is taken as a catalyst, and hydrogenation is catalyzing under the pressure of 5.0-7.0MPa and the temperature of 130-180 DEG C so as to generate methylcyclohexane used for storing hydrogen. Compared with the prior art, the method has the advantages of simple hydrogen storing equipment, large hydrogen storing quantity, low cost, cleanness and environmental protection, has high reversibility of hydrogen storing reaction, can realize the storage of releasing of hydrogen conveniently, and is safe in storage, transportation and maintenance, and high in reaction conversion rate; and hydrogen storage materials and the catalyst can be used repeatedly.

Owner:EAST CHINA NORMAL UNIV

Magnesium-based hydrogen storage alloy prepared by ball milling method

ActiveCN107686903BLarge hydrogen storage capacityImprove convenienceCell electrodesMicrowaveQuenching

By means of the process of components adjustment, microwave smelting, heat treatment and ball milling of a magnesium-based hydrogen storing alloy, the crystalline structure of the alloy is made to change, and an obtained finished product has the characteristic that the sum of the component ratios of an AB2 structure and an A5B19 structure is 40% or above. In order to make the magnesium-based hydrogen storing alloy have larger discharging capacity and hydrogen storing capacity than existing products, the heat treatment process of two times of quenching and two times of tempering is adopted, anda good comprehensive performance effect is acquired. According to the ball milling process, large and small balls are adopted for perform ball milling on the smashed alloy twice in sequence, along with uniform micronization of the magnesium-based hydrogen storing alloy, the surface area is made increased, when the magnesium-based hydrogen storing alloy is applied to a nickel-hydrogen storage battery, the electric power output characteristic of the magnesium-based hydrogen storing alloy is obviously improved, and especially, the hydrogen absorbing / releasing capacity retention rate and the cycle service life of a product are further improved.

Owner:上海中海龙高新技术研究院

Cage-shaped structure composite hydrogen storage method

ActiveCN101798060BGentle conditionsImprove harsh high pressure conditionsHydrogenDouble bondStorage material

The invention discloses a cage-shaped structure composite hydrogen storage method. The invention uses organic matters which contain C-C double bonds and can form hydrogen bonds as hydrogen storage materials, double bonds of the hydrogen storage materials can be broken under the condition of light irradiation and existence of hydrogenation catalysts. Carbon atoms accept hydrogen protons at the broken parts of the double bonds for forming novel single bonds, i.e. the catalytic hydrogenation reaction is carried out. After the organic matter takes the catalytic hydrogenation reaction, cage-shapedcompounds with polyhedral holes can be formed through hydrogen bonds, a plurality of cage-shaped holes are formed in the cage-shaped compounds, and hydrogen gas molecules can enter the holes, i.e. the hydrogen gas molecules are covered in the cage-shaped holes. The invention can use one kind of gas storage materials for simultaneously storing the gas in two modes, in addition, the hydrogen gas stored in the hydrogen cage type hydrates can be easily desorbed, and the invention has the advantages of high gas storage density, safety, convenient transportation and the like.

Owner:SOUTH CHINA UNIV OF TECH

A kind of rare earth hydrogen storage material and its preparation method

ActiveCN111647773BGood reversible hydrogen absorption and desorption characteristicsImprove structural stabilityHydrogenArgon atmosphereIngot

A rare earth hydrogen storage material and preparation method thereof, involving an AB 2 Type yttrium-magnesium-nickel-based rare earth hydrogen storage materials. It is characterized in that its rare earth hydrogen storage material is composed of general formula Y a A b Mg c Ni x B y yttrium-magnesium-nickel-based hydrogen storage material; the material has a 2 Type (Y,A,Mg)(Ni,B) 2 The phase is the main phase and contains A at the same time 2 B 4 Type (Y,A)Mg(Ni,B) 4 Phase and AB 3 Type (Y,A,Mg)(Ni,B) 3 mixed-phase structure. The preparation method adopts the induction melting method, and the obtained alloy ingot is annealed under vacuum or argon atmosphere. An AB of the present invention 2 Type yttrium-magnesium-nickel-based rare earth hydrogen storage material, the A side is partially replaced by Mg, which can significantly improve the AB in the alloy 2 Phase structure stability, reducing hydrogen-induced amorphization and hydrogen-induced disproportionation of the alloy. At the same time, Al, Mn, etc. with a larger atomic radius are used to replace Ni elements to increase the unit cell volume of the alloy, thereby increasing the hydrogen storage capacity of the alloy. The material has good reversible hydrogen absorption and desorption characteristics, and the maximum hydrogen storage capacity is greater than 1.6wt.%. .

Owner:GRIMAT ENG INST CO LTD

Hydrogen storage alloy for vehicle-mounted energy storage

ActiveCN107523737AImprove discharge capacityLarge discharge capacity and hydrogen storage capacityRetention ratioHeat treated

The invention discloses a hydrogen storage alloy for vehicle-mounted energy storage. The crystal structure of the alloy is changed through component adjustment and a heat treatment process for the hydrogen storage alloy; the obtained finished product has the characteristic that the sum of the composition proportions of an AB2 structure and an A5B19 structure is more than 40%; and an AB2-type hydrogen storage alloy and an A5B19-type hydrogen storage alloy have the characteristics of being high in discharge capacity, long in cycle life, easy to activate, and the like, so that the finished hydrogen storage alloy product disclosed by the invention has higher discharge capacity and hydrogen storage amount than a product in the prior art, and moreover, the hydrogen absorption / desorption capacity retention ratio and the residual magnetization performance are also excellent.

Owner:浙江蓝能氢能科技股份有限公司

A magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure and its preparation method

ActiveCN106756369BSimple process equipmentLower activation energyMaterial nanotechnologyTransportation and packagingAdditive ingredientArgon atmosphere

Owner:YANSHAN UNIV

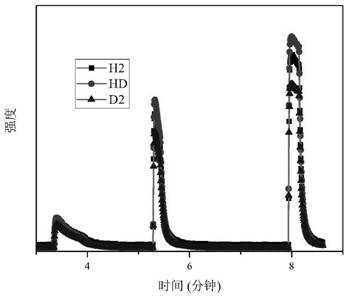

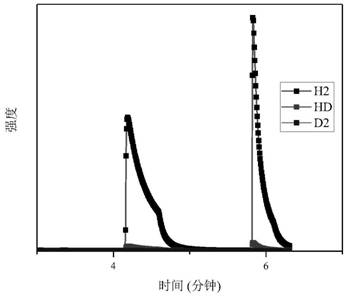

Application of metal nitrogen-based hydrogen storage material in hydrogen isotope separation and preparation method of metal nitride

PendingCN114618300ALarge hydrogen storage capacityEfficient separationNitrogen-metal/silicon/boron binary compoundsIsotope separationHydrogen isotopeMaterials science

The invention discloses application of a metal nitrogen-based hydrogen storage material in hydrogen isotope separation or enrichment and a preparation method of metal nitride. According to the application of the metal nitrogen-based hydrogen storage material in separation or enrichment of hydrogen isotopes, a gas mixture containing the hydrogen isotopes and the metal nitrogen-based hydrogen storage material are contacted and treated, so that the hydrogen isotopes are separated or enriched; the metal nitrogen-based hydrogen storage material comprises at least one of a metal nitride, a metal imino compound and a metal amino compound. The metal nitrogen-based hydrogen storage material provided by the invention has relatively good hydrogen isotope separation efficiency, and T2, D2 and H2 in hydrogen isotopes can be purified and separated or enriched and stored. The preparation method of the metal nitride is a mechanical ball milling method, is simple and low in energy consumption, can be used for large-scale synthesis, and can be used for preparing the high-purity powdery metal nitride without high temperature and high pressure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Magnesium-based hydrogen storage alloy containing long-period ordered accumulation structure and preparation method of magnesium-based hydrogen storage alloy

ActiveCN106756369ASimple process equipmentLower activation energyMaterial nanotechnologyTransportation and packagingDehydrogenationHot Temperature

The invention provides magnesium-based hydrogen storage alloy containing a long-period ordered accumulation structure. The chemical molecular formula of the magnesium-based hydrogen storage alloy is Mg-aX-bY-cLi, X represents one of V or Co, a, b and c represent mass percentage, a is larger than or equal to 3% and smaller than or equal to 8%, b is larger than or equal to 17% and smaller than or equal to 19%, c is larger than or equal to 0.5% and smaller than or equal to 1% and the balance Mg. The preparation method of the magnesium-based hydrogen storage alloy mainly includes the steps that alloy particles containing the above ingredients are put into a ball milling tank, stainless steel grinding balls with the size being 4-6 mm are added into the ball milling tank according to the ball material ratio of (15:1)-(20:1), the rotation speed is 300-400 r / min, rotation is stopped for 10 minutes after operation is performed for 30 minutes, powder with the average particle size being 50-90 nm is obtained after ball milling is performed for 30-50 hours and placed into a vacuum high-temperature furnace, the power is heated to 200 DEG C under an argon gas atmosphere, heat preservation is performed for 24 hours, and the magnesium-based hydrogen storage alloy containing the long-period ordered accumulation structure is prepared. According to the process, equipment is simple and easy to control, the cost is low, the hydrogenation and dehydrogenation temperature of the prepared magnesium-based hydrogen storage alloy is moderate, and hydrogenation and dehydrogenation dynamics performance is good.

Owner:YANSHAN UNIV

A method for manufacturing hydrogen supply device

ActiveCN112158804AAchieve coolingImprove securityHydrogen separation by selective and reversible uptakeHydrogen/synthetic gas productionFiberProcess engineering

The invention discloses a method for manufacturing a hydrogen supply device and belongs to the field of hydrogen supply. The device comprises an air inlet coil pipe, a cabinet, two 0.5 mu m filters, two check valves, two pressure gauges, two ball valves, a fin heat dissipation pipe, a safety valve, a hydrogen pressurization tank, a thermocouple, a temperature controller, a silica gel heating sleeve, a heat preservation sleeve, a magnesium silicate fiber ball, a hydrogen storage tank, a support and an air outlet coil pipe. The manufacturing process of the hydrogen supply device mainly starts from commercially available parts and raw materials and comprises the steps of machining of an air inlet / outlet coil pipe, machining of a cabinet, machining of a hydrogen pressurizing tank, machining ofa hydrogen storage tank, machining of a support and assembling production of the hydrogen supply device. The invention is high in production efficiency, high in safety, low in cost, capable of purifying hydrogen and providing hydrogen of 1-20 MPa, free of vibration noise, small, exquisite, light and particularly suitable for hydrogen supply of laboratory instruments.

Owner:YANGZHOU UNIV

A kind of activated carbon and its preparation method and application

ActiveCN112079354BIncrease the areaHigh pore volumeHydrogenCarbon compoundsActivated carbonTube furnace

The invention relates to the technical field of hydrogen storage materials, in particular to an activated carbon and its preparation method and application. It is obtained by soaking the debris of biomass raw material in LiOH solution, drying and grinding after ultrasonic treatment, putting it into a special puffing kettle, and heating it up. precursor; then the precursor and anhydrous ZnCl 2 Mixed, put into tube furnace for three-stage heating and calcining, and pass N 2 gas, and finally a modified super activated carbon hydrogen storage material is obtained. The activated carbon material is analyzed and tested, and the specific surface area is ≥3000m 2 / g, the micropore volume reaches 2cm 3 About / g, the micropore volume ratio reaches more than 80%, and the average pore diameter is between 0.5 and 1.2nm. Under the operating conditions of room temperature and 40bar, the hydrogen storage capacity can reach more than 2.5wt%, and the adsorption rate is very fast. This method utilizes the principle of biomass flash explosion wall breaking to modify high-performance hydrogen storage materials, which has low cost and simple manufacturing process, and can achieve high hydrogen storage performance at room temperature, medium and high pressure. An effective way is provided.

Owner:SHANDONG UNIV

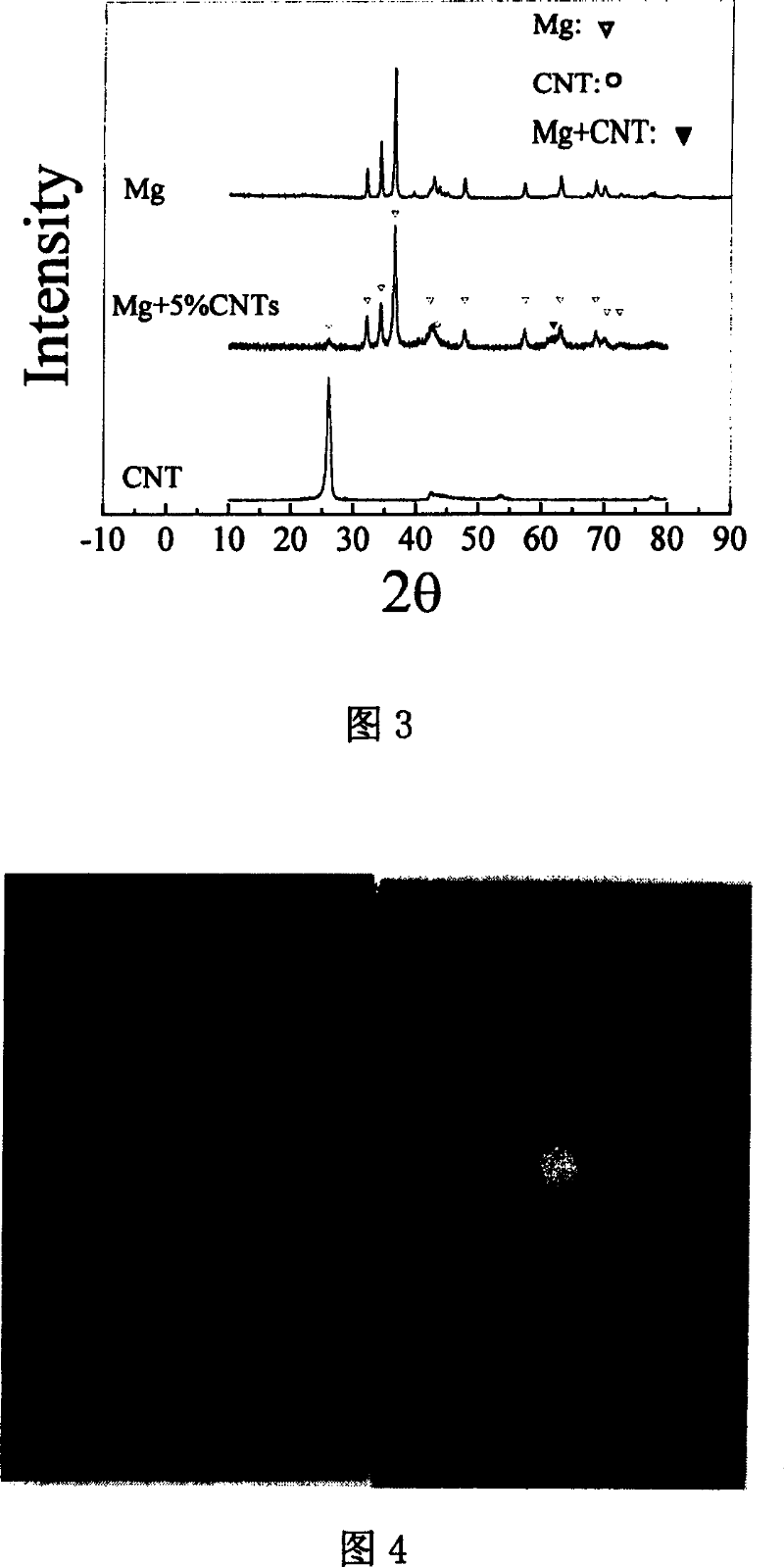

Method for preparing magnesium composite carbon nanometer tube hydrogen-storage material

InactiveCN100357019CEasy to oxidizeAvoid problems such as difficult performance controlOther chemical processesAnthraceneReaction temperature

A process for preparing the Mg compounded carbon nano-tube material as hydrogen-bearing material includes such steps as loading Mg powder, carbon nano-tube and anthracene into reactor under protection of inertial gas, adding tetrahydrofuran, reaction while electromagnetic stirring, ordinary-pressure distilling and thermal decomposing. It has high activity and high hydrogen absorbing and releasing performance.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com