Magnesium-based complex phase hydrogen storage material and preparation thereof

A hydrogen storage material and hydrogen technology, which can be applied to various metal hydrides and other directions, can solve the problems of unsatisfactory thermodynamics and kinetic properties of hydrogen absorption and desorption, and achieve the effects of mild conditions, simple equipment and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of preparation method of magnesium-based composite phase hydrogen storage material, concrete steps are as follows:

[0024] (1) According to the composition of lithium 14%, aluminum 1.0%, and magnesium as the balance, the Mg-Li-Al alloy is smelted in an induction furnace under the protection of argon, and poured into an ingot by a water-cooled mold. This step can be done in a conventional way.

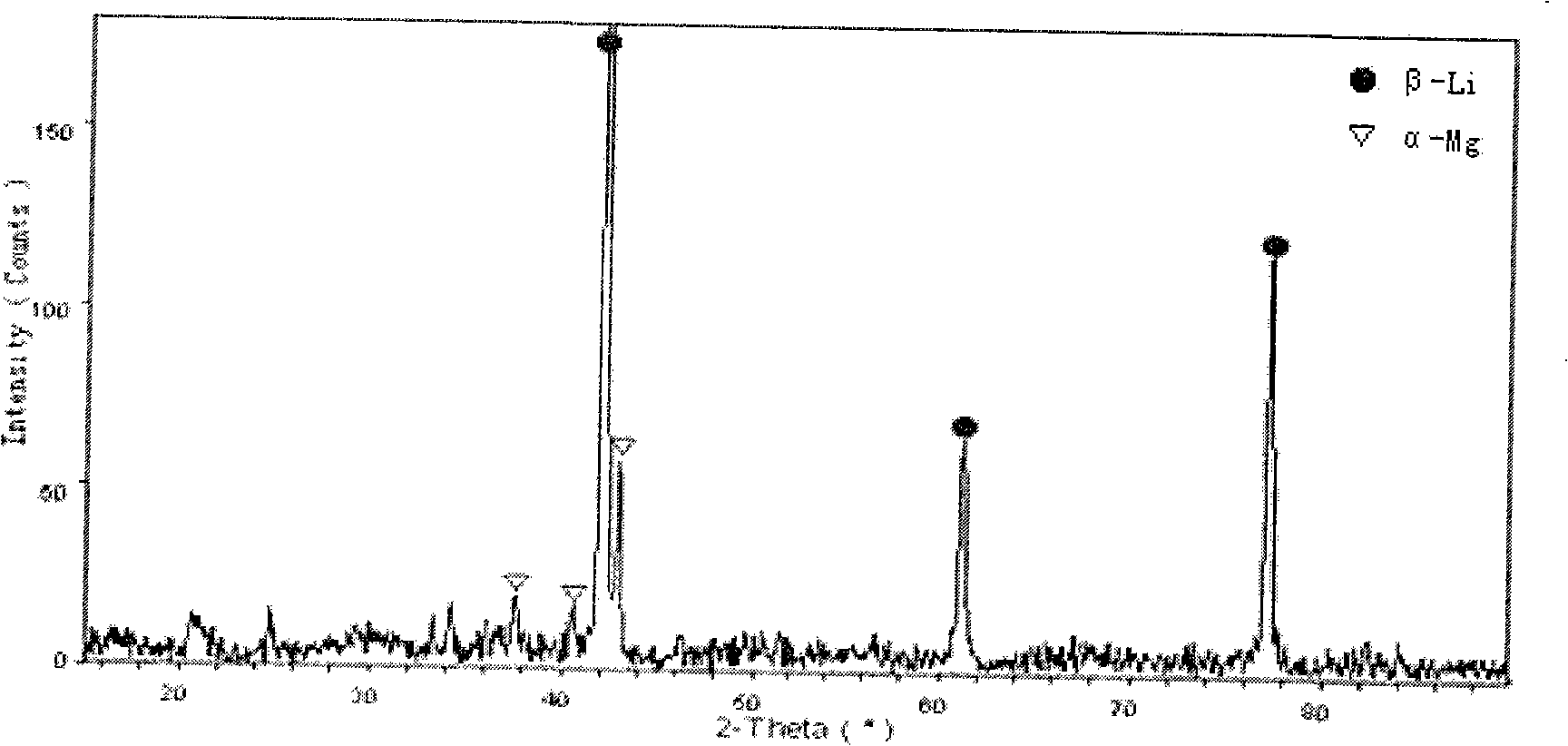

[0025] (2) Mill the above-mentioned Mg-Li-Al alloy ingot into 15-20 mm square fine chips with a milling machine, and then ball mill it in a planetary ball mill for 10 hours under the protection of argon (atmospheric pressure). figure 1 It is the X-ray diffraction pattern of the powder after fine ball milling for 2 hours, and the pattern shows that the powder is mainly composed of two phases of Li(Mg) solid solution and Mg(Li) solid solution.

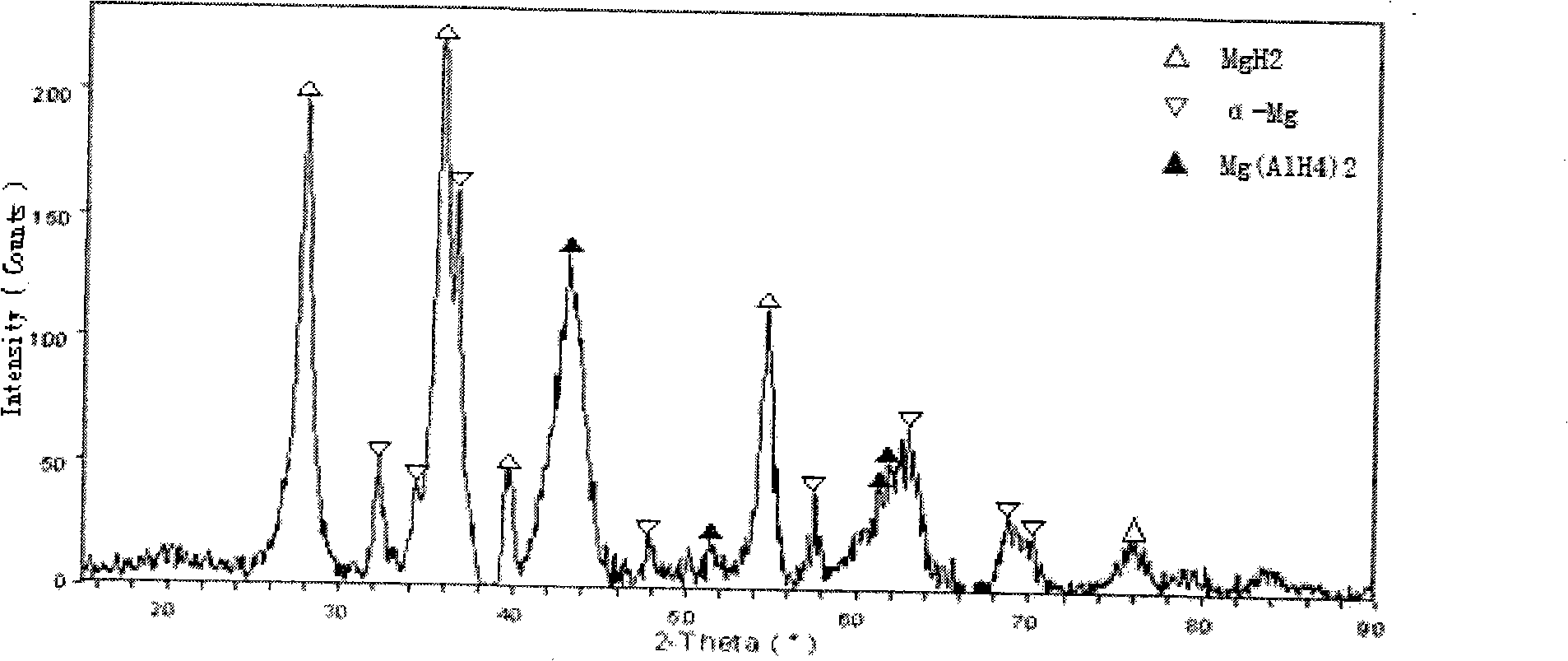

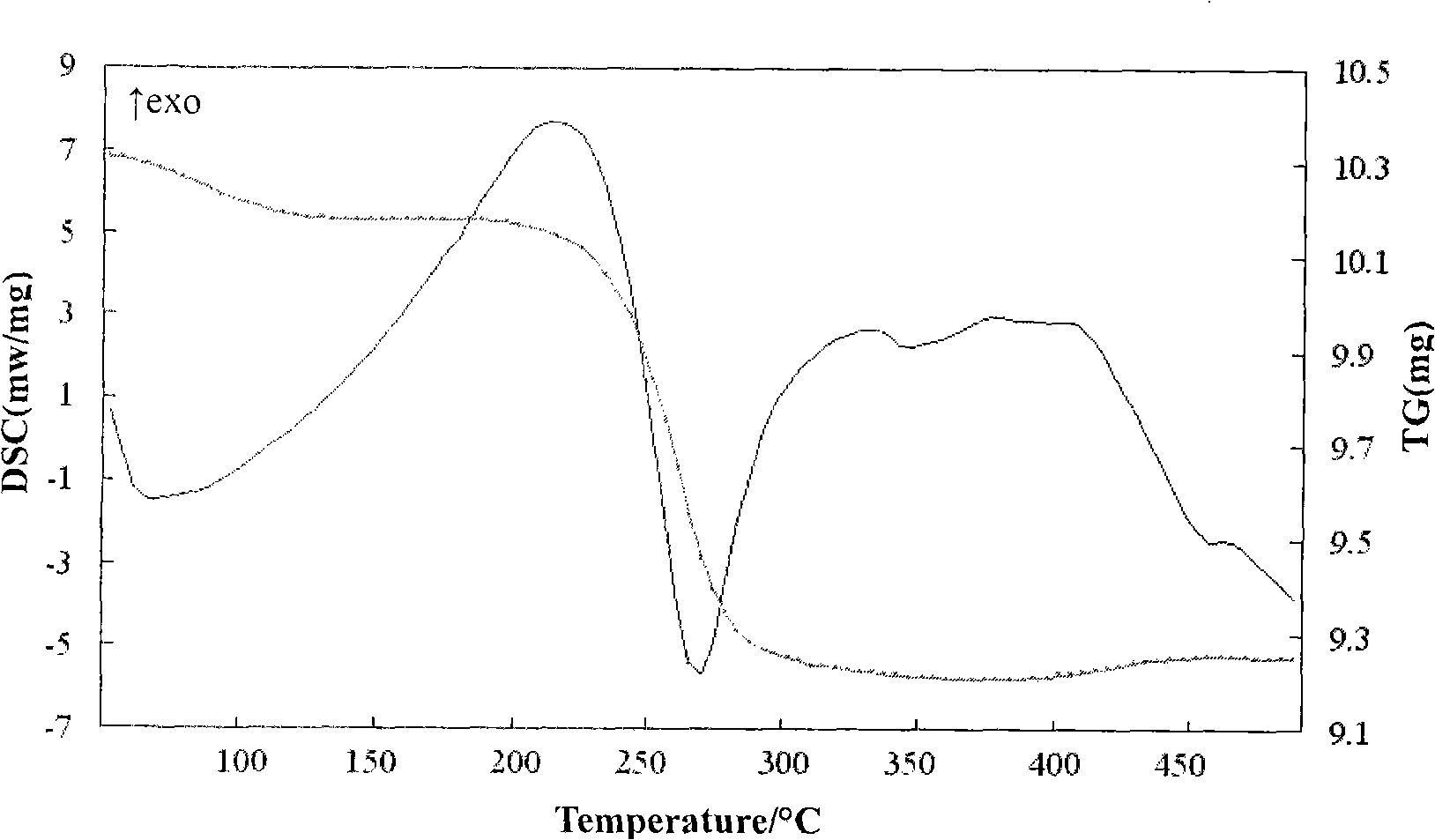

[0026] (3) Reactive ball milling was carried out under a hydrogen atmosphere. First, vacuumize the ball mill syste...

Embodiment 2

[0029] Example 2: A preparation method of a magnesium-based multiphase hydrogen storage material, the specific steps are the same as in Example 1. Wherein the difference is that in the step (1), according to the weight percent content of lithium 21%, aluminum 3.0%, and the balance being magnesium, the Mg-Li-Al alloy is smelted under the protection of argon in an induction furnace, and cast in a water-cooled mold ; In addition, in step (2), the ball milling time is 6 hours, and the reaction ball milling time in step (3) is 8 hours; the hydrogen pressure is 0.2MPa.

Embodiment 3

[0030] Example 3: A preparation method of a magnesium-based composite hydrogen storage material, the specific steps are the same as in Example 1. Wherein the difference is that in the step (1), according to the weight percentage content of lithium 9%, aluminum 1.5%, and the balance being magnesium, the Mg-Li-Al alloy is smelted under the protection of argon in an induction furnace, and the water-cooled mold is poured. ; In addition, in step (2), the ball milling time is 16 hours, and the reaction ball milling time in step (3) is 12 hours; the hydrogen pressure is 0.8MPa.

[0031] By adopting the fusion casting-ball milling hydrogenation reaction synthesis method of the present invention, the magnesium-based coordination hydride is reacted and synthesized while the material is modified, and the hydrogen storage performance of the magnesium-based hydrogen storage material is further improved. The magnesium-based composite hydrogen storage material is nano-scale black powder, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com