Method for preparing magnesium composite carbon nanometer tube hydrogen-storage material

A technology of hydrogen storage materials and carbon nanotubes, which is applied in the field of hydrogen storage energy materials, can solve problems such as easily damaged carbon nanotube structures, and achieve the effects of large hydrogen storage capacity, stable performance, and fast hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

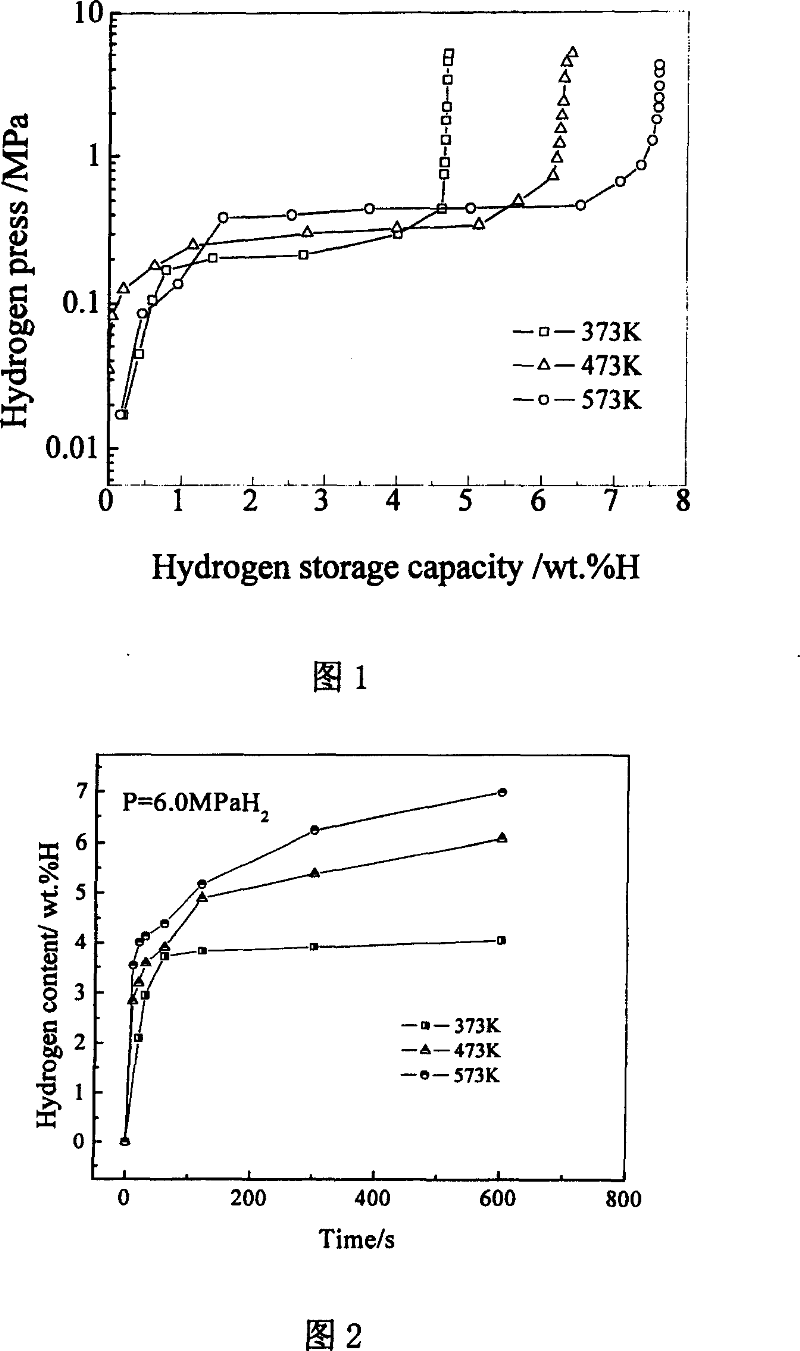

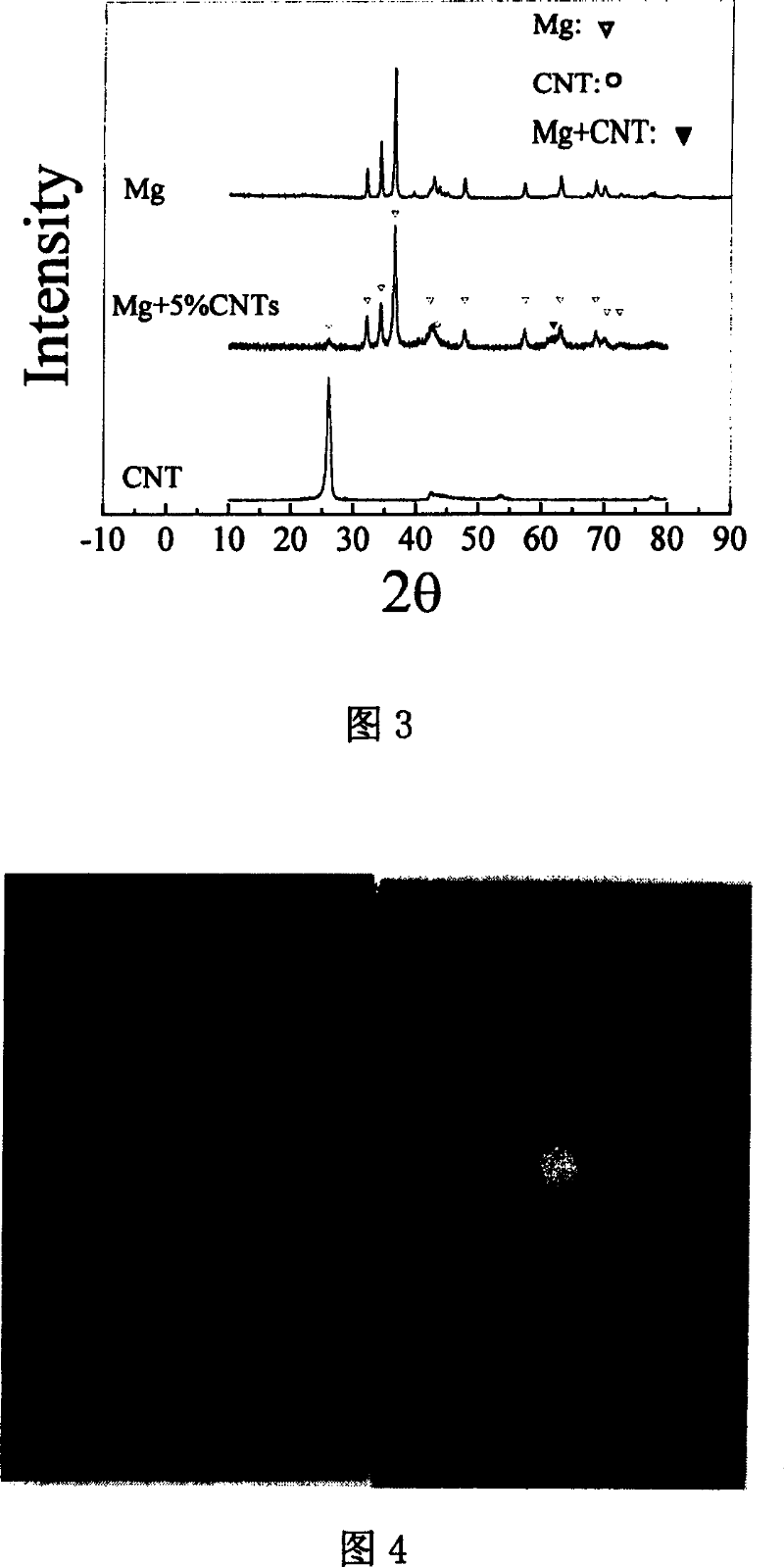

[0021] Under the protection of an inert gas, common magnesium powder, carbon nanotubes and anthracene (carbon nanotubes can be single-walled carbon nanotubes or multi-walled carbon nanotubes) by the mass of magnesium: carbon nanotubes: anthracene=1:0.05:8 Put it in a reaction vessel, add an appropriate amount of tetrahydrofuran (THF) that has been treated with anhydrous and anaerobic treatment, the reaction temperature is 20° C., and electromagnetic stirring is performed for 1 hour. Afterwards, distillation at atmospheric pressure yielded a thick product. The thick material is subjected to vacuum thermal decomposition at 100° C. for 1 hour, and the anthracene is sublimated and then separated. The obtained solid powder material is the magnesium composite carbon nanotube hydrogen storage material, and finally the obtained material is vacuum-sealed and packaged. The magnesium composite carbon nanotube hydrogen storage material was subjected to X-ray diffraction, scanning electron...

Embodiment 2

[0024] Under the protection of an inert gas, common magnesium powder, carbon nanotubes and anthracene (carbon nanotubes can be single-walled carbon nanotubes or multi-walled carbon nanotubes) by the mass of magnesium: carbon nanotubes: anthracene=1:0.1:7 Put it in a reaction vessel, add an appropriate amount of tetrahydrofuran (THF) treated with anhydrous and oxygen-free, and stir it electromagnetically for 2 hours at a reaction temperature of 60° C. under the protection of an inert gas. Afterwards, distillation at atmospheric pressure yielded a thick product. The thick material is thermally decomposed under the protection of an inert gas at 160°C for 4 hours, and the separated solid powder material obtained after sublimation of anthracene is the magnesium composite carbon nanotube hydrogen storage material, and finally the obtained material is vacuum-sealed and packaged. PCT results show that the hydrogen storage capacity of the magnesium composite carbon nanotube hydrogen st...

Embodiment 3

[0026] Under argon protection, magnesium powder, carbon nanotubes and anthracene (carbon nanotubes can be single-walled carbon nanotubes or multi-walled carbon nanotubes) in the mass ratio of magnesium: carbon nanotubes: anthracene=1:0.4:9 , placed in a reaction vessel, added an appropriate amount of anhydrous and oxygen-free tetrahydrofuran (THF), the reaction temperature was 40 ° C, under the protection of argon, and electromagnetically stirred for 5 hours. Afterwards, distillation at atmospheric pressure yielded a thick product. The thick product was subjected to vacuum thermal decomposition at 150°C for 2 hours to separate the sublimed anthracene, and finally the obtained solid powder material was vacuum-sealed and packaged. PCT results show that the hydrogen storage capacity of the magnesium composite carbon nanotube hydrogen storage material is 7.5wt%H at 300°C and 2MPa hydrogen, and the hydrogen absorption capacity reaches 4.4wt%H at 100°C. The hydrogen absorption temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com