A method for manufacturing hydrogen supply device

A manufacturing method and hydrogen supply technology, applied in chemical instruments and methods, sustainable manufacturing/processing, hydrogen, etc., can solve problems such as reducing hydrogen purity, pollution emissions, loud noise and vibration, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

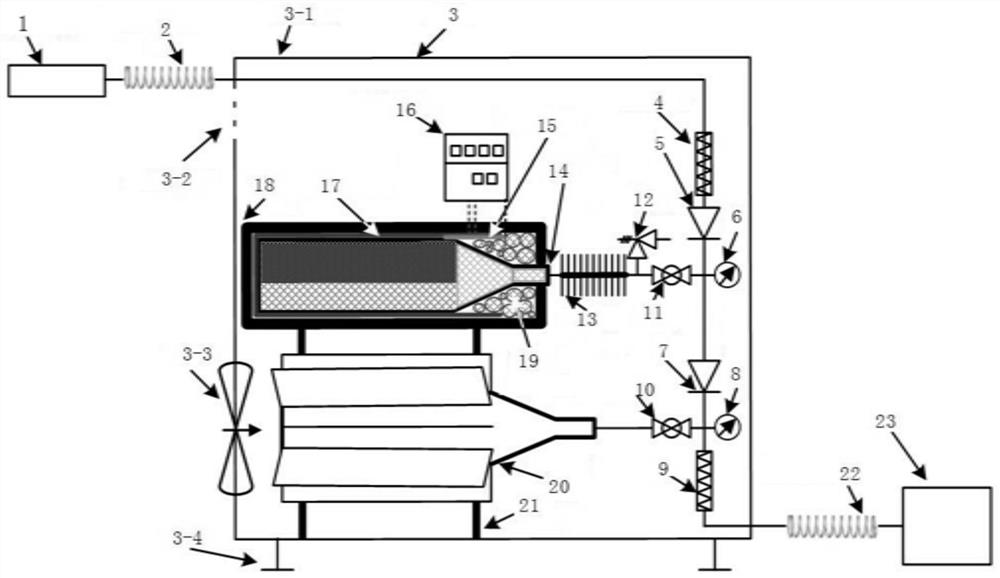

[0083] Such as figure 1 As shown, a hydrogen supply device includes: intake coil 2, cabinet 3, 0.5um filter 4, check valve 5, pressure gauge 6, check valve 7, pressure gauge 8, 0.5um filter 9, Ball valve 10, ball valve 11, safety valve 12, finned cooling pipe 13, hydrogen booster tank 14, thermocouple 15, temperature controller 16, silica gel heating jacket 17, heat preservation jacket 18, magnesium silicate fiber ball 19, hydrogen storage tank 20. Support 21, air outlet coil 22, analysis instrument 23.

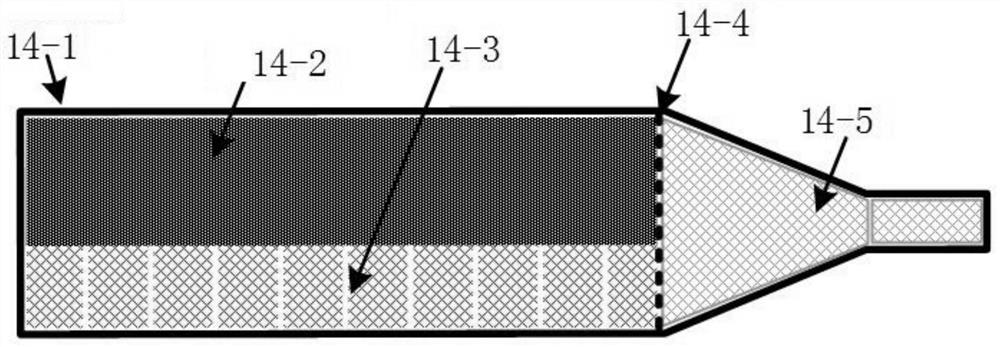

[0084] As shown in Figure 2, the hydrogen pressurized tank of the hydrogen supply device includes a stainless steel bottle 14-1, hydrogen storage alloy powder 14-2, copper foam 14-3, sieve plate 14-4, and quartz wool 14-5.

[0085] As shown in FIG. 3 , the hydrogen storage tank of the hydrogen supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com