Ferrotitanium alloy hydrogen storage material used for fuel cell car and preparing method

A technology of titanium-iron alloy and hydrogen storage material, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor activation and stability of titanium-iron hydrogen storage alloy, poor resistance to gaseous impurity poisoning, difficult alloy surface activation, etc. Improved activation and stability, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

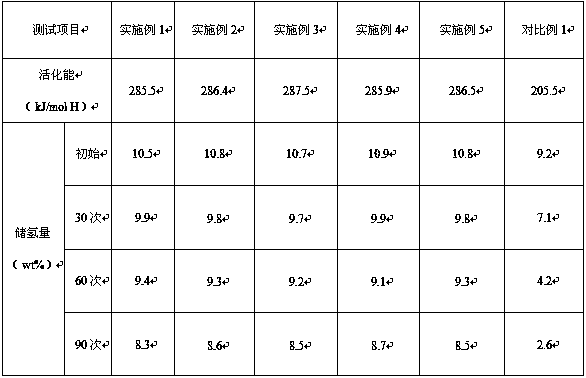

Examples

Embodiment 1

[0030] a. Using tetraethyl orthosilicate as a solvent, slowly add a saturated aqueous solution containing iron trichloride and titanium tetrachloride dropwise, while adding a reducing agent, a pore-forming agent and a flocculant for stirring, and using citric acid to adjust the pH value to 4 , standing and aging after complete reaction to obtain a gel-like material;

[0031] b. Uniformly mixing the gel-like material prepared in step a with doped metal powder, performing low-temperature heat treatment under the mixed gas source of argon / hydrogen, and then performing subsequent molding to obtain a titanium-iron alloy hydrogen storage material.

[0032]In step a, the reducing agent is lithium aluminum hydride, the pore forming agent is sodium bicarbonate, and the flocculant is aluminum sulfate; in step b, the doped metal powder is manganese powder;

[0033] In step a, 56 parts by weight of ethyl orthosilicate, 18 parts by weight of iron salt, 18 parts by weight of titanium salt, ...

Embodiment 2

[0036] a. Using tetraethyl orthosilicate as a solvent, slowly add a saturated aqueous solution containing iron trichloride and titanium tetrachloride dropwise, while adding a reducing agent, a pore-forming agent and a flocculant for stirring, and using citric acid to adjust the pH value to 4 , standing and aging after complete reaction to obtain a gel-like material;

[0037] b. Uniformly mixing the gel-like material prepared in step a with doped metal powder, performing low-temperature heat treatment under the mixed gas source of argon / hydrogen, and then performing subsequent molding to obtain a titanium-iron alloy hydrogen storage material.

[0038] In step a, the reducing agent is stannous chloride, the pore forming agent is potassium bicarbonate, and the flocculant is aluminum chloride; in step b, the doped metal powder is magnesium powder;

[0039] In step a, 65 parts by weight of ethyl orthosilicate, 15 parts by weight of iron salt, 15 parts by weight of titanium salt, 3 ...

Embodiment 3

[0042] a. Using tetraethyl orthosilicate as a solvent, slowly add a saturated aqueous solution containing iron trichloride and titanium tetrachloride dropwise, while adding a reducing agent, a pore-forming agent and a flocculant for stirring, and using citric acid to adjust the pH value to 4 , standing and aging after complete reaction to obtain a gel-like material;

[0043] b. Uniformly mixing the gel-like material prepared in step a with doped metal powder, performing low-temperature heat treatment under the mixed gas source of argon / hydrogen, and then performing subsequent molding to obtain a titanium-iron alloy hydrogen storage material.

[0044] In step a, the reducing agent is potassium borohydride, the pore-forming agent is ammonium bicarbonate, and the flocculant is ferric sulfate; in step b, the doped metal powder is manganese powder;

[0045] In step a, 50 parts by weight of ethyl orthosilicate, 20 parts by weight of iron salt, 20 parts by weight of titanium salt, 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com