Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Large filtration flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of low-temperature sintering acid and alkali resistant porous silicon carbide ceramic film

ActiveCN107663088AImprove hydrophilicityImprove pollutionCeramicwareSeparation technologyPorous ceramics

The invention relates to the technical field of porous ceramic materials and film separation, in particular to a low-temperature sintering acid and alkali resistant porous silicon carbide ceramic filmand a preparation method thereof. The method sequentially comprises the following steps of (1) support body manufacturing; (2) transition layer processing; (3) filtering layer processing; (4) film sintering process. The method provided by the invention has the characteristics that the sintering temperature is low; the production energy consumption is low; the process method is simple; the equipment requirements are low; the production cost and the investment cost are low; the control is flexible; the shaping is easy; the method is suitable for industrial customization and meets the scaled production. The porous silicon carbide ceramic film produced by the method has the characteristics of good hydrophilcity, great filtering flux, high porosity, high filtering precision, high mechanical intensity, good acid and alkali resistant performance and long service life.

Owner:ZHEJIANG SCI-TECH UNIV

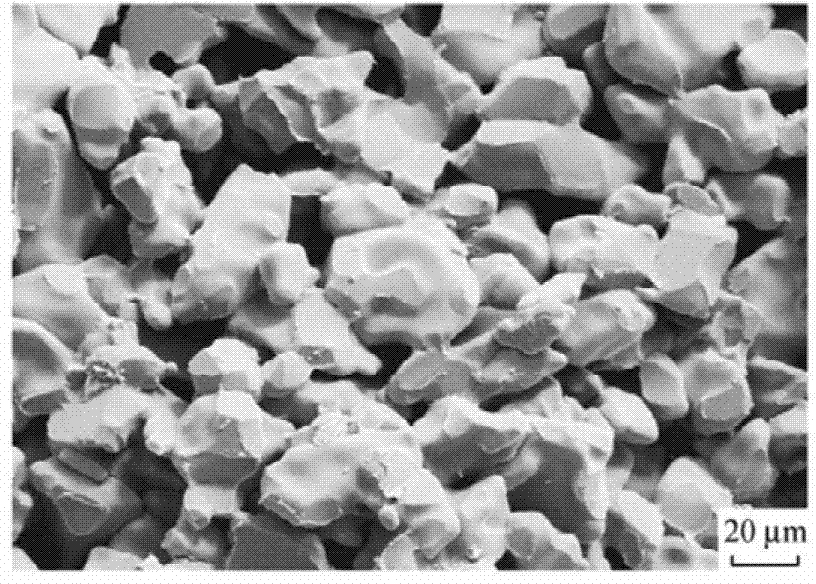

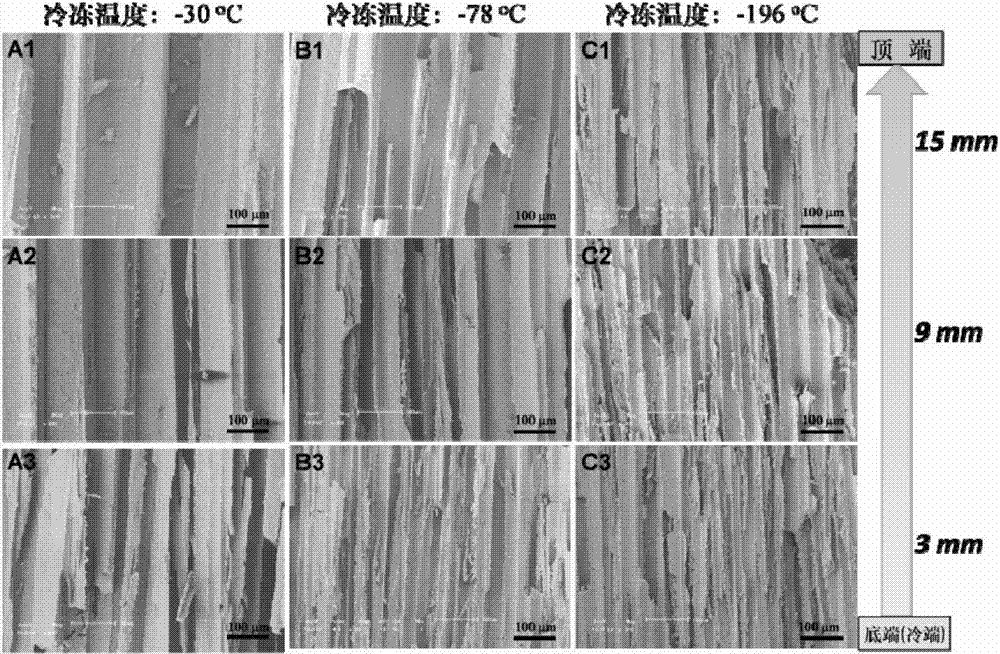

Preparation method of porous ceramic pipe with gradient through hole structure

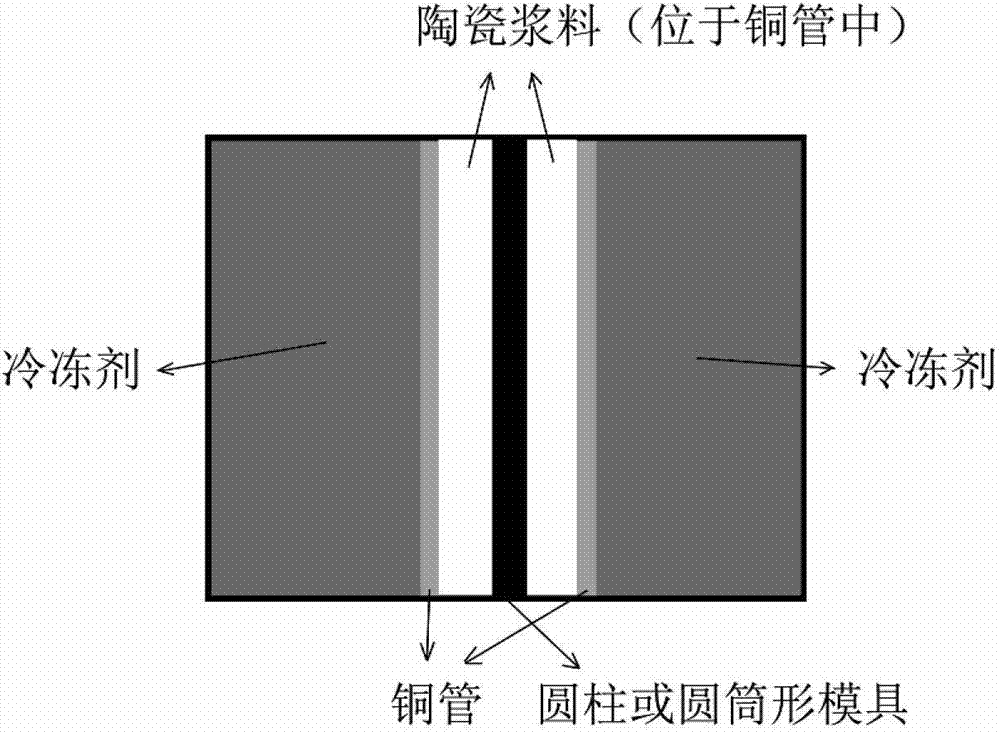

The invention relates to a preparation method of a porous ceramic pipe with a gradient through hole structure. The preparation method is characterized in that the adopted raw materials include freezing medium tertiary butanol, ceramic powder, a dispersing agent, adhesive, a lubricating agent, and refrigerant; and the preparation method comprises the steps of mixing the raw materials based on a certain ratio; freezing and shaping; and sintering at a low temperature of -50 DEG C under an air condition without pressure, thus obtaining the porous ceramic pipe with the gradient through hole structure. The porous ceramic pipe prepared by the method provided by the invention has a radial gradient through hole structure with an axis served as the centre of a circle; and the porous ceramic pipe has the advantages of high strength, high filtration flux, and being easily cleaned. The preparation method is simple in preparation technology, has low requirements on equipment and technological conditions, and is beneficial for being popularized and used.

Owner:TSINGHUA UNIV

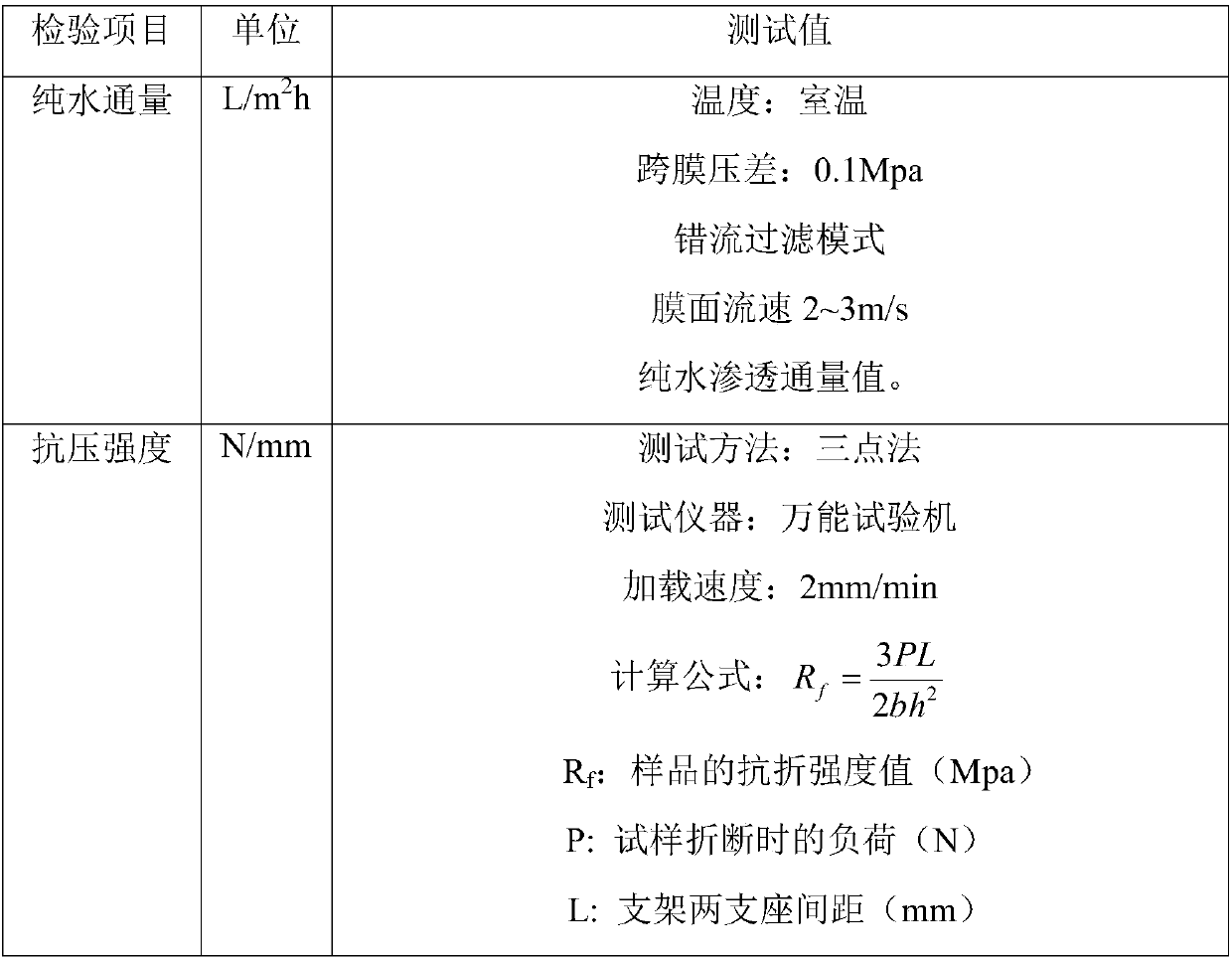

Preparation method of ceramic membrane supporting body

ActiveCN104014252AShorten the production cycleIncrease productivitySemi-permeable membranesAir atmosphereArgon atmosphere

The invention discloses a preparation method of a ceramic filtering membrane supporting body. The method comprises the steps of (1) preparing a raw material, wherein the raw material comprises mixing powder, namely alpha aluminium oxide powder (1) the purity of which is greater than or equal to 99.7% and alpha aluminium oxide powder (2) the purity of which is greater than or equal to 99.8%, the median particle diameter D50 of the alpha aluminium oxide powder (1) is 18-35mum, the median particle diameter D50 of the alpha aluminium oxide powder (2) is 0.8-2mum, and the dosage of the alpha aluminium oxide powder (2) is 2%-10% (weight) of that of the alpha aluminium oxide powder (1); (2), mixing the mixing powder with a water solution of cross-linking agent acrylamide and methylene double crylic acid ammonium to form a suspension, and carrying out gel casting on the suspension; heating a formed product to 40-55 DEG C in a microwave manner, drying for 1-3 hours, calcining the dried formed product for 4-8 hours under 500-800 DEG C in air atmosphere, placing a calcined product in vacuum or atmospheric hydrogen or argon atmosphere, carrying out heat preservation on the calcined product for 4-12 hours under the condition of 1800 DEG C-1950 DEG C so as to form a supporting body of a pure alpha phase aluminum oxide ceramic filtering membrane. The preparation method provided by the invention has the advantages that the porosity of a product is high, the flux is high, and the product is strong-acid-resisting and strong-alkali-corrosion-resisting.

Owner:SANDA FILM SCI & TECH XIAMEN

Membrane separating process for purifying high temperature condensated water

InactiveCN101088922AMiniaturization reducesImprove reuse rateWater/sewage treatment bu osmosis/dialysisChemistrySolubility

The present invention relates to membrane separating process of purifying high temperature condensated water. High temperature condensated water is first microfiltered or ultrafiltered and then deeply treated with nanofiltering film to have the suspended matter, oil, colloid, dissolved small molecular weight organic matter, inorganic ion and other impurities. The process has stable treating effect and capacity of recovering the heat energy in high temperature condensated water, and the treated water may be reused in boiler. The present invention provides one stable and effective way for treating and reusing high temperature condensated water.

Owner:NANJING JIUSI HIGH TECH

Preparation method of multilayered gradient ceramic membrane

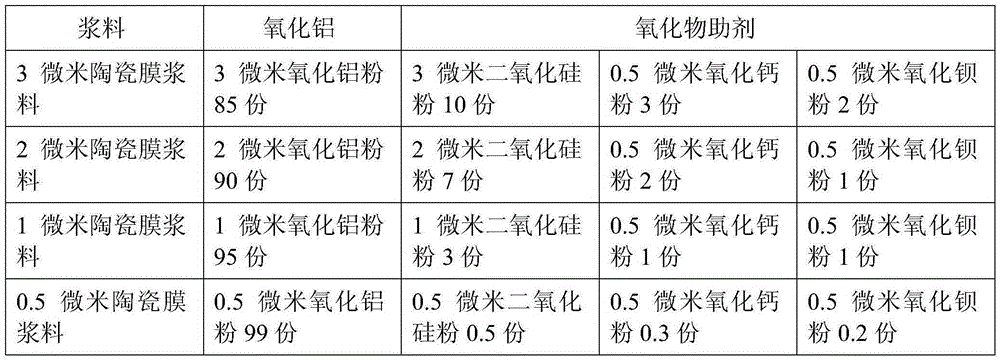

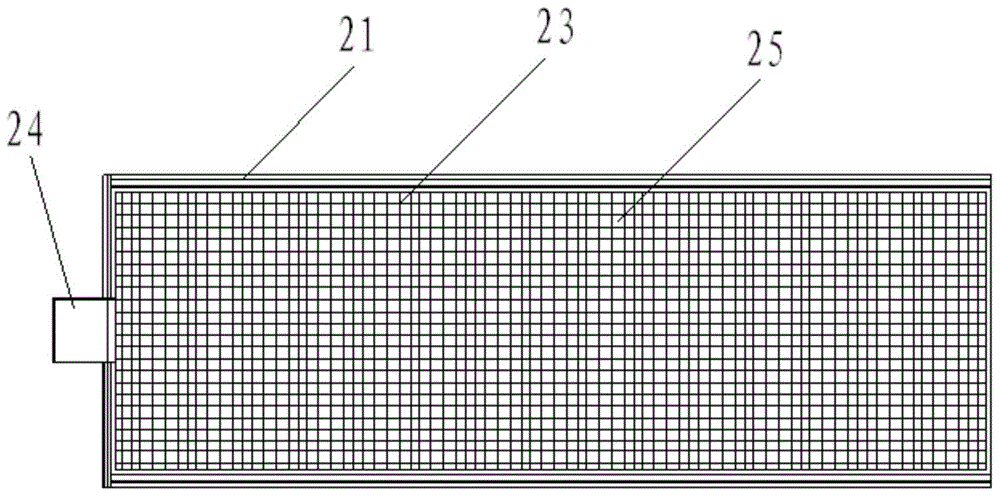

ActiveCN105251375AOvercome technical difficulties of uneven thicknessControl thicknessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisScreen printingThermal expansion

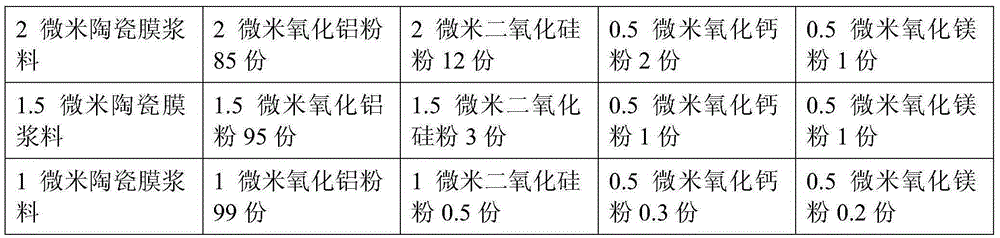

The invention provides a preparation method of a multilayered gradient ceramic membrane. According to the method, ceramic membrane slurry having different chemical components and grain sizes is printed on a flat plate type ceramic membrane supporting body by adopting a silk-screen printing technology and is commonly sintered with the flat plate type ceramic membrane supporting body once, so that the multilayered gradient ceramic membrane having different chemical components and pore structures is formed on the surface of the supporting body. With the adoption of the silk-screen printing technology, the thickness of a single-layer membrane can be controlled in a range of 10-30 microns, and the thickness is uniform and consistent; and the technical difficulties that a dip-coating-method membrane layer is relatively thick and the thickness of a spraying-method membrane layer is not uniform are effectively overcome. The multilayered gradient ceramic membrane is composed of more than three layers of membrane materials having the different chemical components and grains, so that the multilayered gradient ceramic membrane has different coefficients of thermal expansion, porosities and average pore diameters; thermal stress, caused by unmatched expansion coefficients, between the supporting body and the membrane layer is alleviated well; and the binding strength of the membrane layer and the supporting body is improved, and the filtration flux of the membrane layer is increased. The multilayered gradient ceramic membrane is long in service life and low in preparation cost, saves energy and is environmentally friendly.

Owner:湖南科一环保科技股份有限公司

Method for separating and purifying L-hydroxyproline from L-hydroxyproline fermentation liquor

ActiveCN107513030ALarge filtration fluxReduce processing timeOrganic chemistry methodsUltrafiltrationChemistry

The invention belongs to the field of biochemical engineering and specifically relates to a method for separating and purifying L-hydroxyproline from L-hydroxyproline fermentation liquor. The method comprises the following steps: separating bacterial solution of the fermentation liquor, filtering with an ultrafiltration membrane, treating with a compound absorbent, desalting and performing vacuum concentration crystallization. According to the method provided by the invention, the fermentation liquor is pretreated and then is filtered for removing bacteria, so that the filtration flux is increased, the filtering time is shortened and the removal rate of protein is 20% or above; no cation exchange resin is used and the acid-alkali wastewater is greatly reduced; the nanofiltration membrane or reverse osmosis membrane treatment is not required, the qualified product is acquired through primary crystallization, the power cost and energy consumption are greatly reduced and an efficient low-cost method for separating and purifying hydroxyproline is formed; according to the invention, the production process route is simplified, the production period is shortened, the production cost is lowered, the extraction rate of the L-hydroxyproline is increased to 85% or above and the content of the end product is 99.0% or above.

Owner:FUJIAN NORMAL UNIV

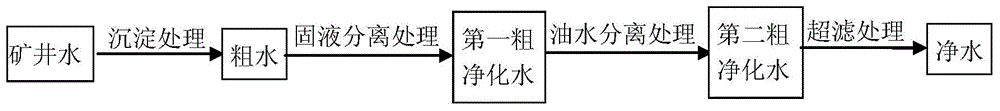

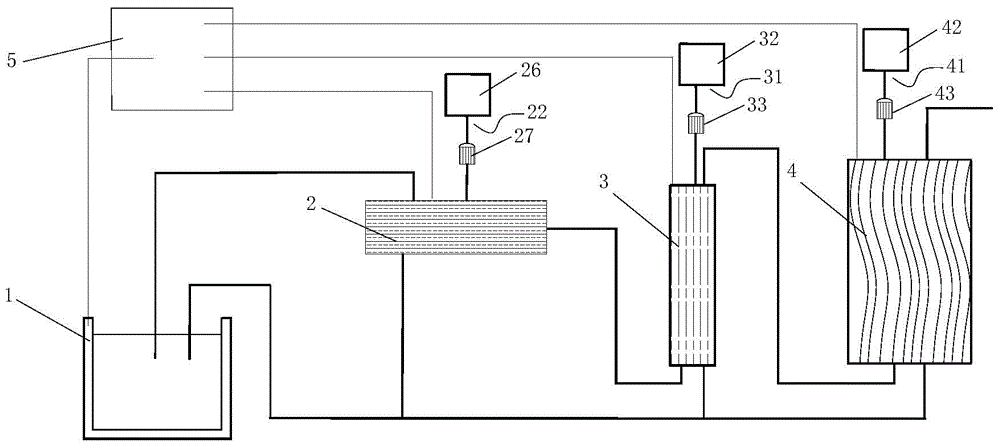

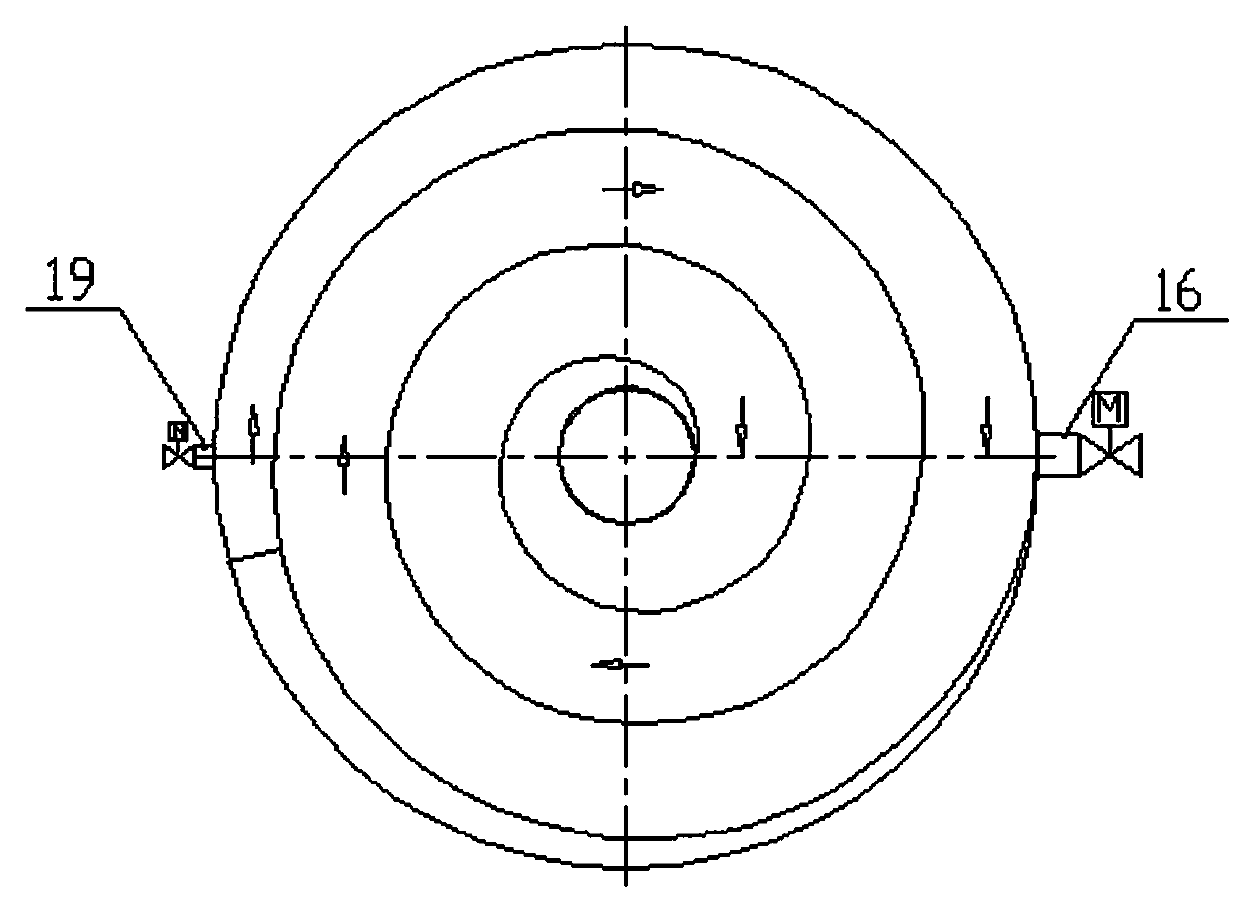

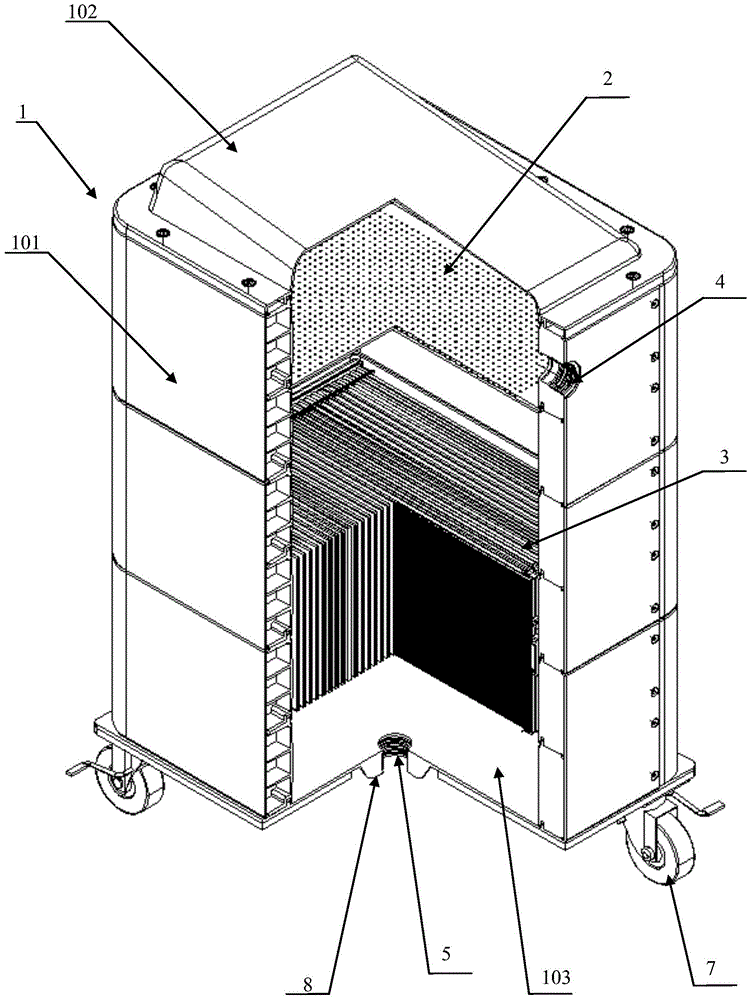

Underground movable modular mine water treatment system

ActiveCN104445677AReduce processing loadLarge filtration fluxWaste water treatment from quariesMultistage water/sewage treatmentUltrafiltrationWaste treatment

The invention provides an underground movable modular mine water treatment system which comprises the following steps: firstly, introducing mine water into a shaft sump for sedimentation treatment; carrying out solid-liquid separation treatment on the settled mine water to remove fine suspended solids therein; carrying out oil water separation treatment on first coarse purified water to remove dissolved oil and emulsified oil to obtain second coarse purified water; and carrying out ultrafiltration treatment on the second coarse purified water to remove organic matters therein so as to obtain purified water. The invention provides a device for treating mine water underground. The device comprises the shaft sump, a solid-liquid separation device, an oil water separation device, an ultrafiltration device and a control device. The system provided by the invention has an obvious effect for removing organic matters in mine waste water. The pollutant concentrations of the mine waste water treated by the system are obviously reduced, and the removal rate is relatively high. The device provided by the invention can be directly arranged in the coal mine and the mine water treated is directly reused in the pit, so that the investment and operating cost of waste water treatment are hugely saved.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

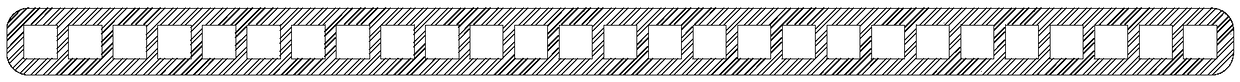

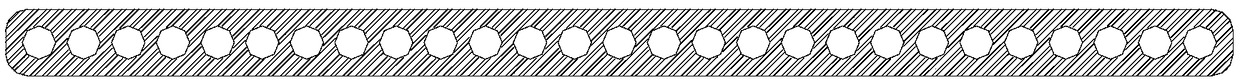

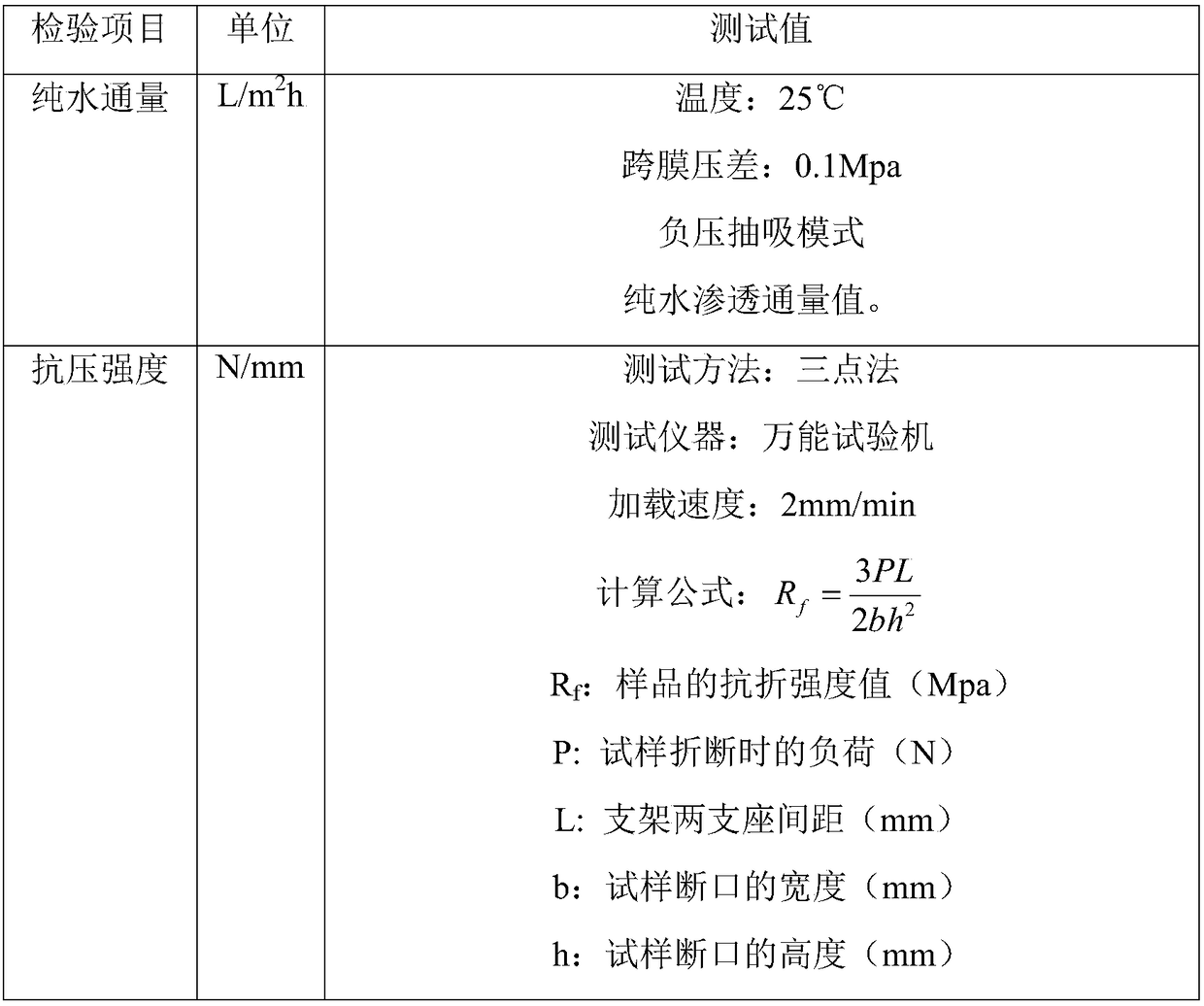

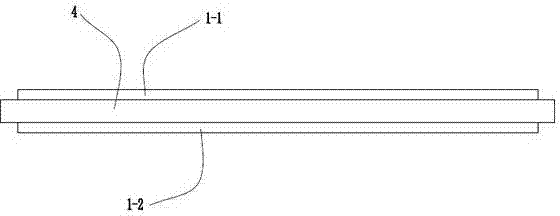

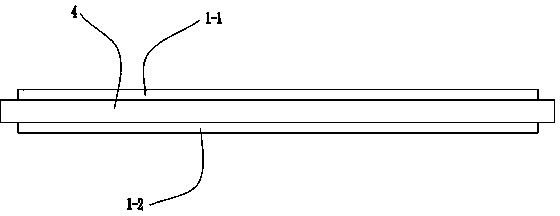

Preparation method of porous silicon carbide flat plate ceramic support

InactiveCN108658604AImprove hydrophilicityGood anti-pollutionSustainable biological treatmentCeramicwareAutomatic controlPapermaking

The invention discloses the technical field of inorganic porous materials, and particularly relates to the technical field of inorganic membrane separation, in particular to a porous silicon carbide flat plate ceramic support and a preparation method thereof. The preparation method includes the steps: (1) pug preparation; (2) extrusion; (3) microwave drying; (4) high temperature firing; finally, natural cooling to room temperature. Compared with a recrystallization sintering method, the preparation method has the advantages of low firing temperature, low energy consumption and production costand simple preparation process. Besides, diffusive flow of a filtering medium in a wider space is ensured, filtering resistance is reduced, back flushing effects can be remarkably improved, so that filtering flux is increased, production cycle is short, production and operation cost is low, and automatic control and stable product performances are easily realized. The porous silicon carbide flat plate ceramic support can be used for special separation in industries such as chemical engineering, biological fermentation, papermaking, food and beverages and mineral processing.

Owner:台州利欧环保新材料有限公司

Preparation method of asymmetric plate ceramic nanofiltration membrane

PendingCN108079788ASolve for uniformitySolve the requestReverse osmosisCeramicwareWater basedEmulsion

The invention discloses a preparation method of an asymmetric plate ceramic nanofiltration membrane. According to the method, ceramic powder with different chemical composition and granular sizes is mixed with a water-based auxiliary, ceramic membrane slurry is prepared and printed on a plate ceramic membrane support body by a special porous emulsion roller, the support body is sintered at different temperatures, and the asymmetric plate ceramic nanofiltration membrane with different chemical composition and pore structures is formed on the surface of the support body. Density, diameter and depth of slurry adsorbing holes in the porous emulsion roller can be adjusted effectively with a laser drilling technology, so that thickness and uniformity of the ceramic membrane can be controlled precisely. The ceramic membrane with different thicknesses and surface pore size being 5-100 nm can be obtained with adoption of the porous emulsion roller with different pore density, pore diameter andpore depth. The asymmetric plate ceramic nanofiltration membrane is low in filtering resistance, high in filtering reflux, long in service life, energy-saving and environmentally friendly, and preparation cost is low.

Owner:肖汉宁

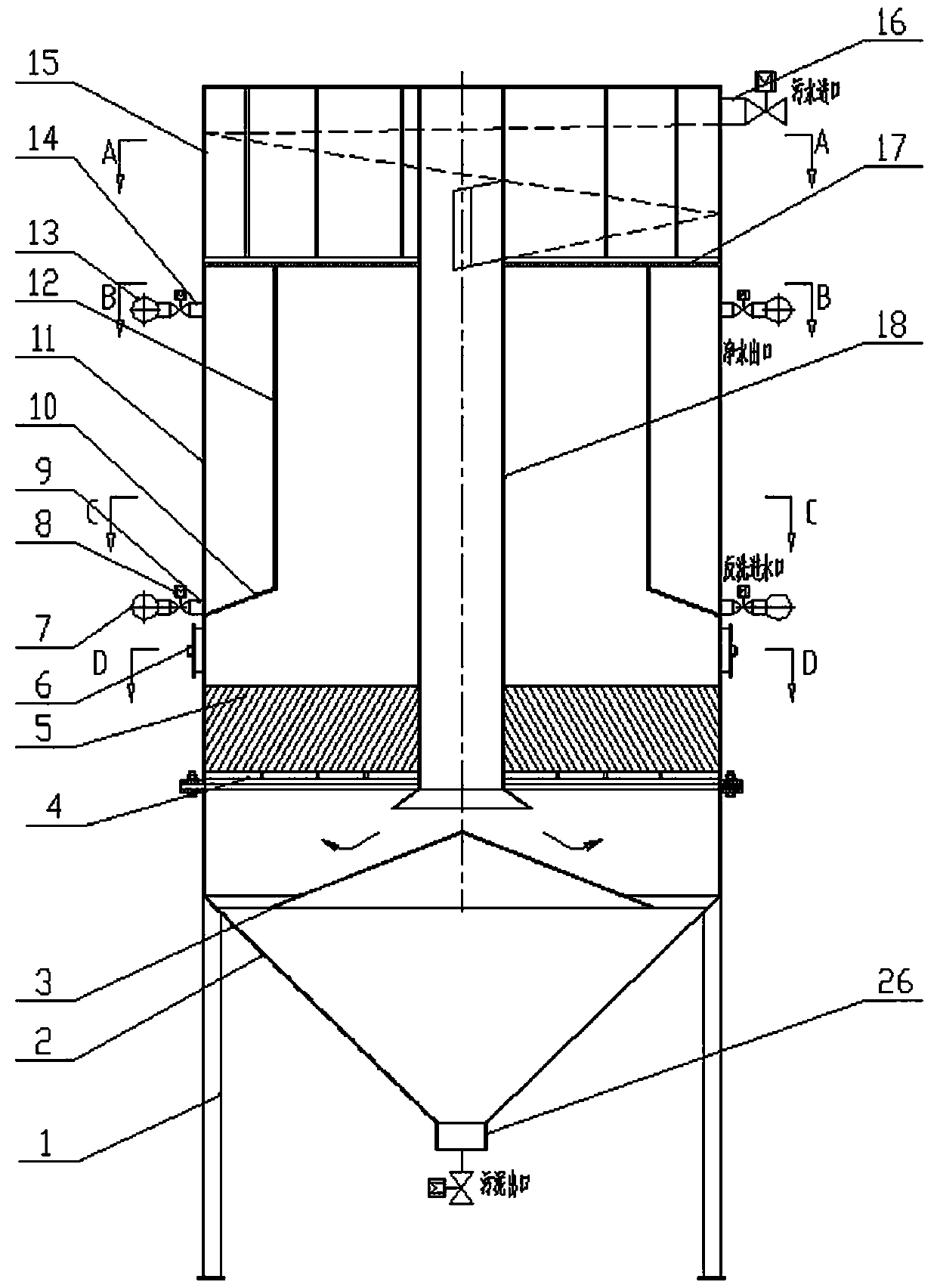

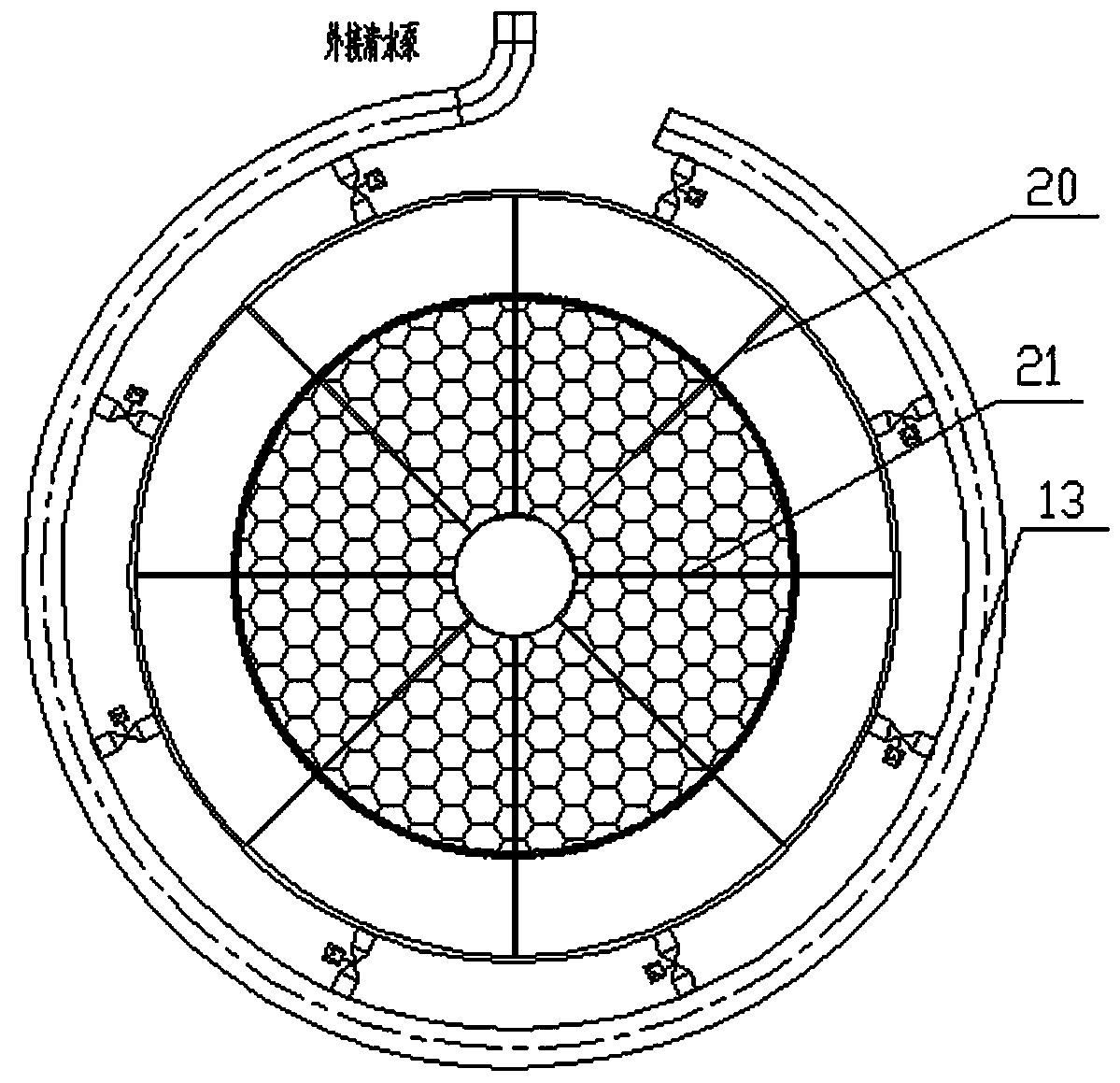

Flocculation, swirling, precipitation and filtration integrated sewage treatment equipment

PendingCN110272150AGood noveltyImprove practicalitySludge treatmentTreatment involving filtrationFlocculationSludge

The invention discloses flocculation, swirling, precipitation and filtration integrated sewage treatment equipment. The equipment mainly comprises an inner cylinder and an outer cylinder, wherein the inner cylinder is coaxially embedded in the outer cylinder; the top of the outer cylinder is provided with a top plate, a swirling-type flocculation tank is installed on the top plate, and the upper end of the inner cylinder extends into the swirling-type flocculation tank and is concentric with the tank body; the junction between the part, extending into the swirling-type flocculation tank, of the inner cylinder and the top is provided with a sewage inlet tangential to the outer diameter of the inner cylinder; an inclined pipe precipitation packing layer is arranged between the bottom of the inner cylinder and the bottom of the outer cylinder and installed on an inclined pipe packing bracket, and the lower end of the inner cylinder slightly protrudes out of the inclined pipe packing bracket; a sludge collection hopper is arranged below the outer cylinder, the bottom of the sludge collection hopper is provided with a sludge outlet and a valve, and a steel bracket is arranged below the sludge collection hopper. An annular filtering layer is arranged between the portion, between the inclined pipe precipitation packing layer and the top plate, of the outer cylinder. The equipment integrates various processes of flocculation, swirling, precipitation and filtration and is simple in structure, convenient to maintain and high in purification efficiency.

Owner:HUNAN UNIV OF SCI & TECH

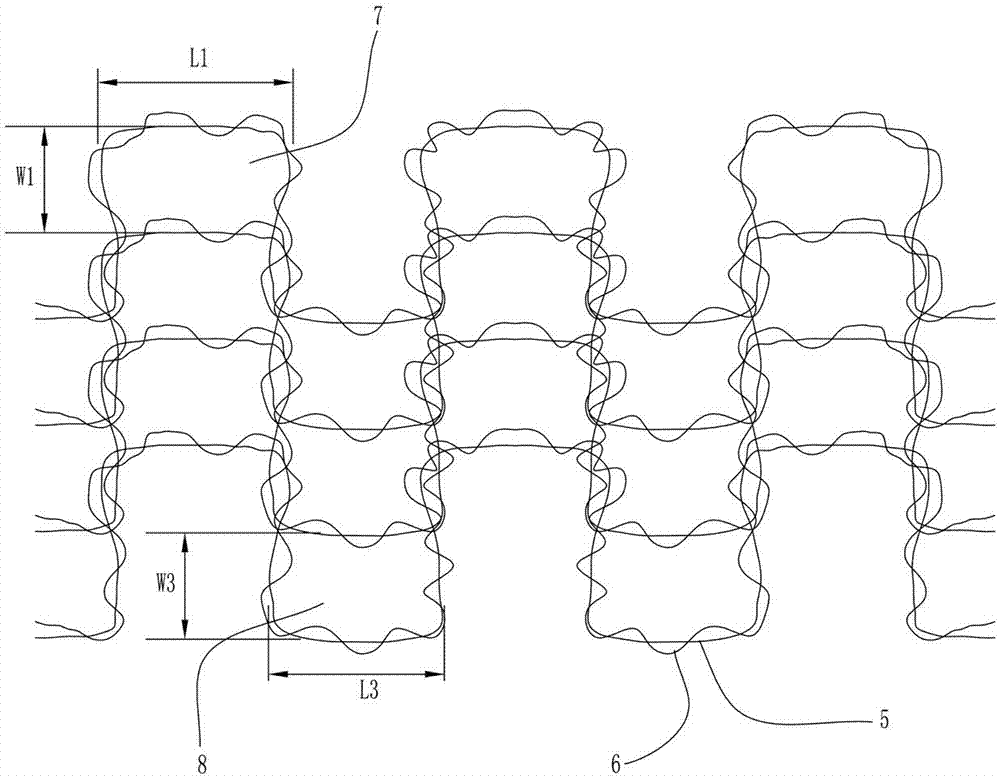

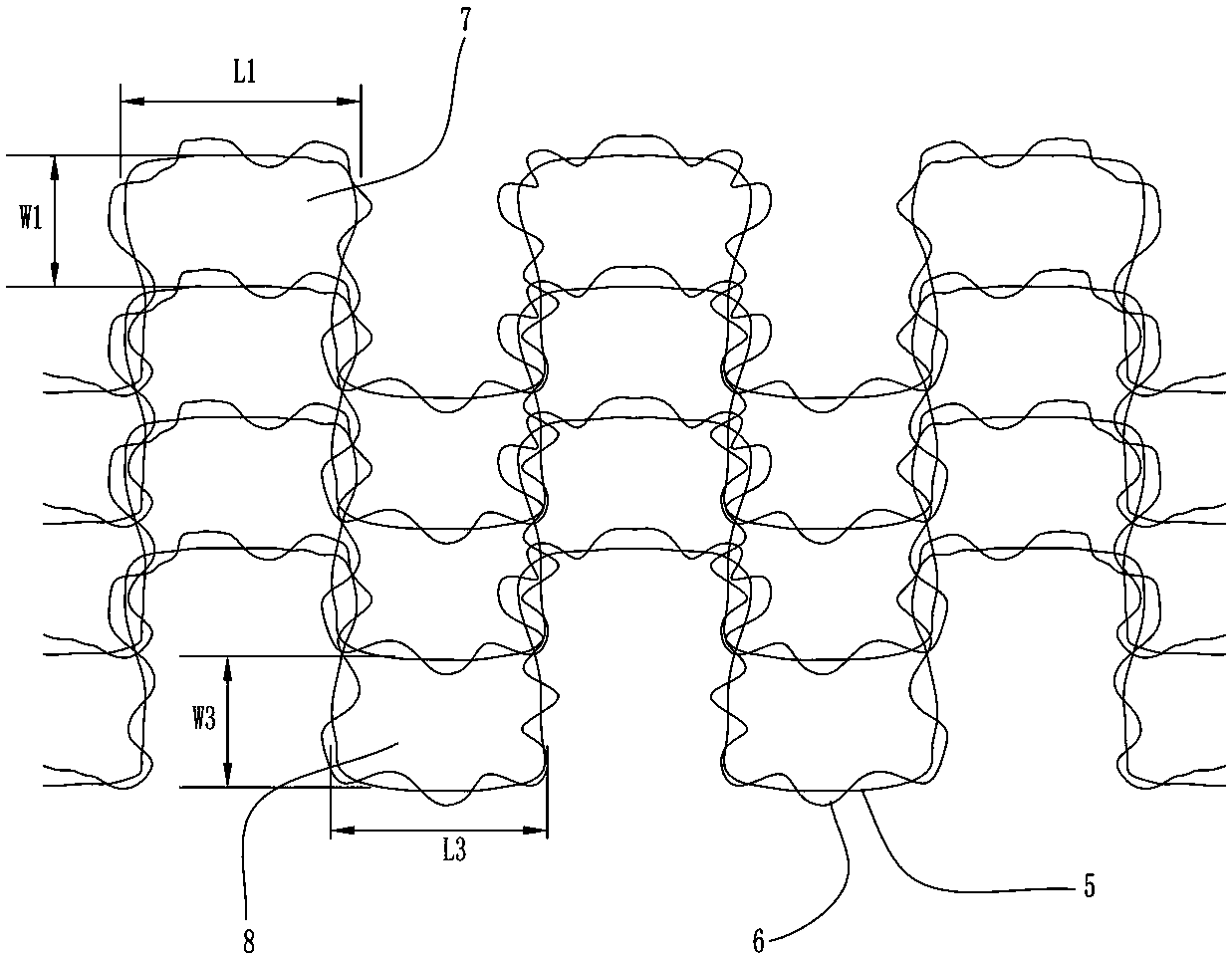

Oil mist purification filter element

InactiveCN103111136AHigh filtration precisionSmall filter resistanceDispersed particle filtrationFiberGlass fiber

The invention discloses a filter element, in particular to an oil mist purification filter element which comprises a gas-liquid filter screen and an outer frame for fixing and unfolding a laminated gas-liquid filter screen which is folded, wherein the gas-liquid filter screen is formed by weaving a steel wire with the diameter of 0.2 layer-05mm and a PP (polypropylene) fiber with the diameter of 1.0 layer-2.0mm or a glass fiber, the steel wire and the PP fiber or the glass fiber are wound, meshes of two specifications are distributed on the gas-liquid filter screen at intervals, the first mesh takes on a rectangle with the length L3 of 4.5mm-6mm and the width W1 of 4mm-5.5mm, and the second mesh takes on a rectangle with the length L3 of 6mm-6.5mm and the width W3 of 4mm-5.5mm. According to the filter element, the technical defect that the existing gas-liquid filter screen is poor in filter quality or low in filter efficiency is overcome, the filter element is mainly applied to an oil mist filter system, and has the advantages that the filtration flux is large and the accuracy is high, and the like.

Owner:ZHEJIANG YUANKAI TECH

Method for producing composite filter tube and filter element made of multilayer metal mesh and metal powders

ActiveUS20150352469A1Low filtration resistanceLarge filtration fluxArc welding apparatusMembrane filtersMolding machineComposite filter

A method for producing a composite filter tube and filter element made of a multilayer metal mesh and metal powders, including: knitting to obtain metal meshes of different mesh numbers, obtaining a layered structure by means of a lamination method, then putting the layered structure in a vacuum furnace for sintering processing, sintering a metal composite layer to obtain a composite filter sheet and tube made of a multilayer metal mesh and metal powders with a multilayer metal mesh as a structure support layer and a metal powder sinter structure as a filter layer, then rolling the composite filter sheet and tube into a tubular filter element by using a shaping machine, and welding to obtain a composite filter tube and filter element product made of a multilayer metal mesh and metal powders.

Owner:WANG DONGWEI

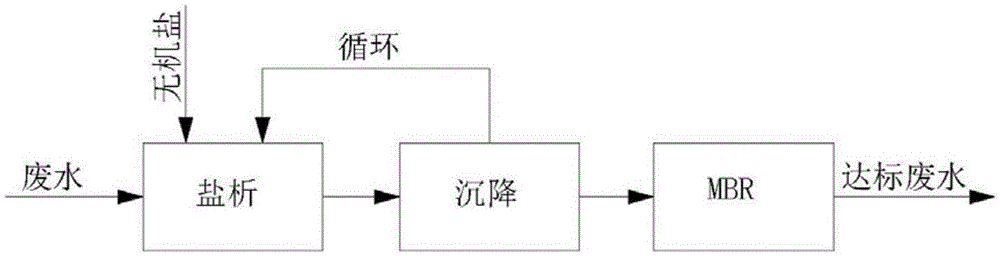

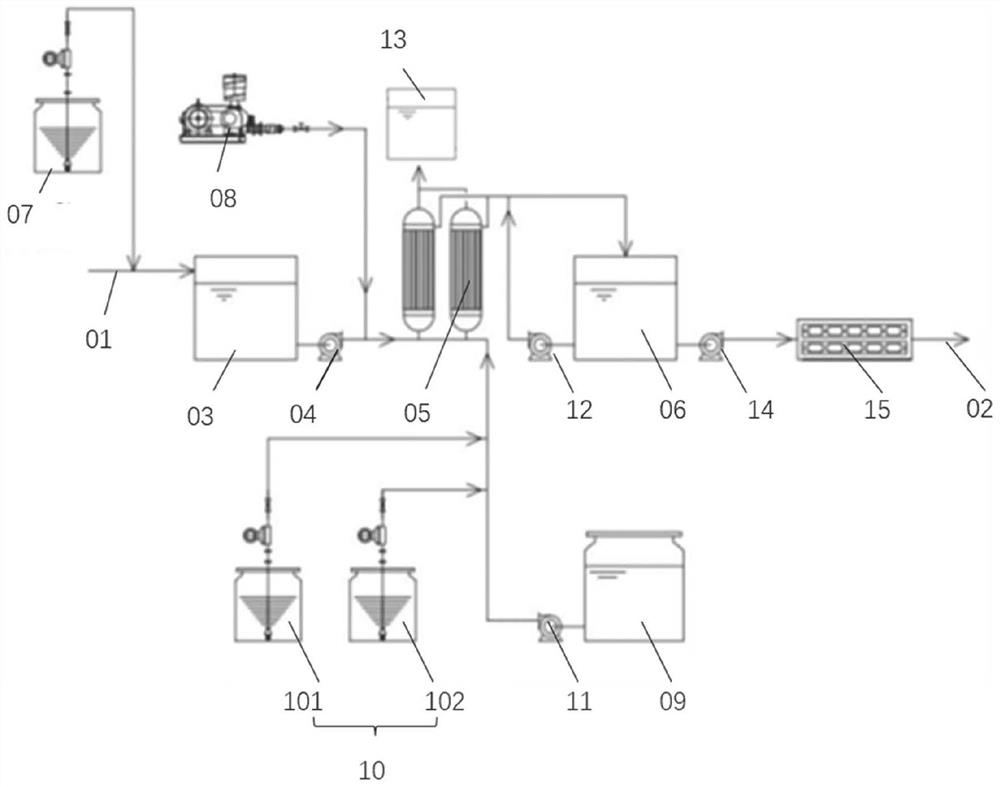

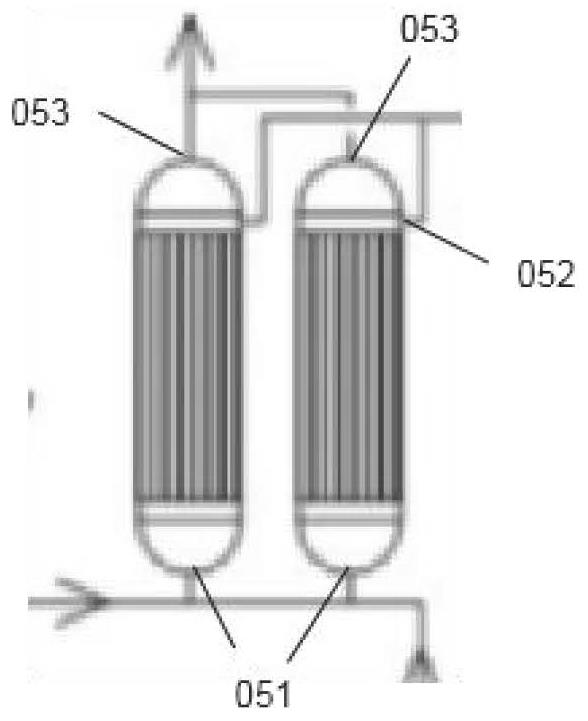

Method for treating caprolactam production wastewater

InactiveCN105541044AReduce CODReduce the impactSpecific water treatment objectivesTreatment with aerobic and anaerobic processesInorganic saltsSalting out

The invention provides a method for treating caprolactam production wastewater. The method comprises the following steps of (1) salting-out: adding inorganic salt into a reactor, while continuously leading the caprolactam production wastewater and / or reflux liquid, continuously evaporating moisture, and precipitating organic matters in the wastewater in a floccule form under the salting-out function; (2) flocculating: continuously leading the wastewater containing the floccule into an overflow tank, adding a flocculant into the overflow tank, flocculating and settling suspensions containing the floccule in the wastewater, and enabling the supernatant of the overflow tank to flow back to the reactor; (3) thinning the wastewater subjected to salting-out and flocculating, sending into a membrane biological reactor, and further performing biochemical treatment, wherein the membrane biological reactor comprises an A / O biochemical system, a dynamic membrane filter, a dynamic membrane preparation system and a hydraulic backflushing device. The method has the advantages that the energy consumption is low, the operation cost is low, and a large amount of caprolactam wastewater can be effectively and quickly treated.

Owner:CHINA TIANCHEN ENG +2

Preparation method of ultra-high molecular weight polyethylene composite microporous membrane

The invention relates to a preparation method of an ultra-high molecular weight polyethylene composite microporous membrane. The preparation method comprises the following steps: (1) carrying out desizing treatment on base cloth which is high-temperature-resistant cloth, then drying, and performing pretreatment with pretreating agents; (2) weighing ultra-high molecular weight polyethylene, diluents and antioxidants in parts by weight, melting and mixing by a double-screw extruder, performing hot-pressing combination on the mixture and the base cloth to obtain a composite jelly membrane by a continuous extrusion process or a gap type mold-pressing process; and (3) removing the diluents in the composite jelly membrane by extraction agents, drying and shaping to obtain the composite microporous membrane. According to the preparation method, the ultra-high molecular weight polyethylene enters the inside of the cloth sufficiently to form a penetrating network, the combined membrane has good penetrating property, high water flux and high mechanical property improved greatly, and the prepared microporous membrane can be used for production of foods, medicines, and ultrapure water, and can meet the requirements of separation, purification, concentration and purification.

Owner:DONGHUA UNIV

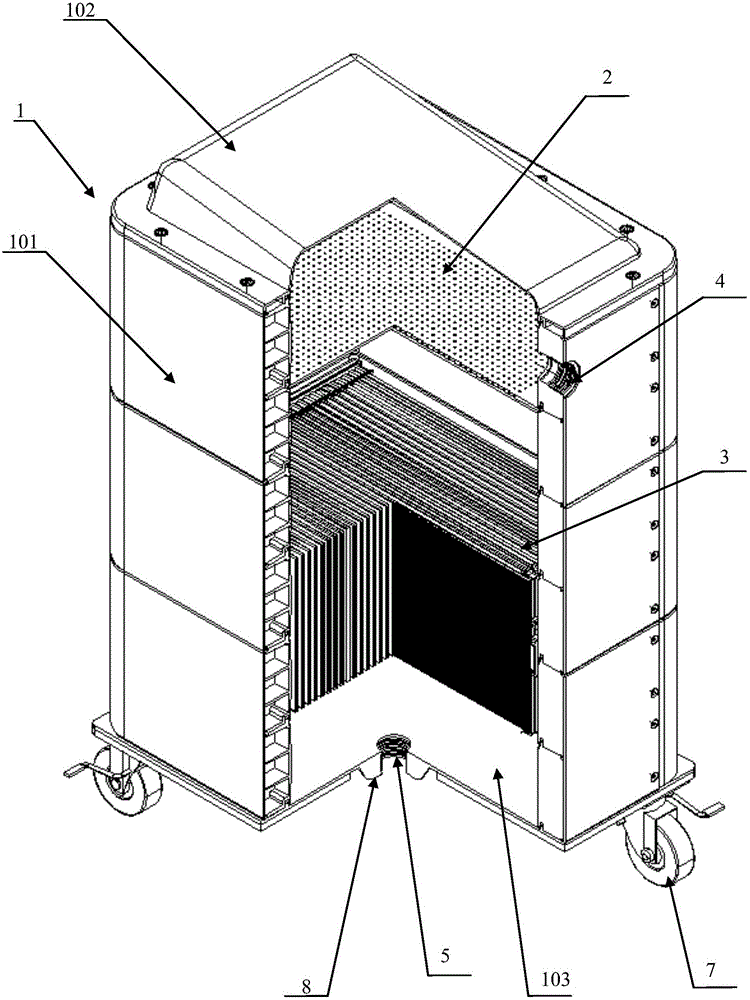

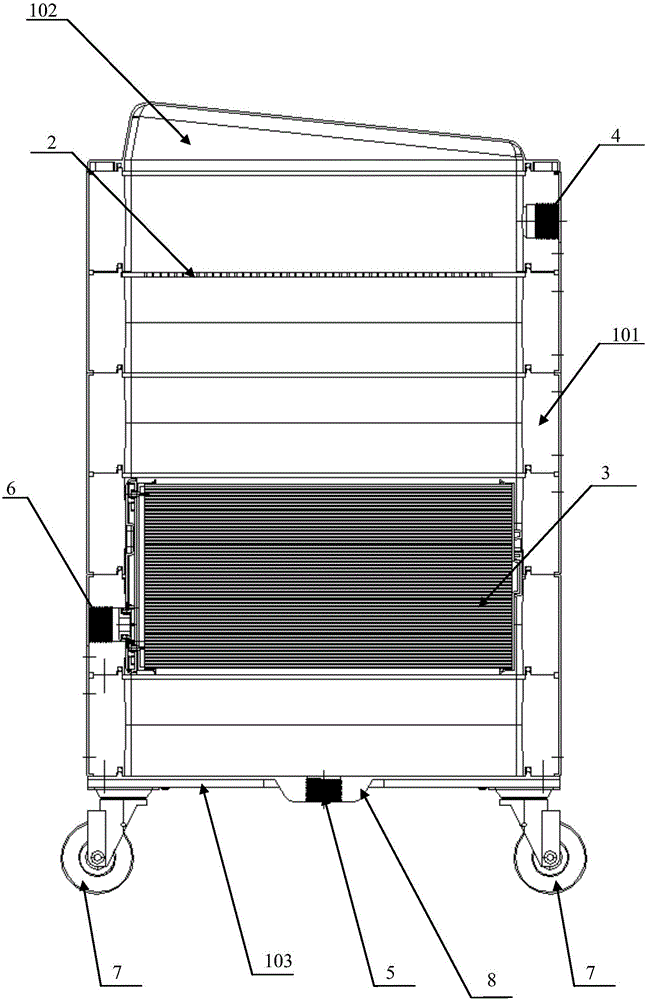

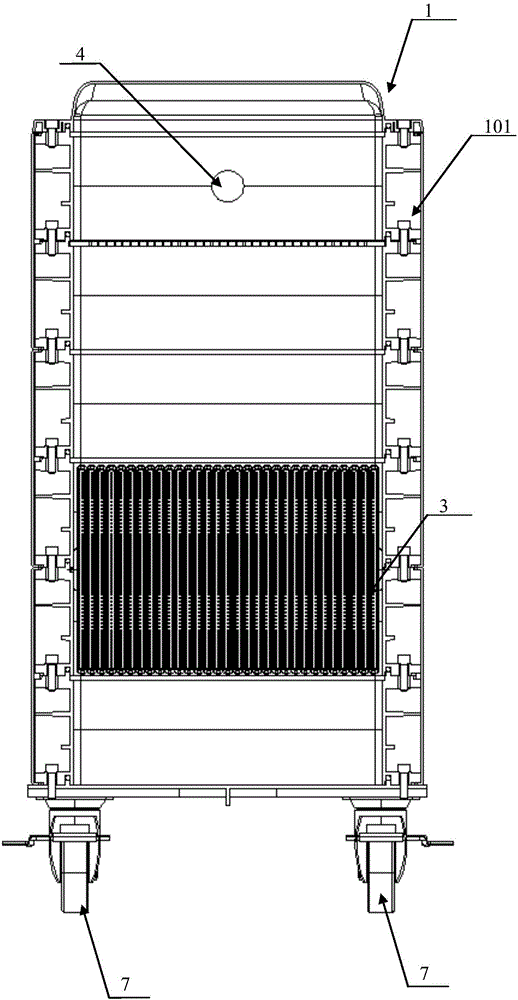

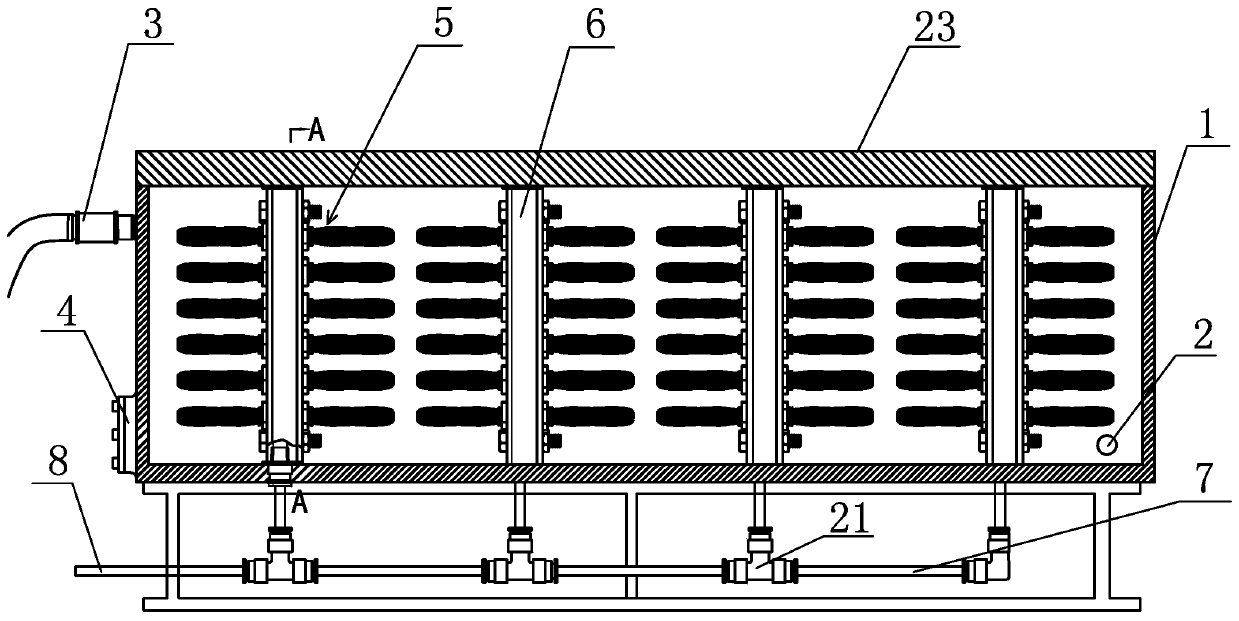

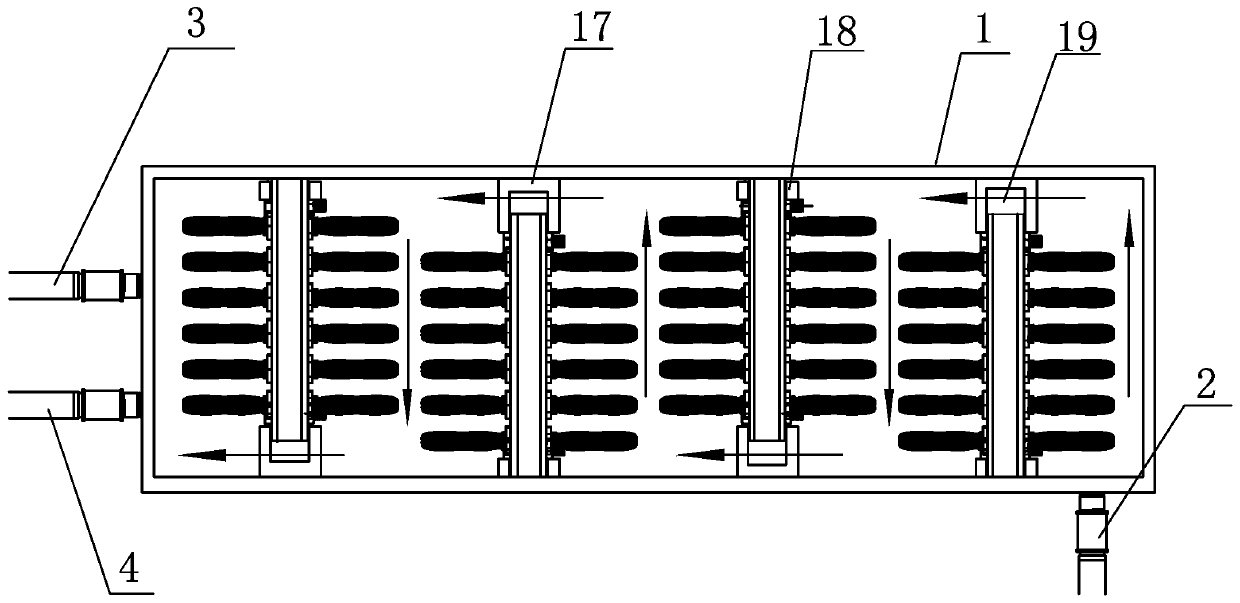

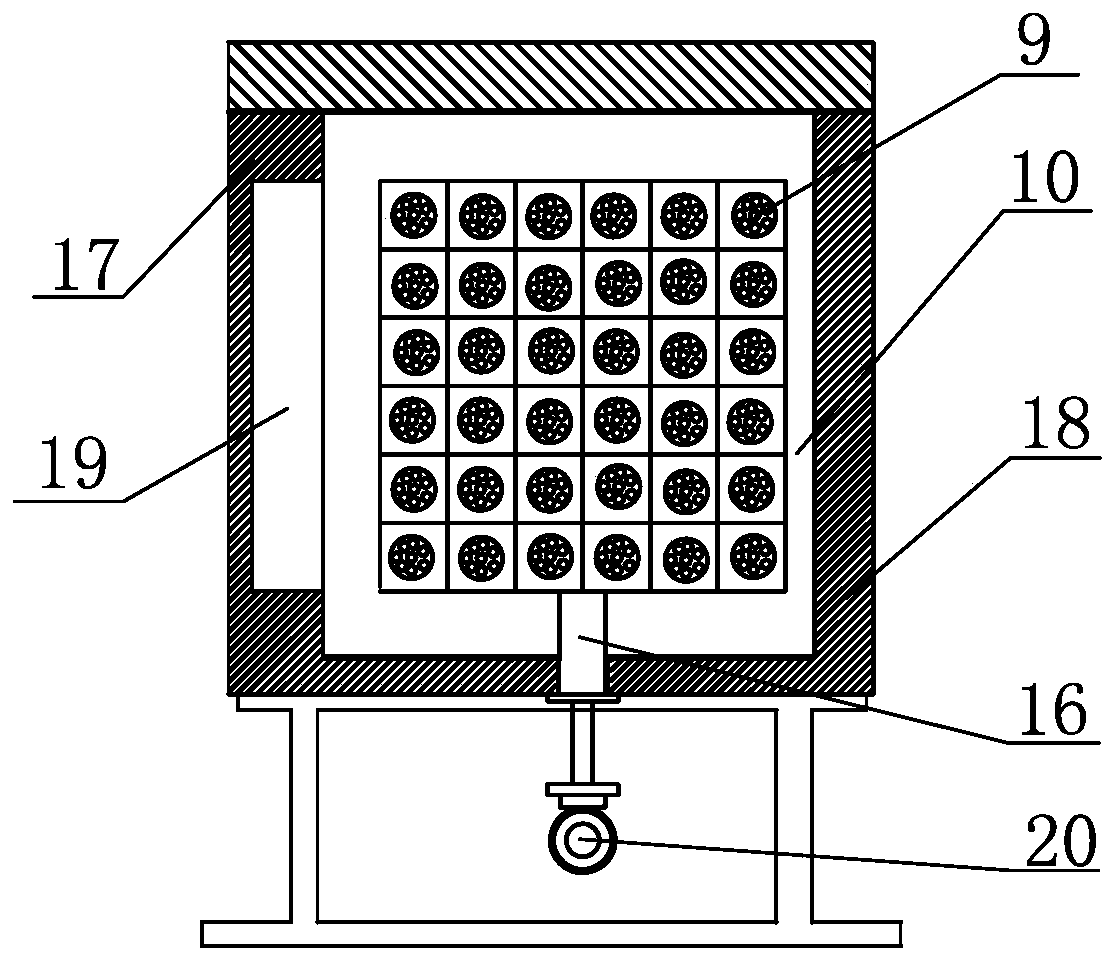

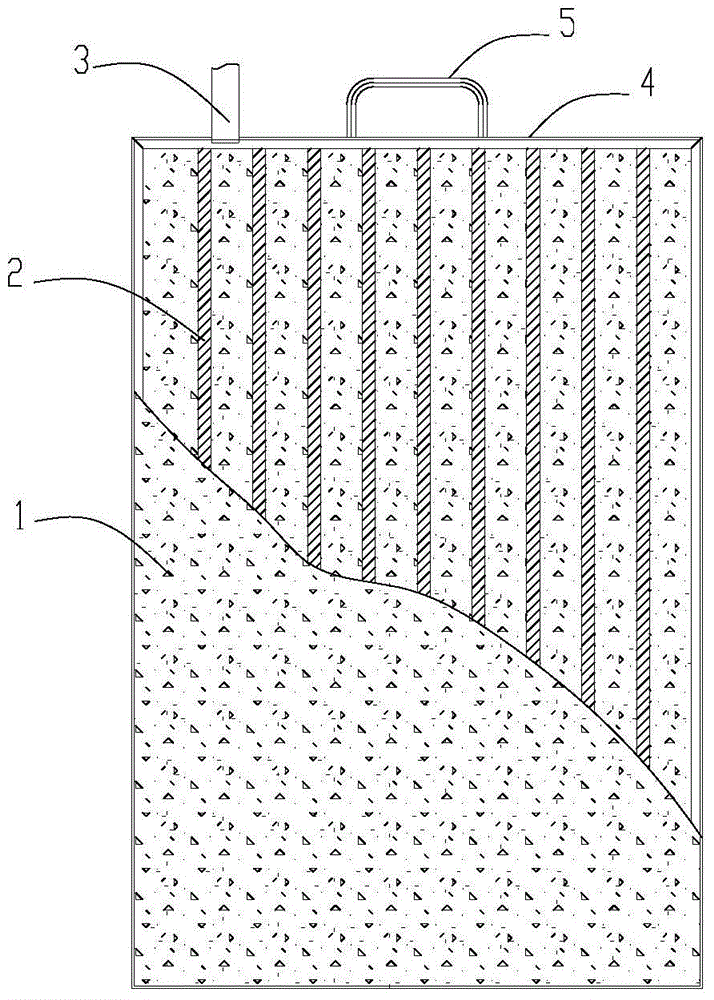

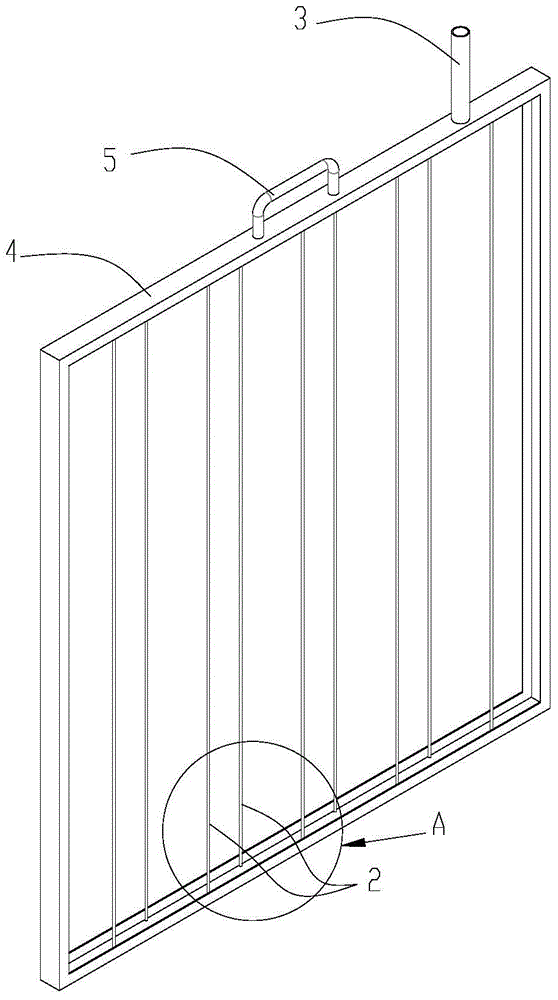

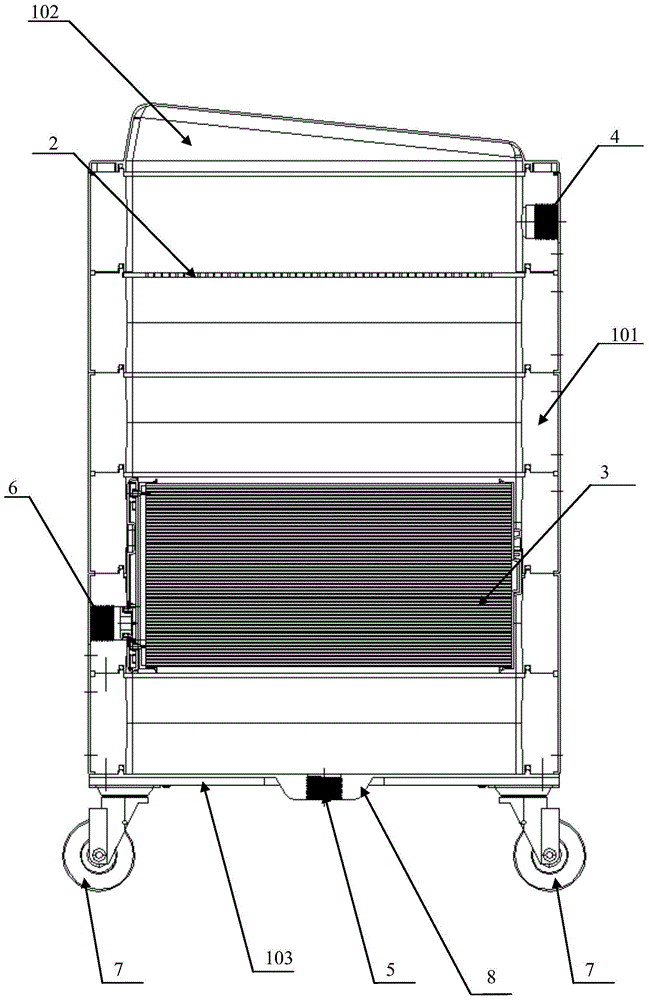

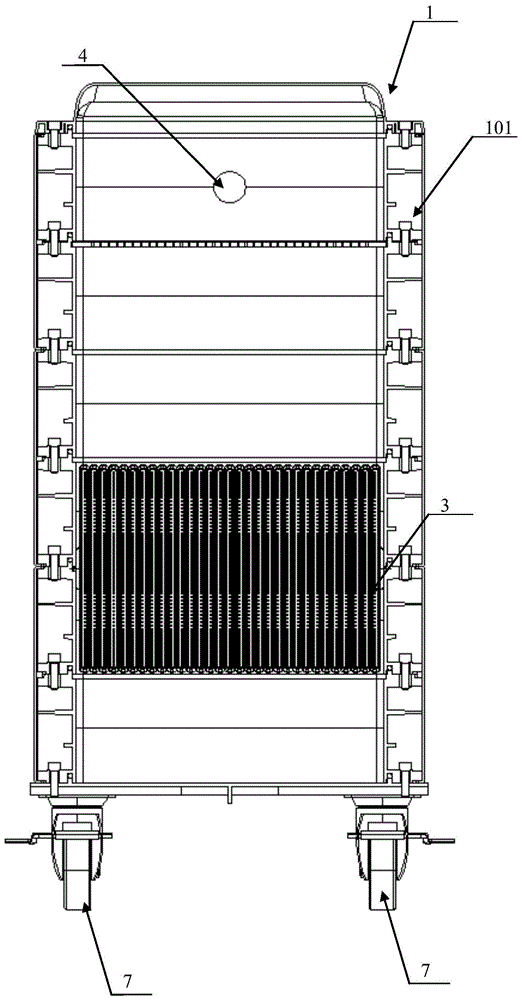

Filtration system for hollow plate ceramic membrane

ActiveCN105169946AEasy to disassembleOrderly rowsSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEngineeringUltimate tensile strength

The invention discloses a filtration system for a hollow plate ceramic membrane. The filtration system comprises a box body, a hollow plate ceramic membrane arranged in the box body, a plate-shaped water output joint, a plate-shaped packaging joint, a first end cover, a second end cover and a water distribution plate. The water distribution plate is located at the upper part of the box body and divides the box body into an upper separation box and a lower separation box. A plurality of spray holes are formed in the water distribution plate. Raw water flows from the upper separation box to the lower separation box through the spray holes. A water inlet is formed in the side wall of the upper separation box. A water outlet is formed in the side wall of the lower separation box. The hollow plate ceramic membrane is fixed in the lower separation box in the vertical direction. The water output joint and the plate-shaped packaging joint sleeve two ends of the hollow plate ceramic membrane respectively, the water flux can be raised, and the intensity can be raised. The packaging joint is fixed on a fixed plate, the water output joint is fixed on the second end cover, which facilitates enrichment of filtered water, and facilitates unified installation and dismounting of the ceramic membrane, and the efficiency is raised.

Owner:北京博鑫精陶环保科技有限公司

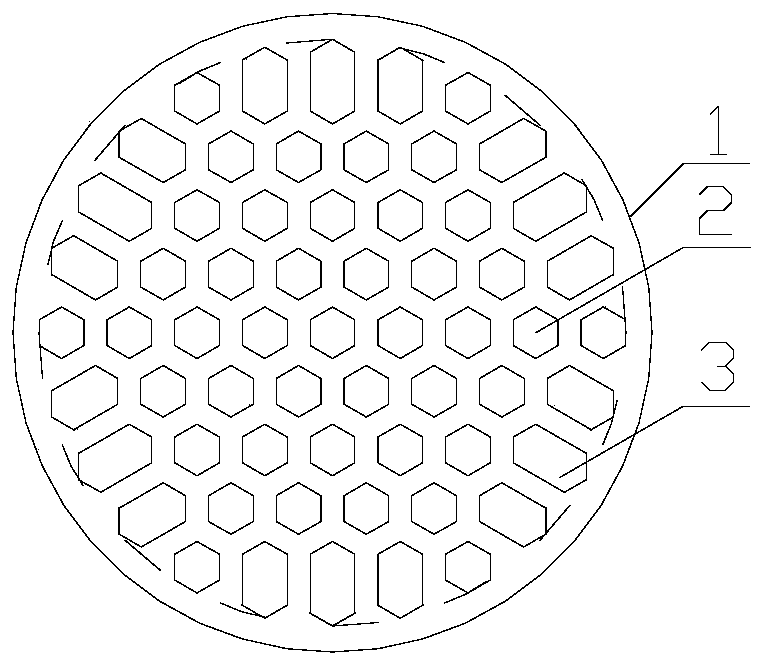

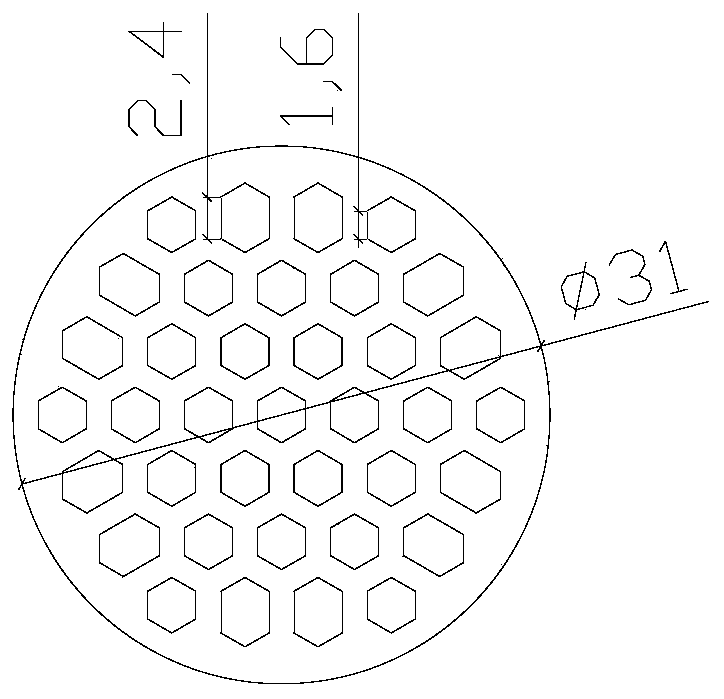

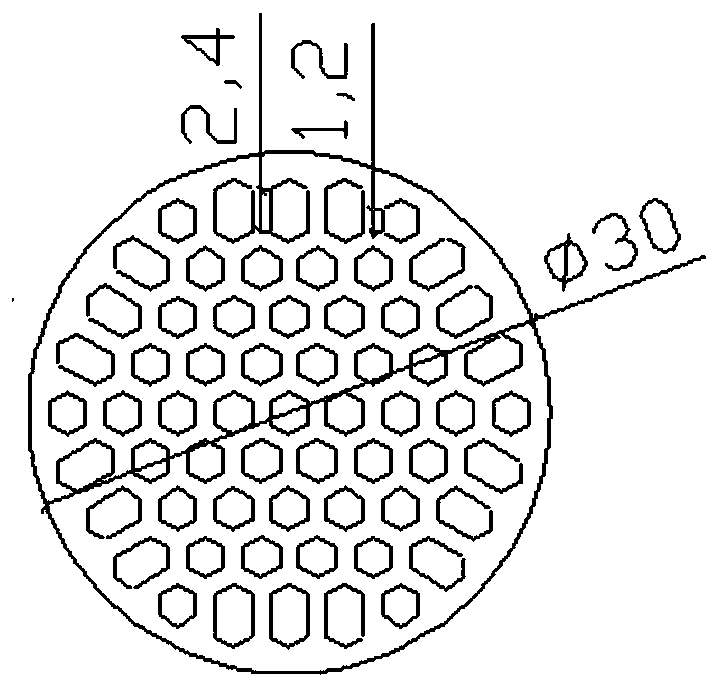

Preparation method of large-flux ceramic membrane

InactiveCN111454050AAvoid crackingInhibit sheddingSemi-permeable membranesCeramicwareHigh fluxCeramic membrane

The invention relates to a preparation method of a ceramic membrane, in particular to a preparation method of a large-flux ceramic membrane. The preparation method comprises the following steps: (1) preparing a support body, namely mixing aluminum oxide powder, titanium oxide powder, zirconium oxide powder and auxiliary materials according to a certain ratio, mixing, kneading, forming and drying the mixture, and finally sintering the mixture at high temperature to form the support body, wherein the flow channels in the support body are arranged in a manner of combining regular hexagonal flow channels and long hexagonal flow channels; 2) preparing a transition layer, namely mixing zirconium oxide powder, titanium oxide powder, aluminum oxide powder and auxiliary materials, and stirring, coating, drying and sintering the mixture at high temperature to form the transition layer; and 3) preparation of a filter membrane layer: mixing zirconium oxide powder, aluminum oxide powder and auxiliary materials, and performing stirring, coating, drying and high-temperature sintering to obtain the filter membrane layer with the filter precision of 20-200 nanometers. The ceramic membrane preparedby the method has the characteristics of high flux, high bending strength, strong pollution resistance and acid and alkali corrosion resistance.

Owner:山东泰禾环保科技股份有限公司

Vertical cross-flow filtration integration device based on hollow fiber membrane

ActiveCN110339720AStrong turbulence effectImprove washing effectSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a vertical cross-flow filtration integration device based on a hollow fiber membrane. The vertical cross-flow filtration integration device includes a pressure vessel, and is characterized in that a feed solution inlet is formed in one end of the pressure vessel, a concentrated solution outlet is formed in the other end of the pressure vessel, the pressure vessel is internally provided with at least one filter element integration assembly, the flow direction of feed liquid in the pressure vessel vertically bypasses the filter membrane surfaces of the filter element integration assemblies, the filter element integration assemblies are internally provided with filtered solution collection chambers, a filtered solution collecting pipeline is arranged on the lower partof a bottom plate of the pressure vessel, each filtered solution collection chamber communicates with the filtered solution collection pipeline, a filtered solution outlet is formed in one end of thefiltered solution collection pipeline, and a waste liquid discharge outlet is formed in the position, at one end of the concentrate solution outlet, of the pressure vessel. The vertical cross-flow filtration integration device based on the hollow fiber membrane has the advantages that the problem of pollution of the hollow fiber membrane is effectively reduced, the filtration efficiency of a membrane assembly is maintained, the effective utilization rate of an internal assembly of the hollow fiber membrane can be significantly increased, and the reuse cycle of the membrane assembly is prolonged.

Owner:NINGBO UNIV

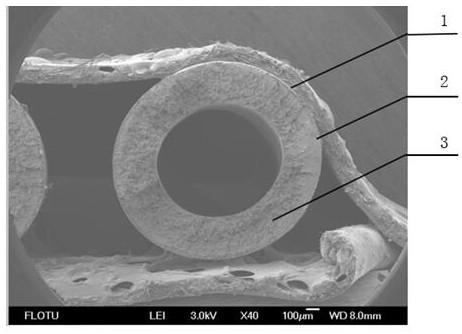

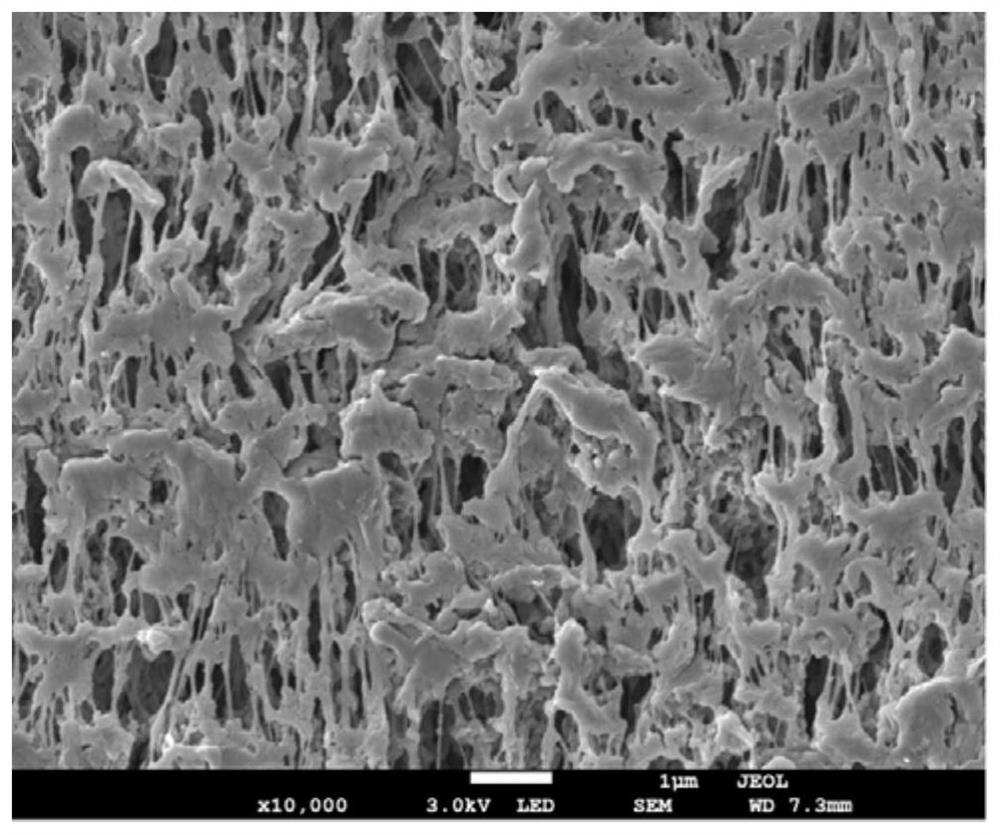

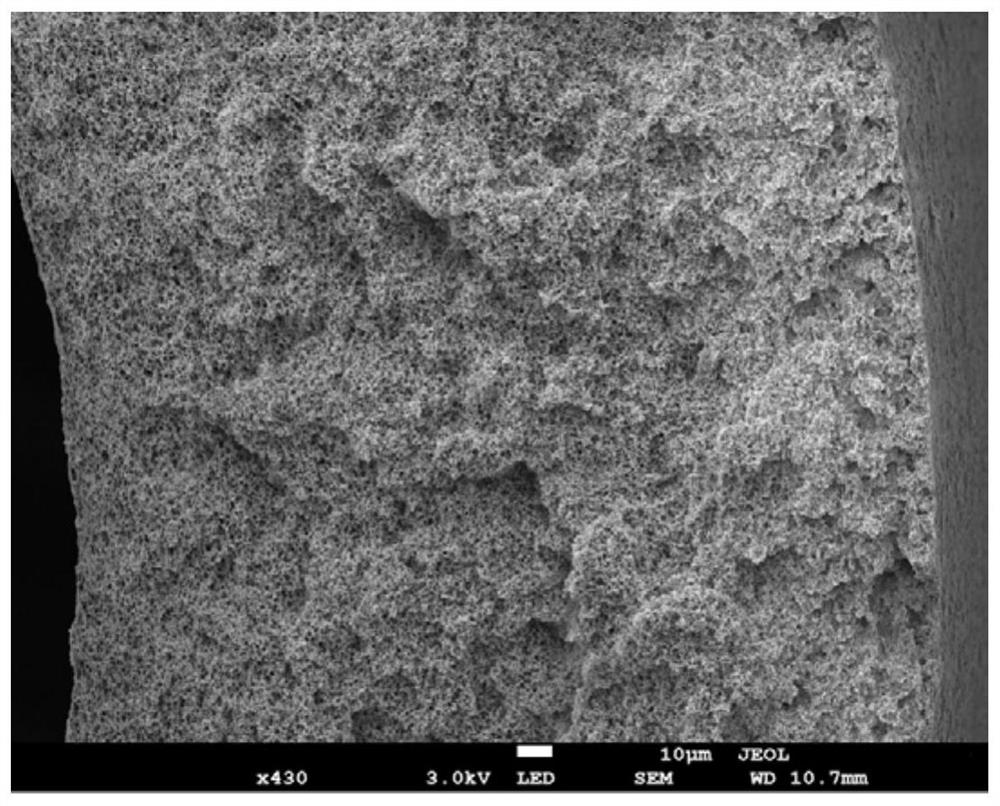

High-flux virus-removing polyvinylidene fluoride hollow fiber microporous membrane and preparation method thereof

ActiveCN111530304AExpand the effective filtration areaIncreased pure water fluxSemi-permeable membranesPolyvinylidene fluorideHollow fibre

The invention relates to a high-flux virus-removing polyvinylidene fluoride hollow fiber microporous membrane with a multi-layer filtering structure and a preparation method thereof. In order to improve the virus interception performance and the pure water flux of the hollow fiber microporous membrane, the polyvinylidene fluoride hollow fiber microporous membrane disclosed by the invention has theadvantages that the outer diameter of membrane filaments is 1.1-1.4 mm, the inner diameter is 0.6-0.8 mm, and the wall thickness is 0.2-0.4 mm, obvious holes are formed in the outer surfaces of the membrane filaments, and a three-layer film pore structure layer with a remarkable boundary is formed from outside to inside. The preparation method comprises the following steps: preparing a membrane casting solution, extruding a hollow fiber membrane, spraying a solvent on the outer layer and exchanging to form a film, performing low-temperature split-phase film forming on the middle layer, carrying out inner-layer low-temperature split-phase film formation and carrying out extraction. The method is based on a thermally induced phase separation membrane preparation method, technologies such asshallow solvent-non-solvent rapid exchange film formation and graded temperature gradient split-phase pore formation are combined, the hollow fiber membrane with the three-layer pore structure, whichhas obvious different boundaries, is prepared by using the method disclosed by the invention, on the premise of ensuring large filtration flux, efficient multi-layer filtration can be formed on pathogenic microorganisms such as viruses, the interception performance reaches 99.99%, and the average interception rate detected by a third party reaches 99.999%.

Owner:BEIJING SCINO MEMBRANCE TECH

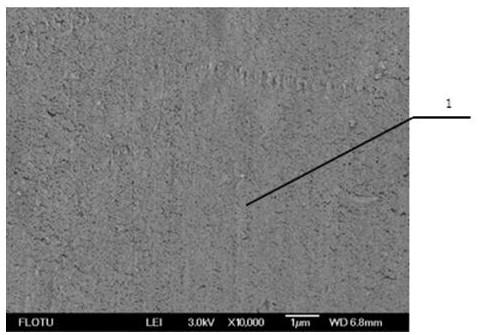

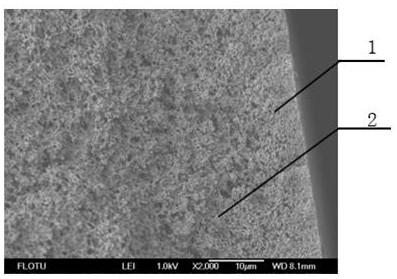

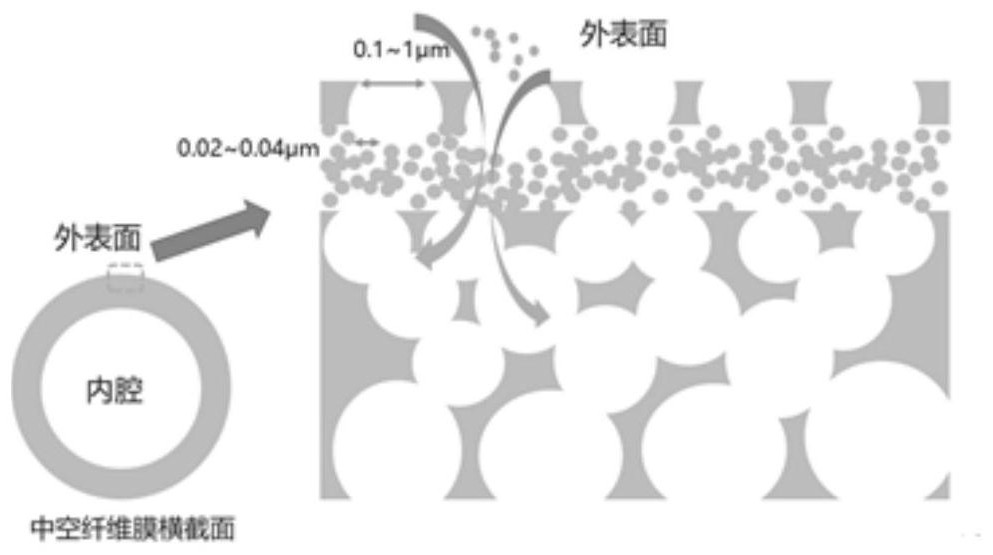

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

ActiveCN114053883AImprove retentionHigh cut-offSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention provides a polyvinylidene fluoride hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is a porous structure prepared by taking polyvinylidene fluoride (PVDF) as a raw material under the action of a diluent. The outer surface layer of the porous structure is of a pit structure, and the pit structure comprises a plurality of pits; the diameter of each pit is 0.1 [mu]m-1 [mu]m, a large number of small holes formed by piling PVDF spherocrystals are uniformly distributed in the pits, and the aperture of the small holes is 0.02 [mu]m-0. 04 [mu]m; a spongy macroporous structure with non-uniform pore diameter is arranged below the outer surface layer, the pore diameter of the spongy macroporous structure is gradually changed from the outer surface layer to the inside, and a change value is gradually increased from 1 micron to 10 microns. According to the PVDF hollow fiber membrane with the hourglass-like pore structure, provided by the invention, the effective filtering surface area of the hollow fiber membrane is obviously increased, so the hollow fiber membrane is large in filtering flux and has a good interception effect; namely, the unification of large flux and high interception of the PVDF hollow fiber membrane is realized.

Owner:BEIJING SCINO MEMBRANCE TECH +1

Liquid filter membrane component

The invention relates to a liquid filter membrane component. The liquid filter membrane component comprises a filter membrane formed by a flexible porous metal membrane, wherein the filter membrane is connected with a frame provided with a liquid discharging pipe and forms a filter structure which has the characteristics that the peripheral surface and the end surface opposite to the liquid discharging pipe are closed except the end surface on which the liquid discharging pipe is positioned, and the filter structure is internally provided with a support flow guide structure which faces to an opening of the liquid discharging pipe along the surface of the filter membrane. The liquid filter membrane component has the advantages of simple structure, small pressure loss in the filter process, flow guiding effect, low liquid flow resistance, good filter effect, repeated cleaning, corrosion resistance, and high temperature (400 DEG C) resistance.

Owner:CHENGDU INTERMENT TECH

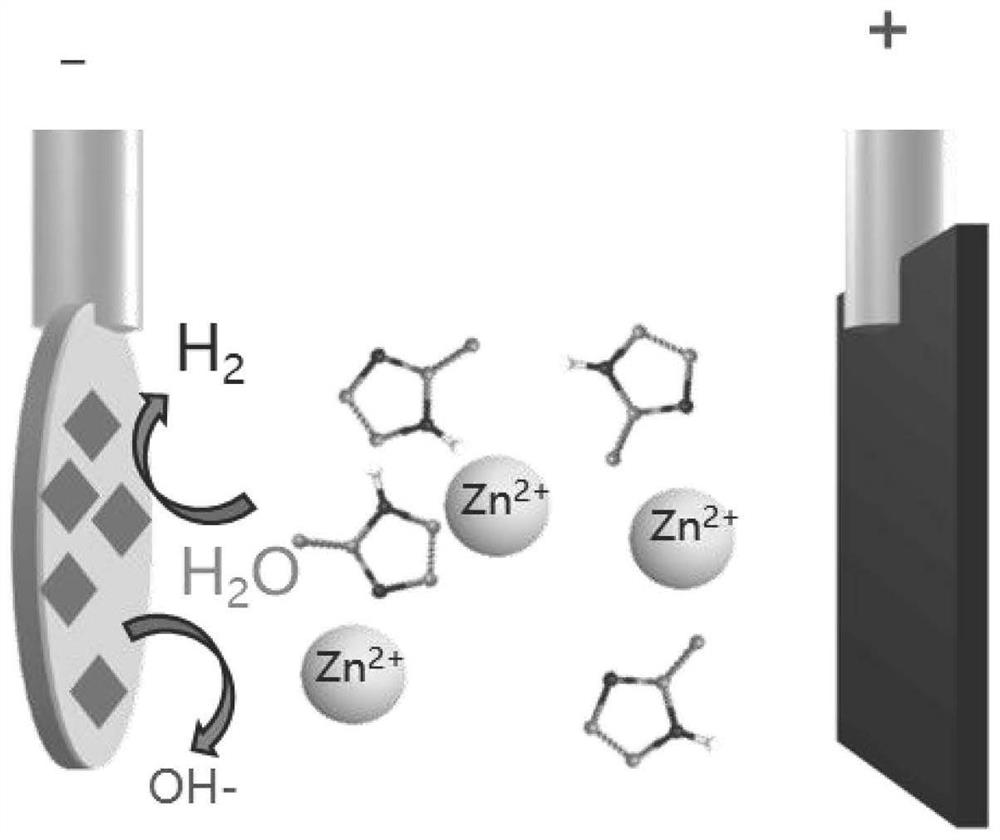

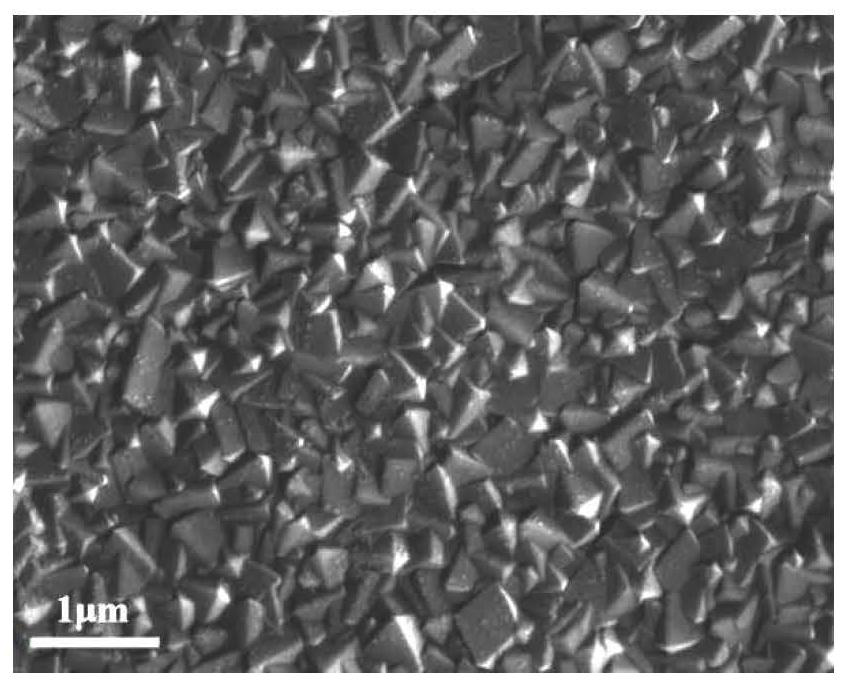

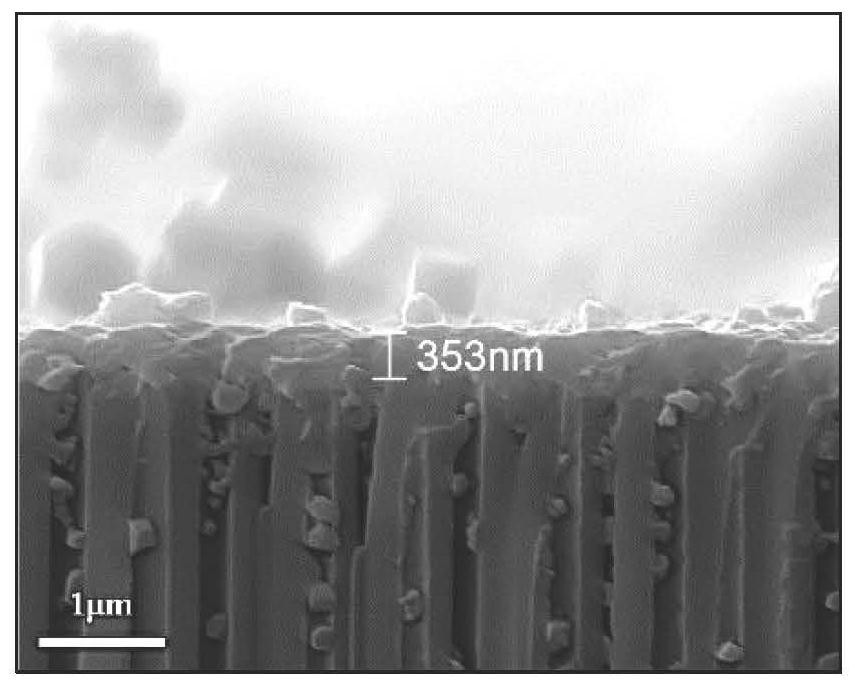

Method for preparing ZIF-8 composite film through electro-deposition and application of ZIF-8 composite film

PendingCN113058431AHigh crystallinityStable structureWater contaminantsReverse osmosisGalvanic depositionGraphite

The invention relates to a method for preparing a ZIF-8 composite film through electro-deposition and an application of the ZIF-8 composite film, and relates to the method for preparing the ZIF-8 composite film through electro-deposition and the application of the ZIF-8 composite film. The invention aims to solve the problems that the thickness is not uniform and the defect is difficult to control in an existing preparation method. The membrane is composed of a substrate membrane and a ZIF-8 separation layer; and the separation layer is a compact ZIF-8 crystal separation layer with uniform thickness, membrane holes are small and uniform, the membrane layer is uniform and thin in thickness, and the separation capacity for small molecular pollutants in water is high. The method comprises the steps: after a noble metal is sputtered on a substrate film for electric conduction, immersing the substrate film and graphite paper respectively serving as a working electrode and a counter electrode into an electrolytic tank containing a precursor solution, taking the substrate film as a cathode, and synthesizing through a one-step electrodeposition method at normal temperature and normal pressure. The prepared composite membrane shows excellent interception performance on small dye molecules, and the flux is larger than that of an MOFs composite membrane prepared through a traditional method. The ZIF-8 composite film is used for intercepting dye wastewater.

Owner:HARBIN INST OF TECH

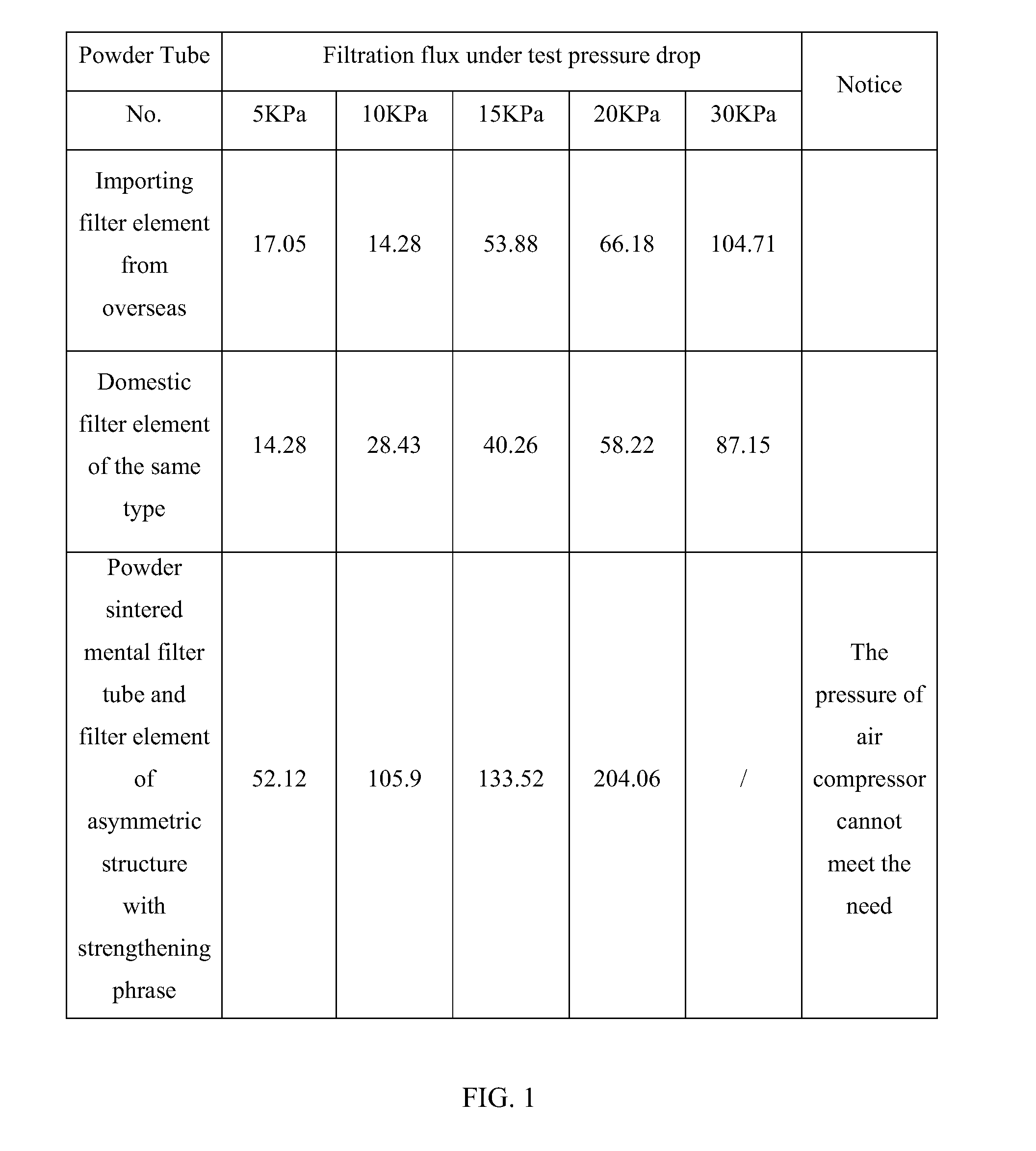

Asymmetric structure powder sintering metal filter pipe and filter element with strengthening phase

InactiveCN103350231ASmall filter resistanceLarge filtration fluxFiltration separationVacuum furnaceMetal mesh

The invention relates to a production method for an asymmetric structure powder sintering metal filter pipe and filter element with a strengthening phase. A molding agent is added to metal powder to be mixed, a casting machine is used for obtaining a powder pipe and a sheet forming blank, ungrease treatment is conducted, and then a metal net and mesh wires are laid on the powder pipe and the sheet forming blank and placed in a vacuum furnace for sintering, so that the powder pipe with the strengthening phase and high porosity, a sheet supporting layer and a composite supporting layer are obtained; a coating is sprayed to obtain an asymmetric structure powder sintering filter material with the strengthening phase which is molded and rolled to be of a tube shape for welding, and therefore the asymmetric structure powder sintering metal filter pipe and filter element with the strengthening phase is manufactured. The asymmetric structure powder sintering metal filter pipe and filter element with the strengthening phase has the advantages of being low in filtration resistance, high in filtration flux and porosity and strong in pressure bearing capacity, is applied to S-Zorb devices of Sinopec, increases the filtration flow by 30-50%, and enables the total yield to be more than doubled substantially.

Owner:王东伟

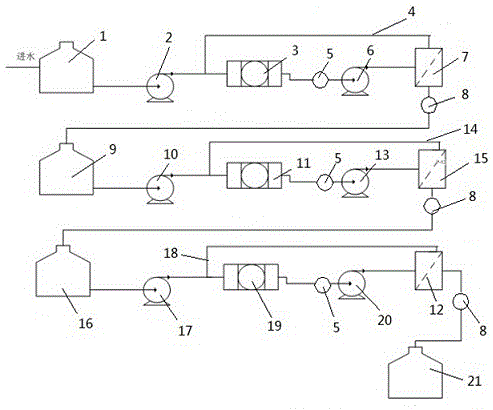

Industrial waste water treatment device after softening treatment and process thereof

InactiveCN105110421AHigh yield of pure waterImprove efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentIndustrial waste waterFiltration

The invention belongs to the technical field of industrial waste water treatment, and specifically provides an industrial waste water treatment device after softening treatment. The device comprises a PLC control system and a primary OCNF processing system, a secondary OCNF processing system and a primary OCRO processing system that are respectively connected to the PLC control system. The primary OCNF processing system, the secondary OCNF processing system and the primary OCRO processing system are sequentially communicated. The device further comprises a membrane cleaning system, wherein the membrane cleaning system is respectively connected to the primary OCNF processing system, the secondary OCNF processing system and the primary OCRO processing system. The waste water treatment process is adopted, so that the pure water yield rate is high, and chemicals do not need to carry out precipitation treatment; the filtration flux is large and low in cost; the structure design is reasonable, the device operation is stable and has high pure water production capability; and the device occupies small area, and is good in treatment effect and high in efficiency.

Owner:国能朗新明环保科技有限公司

Ceramic membrane water filtering device and pretreatment method thereof

PendingCN114230052AWork lessAvoid pollutionSemi-permeable membranesWater treatment parameter controlReclaimed waterWater tanks

Owner:山东泰禾环保科技股份有限公司

A method for separating and purifying L-hydroxyproline from L-hydroxyproline fermentation broth

ActiveCN107513030BReduce processing timeHigh removal rateOrganic chemistry methodsBiotechnologyHydroxyproline

Owner:FUJIAN NORMAL UNIV

Oil mist purification filter element

InactiveCN103111136BHigh filtration precisionSmall filter resistanceDispersed particle filtrationGlass fiberFiber

Owner:ZHEJIANG YUANKAI TECH

Filtration System of Hollow Plate Ceramic Membrane

ActiveCN105169946BEasy to disassembleOrderly rowsSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFilter systemEngineering

The invention discloses a filtration system for a hollow plate ceramic membrane. The filtration system comprises a box body, a hollow plate ceramic membrane arranged in the box body, a plate-shaped water output joint, a plate-shaped packaging joint, a first end cover, a second end cover and a water distribution plate. The water distribution plate is located at the upper part of the box body and divides the box body into an upper separation box and a lower separation box. A plurality of spray holes are formed in the water distribution plate. Raw water flows from the upper separation box to the lower separation box through the spray holes. A water inlet is formed in the side wall of the upper separation box. A water outlet is formed in the side wall of the lower separation box. The hollow plate ceramic membrane is fixed in the lower separation box in the vertical direction. The water output joint and the plate-shaped packaging joint sleeve two ends of the hollow plate ceramic membrane respectively, the water flux can be raised, and the intensity can be raised. The packaging joint is fixed on a fixed plate, the water output joint is fixed on the second end cover, which facilitates enrichment of filtered water, and facilitates unified installation and dismounting of the ceramic membrane, and the efficiency is raised.

Owner:北京博鑫精陶环保科技有限公司

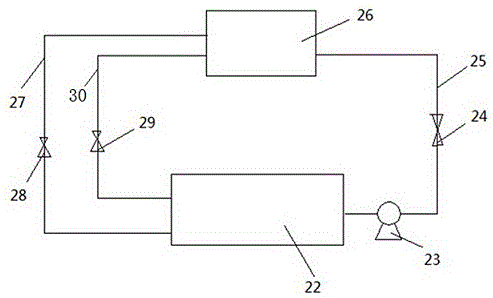

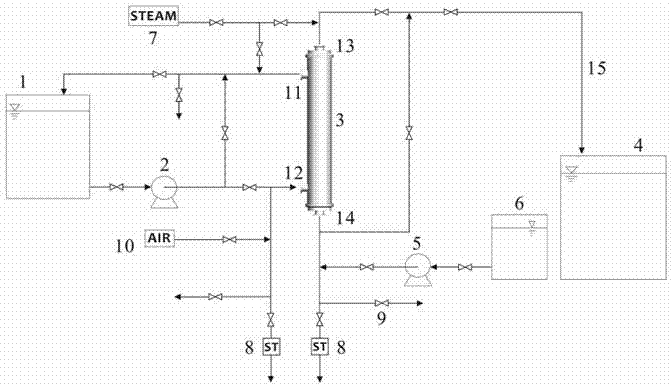

High-temperature-resistance organic film filtering system and process

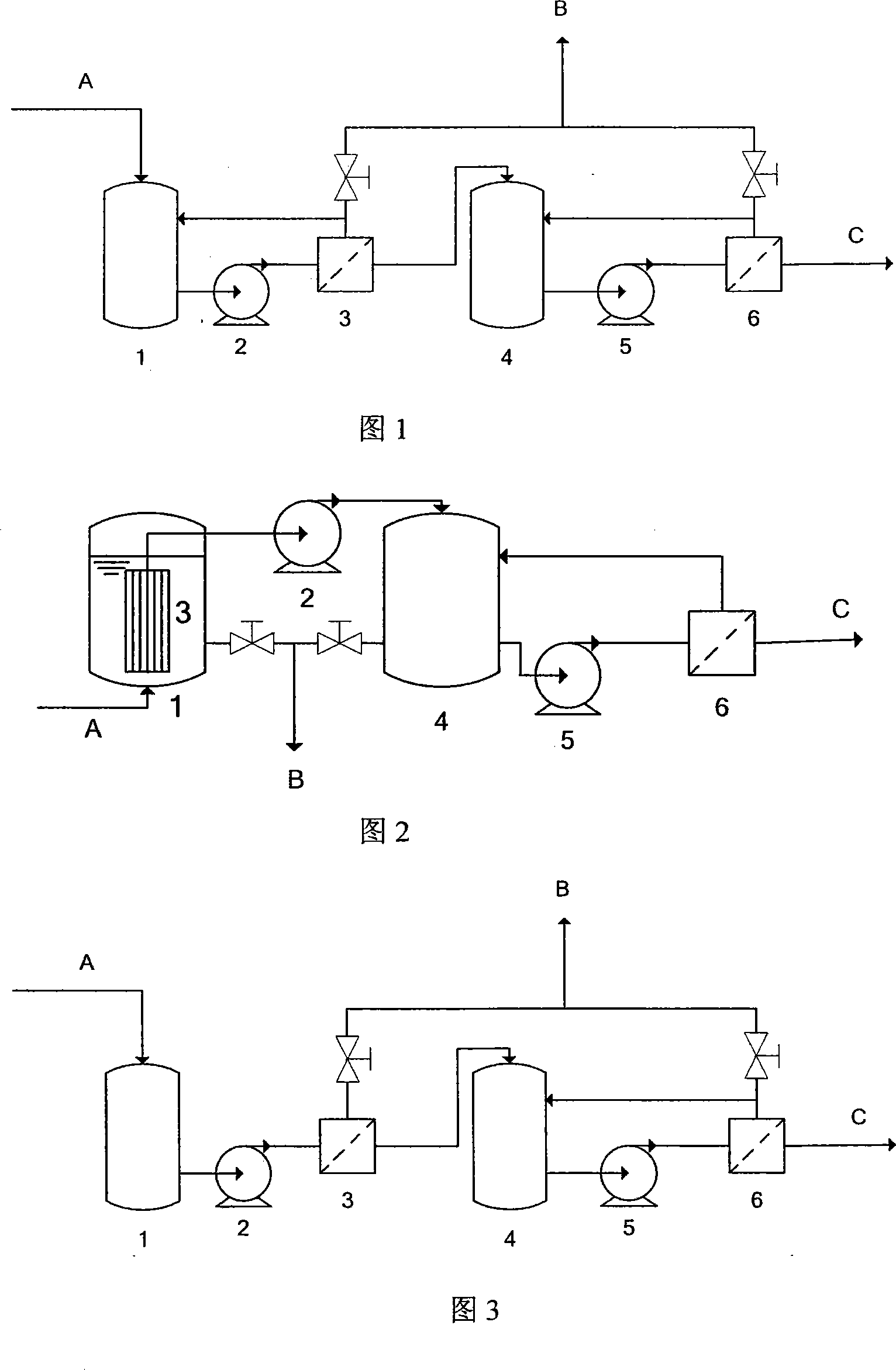

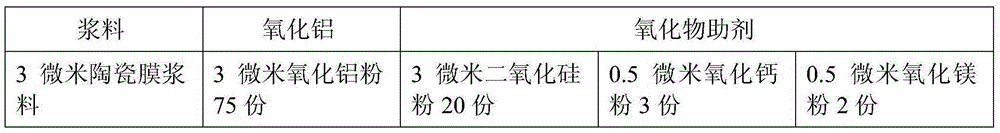

ActiveCN102974219BReduce energy consumptionIncrease productivitySemi-permeable membranesOrganic filmLiquid storage tank

The invention relates to the technical field of film filtration, and in particular relates to a high-temperature-resistance organic film filtering system and process. The system comprises a raw material box, a feeding pump, a film component, a filtering liquid storage tank, a backwashing pump, a hot water storage tank, a steam generator and a valve, wherein a high-temperature organic film component is used as the film component; the feeding pump is connected with the raw material box; the other end of the feeding pump is connected with a inlet I and a inlet II of the film component; a outlet I and a outlet II of the film component are connected with the filtering liquid storage tank; the outlet II of the film component is connected with a backwashing pipeline; the backwashing pump and the hot water storage tank are arranged in the backwashing pipeline; the inlet II of the film component is connected with oilless compressed air; the inlet I and the outlet I of the film component are connected with the steam generator; the inlet II and the outlet II of the film component are connected with a condensing liquid discharge pipeline; and the feeding pump, the backwashing pump and the valve are connected with an electric control system through circuits. The system can operate in a high-temperature fluid environment, the film component is disinfected and washed by using air, steam and hot water, the film filtration flux is large, the occupied space is small, and the investment is saved.

Owner:上海膜源环保科技有限公司

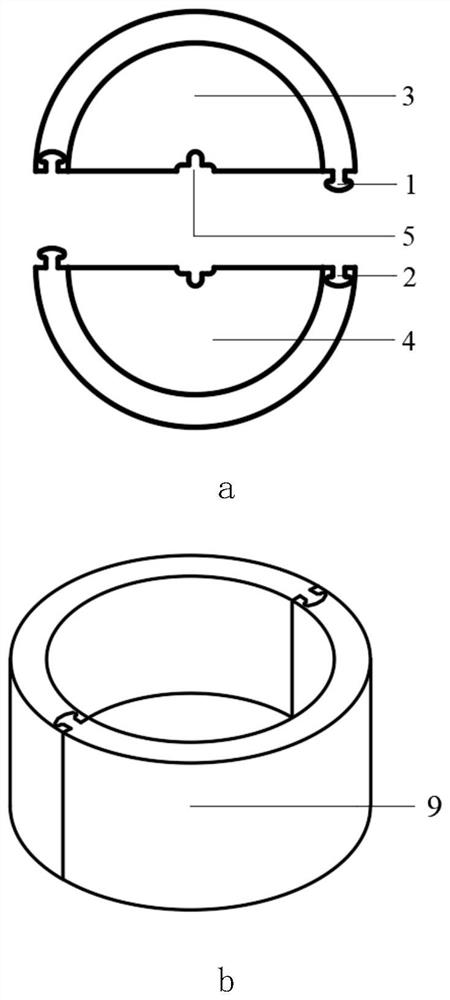

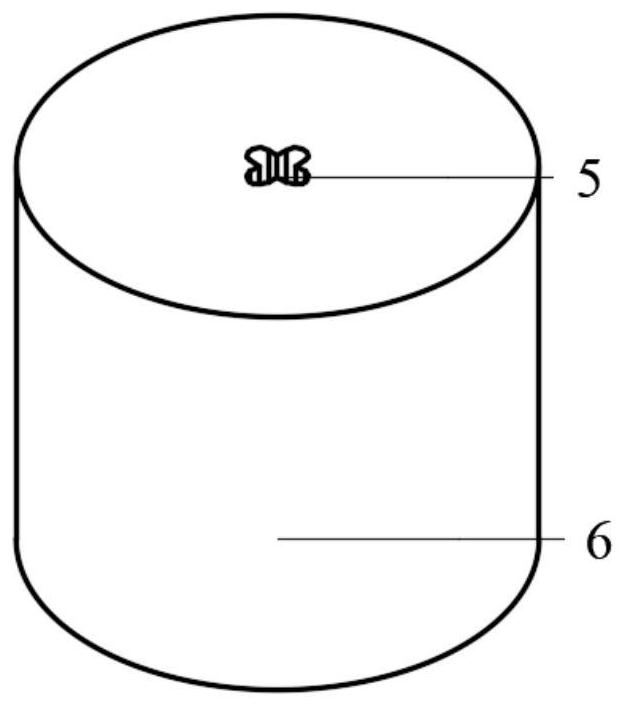

A ceramic irrigation membrane preparation mold and gradient ceramic irrigation membrane preparation process

ActiveCN110978228BRelieve heat stressHigh bonding strengthWatering devicesCultivating equipmentsWater flowSlurry

Owner:NORTHWEST A & F UNIV

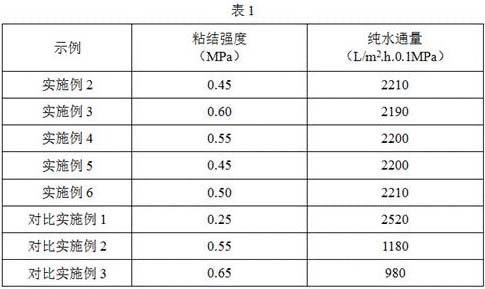

Preparation method of high bonding strength polytetrafluoroethylene hollow fiber membrane

ActiveCN109529639BHigh bonding strengthLarge filtration fluxMembranesSemi-permeable membranesTetrafluoroethylenePolymer science

The invention discloses a preparation method of a polytetrafluoroethylene hollow fiber membrane with high bonding strength, which aims to solve the problem that the polytetrafluoroethylene hollow fiber membrane has a large pore size and cannot meet the requirements of high-precision separation and filtration. The pore size of the vinyl fluoride hollow fiber membrane is unstable, the bonding strength is not enough, and the phenomenon of shedding is prone to occur. The invention includes the following steps: (1) cutting, cutting the biaxially stretched polytetrafluoroethylene fully sintered flat film with an average pore size range of 0.05 μm-0.5 μm into polytetrafluoroethylene strip membranes; (2) impregnating, Immerse the polytetrafluoroethylene strip membrane in the low molecular weight polytetrafluoroethylene organic dispersion; (3) Wrap and shape, wrap the dipped polytetrafluoroethylene strip membrane in the average pore diameter range of 1μm-5μm Stretch on the outer wall of the polytetrafluoroethylene hollow fiber membrane, wrap 1-3 layers, and then heat-treat at 280-360°C for 5-30 seconds.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com