Oil mist purification filter element

A filter element and oil mist technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy deformation of fiber mesh, poor oil mist filtration effect, increased disease incidence, etc., and achieve structural stability. Good, simple production method, large filter flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

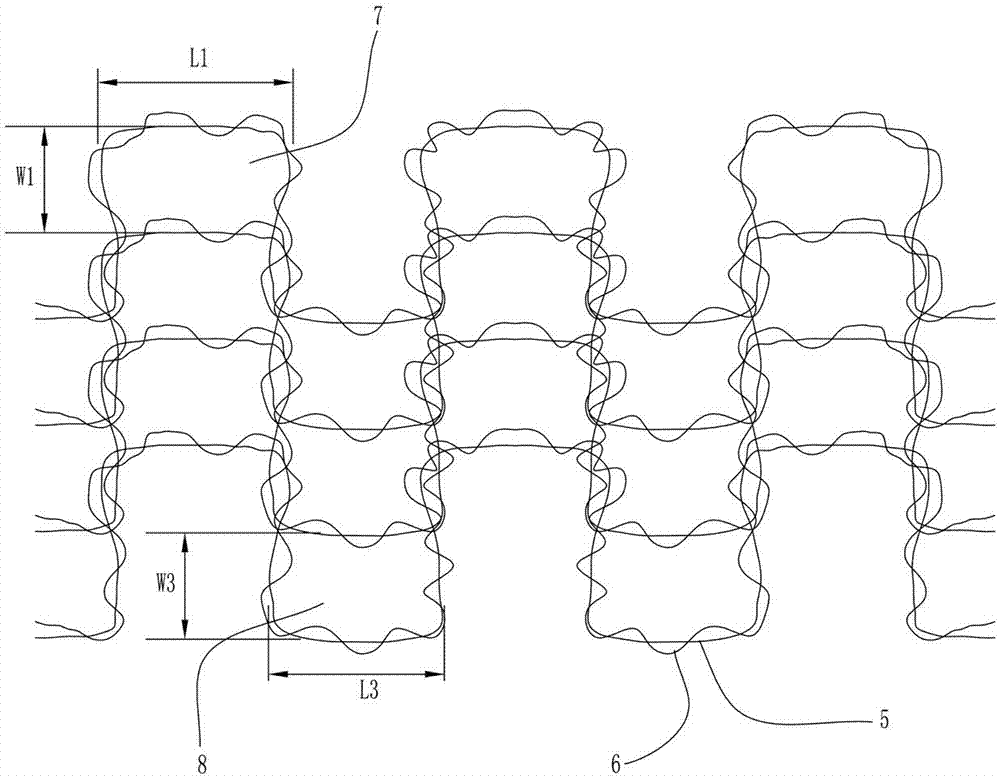

[0027] Such as figure 1 and figure 2 As shown, the oil mist purification filter element provided in this embodiment includes a gas-liquid filter 4 and an outer frame 1, and the gas-liquid filter 4 is folded into twenty layers, and the outer frame 1 is used to fix and stretch the stacked gas-liquid filter 4, such as image 3 As shown, the gas-liquid filter screen 4 is made of steel wire 5 with a diameter of 0.2 mm and PP fiber wire 6 with a diameter of 1.0 mm, wherein the steel wire 5 and the PP fiber wire 6 are twisted, and the gas-liquid filter screen 4 Mesh holes of two specifications are distributed on the top, and they are distributed at intervals, wherein the first mesh hole 7 has a length L 1 4.5 mm, width W 1 is a rectangular shape of 4 mm, and the second mesh 8 has a length L 3 6 mm, width W 3 4mm rectangular shape.

[0028] In the above structure, the gas-liquid filter 4 is braided by steel wire 5 with a diameter of 0.2 mm and PP fiber wire 6 with a diameter of...

Embodiment 2

[0031] The general structure of the oil mist purification filter element provided in this embodiment is consistent with that of Embodiment 1, as Figure 4 As shown, but the gas-liquid filter screen 4 described in the present embodiment is wavy, and its wave height H and wave distance L 2 Both are 10mm, and the included angle α between two adjacent crests or troughs is 30°. The specific surface area of the gas-liquid filter 4 is increased, the residence time of the oil mist in the gas-liquid filter 4 is increased, and the filtration accuracy is improved.

[0032] Certainly in specific implementation, the wave height H and the wave distance L of the gas-liquid filter screen 4 described in the present embodiment 2 They can also be 11 mm or 12 mm, and the angle α between two adjacent crests or troughs can also be 40° or 50°.

Embodiment 3

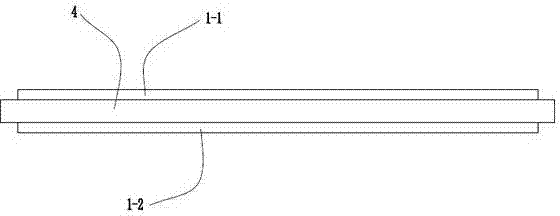

[0034] Such as Figure 5 As shown, the general structure of the oil mist purification filter element provided in this embodiment is consistent with that of Embodiment 5. In this embodiment, the outer frame 1 includes a symmetrical upper flat frame 1-1 and a lower flat frame 1-2. , the frames of the upper flat frame 1-1 and the lower flat frame 1-2 are all arranged with transverse pressing rods 2 for compressing the laminated gas-liquid filter screen 4, and the frame of the lower flat frame 1-2 is also provided with There are longitudinal distance rods 3, which face the upper flat frame 1-1 and are fixed with the frame of the upper flat frame 1-1. The gas-liquid filter screen 4 in the lower flat frame 1-2 and the upper flat frame 1-1 has a certain degree of tightness, so that it will not be too tight or too loose, which will affect the filtration efficiency or quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com