Preparation method of multilayered gradient ceramic membrane

A technology of ceramic membranes and ceramic membrane supports, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven thickness of the membrane layer, thickness of the membrane layer, etc., achieve uniform pore size distribution, increase filtration Flux, porosity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0029] (1) The plastic clay with a mass content of alumina of 60% is formed into a flat ceramic membrane support body with a width of 300 mm, a length of 1024 mm, and a thickness of 8 mm by a vacuum agent process, and after drying, the surface and edges are polished to smooth and flat ;

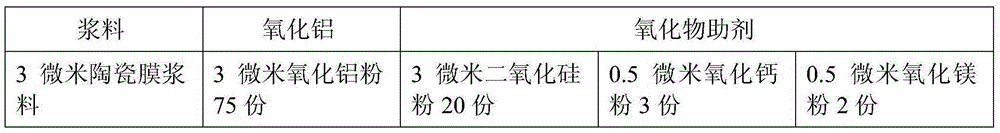

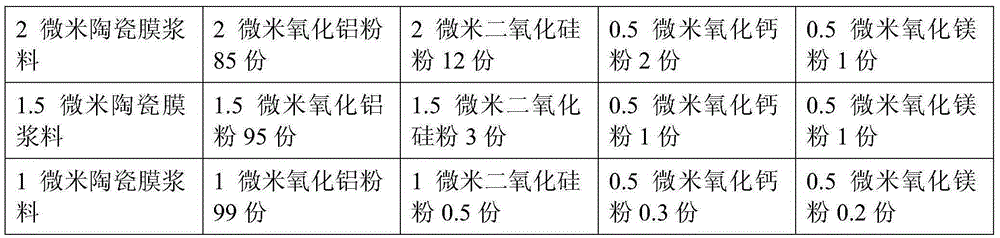

[0030] (2) Fully mix alumina with silica, calcium oxide, magnesia, carboxymethyl cellulose, polyvinyl alcohol and water, and prepare alumina mass content of 75% (average particle diameter 3 microns), 85 % (average particle size 2 microns), 95% (average particle size 1.5 microns) and 99% (average particle size 1 micron) of ceramic film paste for screen printing; of which carboxymethyl cellulose and polyvinyl alcohol The total consumption is 3% of the total mass of solid matter (aluminum oxide and oxide auxiliary agent), and the particle size and proportioning ratio of alumi...

Embodiment 2

[0038] Embodiment 2: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0039] (1) The plastic clay with a mass content of alumina of 80% is formed into a flat ceramic membrane support body with a width of 240mm, a length of 512mm and a thickness of 6mm by a vacuum process, and after drying, the surface and edges are polished to be smooth and flat ;

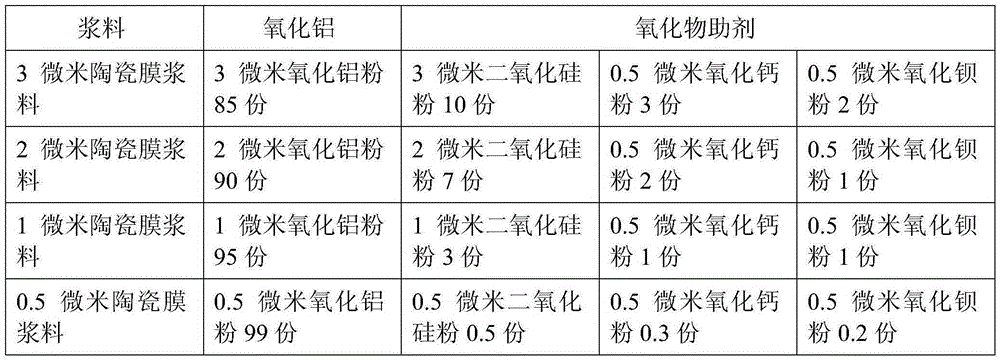

[0040] (2) Fully mix alumina, silicon dioxide, calcium oxide, barium oxide, dextrin, polyvinyl alcohol and water, and prepare alumina mass content of 85% (average particle size 3 microns), 90% respectively (average particle diameter 2 microns), 95% (average particle diameter 1 micron) and 99% (average particle diameter 0.5 micron) ceramic film slurry that can be screen printed; Wherein the total consumption of dextrin and polyvinyl alcohol is 5% of the total mass of solid matter (alumina and oxide additives), the particle size and proportioning ratio of alumina and oxide additives...

Embodiment 3

[0046] Embodiment 3: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0047](1) the plastic clay of the ceramic membrane support body with alumina mass content being 92% is formed into a wide 130mm, long 512mm, thick 5mm flat plate hollow structure ceramic membrane support body with a vacuum agent process, after drying, the surface and Edges are ground to a smooth finish;

[0048] (2) Alumina, silicon dioxide, magnesia, barium oxide, hydroxypropyl cellulose and polyvinyl alcohol, and water are fully mixed and uniformly prepared as alumina with a mass content of 95% (average particle diameter of 2 microns) ), 97% (average particle size 1 micron) and 99% (average particle size 0.3 micron) ceramic membrane slurry for screen printing; wherein the total amount of hydroxypropyl cellulose and polyvinyl alcohol is solid matter ( 2% of the total mass of aluminum oxide and oxide additives), the particle size and proportioning ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com