A kind of preparation method of multilayer gradient ceramic membrane

A technology of ceramic membranes and ceramic membrane supports, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven thickness of the membrane layer, thickness of the membrane layer, etc., achieve uniform pore size distribution, increase filtration flux, porosity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0029] (1) The plastic clay with a mass content of alumina of 60% is formed into a flat ceramic membrane support body with a width of 300 mm, a length of 1024 mm, and a thickness of 8 mm by a vacuum agent process, and after drying, the surface and edges are polished to smooth and flat ;

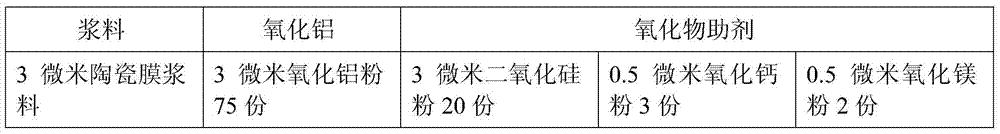

[0030] (2) Fully mix alumina with silica, calcium oxide, magnesia, carboxymethyl cellulose, polyvinyl alcohol and water, and prepare alumina mass content of 75% (average particle diameter 3 microns), 85 % (average particle size 2 microns), 95% (average particle size 1.5 microns) and 99% (average particle size 1 micron) of ceramic film paste for screen printing; of which carboxymethyl cellulose and polyvinyl alcohol The total consumption is 3% of the total mass of solid matter (aluminum oxide and oxide auxiliary agent), and the particle size and proportioning ratio of alumi...

Embodiment 2

[0038] Embodiment 2: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0039] (1) The plastic clay with a mass content of alumina of 80% is formed into a flat ceramic membrane support body with a width of 240mm, a length of 512mm and a thickness of 6mm by a vacuum process, and after drying, the surface and edges are polished to be smooth and flat ;

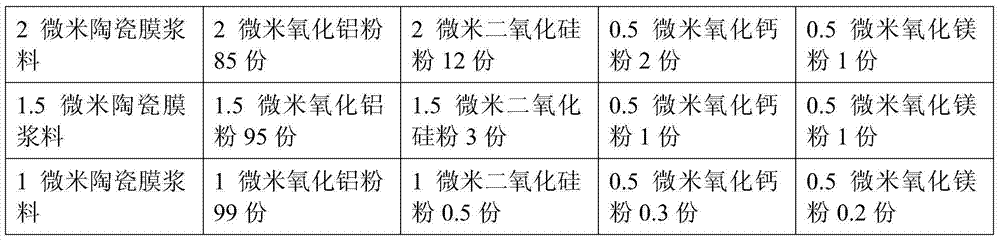

[0040] (2) Fully mix alumina, silicon dioxide, calcium oxide, barium oxide, dextrin, polyvinyl alcohol and water, and prepare alumina mass content of 85% (average particle size 3 microns), 90% respectively (average particle diameter 2 microns), 95% (average particle diameter 1 micron) and 99% (average particle diameter 0.5 micron) ceramic film slurry that can be screen printed; Wherein the total consumption of dextrin and polyvinyl alcohol is 5% of the total mass of solid matter (alumina and oxide additives), the particle size and proportioning ratio of alumina and oxide additives...

Embodiment 3

[0046] Embodiment 3: the preparation method of described a kind of multilayer gradient ceramic membrane, specifically:

[0047](1) the plastic clay of the ceramic membrane support body with alumina mass content being 92% is formed into a wide 130mm, long 512mm, thick 5mm flat plate hollow structure ceramic membrane support body with a vacuum agent process, after drying, the surface and Edges are ground to a smooth finish;

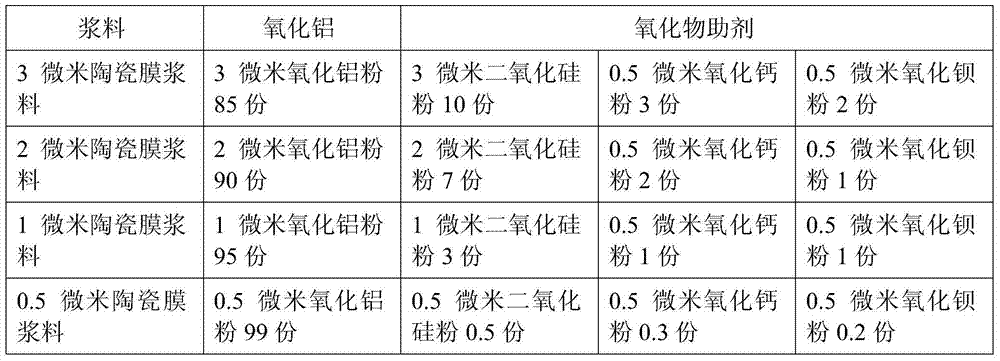

[0048] (2) Alumina, silicon dioxide, magnesia, barium oxide, hydroxypropyl cellulose and polyvinyl alcohol, and water are fully mixed and uniformly prepared as alumina with a mass content of 95% (average particle diameter of 2 microns) ), 97% (average particle size 1 micron) and 99% (average particle size 0.3 micron) ceramic membrane slurry for screen printing; wherein the total amount of hydroxypropyl cellulose and polyvinyl alcohol is solid matter ( 2% of the total mass of aluminum oxide and oxide additives), the particle size and proportioning ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com