Preparation method of porous silicon carbide flat plate ceramic support

A technology of porous silicon carbide and support body is applied in the field of inorganic membrane separation materials and inorganic porous materials, and can solve the problems of expensive sintering furnace, high sintering temperature and complicated sintering process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

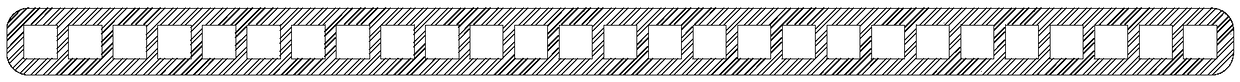

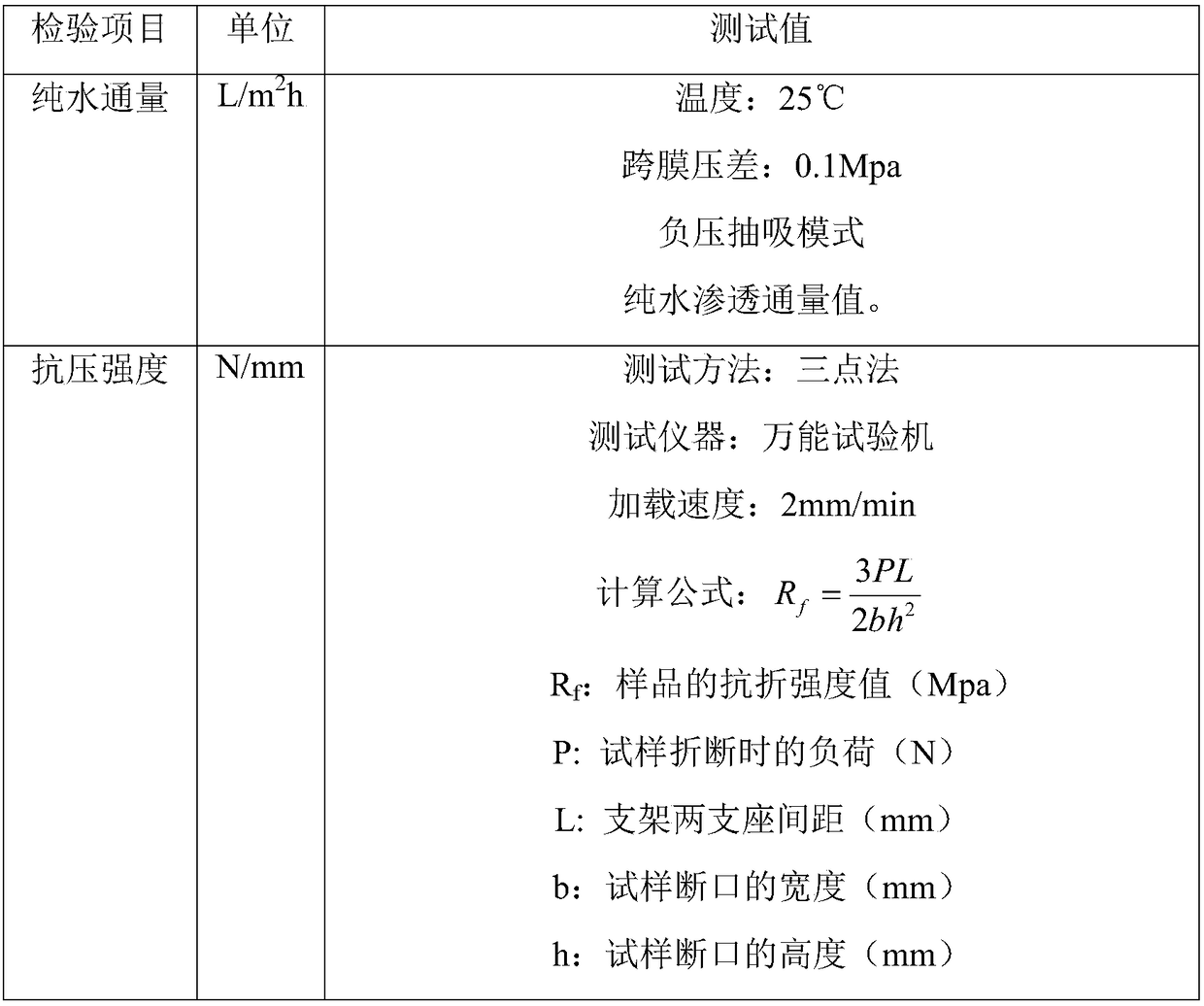

Embodiment 1

[0043] 18μm silicon carbide particles, hot melt additives, methyl cellulose, starch, triglycerin, oleic acid, ammonium polyacrylate, and cooked tung oil are 80.0: 7.0: 4.0: 2.5: 1.5: 1.0: 1.5: 2.5 by mass percentage Blended in water and ethanol (V / V=3:1) mixed solvent, the mixed solvent accounted for 30wt% of the total, dry mixed in a strong mixer for 10 minutes, added solvent and wet mixed for 120 minutes, and then smelted once in vacuum, Put the trained mud base at 20°C for 24 hours, and vacuum train the mud again before extrusion. The extruded mud is 110mm wide, 6mm thick, the middle channel is a 3mm×3mm square hole, the distance between the channels is 1mm, the distance from the channel to the surface of the plate support is 1.5mm, and the cutting length set during extrusion is 516mm. Porous silicon carbide Flat ceramic support mud body, extrusion pressure 10Mpa, extrusion speed 25mm / s. The trolley speed of the mud billet in the continuous microwave is 1000mm / min, and the...

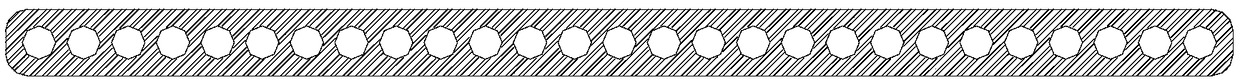

Embodiment 2

[0045] 45 μm silicon carbide particles, hot melt additives, methyl cellulose, starch, triglycerin, oleic acid, ammonium polyacrylate, and cooked tung oil are 75.0: 10.0: 4.0: 3.0: 1.5: 1.0: 1.5: 4.0 by mass percentage Blended in a mixed solvent of water and ethanol (V / V=4:1), the mixed solvent accounts for 30wt% of the total, dry mixed in a strong mixer for 10 minutes, added solvent and wet mixed for 180 minutes, and then smelted once in vacuum, Put the trained mud base at 20°C for 24 hours, and vacuum train the mud again before extrusion. The extruded mud is 110mm wide, 6mm thick, the middle channel is a round hole with a diameter of 3mm, the distance between the channels is 1mm, the distance from the channel to the surface of the flat support body is 1.5mm, and the cutting length set during extrusion is 516mm. Porous silicon carbide Flat ceramic support mud body, extrusion pressure 8Mpa, extrusion speed 20mm / s. The trolley speed of the mud billet in the continuous microwave...

Embodiment 3

[0047]82 μm silicon carbide particles, hot melt additives, methyl cellulose, starch, triglycerin, oleic acid, ammonium polyacrylate, and cooked tung oil are 70.0: 12.0: 4.0: 4.0: 2.5: 1.5: 2.5: 3.5 by mass percentage Blended in a mixed solvent of water and ethanol (V / V=5:1), the mixed solvent accounts for 30wt% of the total, dry mixed in a strong mixer for 10 minutes, added solvent and wet mixed for 240 minutes, and then smelted once in a vacuum, Put the trained mud base at 20°C for 24 hours, and vacuum train the mud again before extrusion. The extruded mud is 250mm wide, 6mm thick, the middle channel is a 3mm×3mm square hole, the distance between the channels is 1mm, the distance from the channel to the surface of the plate support is 1.5mm, and the cutting length set during extrusion is 1016mm. Porous silicon carbide Flat ceramic support mud body, extrusion pressure 6Mpa, extrusion speed 20mm / s. The trolley speed of the mud billet in the continuous microwave is 1000mm / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com