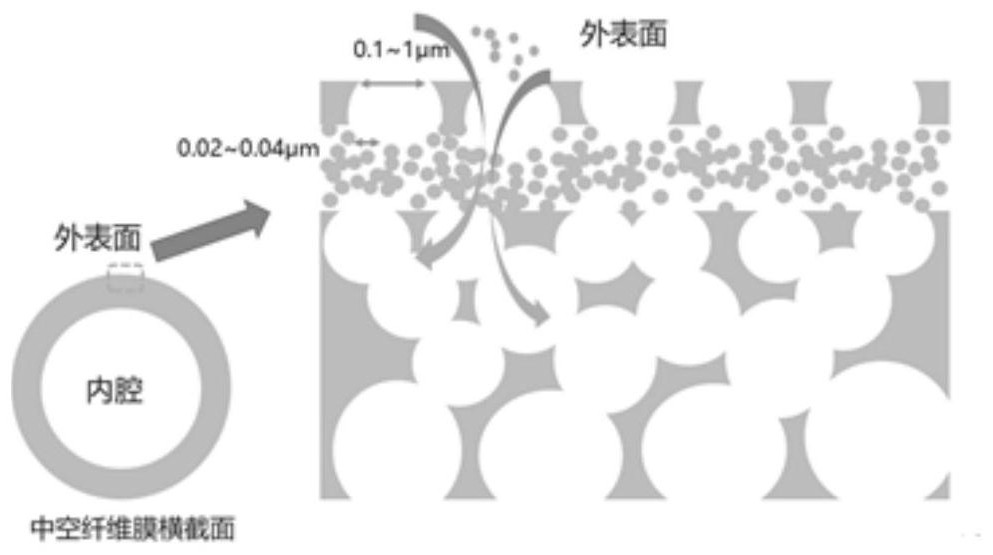

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

A polyvinylidene fluoride and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large permeable flux and high retention performance of ultra/microfiltration membranes, and achieve good retention effect , Filtration flux is large, the effect of increasing the effective filtration surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

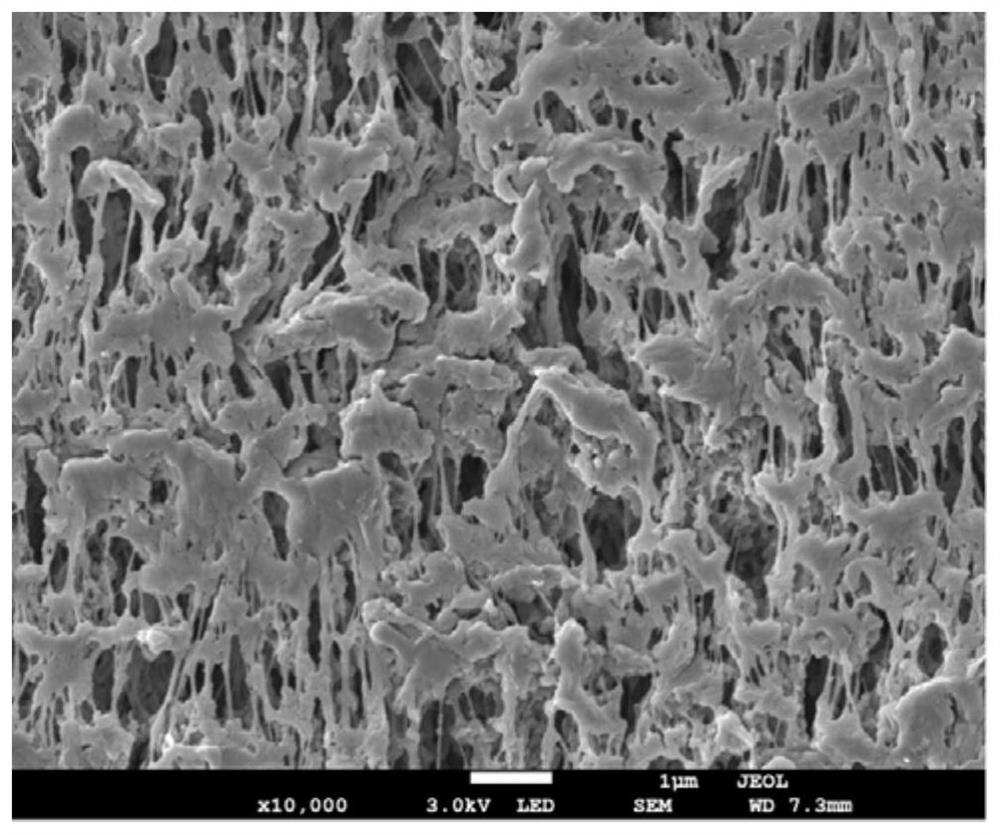

Embodiment 1

[0070] The specific implementation steps are as follows:

[0071](1) Prepare the casting solution: mix the diluent with PVDF, wherein the mass concentration of PVDF is 24wt%, the diluent is a mixture of benzophenone and myristyl alcohol, the mass concentration ratio is 80:20, and the temperature is raised to 220°C, Static defoaming and mixing uniformly to obtain casting solution;

[0072] (2) Extrusion of hollow fiber membrane: the casting liquid is further sheared and mixed at high temperature through a twin-screw extruder, and finally merged with the inner core liquid at the spinneret, and extruded through the spinneret together to form A hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity, and the inner core liquid is glycerol;

[0073] (3) Cooling and solidification to form a film: the hollow fiber-shaped homogeneous high-temperature solution is directly immersed in a water bath at 45° C. to cool, ...

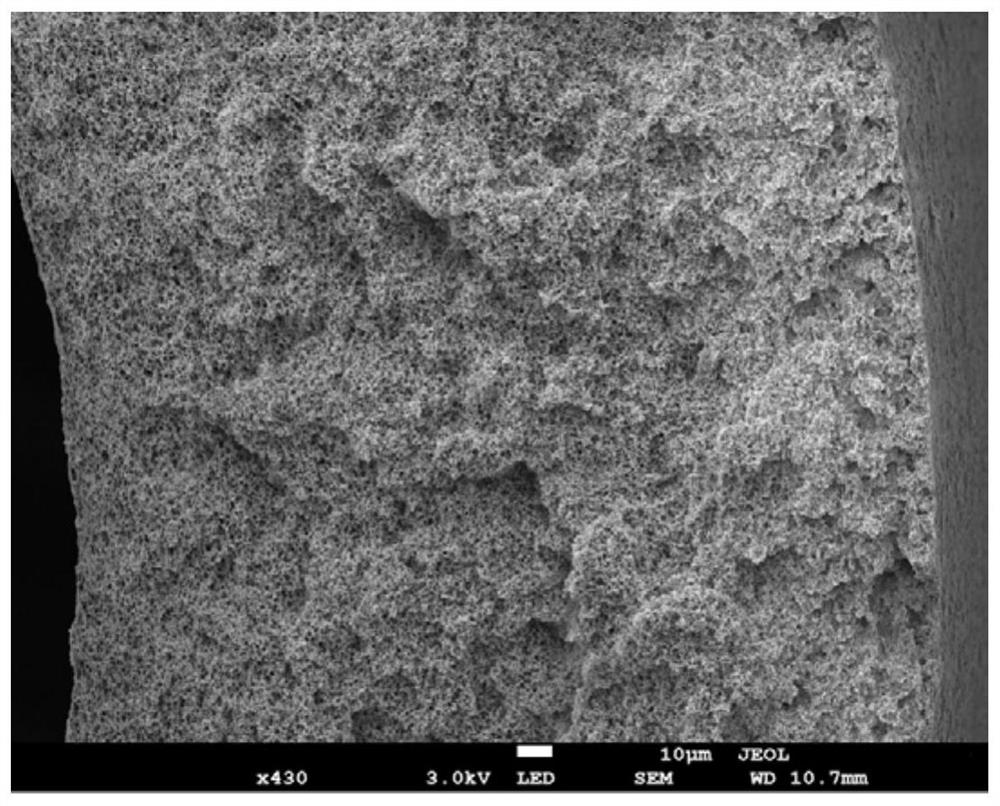

Embodiment 2

[0085] The specific implementation steps are as follows:

[0086] (1) Preparation of casting solution: diluent and PVDF, wherein the mass concentration of PVDF is 22wt%, the diluent is a mixture of benzophenone and myristyl alcohol, the mass concentration ratio is 80:20, the temperature is raised to 220 ° C, and the Place defoaming and mix uniformly to obtain casting solution;

[0087] (2) Extrusion of hollow fiber membrane: the casting liquid is further sheared and mixed at high temperature through a twin-screw extruder, and finally merged with the inner core liquid at the spinneret, and extruded through the spinneret together to form A hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity, and the inner core liquid is glycerol;

[0088] (3) Cooling and solidification to form a film: the hollow fiber-shaped homogeneous high-temperature solution is directly immersed in a water bath at 45° C. to cool, sta...

Embodiment 3

[0093] The specific implementation steps are as follows:

[0094] (1) Prepare the casting solution: mix the diluent with PVDF, wherein the mass concentration of PVDF is 26wt%, the diluent is a mixture of benzophenone and myristyl alcohol, the mass concentration ratio is 80:20, and the temperature is raised to 220°C, Static defoaming and mixing uniformly to obtain casting solution;

[0095] (2) Extrusion of hollow fiber membrane: the casting liquid is further sheared and mixed at high temperature through a twin-screw extruder, and finally merged with the inner core liquid at the spinneret, and extruded through the spinneret together to form A hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity, and the inner core liquid is glycerol;

[0096] (3) Cooling and solidification to form a film: the hollow fiber-shaped homogeneous high-temperature solution is directly immersed in a water bath at 40° C. to cool,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com