Preparation method of large-flux ceramic membrane

A ceramic membrane, high-flux technology, used in ceramic products, chemical instruments and methods, membrane technology, etc., can solve the problems of weak acid and alkali resistance, low strength, membrane peeling, etc., and achieve acid and alkali corrosion resistance. The effect of increasing, bonding tightly and firmly, and improving the anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

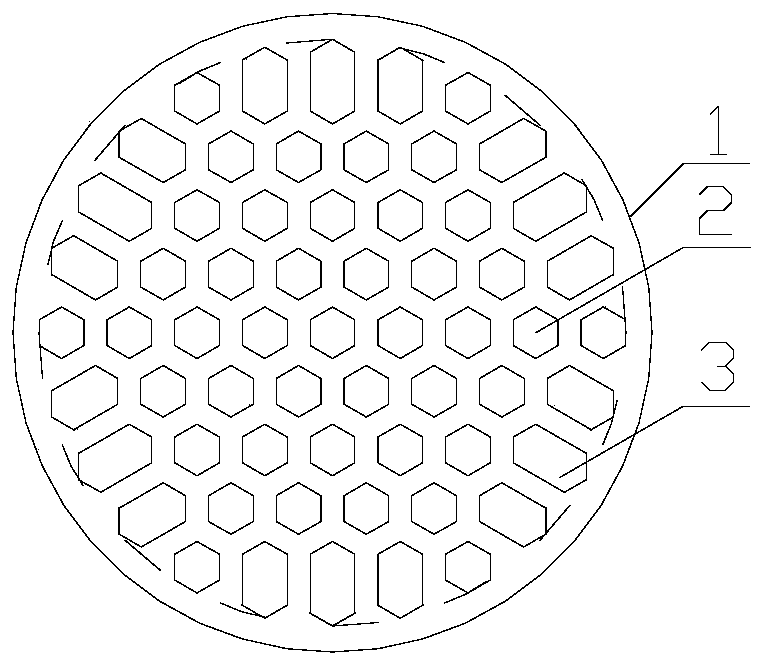

Image

Examples

Embodiment 1

[0042] The preparation method of the described large-flux ceramic membrane consists of the following steps:

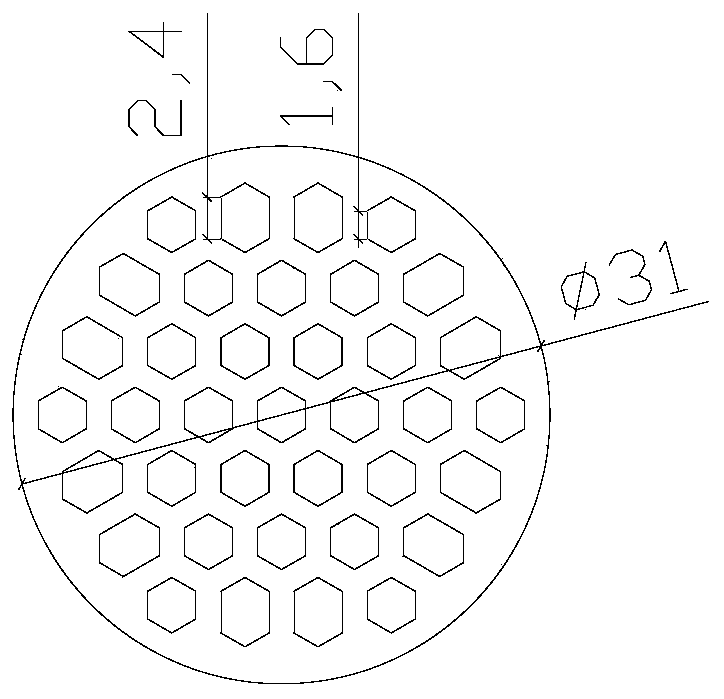

[0043] 1) Support body preparation:

[0044] Al with a median particle size of 30-40 μm 2 o 3 Powder, titanium oxide powder, zirconia powder and dry powder auxiliary materials are composed of dry powder materials according to the ratio of 88%: 1%: 2%: 9%. Among them, the dry powder auxiliary materials are 0.5-5μm alumina, talc, rare earth materials, cellulose , starch (mass ratio is 3:1:1:3:2), put the dry powder material into the mixer and mix evenly, then move to the kneader, add water, PVA and oil of 20% of the above dry powder weight The material is kneaded, and after the mud is practiced by the mud refining machine, it is stale for 24 hours, and the stale mud is extruded by an extruder, and the mold adopts a structural form combining regular hexagons and long hexagons (see figure 2 ), the formed embryo body is dried and shaped, and the dried embryo body is sin...

Embodiment 2

[0051] The preparation method of the described large-flux ceramic membrane consists of the following steps:

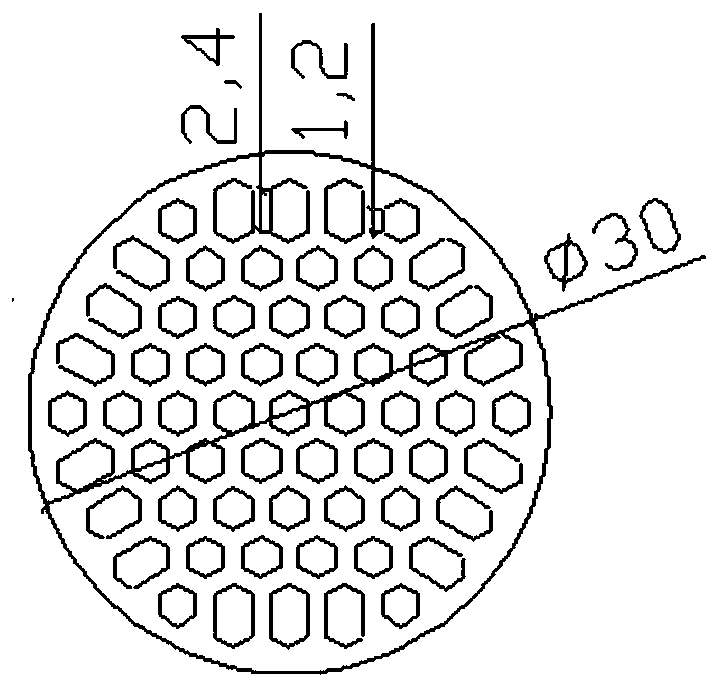

[0052] 1) Support body preparation:

[0053] The median particle size is 25-35μm Al 2 o 3 Powder, titanium oxide powder, zirconia powder and dry powder auxiliary materials are composed of dry powder materials according to the ratio of 80%: 3%; 6%: 11%. The dry powder auxiliary materials are 0.5-5μm alumina, potassium feldspar, rare earth materials, fibers Vegetarian, starch (mass ratio is 5:1:1:3:2), the dry powder material of composition is added in the mixer and mixed evenly, then moves to the kneader, adds the water and PVA of above dry powder weight 18% , oily materials kneading, and then stale for 36 hours after passing through the mud refining machine, and the stale mud is extruded by an extruder, and the mold adopts a structural form combining regular hexagons and long hexagons (see image 3 ), the formed embryo body is dried and shaped, and the dried embryo ...

Embodiment 3

[0060] The preparation method of the described large-flux ceramic membrane consists of the following steps:

[0061] 1) Support body preparation: Al with a median particle size of 15-30 μm 2 o 3 Powder, titanium oxide powder, zirconia powder and dry powder auxiliary materials are composed of dry powder materials according to the ratio of 63%: 9%; 16%: 12%. The dry powder auxiliary materials are 0.5-5μm alumina, talc, rare earth materials, cellulose, Starch (mass ratio is 6:1:1:3:2), the dry powder material of composition is fed into the mixer and mixed evenly, then moved to the kneader, add water and PVA, oil of 18% of the above dry powder weight kneading of similar materials, and then stale for 48 hours after passing through the mud refining machine, and the stale mud is extruded by an extruder, and the mold adopts a structural form combining a honeycomb structure and a special-shaped hexagonal structure (see Figure 4 ), the formed embryo body is dried and shaped, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com