Liquid filter membrane component

A filter membrane and component technology, applied in the field of liquid filter membrane components, can solve problems such as difficult regeneration, high pressure loss, and large filtration resistance, and achieve increased effective filtration area, high temperature resistance of 400°C, and low liquid flow resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

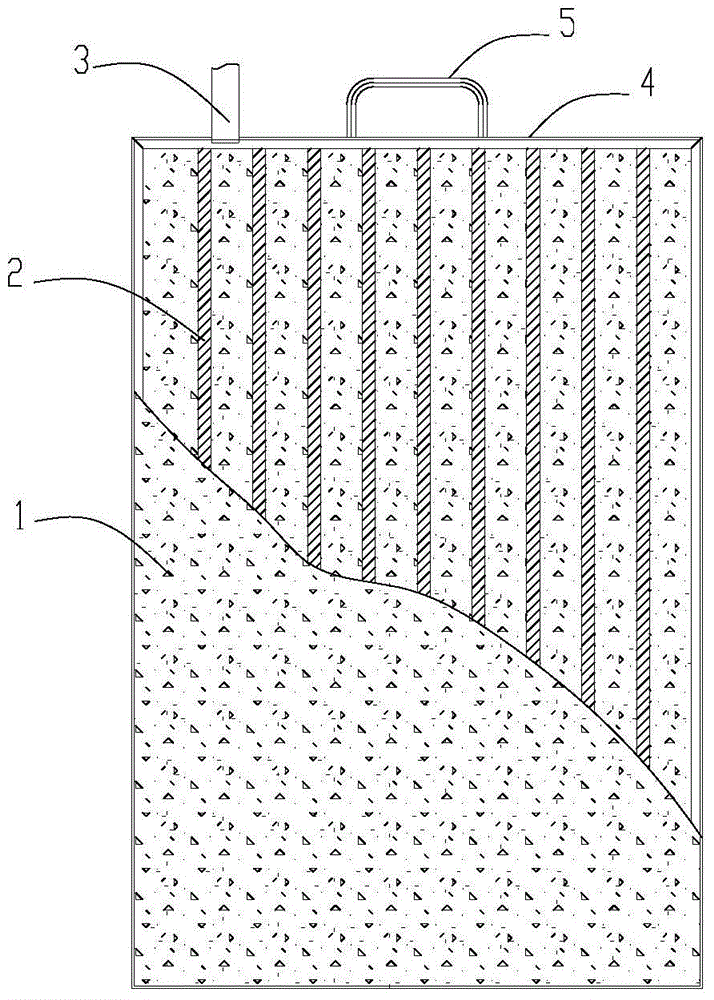

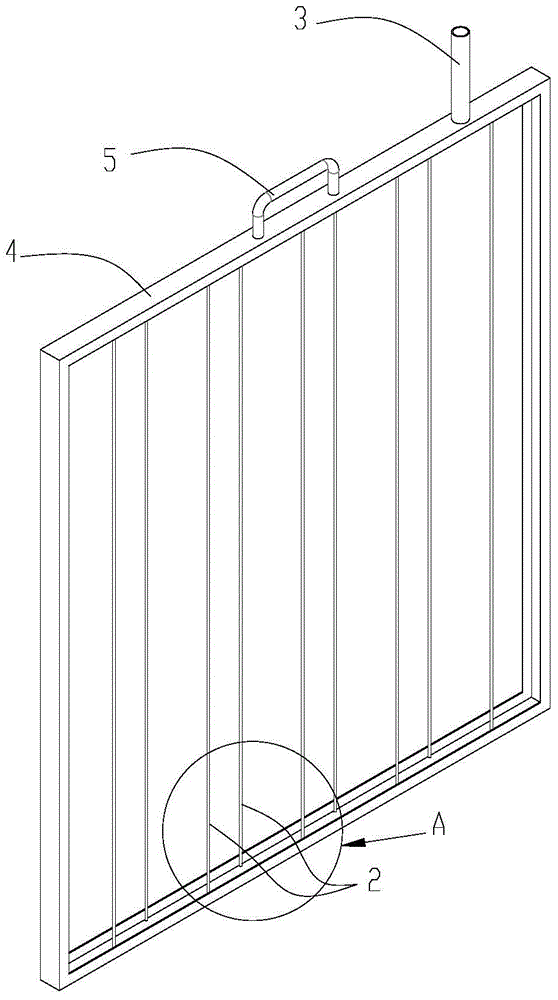

[0022] Such as figure 1 and figure 2 The liquid filtration membrane assembly shown includes a filter membrane 1 made of a flexible porous metal membrane, and the filter membrane 1 is connected to a frame 4 provided with a drain pipe 3, and forms a circumferential A filter structure with a closed end face opposite to the drain pipe 3, in which a support guide structure 2 facing the outlet of the drain pipe 3 is provided along the surface of the filter membrane 1.

[0023] The filter membrane 1 is made of a flexible porous metal membrane. The porosity of the filter membrane 1 is 50%-70%, the pore diameter is 10-20 μm, and the thickness is 200-1500 μm. The filter membrane 1 is preferably composed of a metal porous material with Ag-Au solid solution, Ti-Zr solid solution, Mg-Cd solid solution, Fe-Cr solid solution or Ni-Cu solid solution as the matrix phase. The filter membrane 1 composed of the flexible porous metal membrane under the above conditions has corrosion resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com