High-flux virus-removing polyvinylidene fluoride hollow fiber microporous membrane and preparation method thereof

A polyvinylidene fluoride, high-flux technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. To achieve the effect of expanding the effective filtration area, providing strength, and improving the flux of pure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 25wt%, and diethyl phthalate as diluent, the mass percentage concentration is 75wt%, and the temperature is raised to 220°C, stand still for degassing and mix uniformly to obtain a casting solution.

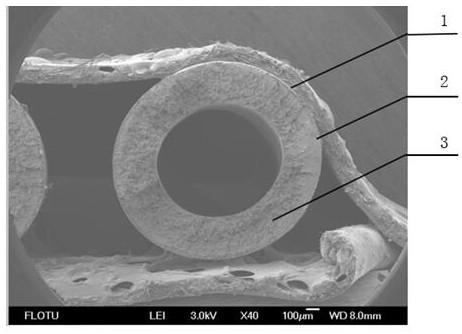

[0039] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 7°C. The core liquid is glycerol.

[0040] (3) Outer layer spray-solvent exchange ...

Embodiment 2

[0046] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 20wt%, diethyl phthalate as diluent, mass concentration is 80wt%, and the temperature is raised to At 220°C, let stand to defoam and mix evenly to obtain a casting solution.

[0047] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 10°C. The core fluid is 1,2-propanediol.

[0048] (3) Outer layer spray-solvent exchange film formation: th...

Embodiment 3

[0054] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 30wt%, diethyl phthalate as diluent, mass concentration is 70wt%, and the temperature is raised to 220°C, stand still for defoaming and mix evenly to obtain casting solution;

[0055] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 5°C. The inner core fluid is composed of glycerol and 2,3-butanediol mixed in any proportion.

[0056] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com