Underground movable modular mine water treatment system

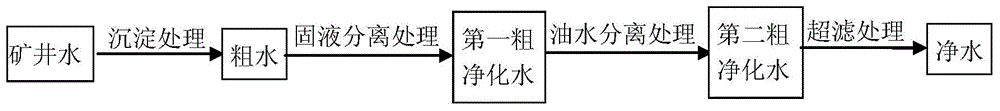

A technology of mine water and mine, which is applied in the field of underground treatment and reuse of coal mine wastewater, and can solve the problems of high oil-containing suspended solids, high dosage of chemicals, and high treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

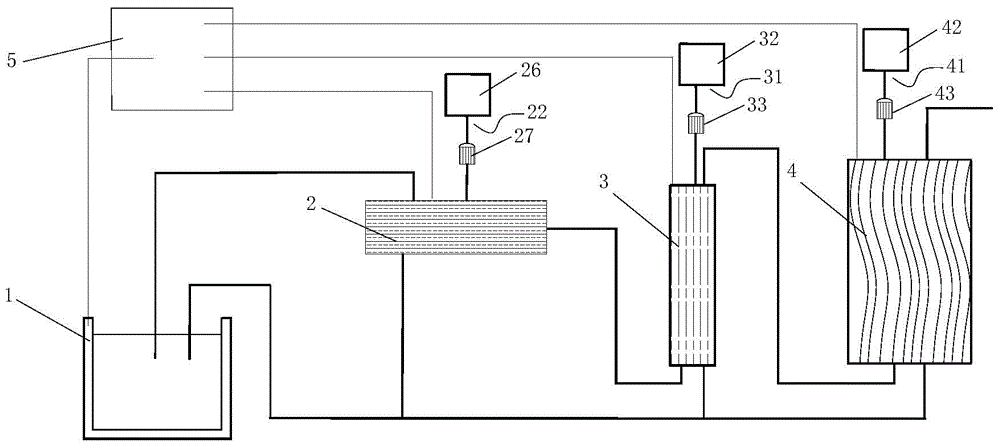

Embodiment 1

[0103] The experimental water was taken from the underground mine water test project of China Shenhua Shendong Cunyi Mine, and the treated water volume was 12t / d. The concentration of each pollutant in the influent is: suspended solids (SS) value 70mg / L, turbidity value 5.65NTU, oil value 15.3mg / L, DOC value 6.72mg / L, UV 254 Value 0.09cm -1 .

[0104] Firstly, the waste water to be treated is introduced into the downhole water tank for sedimentation treatment, and the large solid matter is removed to obtain rough water. The hydraulic retention time of the sedimentation treatment is 10h.

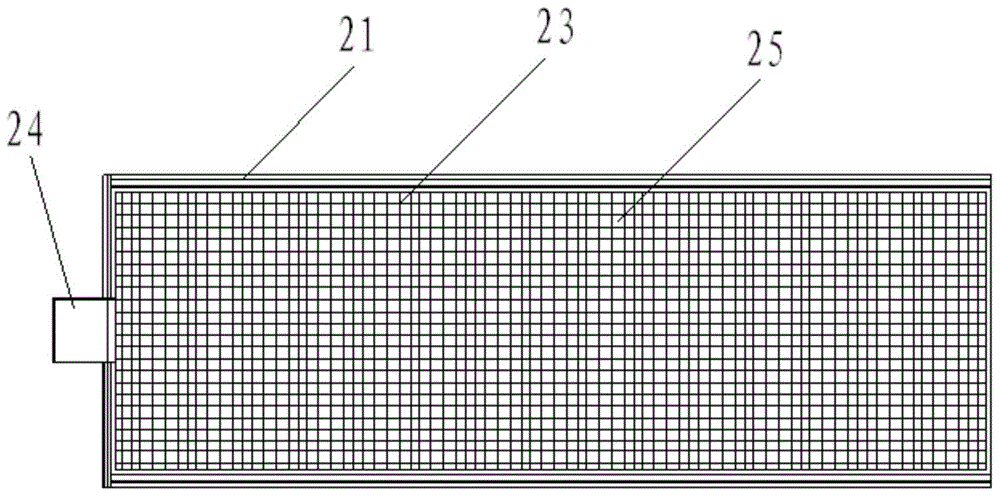

[0105] The coarse water after sedimentation treatment is subjected to rotary filtration treatment, and the mine water after sedimentation treatment flows into the rotary filter from top to bottom, and the fine suspended matter in it is intercepted to obtain the first rough purified water. When the filtration throughput of the rotary filter is reduced by 25%, the nozzle-type high-pressure wa...

Embodiment 2

[0110] The experimental water was taken from the underground mine water test project of China Shenhua Shendong Cunyi Mine, and the treated water volume was 12t / d. The concentration of each pollutant in the influent water is: suspended solids (SS) 100mg / L, turbidity 12.1NTU, oil 18.7mg / L, DOC 7.63mg / L, UV 254 0.10cm -1 .

[0111] Firstly, the waste water to be treated is introduced into the downhole water tank for sedimentation treatment, and the large solid matter is removed to obtain rough water. The hydraulic retention time of the sedimentation treatment is 15h.

[0112] The coarse water after sedimentation treatment is subjected to rotary filtration treatment, and the mine water after sedimentation treatment flows into the rotary filter from top to bottom, and the fine suspended matter in it is intercepted to obtain the first rough purified water. When the filtration throughput of the rotary filter is reduced by 35%, the nozzle-type high-pressure water backwashing system ...

Embodiment 3

[0117] The experimental water was taken from the underground mine water test project of China Shenhua Shendong Cunyi Mine, and the treated water volume was 12t / d. The concentration of each pollutant in the influent water is: suspended solids (SS) 110.2mg / L, turbidity 10.5NTU, oil 20.3mg / L, DOC 7.89mg / L, UV 254 0.11cm -1 .

[0118] Firstly, the waste water to be treated is introduced into the downhole water tank for sedimentation treatment to remove the large solid matter in it to obtain rough water, and the hydraulic retention time of the sedimentation treatment is 20h.

[0119] The mine water after sedimentation treatment is subjected to rotary filtration treatment, and the mine water after sedimentation treatment flows into the rotary filter from top to bottom, and the fine suspended matter in it is intercepted to obtain the first rough purified water. When the filtration throughput of the rotary filter is reduced by 30%, the nozzle-type high-pressure water backwashing sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com